DOI:10.32604/cmc.2021.018686

| Computers, Materials & Continua DOI:10.32604/cmc.2021.018686 |  |

| Article |

Design and Implementation of a Low-Cost Portable Water Quality Monitoring System

1Department of Aerospace Engineering, College of Engineering, AirForce Institute of Technology, Kaduna, Nigeria

2Department of Electrical Engineering, College of Electronics and Information Engineering, Sejong University, Gwangjin-gu, Seoul, 05006, Korea

3Department of Electrical Engineering and Information Engineering, College of Engineering, Covenant University, Canaanland, Ota, P.M.B 1023, Ogun, Nigeria

4School of Telecommunication Engineering, Suranaree University of Technology, Nakhon Ratchasima, Thailand

5Prince Sattam bin Abdulaziz University, College of Computer Engineering and Sciences, Alkharj, 11942, Saudi Arabia

6Department of Mechanical Engineering, College of Engineering, Taif University, Taif, 21944, Saudi Arabia

*Corresponding Author: Peerapong Uthansakul. Email: uthansakul@sut.ac.th

Received: 16 March 2021; Accepted: 17 April 2021

Abstract: Water is one of the needs with remarkable significance to man and other living things. Water quality management is a concept based on the continuous monitoring of water quality. The monitoring scheme aims to accumulate data to make decisions on water resource descriptions, identify real and emergent issues involving water pollution, formulate priorities, and plan for water quality management. The regularly considered parameters when conducting water quality monitoring are turbidity, pH, temperature, conductivity, dissolved oxygen, chemical oxygen demand, biochemical oxygen demand, ammonia, and metal ions. The usual method employed in capturing these water parameters is the manual collection and sending of samples to a laboratory for detection and analysis. However, this method is impractical in the long run because it is laborious and consumes a considerable amount of human resources. Sensors integrated into a mobile phone application interface can address this issue. This paper aims to design and implement an Internet of Things-based system comprising pH, temperature, and turbidity sensors, which are all integrated into a mobile phone application interface for a water monitoring system. This project utilizes the Bluetooth Standard (IEEE 802.15.1) for communication/transfer of data, while the water quality monitoring system relies on the pH, turbidity, and temperature of the test water.

Keywords: Temperature sensor; pH sensor; turbidity; IoT; water monitoring

Waterborne disease, which is the primary source of many diseases, such as cholera and diarrhea, is prevalent globally. The most effective approach to curtail the spread of such diseases is to monitor the drinking water quality, which is the primary duty of the public health department [1]. The WHO has defined water quality standards for drinking water [2]. Approximately 75% of drinking water in Africa is derived from underground water sources [3]. This finding places emphasis on the importance of water quality monitoring due to the changes in the water quality.

In agricultural practice, the continuous use of fertilizers can accelerate the rise in the level of nutrients in nearby water, leading to eutrophication [4]. Human causes of water pollution include the discharge of chemicals, which can lead to the loss of animal life. These kinds of human-related activities can also lead to water pollution, which induces excessive growth in algae when eaten by marine animals, eventually leading to an outbreak of fish disease or death. The development and reproduction of aquatic creatures are significantly retarded in polluted water. Another cause of death or decline in adaptation and deviant conduct of marine animals is the excessive mercury in water. Photosynthesis in plants and trees could be affected by water pollution, which influences the entire dependence on plants and trees by other entities in the ecosystems [5]. The 2020 Environmental Performance Index (EPI) exhibits a strong correlation between EPI Score and GDP per capita, as shown in Fig. 1 [6]. Thus, countries with high GDP have improved water quality at their disposal.

Figure 1: Relationship between 2020 EPI score and GDP per capita [6]

According to [7], contaminated water has been identified as the cause of at least 200 million cases of diseased individuals and deaths ranging from 5 million and above (yearly). The adoption and integration of IoT as a key enabler for wireless sensor communication has opened many frontiers in object monitoring, information gathering, and transportation over secured wireless protocols. Some of the major drivers of the IoT platforms are as follows: low power consumption of the sensor unit [8], strong connectivity efficiency using the HTTP and HTTPS secured protocols [8,9], trustworthy/authentic means of data transfer [8,10], colossal market size [11], data management considerations [11,12], and storage management considerations [13]. Some of the companies implementing and investing in IoT systems include Verizon, Nokia, Honeywell Int’l, Amazon, Intel, and Cisco systems [14]. This study aims to develop a low-cost, high-precision water pollution monitoring device capable of measuring portal water quality under real-time architecture using an IoT platform. The system working principle was subdivided into sub-routine/objectives and tested to ensure that the system is efficiently functioning. The goals of this study are as follows.

• Design a water monitoring system based on Arduino Uno platform comprising temperature, pH, and turbid sensors.

• Interface the system with an MIT App inventor user interface to display the water quality index.

• Integrate the system with an Internet of Things (IoT) platform to enable remote monitoring of the water quality index.

The organization of the paper is as follows. Section 2 details a standard and structured review of past work in this area of study, drawing parallels between them and highlighting each weakness and strength. Section 3 introduces the methodologies used in this system design and explains the methods and the reasons for using such methods. Section 4 focuses on the actual design and implementation. Section 5 presents the results and discussions.

The protocols and standards required for implementing the wireless sensor network in various industries differ. Hence, new/existing standards and protocols must expand the wireless sensor network application to the industrial circle [15]. The majority of the standards used in wireless communication are supported by the IEEE standards, which include IEEE802.11, IEEE802.15.1, IEEE802.15.4, and IEEE 802.16 [16]. This standard applies to the physical (PHY) and media access control layers of the wireless personal area network. The IEEE802.11 is a networking infrastructure used by wireless fidelity (Wi-Fi) local area wireless networking. The Bluetooth network (IEEE802.15.1) is configured as a wireless personal area network with one main function, that is, to link devices to a personal computer or cell phone. The IEEE802.15.4 is designed for low-cost, minimal power, low to moderate/average information rate and optimization applications [16]. IEEE802.16 is the foundation for wireless metropolitan area network design. Another protocol that supports IoT technology is the ZigBee, which was developed in 2004 by ZigBee Alliance. The protocol currently has three models: ZigBee 2006, ZigBee 2007 otherwise known as ZigBee, and ZigBee PRO. All the models of the ZigBee standard generally have some features. For instance, the models are capable of handling mesh networks utilizing multiple types of network equipment.

Wireless networking is one of the most desired innovations because it delivers the same benefits as a wired connection, including minimum deployment and operating costs. However, specific problems must be considered when merging several wireless technologies into the same vital network. The issues principally include the interaction between wireless structures (Bluetooth), radio frequency identification, wireless sensor networks utilizing IEEE 802.15.4, WiMAX (that is, IEEE 802.16), and Wi-Fi/IEEE 802.11, compatibility with current hardware–software elements, privacy, and connectivity efficiency. Each of these specifications was recently proposed by HART to describe a particular framework as a component of the HART Field Communication Protocol Revision 7. The latest standard, which is known as WirelessHART, aims to provide commercial solutions via wireless mesh networks comprising node classes [17]. ISA100.11 version one is an open platform accepted by the ISA100 protocol board in 2009. This model emphasizes the delivery of a range of automation and process control facilities.

The fundamental purpose is to maintain information sharing with other contact networks, compliance with current hardware and software networks, energy efficiency, durability, and stability. The specification provides a collection of rules and procedures for controlling a non-sensitive and essential process, including manufacturing and management structures, such as the supervisory control and data acquisition system. LoRa, which means long range, is classified as a low-power wide-area network system. Spread spectrum modulation, which is derived from the chirp spread spectrum system, is the foundation of the LoRa [18]. The LoRa wide area network was developed on the basis of energy optimization because batteries power most of the nodes in the system. Tab. 1 presents a summary of previously executed water quality measurement campaigns.

This section describes an IoT-based water quality monitoring system comprising hardware components and software platforms. Some of the tasks performed include design specification, design concept and materials, and method.

The water quality monitoring system comprises five different sections/parts, as indicated in Tab. 2. The first section is the power supply unit comprised an AC adapter, which supplies 5 V power to the entire system. The second section comprised the microcontroller unit, specifically ATmega328p Microcontroller. The third module is the sensing unit, which comprised the temperature, pH, and turbidity sensors. The fourth is the communication module (Bluetooth Module) used to transfer data from the microcontroller unit to the Android device. The fifth and sixth sections of this project will be the Android device equipped with an Android app (explicitly built for this project).

3.2 Design Concept and Flowchart

As illustrated by the flow chart diagram in Fig. 2, the sensors take their reading (data) from the test water. The data from the pH and turbidity sensors are in an analog form, which is incompatible with the Arduino microcontroller. Therefore, these data are converted into digital values by the microcontroller. The Bluetooth module is then initialized to facilitate the connection of an Android device. The sensor data obtained from the sensor are then transferred to the Android device when the Android device is paired with the Bluetooth module and will be displayed by the Android application built for this project.

Figure 2: Flowchart of the project

The design concept is summarized as follows.

i) A DC jack would supply power to the system after power conversion. The DC jack is connected to the microcontroller unit, which controls the sub-units.

ii) The DS18B20 temperature sensor is designed to measure the water temperature while the turbidity sensor analyzes the water quality. The analog pH sensor is precisely built to detect the acidity or alkalinity of a solution.

iii) A programmed Arduino Uno microcontroller is the brain of the system that conducts the necessary mathematical operations regarding the comparison of the received analog signals from the sensors and the pre-set value. This microcontroller also synchronizes tasks relating to other components in the system.

iv) The HC-05 Bluetooth module is used as the gateway to allow the Arduino Uno microcontroller to interact with the MIT App Inventor (which is a web application integrated development environment for Android and IOS).

v) The water quality results will be displayed on Samsung Galaxy A8.0 using the developed mobile app powered by the MIT App Inventor.

The water quality monitoring system design is divided into two interdependent sections: the software and the hardware. This section briefly describes the hardware design of the system. The following hardware components were used in the realization of this project.

3.3.1 Atmega328p Microcontroller

The microcontroller chip ATmega328p comprises 14 digital pins, 6 analog pins, 2 ground pins, 2 VCC pins, 2 crystal inputs 16 MHZ, reset pin, and 28 analog referencing pins. The chip is mounted on the Arduino Uno board and programmed with the open-source Arduino (Arduino IDE) environment and a platform for compiling, uploading, and simulating codes using the Arduino Uno USB connector to implement the code functionality. The Arduino one needs an AC/DC adapter or a battery and a reset button in the board that allows the program to be uploaded onto the microcontroller to restart. The Arduino Uno is designed to control the sensor data transfer from the sensing circuit to the control board by the ATmega328p microcontroller. Fig. 3 depicts the Arduino Uno image.

Figure 3: ATmega328p microcontroller [35]

The HC-05 Bluetooth module runs on the serial port profile concept. This module is built exclusively for serial wireless communication. Moreover, the Bluetooth module is designed for the 3 Mbps modulation with a complete 2.4 GHz wireless transceiver and baseband Bluetooth V2.0 + enhanced data rate. The Bluetooth device with CMOS and adaptive frequency hopping feature is based on CSR Bluecore 04-External single chip. The Bluetooth module has low prices, reduced power usage, and a high degree of connectivity from a wide distance. The sensitivity of the Bluetooth module is −80 dBm. This module also uses the UART protocol, which has a baud rate that can be configured. The baud speed used is typically 36,800, and the data packet normally comprises 8 bits, 1 stop, and no parity bits. These Bluetooth modules have two modes: master and slave device. The consumer can customize modes as a master or slave with AT commands for a device with an odd number, such as HC-05 [36].

Fig. 4 depicts the Bluetooth module indicating the following six pins [36]:

i) The first is the Enable/Key (with a default data mode), which is used to alternate between data mode and AT command.

ii) The VCC pin, which powers the module with a +5 V voltage supply.

iii) Ground pin, which connects the system to the ground

iv) TX-Transmitter pin–Transfer Serial data. All data received through Bluetooth are given as serial data through this pin.

v) RX Receiver–Retrieves serial data. Each serial information given to this pin is transmitted via Bluetooth.

vi) State pin, which indicates whether the module is or is not connected.

Figure 4: HC-05 Bluetooth module [36]

The Arduino Uno board utilizes an ATmega328p chip as shown in Fig. 5. The datasheet is available on [37]. The microcontroller board comprises 14 digital input and output pins, 6 analog input pins, and a 16 MHz crystal oscillator, which can be connected to a computer via a USB connector [35]. The board is controlled via Arduino IDE, which is an open-source environment where codes are written/compiled and uploaded onto the Arduino Uno microcontroller board using the USB connection from the cable and the computer. The Arduino Uno board is used to program the ATmega328p microcontroller [38].

Figure 5: Arduino Uno board [38]

3.3.4 DS18B20 Temperature Sensor

The DS18B20 temperature sensor is a single bus digital temperature sensor shown in Fig. 6. This sensor interacts with the microprocessor via the single bus port, the temperature range of the sensor goes from −55°C to +125°C, and the incremental value is 0.5°C. The temperature can be changed into figures within 720 ms, and each DS18B20 has a distinctive 64-bit serial code, which then permits various DS18B20s to operate on the same 1-Wire bus. Two 8-bit storages are available for storing temperature values in the DS18B20: No. 0 and No. 1. No. 0 storage stores complement the temperature value, and No. 1 stores symbols of the temperature value [39]. Thus, using one microprocessor to control many DS18B20s distributed over a large area is easy.

Figure 6: DS18B20 temperature sensor [39]

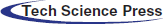

The turbidity sensor analyzes the water quality by evaluating turbidity rate and opacity as shown in Fig. 7. The sensor uses light to assess the light absorption and the dispersion intensity for suspended particles in water, which varies with the amount of total suspended solids in water [40]. An amplifier board and sensor are included in this sensor system. The module is attached to Arduino by utilizing only three pins: VCC, GND, and SIGNAL. A light transmitter and receiver are used in the turbidity sensor. The light dispersion is small in cleansed waters, which indicates that the light receiver accepts the lightest. The light receiver secures less illumination as the water turbidity grows. If the received light is under a certain threshold, then the sensor is triggered. Notably, an “analog to digital/digital to analog” option is found on this amplifier board, which will move between analog and digital modes. Suppose the goal is only to detect whether the water is too turbid; thus, the digital mode is utilized. The analog mode must be activated to measure turbidity levels. The sensor has an operating voltage of 5 V dc, a maximum operating current of 40 mA, and a response time of less than 500 ms [40].

Figure 7: Analog turbidity sensor [40]

The analog pH sensor is precisely built to detect the acidity or alkalinity of a solution. The pH sensor is in the form of a rod-like unit commonly made of glass, with a bulb encompassing the sensor at the underside, as depicted in Fig. 8. A glass bulb fashioned to be a very detective of hydrogen-ion concentration is attached to the electrode for pH measurement (which is made of glass). The positively charged ions on the glass bulb exchange with the test solution hydrogen ion when the glass electrode is immersed into the solution for analysis, which then creates an electrochemical potential/potential difference across the bulb. The electronic amplifier measures the electrical potential difference in the calculation between the pH and reference electrodes and transforms the potential difference into pH units. The magnitude of the glass bulb’s electrochemical potential is proportional to the pH based on the Nernst equation (measured in millivolts) [35]. Calculating the pH values of different aqueous solutions is easy using this pH sensor.

Figure 8: Analog pH sensor

3.4 Software Design Requirement

The Arduino microcontroller was programmed with the Arduino Integrated Development Environment (IDE) while using a Windows operating system. The codes from the Arduino IDE can be directly uploaded to the Arduino microprocessor using the bootloader in the microcontroller. Afterward, the MIT App Inventor, which is a web application IDE for Android and IOS [41], was used to write the codes in the development of the Android application for this project.

This section contains a detailed description of the implementation and testing of an IoT-based water quality monitoring system. The working operation of the project at all levels is comprehensively explained. The proper functioning of each subunit that comprises the system is required to meet the stated requirements because a fault in one unit can affect the functionality of the entire system [42]. This condition is achieved by conducting circuit simulation, hardware implementation, and software implementation.

The hardware implementation of this project is divided into the following three stages.

• Circuit simulation.

• Coupling of the components.

• Packaging of the project.

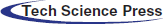

The project was first simulated using Fritzing software as shown in Fig. 9. Fritzing software is utilized to simulate electronic designs. This simulation is conducted to determine if the project is bound to function properly after the hardware connection. The simulation highlights the complete process/behavior of the electronic system during its operation. The simulation of the power supply components, the control unit (Arduino Uno), the communication unit (Bluetooth module), the temperature sensor, and the pH and turbidity sensors was achieved using Fritzing software.

Figure 9: Pin connection of the entire system (modeled with Fritzing)

4.1.2 Coupling of the Components

The project is a prototype. Thus, a breadboard was utilized in coupling the components together as illustrated in Fig. 10 to ensure an easily correctable circuit. Each stage of the project coupling was tested for appropriate and accurate individual functionality. Continuity was also tested on the breadboard ports to prevent errors.

Figure 10: Low-cost water monitoring quality monitoring system

4.1.3 Low-Cost Water Monitoring Quality Monitoring System Packaging

The packaging of the components/projects was conducted after the proper coupling of components as shown in Fig. 11. The project was placed inside a plastic container/case. The case is designed such that the probes of the temperature, pH, and turbidity sensors were extended from the plastic case to allow the sensors to take their reading from the test liquid. The Arduino microcontroller, Bluetooth module, and all the jumper wire connections are placed inside the case. An opening was made for the Arduino USB connection for easy reconfiguration. The opening also extends to the power inlet of the Arduino. The Android device was held by the user.

Figure 11: Packing of the system with the extended pH, turbidity, and temperature sensors

Along with the mobile application, the programming of the Arduino microcontroller is discussed in this section. The project goals and functionality will not be achieved without adequate software knowledge.

The Arduino Uno microcontroller is programmed with the C-Programming language (receive and store data collected from the sensors) using the Arduino IDE. The programming involved the declaration of libraries (which were downloaded and added to the IDE) to be utilized by the sensors and the Bluetooth module, the initialization of pins used in the Arduino microcontroller, void setup, and void loop (which is compulsory in C-Programming language).

All the codes used to allow the sensors to read their respective data were also included in the program. The codes were then uploaded to the Arduino microcontroller to ensure compatibility of the system with the code and allow debugging of possible errors. The Arduino Uno interface is shown in Fig. 12.

Figure 12: Arduino IDE interface showing some codes

4.2.2 Android Application Programming

This programming involves the development of the Android application, which receives data from the three sensor readings via the Bluetooth module. The application was designed using the MIT APP inventor. The user interface design layout and the backend interface of the MIT App inventor are respectively shown in Figs. 13 and 14.

Figure 13: User interface design layout of the MIT app inventor

Figure 14: MIT app inventor backend interface

The MIT App inventor uses a block-based programming language to develop apps for Android devices. The design of the user interface and the backend of the application was developed using the MIT App inventor block-based programming language. The application was also developed such that the values for each of the read sensors are displayed in a “textbox” when the sensors take their reading and transfer it through Bluetooth to the Android device. A graph is implemented in the application. This graph is used to illustrate the relations between the monitoring time and the parameters measured by the sensors. The graph will be discussed in the next section.

Results and discussions are some of the most critical aspects in the design and implementation of the project. Five different tests were conducted in this project to ensure that the proposed system meets the requirements. The power supply was tested before its implementation in the project to ensure an output voltage of 5 V. The testing of the power supply was also performed to avoid damages to components due to high voltage and ensure sufficient power supply for the proper functioning of the various components. The pH sensor was tested to determine the acquisition of accurate values. This sensor was tested using a soap solution (which is basic), water (neutral), and lemon juice (acidic). The pH sensor was recalibrated after testing to read the correct values. The temperature sensor was also tested to determine its capability to read the hotness and coldness of the water. The turbidity sensor was also then tested with clear water and water solution filled with dust and sand to ensure the reading of accurate values. Some of the selected reading is shown in Fig. 15. As previously stated, the Bluetooth module in this project was implemented to ensure the passage of data to the Android application through the Bluetooth connection. This module was tested to determine if the pH, temperature, and turbidity values were received by the mobile application using a Bluetooth connection.

Figure 15: Sensors reading interface

After the mobile app was developed with MIT App Inventor, it was then installed into the Android device. The application was tested to determine if all the sensor values are received and inform the user if the water solution in question was suitable for drinking. The Android device used in conducting this project is a Samsung Galaxy A8.0 as shown in Figs. 16a–16c. The project was subjected to the power supply. The temperature, pH, and turbidity sensors were then inserted into a water sample to determine the extraction, transfer, and display of the values for the temperature, pH, and turbidity parameters by the Android application via a Bluetooth connection.

Figure 16: (a) Project app interface (not connected to the Bluetooth module) (b) Project app attempting to connect with the HC-05 Bluetooth modules (c) Project app connected to the HC_05 and taking reading from the sensors

The entire project system was tested as shown in Figs. 17a–17c to finalize the functionality of the project.

Figure 17: (a) Temperature measurement of tap water via DS18B20 temperature sensor for six hours (b) Graph showing pH measurement of tap water via pH sensor of for six hours (c) Turbidity measurement of tap water via pH sensor of for six hours

Water is one of the needs with considerable significance to man and other living things. However, this project reveals that a large amount of water remains unmonitored and polluted. This project attempts to address the question of utilizing WSN as a water quality monitoring system. Based on the aforementioned literature in this project, IoT has been proven to be a reliable method of monitoring and measuring water quality via the utilization of various water property sensors. This form of monitoring is flexible and economical because sensors could easily be replaced along with the required changes in the software to draw data of other parameters in water. The sensors can measure the various required parameters and send the data to the receiving/monitoring device or center through the implementation of real-time monitoring systems.

Concerns related to the daily impact on human health and the environment are increasing due to the rise in mortality rate caused by the emission of gaseous and particulate pollutants from machines and industries. Therefore, monitoring air quality and creating public awareness is crucial for a safe future. Therefore, the future work aims to design a real-time IoT low-cost air quality monitoring system. The system utilizes air quality and carbon monoxide sensors for monitoring gaseous pollutants. Moreover, the system utilizes an Arduino Nano development board equipped with a Wi-Fi module to send readings to a ThingSpeak channel platform effectively.

Funding Statement: This work was supported by SUT Research and Development Funds and by Thailand Science Research and Innovation (TSRI). Also, this work was supported by the Deanship of Scientific Research at Prince Sattam bin Abdulaziz University, Saudi Arabia. In addition, support by the Taif University Researchers Supporting Project number (TURSP-2020/77), Taif University, Taif, Saudi Arabia.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |