DOI:10.32604/sv.2020.011011

| Sound & Vibration DOI:10.32604/sv.2020.011011 |  |

| Article |

Noise Control of a Domestic Refrigerator Using a Natural Material Based Composite

1Department of Mechanical Engineering, Indian Institute of Technology Kharagpur, Kharagpur, 721302, India

2CART, Indian Institute of Technology Delhi, Delhi, 110016, India

*Corresponding Author: A. R. Mohanty. Email: amohanty@mech.iitkgp.ac.in

Received: 14 April 2020; Accepted: 16 October 2020

Abstract: This paper studies the acoustics of a frost free three door domestic refrigerator. Then, as a case study, the radiated noise reduction in the refrigerator using a natural material base composite is presented. Composites manufactured out of Jute, which is a plant fiber abundantly and cheaply available in India and Bangladesh are used in the noise reduction in the refrigerator. Mostly in this work, composites made out of felts of jute were used as barriers for noise control of the refrigerator. Measured acoustical, thermal and physical properties of various jute composites are reported. Noise sources in the refrigerator were characterized using sound intensity method and sound pressure level measurements. It is found that the compressor and the evaporator fan are the predominant noise sources. The jute composite treatment done to the refrigerator shell around the evaporator fan reduced the refrigerator noise level by 5 dB and improved its measured sound quality metrics without affecting the cooling performance of the refrigerator.

Keywords: Compressor; evaporator; green; sound intensity; sound quality

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |

With the advent of technological advancement household appliances such as refrigerators, vacuum cleaners, washing machines, dryers, etc. have become more compact and efficient which are widely used inside residential buildings. These household appliances are the major noise source inside a residential building, particularly in small single room apartments, therefore it is important to control the noise radiated from these appliances. Conventional materials used for passive noise control such as fiberglass, polypropylene, and microperforates are costly as their manufacturing requires high-end equipment or high temperature extrusion and synthetic chemical processes [1]. For the same reasons, these noise control materials have higher carbon footprints, and are neither biodegradable nor recyclable. Due to these effects of synthetic materials, in the past decade a trend in passive noise control has been to use materials made from natural occurring plant and animal fibers or ‘green materials’ [1]. Several researchers around the world have developed naturally occurring green materials such as jute, cotton, flax, kenaf, hemp, coconut coir, bamboo curls, and banana for industrial and automotive noise control [1–5]. The use of natural material for noise control is an active research area and some of them have been used in the past for noise control in home appliance [1,6,7]. These materials can provide good sound absorption, are low-cost, light-weight and biodegradable.

Refrigerator is a very common appliance in every household. There is need for noise control in refrigerators especially in situations when the refrigerator is kept in small apartments with just one to two rooms. Refrigerator noise control is particularly important as it operates round the clock, and especially during the night time in such small dwellings this becomes a major source of excessive noise that in turn leads to sleep discomfort among the residents. Designers have focused on refrigerator noise control using methods such as design changes in the compressor [8–10], and the evaporator fan [11–13]. Some researchers have also studied the sound quality of refrigerator noise in real household living environments [14]. However, there is no research so far on controlling refrigerator noise and vibration using naturally occurring fibrous materials.

One of the abundantly available natural occurring fibrous materials is jute. Jute is a naturally occurring plant that is readily grown at very low cost in the hot tropical and rainy regions of the eastern parts of India and Bangladesh. Jute fiber is a lignin-cellulose fiber composed primarily of cellulose (major component of plant fiber) and lignin (major component of wood fiber). It falls into the bast fiber category (fiber collected from bast or skin of the plant) along with other noise control materials such as kenaf, industrial hemp, flax (linen), and ramie. Raw jute fibers have high aspect ratio (length/diameter), high specific modulus, and high tensile strength [15].

In this paper a case study of a novel application of jute material as a sound absorber and a sound barrier in a household refrigerator is presented. After a brief description of the acoustical properties of the jute material, the procedure and characterization of predominant noise sources in a 3 door frost free 300 litre capacity domestic refrigerator is presented. Finally, the paper concludes with the results on the noise reduction made in the refrigerator using implementation of jute material. Improvements in sound quality of radiated noise from the refrigerator after implementation of the jute material are also presented.

2 Manufacturing and Properties of Jute Composite

Raw jute fibers are cleaned and spun into a jute yarn. The jute yarn is then weaved to make jute textile or cloth. Stacks of jute yarn laid in a random or a definite sequence are pressed under temperature to produce jute felt. The jute felt/fiber in turn can be chemically treated with different percentages of natural rubber (NR) latex resin as a bonding agent and pressed under certain load and temperature to produce various jute composites. The resulting jute-based composite is biodegradable and recyclable, and thus environment-friendly. Jute felt has been extensively tested by Fatima and Mohanty [15], and composites can be made out of such material to have high transmission loss. In few instances even the raw jute fibers after appropriate processing can be chopped and used as fills in noise control blankets and pads [16].

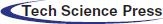

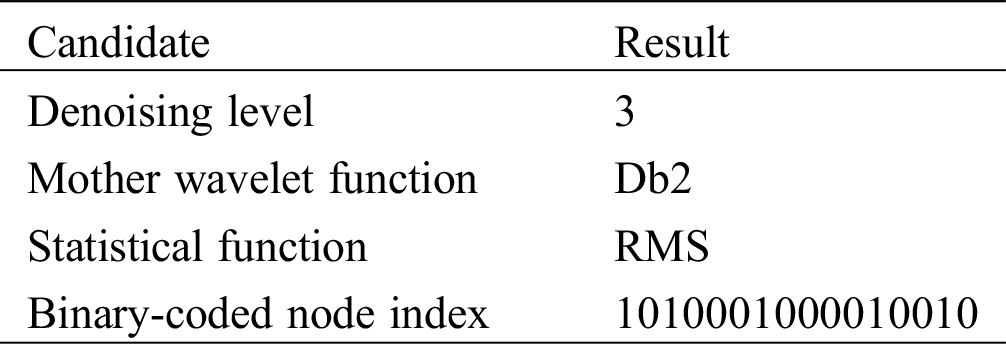

NR latex based jute composites with varying composition of NR latex were prepared. The transmission loss of 5 mm thick samples of these jute composites were measured in the laboratory as per SAE J 1400 standard [17] and their STC (Sound Transmission Class) was noted. Tab. 1 gives the STC rating and transmission loss of these jute composites. 5%, 10% and 15% NR jute composite were found to have higher transmission loss values. The STC of these jute composites are 39 to 40 whereas fiberglass of 88.9 mm thickness has a STC of 52 [15].

Table 1: Transmission loss of 5 mm thick NR latex jute composite (152.4 mm × 152.4) [16]

However, to apply the jute composite on the refrigerator, its thermal properties needs to be known in terms of flammability and thermal stability, less it create a fire hazard when applied in closed spaces in domestic appliances. Measurements of thermal properties of 2.5% and 5% NR latex jute composites and comparison with synthetic materials such as fiberglass and synthetic cotton have been reported [15]. Limiting oxygen index tests show that the minimum concentration of oxygen to support flaming combustion is higher for jute composites than fiberglass and synthetic cotton [15]. Additionally, 5% NR latex jute composite showed the least smoke density rating among fiberglass and synthetic cotton, and least flame propagation when 1% of fire retardant (sodium phosphate) was added to the composite [15]. To summarize, NR latex based jute composites possesses better flammability properties than fiberglass and synthetic cotton. Thermo Gravimetric Analysis (TGA) shows that the thermal stability of raw jute felt is at 260.92°C whereas NR latex jute composite is at 269.30°C [16]. Jute composites are also thermal insulators due to their low thermal conductivity of 0.064 W/m-K in the range of 50°C–80°C, and low thermal diffusivity of 0.259 mm2/s [16]. Thus, jute composites are deemed safe for use in domestic appliances.

Based on these results, 5% NR latex jute composite was selected for noise control in the refrigerator because of its high sound transmission loss, low density, thermal insulation, poor flammability, and high thermal stability.

3 Noise Source Characterization of the Refrigerator

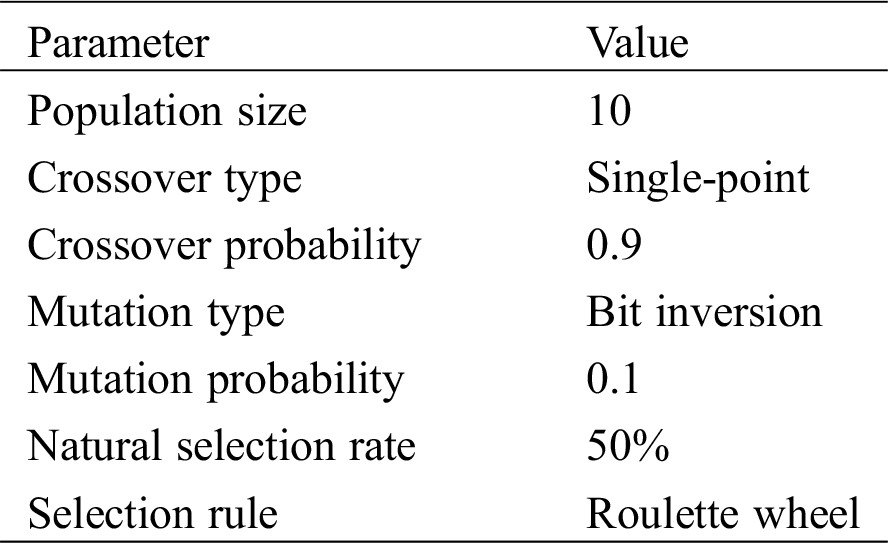

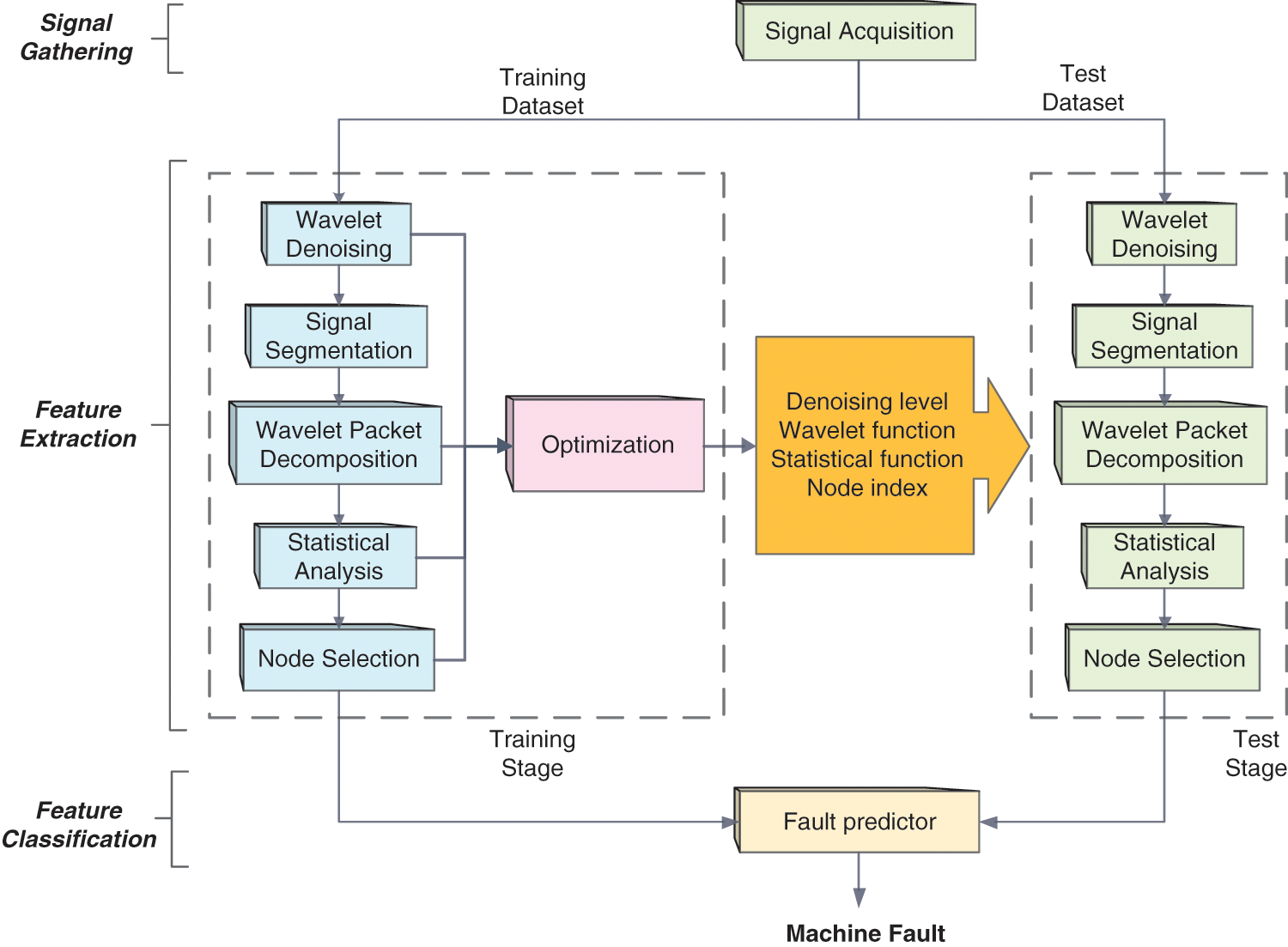

A three door frost free 300 litre domestic refrigerator was used as the test specimen to investigate and implement green noise control in home appliances. Traditionally in order to implement noise control measures on any machinery or product, a characterization of the noise and vibration sources in terms of their significance and frequency content is done. Once the source ranking and characterization is done, source noise control, path noise control or a combination of the two is done. In path noise control, noise control materials like sound absorbing material, sound barrier or sound dampening material are used.

3.1 Sound Intensity Measurement

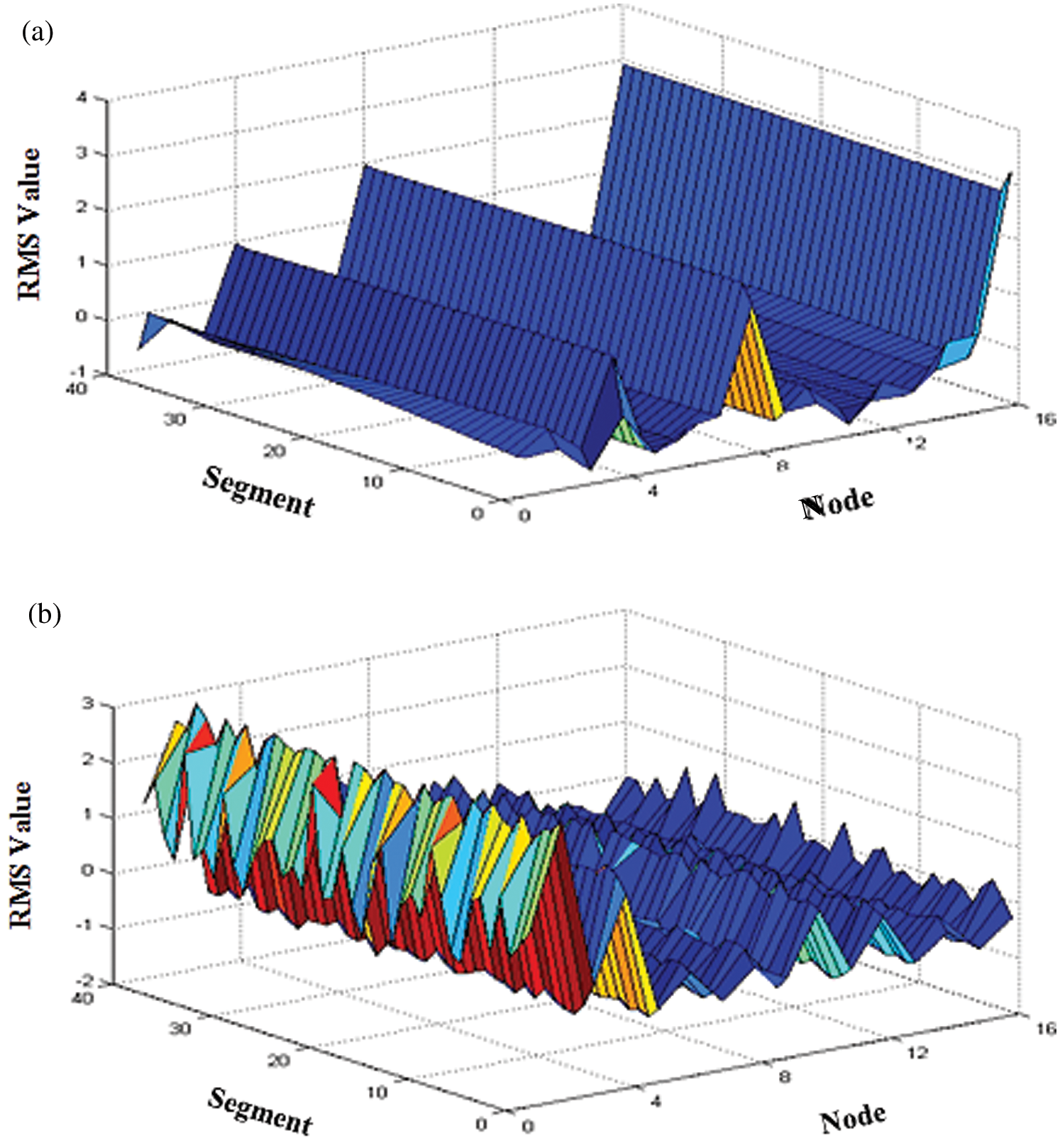

The noise from a refrigerator usually radiates out of its five sides. In order to identify the most predominant noise radiating surface(s) sound intensity measurements were done. The sound intensity was measured using a two microphone probe (B&K 4197) by roving the probe all over the five refrigerator sides (left, front, right, rear and top) at a distance of 10 cm normal to the surface. The four sides of the refrigerator were divided into 4 × 12 grid of 48 blocks of equal sizes and the top side of the refrigerator was divided into 4 × 4 grid of 16 blocks of equal sizes. At the centre of every block the sound intensity probe was held for duration of 20 seconds. By moving the sound intensity probe to various hypothetical blocks around the refrigerator the radiated sound intensity level was measured. Fig. 1 shows the distribution of the SIL (sound intensity level) as a contour plot over the radiating five sides of the refrigerator.

Figure 1: Measured overall sound intensity level (SIL) contours in dBA

From the contours in Fig. 1, the area with low and high SIL can be clearly identified. For clarity, at few locations of the refrigerator sides on the contour plot the overall SIL value in dBA are shown. The SIL was measured while the refrigerator and all its components (evaporator fan and compressor) were switched on. From the SIL contours it is observed that the compressor located at the rear bottom section of the refrigerator contributes the most radiated noise followed by the evaporator fan at the top of the refrigerator. Thus, an effective noise control measure should focus on reducing noise primarily at the compressor, and then at the evaporator fan.

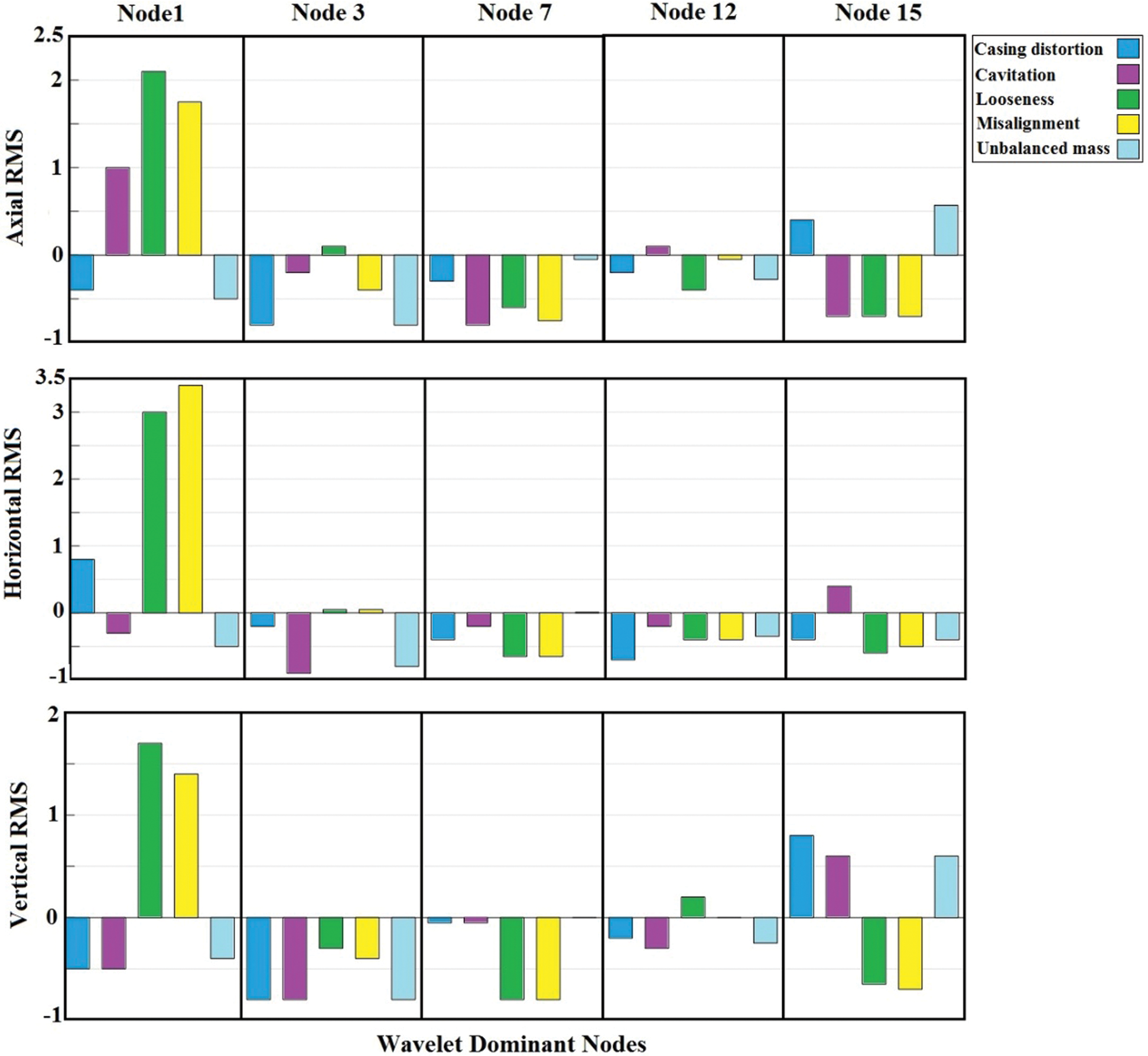

3.2 Sound Pressure Level Measurement

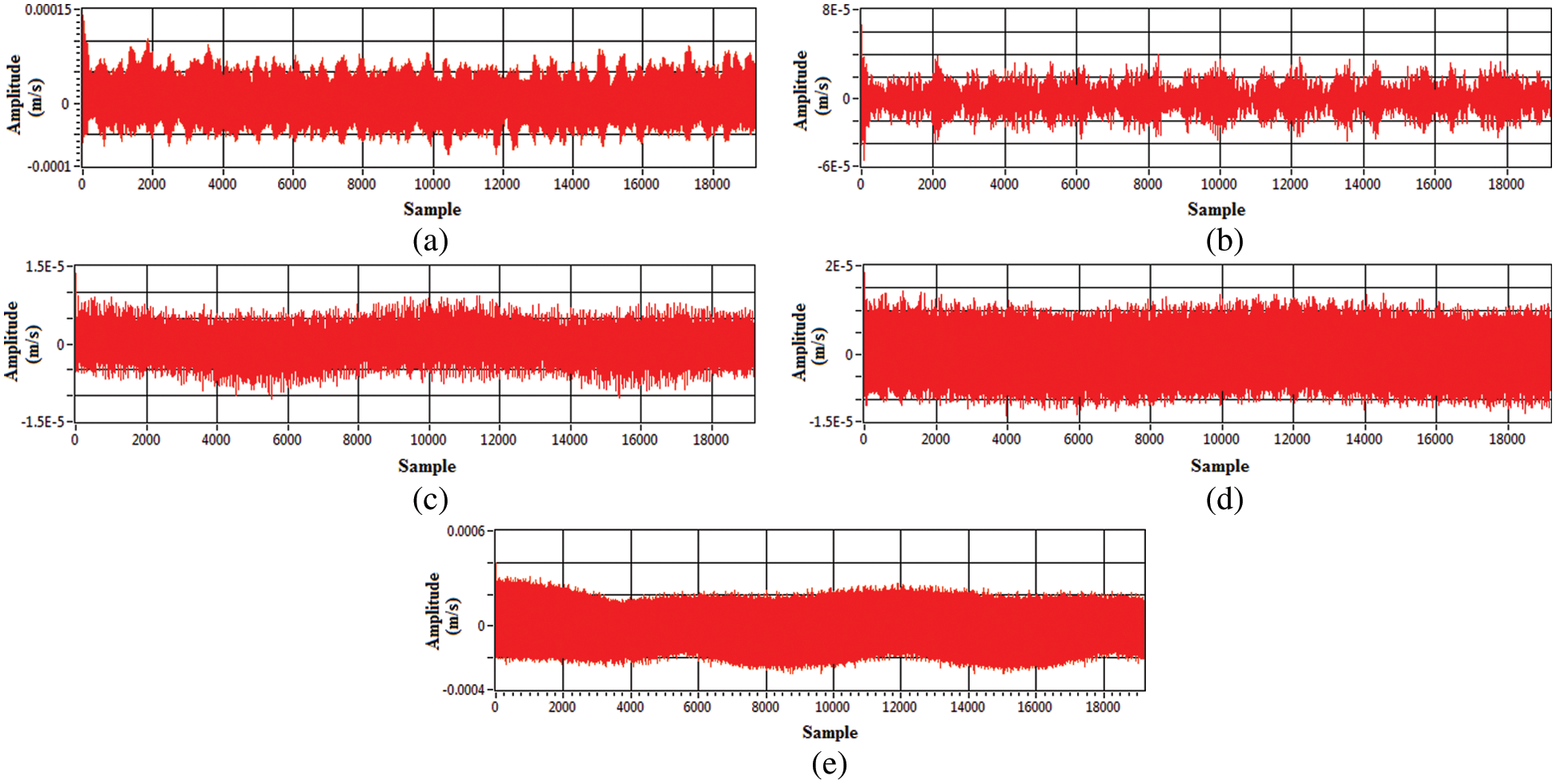

In the previous section compressor and evaporator fan were identified as most dominant noise sources. A calibrated B&K 4189 (1/2” condenser microphone) was used to measure the sound pressure level at a distance of 1 m from each of the four vertical sides of the refrigerator and at a height of 1.2 m from the ground. All the noise and vibration measurements were done in a large quiet room with an overall background sound pressure level of 28.8 dBA (see Fig. 2). Switches were provided in the electrical circuit of the refrigerator so that it could run on the three modes: (a) Compressor OFF, evaporator ON, (b) Compressor ON, evaporator fan OFF, and (c) Both compressor and evaporator fan ON. The maximum measured overall SPL with the compressor ON only was found to be 36.6 dBA, with the fan ON only was 35.8 dBA, and with both the compressor and fan ON was 38.4 dBA. 1/3rd octave spectra SPL for the above operating conditions of the refrigerator are given in Fig. 3.

Figure 2: Experimental setup for sound pressure level measurement

Figure 3: Measured 1/3rd octave SPL spectra of the refrigerator

The refrigerator has a hermetically sealed reciprocating compressor located at the rear bottom of the refrigerator next to the pedestal compartment on four elastomeric grommets. It uses R-134a refrigerant and the compressor operates at 2900–2985 RPM (≈50 Hz). The axial flow evaporator fan is mounted on a thermoplastic plenum located in the top rear portion of the refrigerator in the freezer compartment with 4 vanes rotating at 2560 RPM. The vane pass frequency of the evaporator fan is fvp = 2560/60*4 = 170.7 Hz. From Fig. 3 it is seen that the peaks in the SPL spectra is obtained in the 1/3 octave band frequency of 50 Hz and 100 Hz which is due to harmonics of the compressor at its operating speed of 50 Hz. The other rise in SPL is seen around the frequency range of 160–1250 Hz correspond to the harmonics of the evaporator at vane pass frequency (peaks near 200, 500, and 1250 Hz 1/3 octave frequency band). The SPL reduces significantly beyond 2000 Hz, though the compressor makes a more dominant contribution to the overall noise than the evaporator fan in high frequency bands beyond 1250 Hz. Thus in summary to reduce the overall noise of the refrigerator, noise control measures needs to be put around the compressor and the evaporator fan from 63 Hz to 1250 Hz.

4 Implementation of Noise Control

From the noise source characterization, it was found that at frequencies less than 100 Hz, the compressor is the most noise producing component in the refrigerator followed by the evaporator fan at frequencies beyond 160 Hz. An optimum noise control strategy should be to control compressor noise at low frequencies particular in its harmonics, and control evaporator fan induced air radiated noise at the frequency range of 160 to 1250 Hz.

The noise and vibration produced by the compressor is predominant at frequencies less than equal to 100 Hz. In order to reduce the transmitted vibration, the grommet stiffness can be modified, though in the present research the grommets were not changed. The bottom rear of the refrigerator housing the compressor was open. This uncovered portion was partially covered by a lining of jute comprising 50.4 mm thick jute felt as sound absorber on the side exposed to the compressor and backed by 5 mm thick 5% NR latex jute composite as barrier. The jute based barrier was screwed to the rear metal cabinet of the refrigerator, while taking care that there was large enough opening for air to flow through so as to not affect the cooling performance of the refrigerator. Fig. 4 shows the schematic of jute-based noise control treatment for compressor.

Figure 4: Schematic of the noise control treatment done for the compressor

The evaporator fan operating at a constant speed of 2850 RPM is the next important noise source as found in the SIL ranking plots of Fig. 1. In order to reduce the radiated noise from the evaporator fan area a jute composite based acoustical treatment is done. In a frost free refrigerator of the type used in the present study, condenser tubes are placed all along the inner side walls and rear of the refrigerator for heat dissipation. Then, 5% NR latex jute composite panels were attached on these walls while making sure that the jute composite panels did not cover the condenser tubes as that would affect the heat transfer. The areas around the refrigerator rear, sides and top were pasted with the jute composite panels of size 300 mm × 300 mm × 5 mm to reduce the radiated noise due to the evaporator fan. Fig. 5 shows the schematic of jute-based noise control treatment for evaporator fan, and the post treatment picture of refrigerator. These panels are pasted at locations which correspond to regions of maximum sound intensity as indicated in Fig. 1. A white polyurethane shell is placed on top of the shell with the composite panels during the manufacturing of the refrigerator. And this white polyurethane interior is visible once we open the refrigerator door.

Figure 5: (a) Schematic of the noise control treatment done for evaporator fan. (b) Inside view of the refrigerator compartment with jute composite treatment

5 Performance Evaluation of the Refrigerator

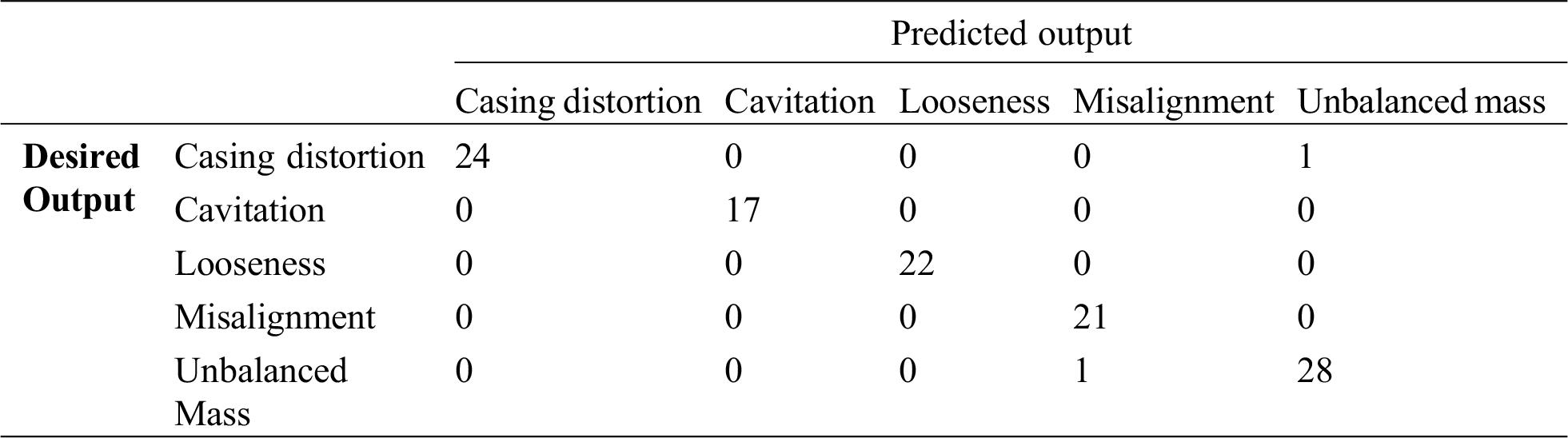

In order to evaluate the effectiveness of the noise control treatments done to the refrigerator, SPL were measured at a distance of 1 m from the front side of the refrigerator. The measured 1/3rd octave spectra SPL of the refrigerator with and without the treatment are shown in Fig. 6. Considerable noise reduction of around 8 dB was obtained at 50 Hz with the noise control treatments done in the compressor and evaporator areas. And an overall noise reduction of 5 dB is obtained in the audible range. Further, the radiated noise of the treated and untreated refrigerators were also recorded with a B&K 4100 sound quality Head and Torso simulator (HATS) location 1.0 m away along the diagonal line from the refrigerator front side as shown in Fig. 7. The evaluated sound quality metrics of the noise before and after the treatment are shown in Tab. 2. As observed, after the jute-based noise control the roughness of the refrigerator noise significantly reduced by 30% (0.725 asper) and sharpness of the refrigerator noise significantly reduced by 30% (0.34 acum). Both roughness and sharpness are the well known sound quality metrics that describe the annoying quality of a sound. Thus, it can be inferred that the noise control treatment led to a significant reduction in annoyance due to the refrigerator noise.

Figure 6: Measured 1/3rd Octave SPL of treated and untreated refrigerator

Figure 7: Experimental setup for sound quality measurements

Table 2: Measured sound quality metrics of radiated noise

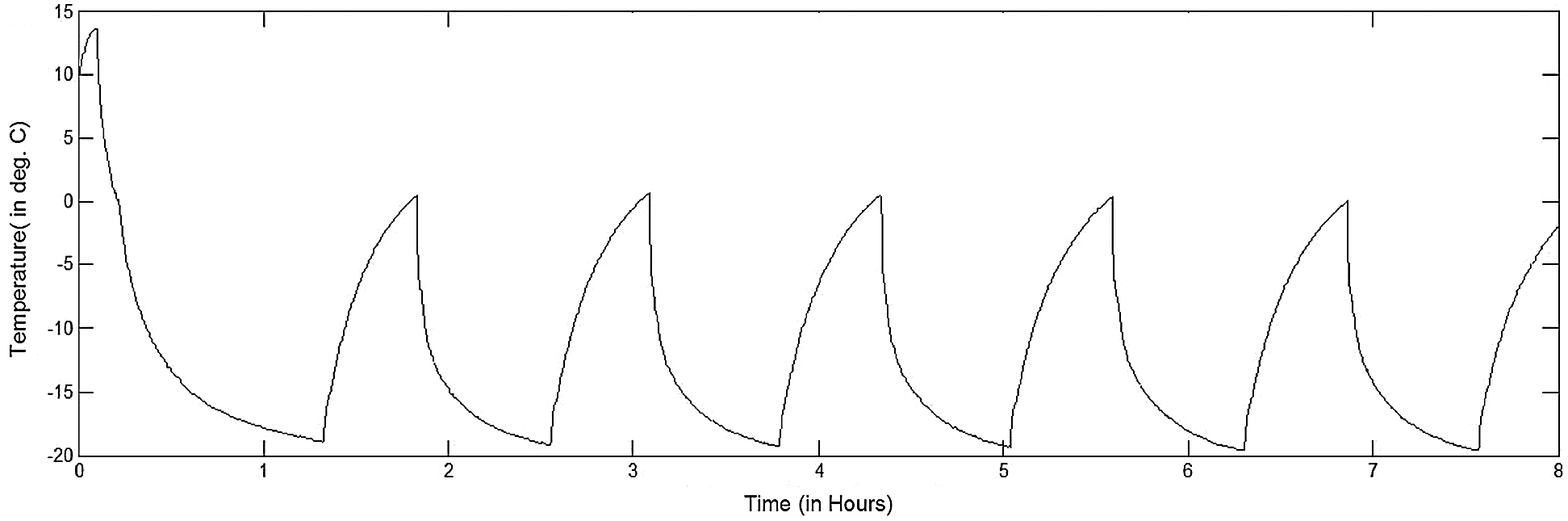

A matter of concern after implementing the noise control measures around the evaporator fan and the compressor compartment is the cooling performance of the refrigerator. An indirect method was adopted for the same by monitoring the temperature at different locations of the refrigerator over an 8 hour period. Thermocouples of the K-Type were installed at around 16 locations on the refrigerator as described in Tab. 3. The measured temperature time history over an 8 hour period in the evaporator compartment of the treated refrigerator is shown in Fig. 8. The original refrigerator freezer compartment was designed to operate at a temperature range of 0 to −20°C. No rise in the temperature was observed at the various locations in the refrigerator after implementing the jute-based materials.

Table 3: Thermocouple location for refrigerator temperature measurement

Figure 8: Measured freezer compartment temperature time history for 8 hours

This paper proposes the use of jute composites a biodegradable, recyclable, lightweight green material for noise control in home appliances. The jute felt based composite was used for noise control in a three door frost free domestic refrigerator. The compressor and the evaporator fan were the predominant noise sources. Jute based composites have been found to have high transmission loss, low flammability, thermal insulation and high thermal stability. A significant noise reduction of 5 dB was obtained using jute felt based composite while maintaining the refrigerator cooling performance. The sound quality particularly roughness and sharpness of the jute material treated refrigerator also improved. Thus, proposed noise control methods can be directly applied on a large scale to all domestic appliances like washing machines, air conditioners, vacuum cleaners, and refrigerators.

Acknowledgement: The authors would like to acknowledge the Global Technology Centre of Whirlpool Corporation of India for providing the refrigerators for conducting the experimental trials at the Indian Institute of Technology Kharagpur.

Funding Statement: The author(s) received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Arenas, J. P., Crocker, M. J. (2010). Recent trends in porous sound-absorbing materials. Sound & Vibration, 44, 12–17.

2. Fatima, S., Mohanty, A. R. (2012). Noise control of home appliances—The green way. Noise & Vibration Worldwide, 43(7), 26–34. DOI 10.1260/0957-4565.43.7.26.

3. Asdrubali, F., Schiavoni, S., Horoshenkov, K. V. (2012). A review of sustainable materials for acoustic applications. Building Acoustics, 19(4), 283–312. DOI 10.1260/1351-010X.19.4.283.

4. Zulkifli, R., Zulkarnain,Nor, M. J. M. (2010). Noise control using coconut coir fiber sound absorber with porous layer backing and perforated panel. American Journal of Applied Sciences, 7(2), 260–264. DOI 10.3844/ajassp.2010.260.264.

5. Thilagavathi, G., Pradeep, E., Kannaian, T., Sasikala, L. (2010). Development of natural fiber nonwovens for application as car interiors for noise control. Journal of Industrial Textiles, 39(3), 267–278. DOI 10.1177/1528083709347124. [Google Scholar] [CrossRef]

6. Mohanty, A. R., Fatima, S. (2015). Noise control using green materials. Sound & Vibration, 49, 13–15. [Google Scholar]

7. Raj, M., Fatima, S., Tandon, N. (2020). Recycled materials as a potential sound absorbers: A study on denim shoddy and waste jute fibers. Applied Acoustics, 159, 107070. [Google Scholar]

8. Saito, F., Maeda, S., Okubo, N., Uetsuji, T. (1980). Noise reduction of hermetic compressor by improvement on its shell shape. International Compressor Engineering Conference, Paper 337, West Lafayette, USA, 228–234. [Google Scholar]

9. Lee, H. K., Park, J. S., Hur, K. B. (2000). The reduction of the noise / vibration generated by the discharge valve system in hermetic compressor for refrigerator. International Compressor Engineering Conference, Paper 1438. West Lafayette, USA.

10. Speich, C. F. (1981). Elements of compressor noise control. International Journal of Refrigeration, 4(5), 281–287. DOI 10.1016/0140-7007(81)90008-6. [Google Scholar] [CrossRef]

11. Jung, B. K., Jeong, W. B. (2011). Estimation of vibration source and sound radiation of a refrigerator fan by using measured acceleration signals. Transactions of the Korean Society for Noise and Vibration Engineering, 21(9), 834–841. DOI 10.5050/KSNVE.2011.21.9.834. [Google Scholar] [CrossRef]

12. Gue, F., Cheong, C., Kim, T. (2011). Development of low-noise axial cooling fans in a household refrigerator. Journal of Mechanical Science and Technology, 25(12), 2995–3004. DOI 10.1007/s12206-011-0818-9.

13. Marques, A. C., Gomez-Agustina, L., Dance, S., Hammond, E., Wood, I. (2013). Noise reduction in commercial refrigerators - A practical approach. 20th International Congress on Sound and Vibration. Bangkok, Thailand. [Google Scholar]

14. Sato, S., You, J., Jeon, J. Y. (2007). Sound quality characteristics of refrigerator noise in real living environments with relation to psychoacoustical and autocorrelation function parameters. Journal of Acoustical Society of America, 122(1), 314–325. [Google Scholar]

15. Fatima, S., Mohanty, A. R. (2011). Acoustical and fire-retardant properties of jute composite materials. Applied Acoustics, 72(2–3), 108–114. [Google Scholar]

16. Mohanty, A. R., Fatima, S. (2015). Biocomposites for industrial noise control. In: Thakur, V. K., Kessler, M. R. (eds.Green biorenewable biocomposites from knowledge to industrial applications, pp. 220–261. Apple Academic Press, Florida. [Google Scholar]

17. SAE International. (2017). SAE J 1400. Laboratory measurement of the airborne sound barrier performance of automotive materials and assemblies. Surface Vehicle Recommended Practice An American National Standard. [Google Scholar]