Open Access

Open Access

REVIEW

Research Progress on the Influence of Varying Fiber Contents on Mechanical Properties of Recycled Concrete

1 College of Civil and Architecture Engineering, Chuzhou University, Chuzhou, China

2 Engineering Research Center of Underground Mine Construction, Ministry of Education (Anhui University of Science and Technology), Huainan, China

* Corresponding Author: Jianyong Pang. Email:

Structural Durability & Health Monitoring 2023, 17(3), 239-255. https://doi.org/10.32604/sdhm.2023.022816

Received 28 March 2022; Accepted 19 August 2022; Issue published 25 June 2023

Abstract

Applying recycled concrete for engineered projects not only protects the ecological environment but also improves the utilization rate of waste concrete to satisfy sustainable development requirements. However, the mechanical properties of recycled concrete are not as good as those of ordinary concrete. To enhance the former’s performance and increase its popularity and application in engineering fields, notable advances have been made by using steel, synthetic, plant, and mineral fiber materials. These materials are added to recycled concrete to improve its mechanical properties. Studies have shown that (1) steel fibers have a distinct reinforcing effect and improve the strength, toughness, and elastic modulus of recycled concrete; (2) the addition of synthetic fibers can improve the tension, crack resistance, and durability of concrete, but the size effect needs to be further explored and elaborated; (3) plant fiber concrete is lightweight and environmentally friendly and provides high toughness and good thermal insulation, but the fibers corrode in alkaline environments; in addition, plant fibers have high water absorption capacity, which leads to wet expansion and dry shrinkage phenomena, which need to be further studied; and (4) the cost of basalt fiber, a mineral fiber, is relatively low, and a suitable basalt content can improve the mechanical properties of recycled concrete to a certain extent.Keywords

Recently, construction waste has accounted for 30%–40% of the total urban waste. The National Bureau of Statistics has reported that construction waste is increasing yearly [1], adversely impacting the ecological environment. The effect of pollution caused by construction waste on the environment cannot be underestimated. It includes water pollution, land pollution, and air pollution. In addition, the cost of treating construction waste is very high. In such a severe situation, construction waste recycling is particularly important. Some construction wastes can be further processed to produce recycled concrete. Recycled concrete is a new kind of concrete made from waste concrete that is treated to form recycled aggregates. It partially or completely replaces natural aggregates such as sand and stone (Fig. 1) [2]. However, the mechanical properties of these recycled aggregates are not as good as those of natural aggregates [3]. Recycled aggregates have high porosity and high-water absorption capacity [4].

Figure 1: Construction waste and recycled coarse aggregate

Moreover, microcracks and pore damage can appear in recycled concrete before loading. Research and engineering practices have displayed that these problems can be mitigated by doping with fibers so that recycled concrete meets the developmental requirements of engineered construction projects [5]. Therefore, research and discussions are needed on mixing different fibers into recycled concrete.

The research results on the effects of different fibers on the mechanical properties of recycled concrete can provide a reference point for continuous improvement. In the last few years, scholars have carried out research on the mechanical properties of recycled concrete compared with the mechanical properties of ordinary concrete, such as tests for compressive strength [6–11], elastic modulus [4,6], dry shrinkage, and the creep variable [2]. Studies have investigated the mechanical properties of recycled concrete mixed with different fibers, such as employing tests to detect crack resistance [12] and impact resistance [12,13]. The addition of fibers to recycled concrete can significantly improve the mechanical properties of recycled concrete [14], such as its compressive strength, splitting tensile strength [15–17], flexural strength [17], and bending strength [18]. However, the research on the mechanical properties of recycled concrete using different fibers is uncomprehensive and needs to be supplemented.

This work considers the effects of different kinds of fibers on the mechanical properties of recycled concrete and presents the research advances scholars in related fields achieved. This review aims to provide a reference for scholars in the field of recycled concrete and related fields to promote the research and application of recycled concrete.

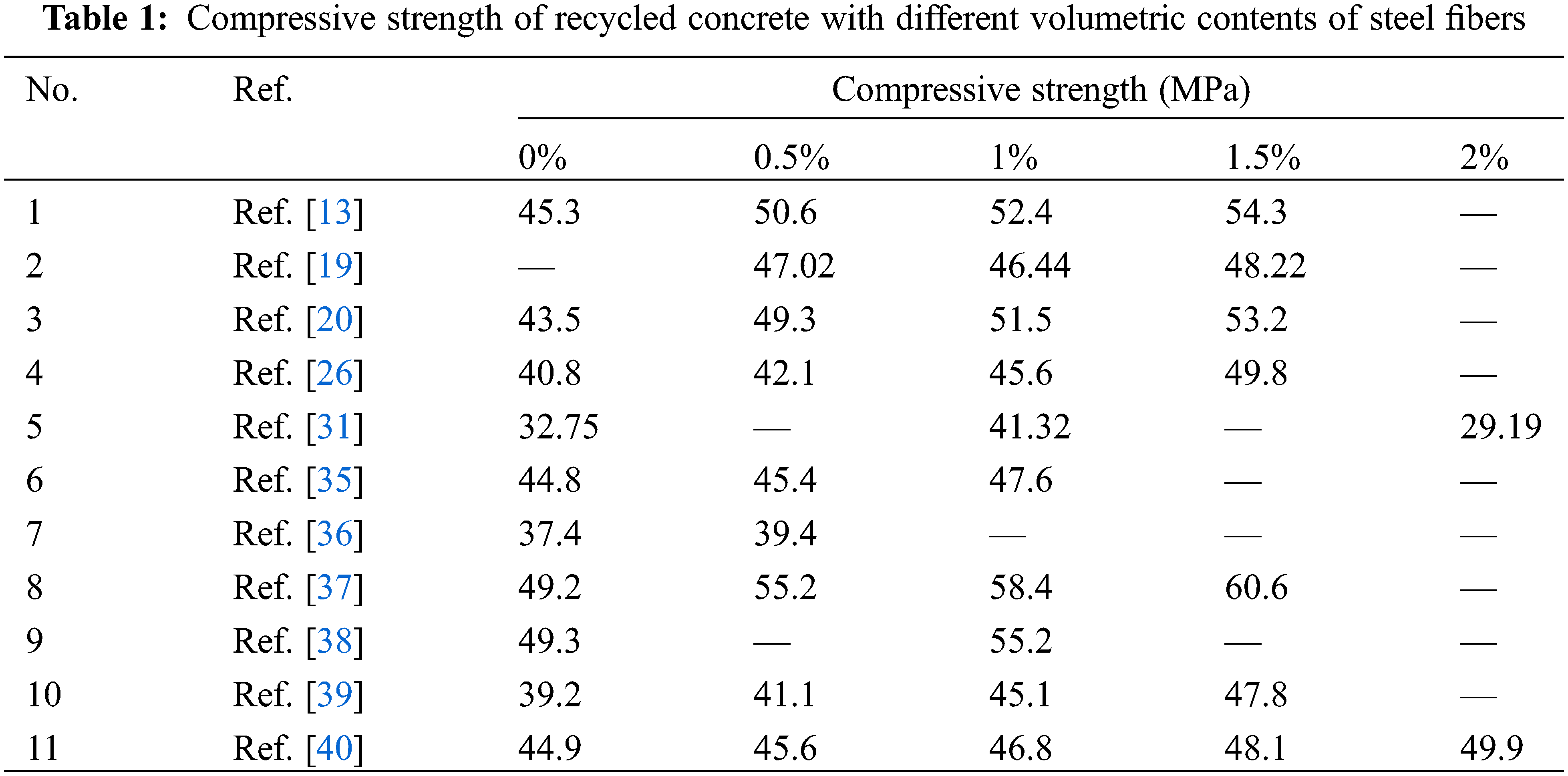

The good thermal conductivity of steel fibers is advantageous because it can reduce temperature increase while promoting cement hydration and improving interfacial bonding to compensate for the internal defects of recycled concrete to a certain extent (Fig. 2) [19,20]. Adding steel fibers to recycled concrete can counteract the negative impacts of recycled aggregates on the mechanical and impact properties of concrete [21] and further improve the strength and toughness of material. Compared with the influence of flexible fibers, the influence of steel fibers on the mechanical properties of concrete is more significant [22]. Thus, steel fibers have attracted the attention of scholars worldwide [23–25].

Figure 2: Steel fibers [20]

A series of studies have shown that the addition of steel fibers to recycled concrete can increase the compressive strength [16,26], tensile strength [17,27–30], and flexural strength [16,27–29] of recycled concrete to a certain extent.

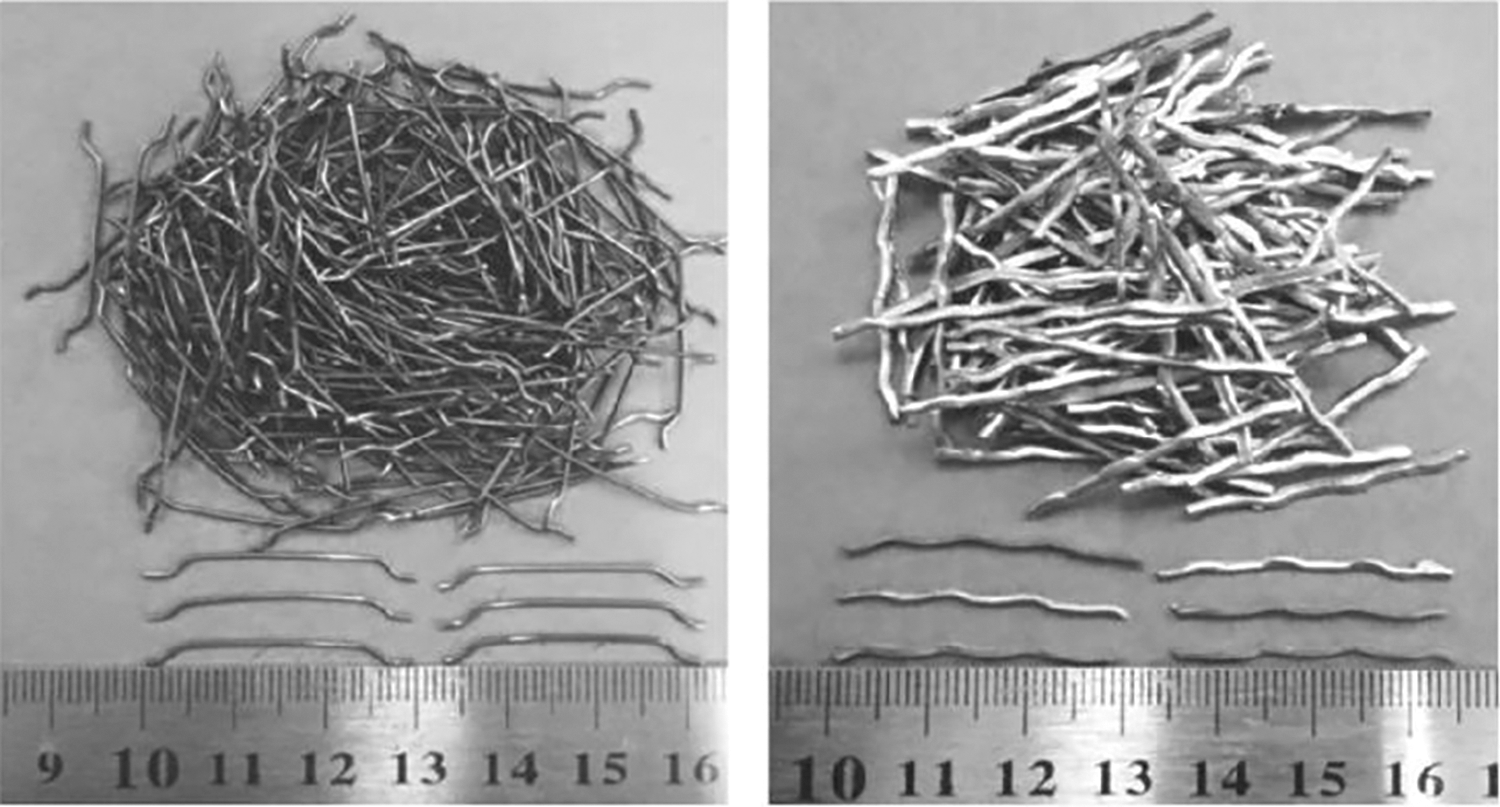

The compressive properties of recycled concrete containing 0%–2.0% by volume of steel fibers have been investigated by scholars in the last decade. Volumetric contents of 0.5% and 1% have been extensively studied. Studies have reported that the compressive strength of recycled concrete tends to increase when the content of steel fiber increases from 0% to 1.5%. Compared with the compressive strength of steel fiber pebble concrete, the compressive strength of steel fiber recycled coarse aggregate concrete can be increased by 26% [16]. When the steel fiber content is 1.5%, its axial compressive strength increases to 19.4% [29]. Danying investigated the influence of volume ratio and the type of steel fibers on the compressive strength of cubic samples of steel fiber-reinforced recycled concrete. The cubic compressive strength of milled prewetted steel fiber concrete materials was reported to be higher than that of reference concrete materials [26]. Zhou et al. investigated the changes in the compressive strength and other mechanical properties of recycled concrete by increasing the content of brazed steel fibers and noted that an excess of steel fibers could reduce the compressive strength of concrete [31]. The main reasons for the decrease are as follows: (1) small bubbles are introduced with the addition of fibers; (2) the introduction of fibers increases the interfacial porosity of concrete, and this increase is proportional to the length and volume of fibers, and (3) fiber agglomeration occurs due to insufficient homogeneity in the mixing of fibers and aggregates [32–34]. Table 1 demonstrates the compressive strength of recycled concrete materials with different steel fiber volumes.

2.2 Splitting Strength and Flexural Strength

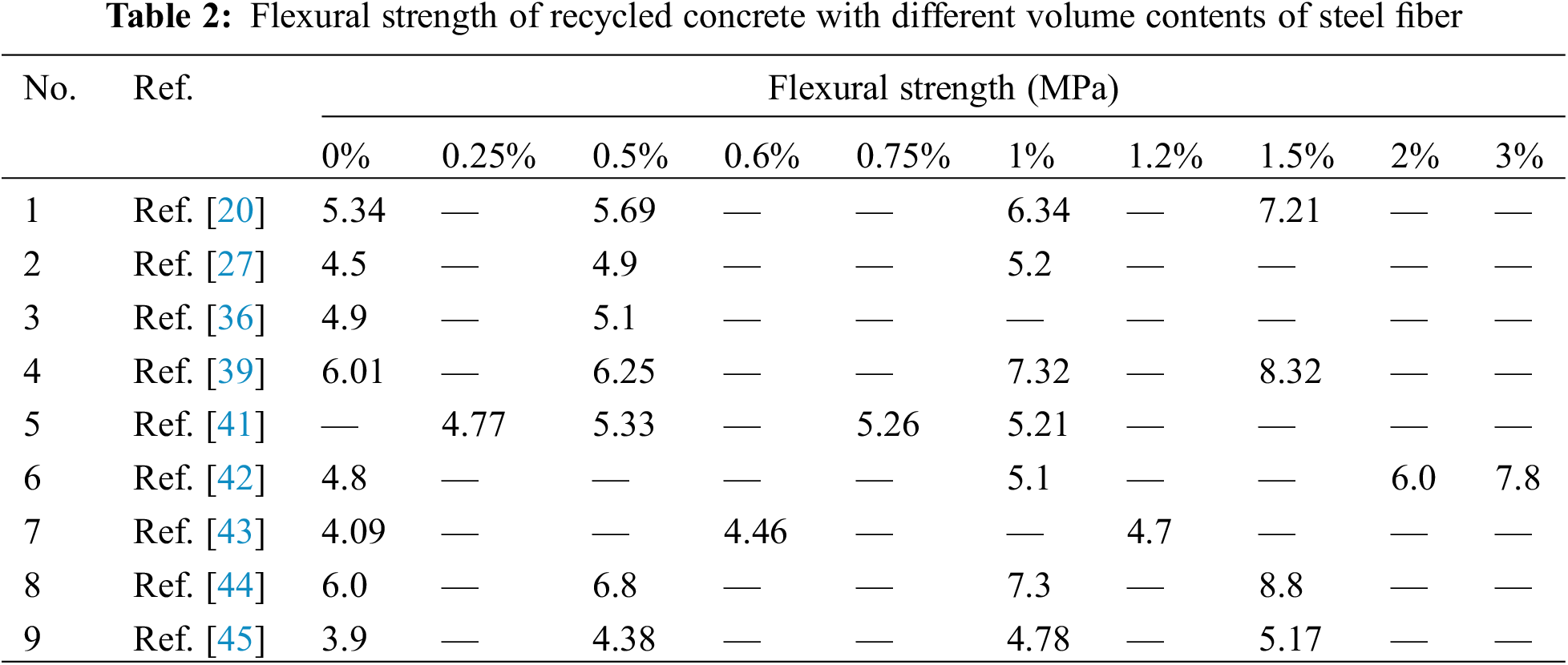

Various research groups have investigated the flexural properties of steel fiber recycled concrete with volumetric contents of 0%–3.0%. Steel fiber additions of 0.5% and 1% by volume have received special attention. In general, when the volumetric content of steel fibers increases in the range of 0%–1.5%, the flexural strength of recycled concrete demonstrates an upward trend [20,39]. SEM and other analyses have shown that connections between steel fibers can prevent crack generation and development in the cement base, reducing the stress concentration in the structure and enabling the formation of a more cohesive structure to improve the flexural and splitting properties of recycled concrete [27,28]. With an increase in the percentage of steel fiber by volume, the maximum tensile strength and peak strain of steel fiber-reinforced recycled aggregate concrete increase by 55.90% and 48.03%, respectively [30]. When the content of steel fiber is 2%, the increase in the splitting tensile strength and flexural strength is the largest, at 44.8% and 34.0%, respectively [29]. Researchers have found that the splitting tensile strength can be increased by 43%–52% upon adding steel fibers [17]. Compared with the splitting strength of steel fiber pebble concrete, the splitting strength of steel fiber recycled coarse aggregate concrete is 18.1% higher [16]. The flexural strength values of recycled concrete with different volumetric contents of steel fiber are listed in Table 2.

2.3 Other Performance Parameters

The toughness of steel fiber-reinforced recycled aggregate concrete increases upon increasing the steel fiber content [24,46]. Adding steel fiber helps prevent spalling and significantly improves the ductility and crack resistance of recycled concrete after exposure to high temperatures [26]. Studies have also revealed that the addition of steel fiber has a certain restraint and inhibition effect on the micro-expansion of concrete [43].

In conclusion, although replacing natural aggregates with recycled aggregates can reduce the mechanical properties of concrete, the addition of steel fibers to the latter can have a certain reinforcing effect and a positive effect on improving its compressive and splitting tensile strength. Steel fibers can significantly improve the shear responses of recycled concrete aggregate-based beams [47]. As a green concrete material, steel fiber recycled concrete is feasible to fabricate. It can better solve the environmental pollution problems associated with the disposal of waste aggregates to produce economic and social benefits [19].

Polypropylene fiber is the major synthetic fiber used in concrete. In China, scholars and practitioners have conducted in-depth research on polypropylene fibers to improve the performance of ordinary concrete. However, only a few studies have examined its ability to improve recycled concrete [48]. Adding polypropylene fiber can effectively inhibit the plastic shrinkage cracking of concrete and improve its impermeability, frost resistance, and corrosion resistance. Furthermore, the diameter of polypropylene fiber is between 0.22–0.25 mm, which is close to the diameter of steel fibers, but its cost for the same volume is only one-fifth that of steel fiber. Thus, it can economically replace steel fibers [49,50]. Lastly, adding polypropylene fibers can improve the mechanical properties of recycled concrete [51].

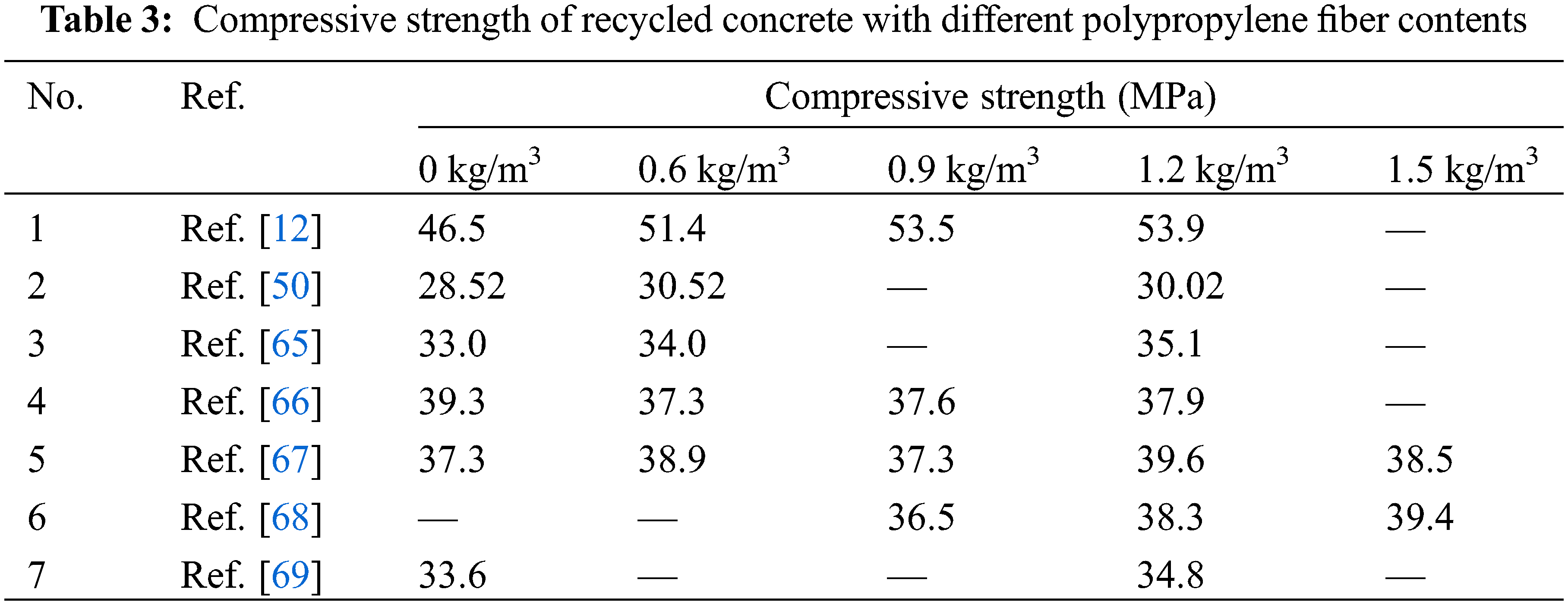

Scholars have investigated the compressive and flexural properties of polypropylene fiber recycled concrete with volumetric fiber contents of 0–1.5 kg/m3. The present review focuses on materials with volumetric fiber contents of 0.6, 0.9, and 1.2 kg/m3. In general, when the content of polypropylene fiber increases in the range of 0–1.2 kg/m3, the compressive strength and flexural strength of a recycled concrete show an increasing trend. Studies have revealed that the content of polypropylene fibers has no significant effect on the compressive strength of recycled concrete, but it can improve its ductility and impact resistance [52]. Adding 1% polypropylene fiber can increase the splitting tensile strength of concrete [53]. Yuan et al. conducted a series of tests and found that a fiber content of 1.2 kg/m3 can significantly improve concrete’s flexural and splitting tensile properties, with the highest flexural strength being 5.1 MPa and splitting tensile strength being 2.93 MPa [54]. A previous study has revealed that the splitting tensile strength of recycled concrete with a volumetric fraction of 1.0% polypropylene fiber was increased by 57% [55]. Zhu et al. made prismatic specimens of five kinds of recycled concrete reinforced with polypropylene fiber contents of 0, 0.7, 1.0, 1.3, and 1.6 kg/m3. The results presented that when the fiber content is 1.6 kg/m3, the flexural strength of recycled concrete increases by 23.9% compared with that without polypropylene fibers [56].

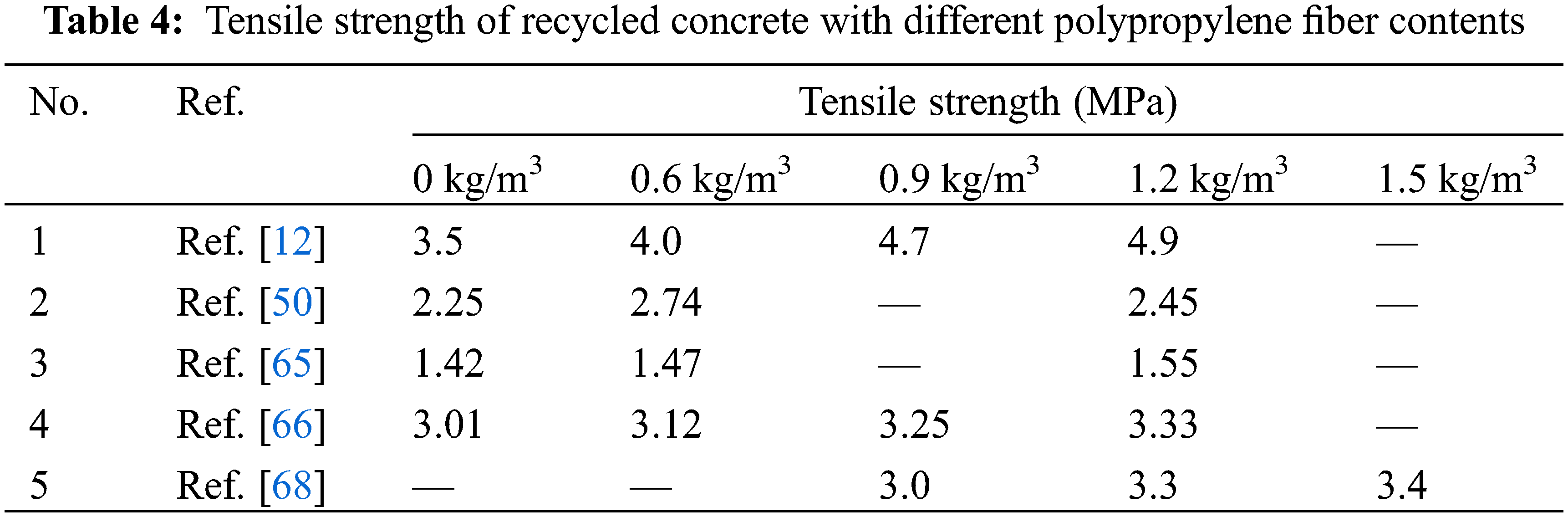

During the early stages of recycled concrete development, some scholars believed that the influence of polypropylene fiber content on compressive strength could be ignored [57]. However, scholars have reported that as the volume fraction of polypropylene fiber increases from 1% to 2%, the compressive strength of recycled concrete with 50% and 100% substitution rates increases by 20.7%–45% and 15.7%–35.7%, respectively [58]. When recycled aggregates are completely replaced, and the fiber content is 0, 4.5, and 1 kg/m3, the 28-day strength decreases by 25.7%, 23.8%, and 24.2%, respectively [59]. Adding polypropylene fibers helps increase the compressive strength of artificial sand recycled concrete specimens at various strength levels. However, the reinforcement is unobvious for specimens with high strength levels [60]. It is found that the axial compressive strength, flexural strength, and splitting tensile strength of recycled concrete present the highest level of increase when the fiber content is 0.8 kg/m3, reaching 15.8%, 39.6%, and 40.5%, respectively [29]. Furthermore, some research results have revealed that the optimal percentage of polypropylene fiber is 0.6%, for which the compressive strengths of concrete materials with 50% and 100% substitution rates are increased by 24.8% and 24.4%, respectively [61]. With an increase in the polypropylene fiber content from 0.25% to 1%, the compressive strength at substitution rates of 25%, 30%, and 35% increased by 57.6%–108.0%, 40.5%–90.9%, and 45.5%–102.3%, respectively [62]. The compressive strength, splitting tensile strength, and flexural strength increase upon increasing the polypropylene fiber content. The sample with a 30% substitution rate and 2% fiber content presented the highest compressive strength, which was 26.9% higher than the control sample on day 28 [63]. In addition, the compressive strength of polypropylene fiber concrete increases with increasing curing age. Curing for 91 days increases its compressive strength by 11.5% [64]. The compressive and tensile strengths of recycled concrete with different volumetric contents of polypropylene fibers are listed in Tables 3 and 4, respectively.

3.2 Other Mechanical Properties

Concerning other mechanical properties, the effect of fiber on increasing the peak strain of concrete is obvious. The ultimate strain is inversely proportional to the grade of concrete strength and is directly proportional to the increase of fiber content. Fiber can improve concrete’s deformation and ductility [67]. Adding polypropylene fiber reduces the dynamic elastic modulus and increases the static modulus. When the fiber content is 0.45%, the 28-day dynamic elastic modulus is 3% lower than that of ordinary concrete, and the 91-day static elastic modulus increases by 6%, reaching 37.5 GPA [64]. A research group has noted that adding polypropylene fiber to concrete can slightly reduce the latter’s elastic modulus and Poisson’s ratio [70]. When recycled aggregates are completely replaced, compared with the case without recycled aggregates, the elastic modulus of test blocks with fiber contents of 0, 4.5, and 1 kg/m3 decreases by 49.2%, 44.1%, and 46.4%, respectively [59]. The XCT analysis results have shown positive and negative effects of incorporating polypropylene fiber, and a reasonable fiber dosage range needs to be considered to enhance concrete performance [54].

The fiber size affects the compressive strength and tensile strength of polypropylene fiber recycled concrete, and the influence is more distinct with an increase in size [50]. The size effect is influenced by the replacement rate of the recycled aggregates, the amount of waste fiber, and the strength grade of concrete [71]. In addition, when adding hybrid fibers to recycled concrete with volumetric contents within a certain defined value, there are synergistic effects between the two fibers that can increase the bonding strength of matrix. If the volumetric content exceeds the defined range, it will indirectly reduce the bonding strength of matrix [72].

Although the effect of synthetic fibers on the compressive strength, elastic modulus, and Poisson’s concrete ratio is unobvious and even leads to a reduction in its indices, a series of studies have displayed that synthetic fibers can improve many other properties of concrete to a certain extent. For example, synthetic fibers have achieved promising results in the preparation of waterproof concrete, As a new type of polymer building material, synthetic fibers can replace traditional reinforcement meshes and steel fibers in concrete, reducing construction costs, saving time, and making recycled concrete more convenient to use and apply, thus presenting a wider application potential for it [73–75]. There are still some problems associated with the combined influences of synthetic fibers and cement substrates, which need to be addressed before their use [76].

As a complex natural composite with cellulosic structures, plant fibers can be produced in large quantities and are renewable. Additionally, their strength and stiffness are similar to those of ordinary synthetic fibers, and their densities are lower. Therefore, their specific strength and specific stiffness (ratio of elastic modulus to density) are high, reducing the weight of concrete at a low cost. They are being developed as cement-filling materials [77]. The traditional fibers widely used in engineering have many environmental and health problems associated with them [78,79], and the application of plant fibers is conducive to environmental protection. It is in line with the purpose of China’s sustainable development plans. It plays a role in promoting the realization of major national policies such as energy conservation and emission reduction, circular economy, and environmental harmony. However, research on the application of plant fibers in recycled concrete needs to be expanded, and there are many studies on the application of plant fiber in ordinary concrete. The research advances related to plant fiber concrete are summarized below; this summary is expected to provide a reference for scholars in the field of plant fiber recycled concrete and related materials.

Adding plant fibers to concrete can improve the internal defects in concrete [80]. Common natural plant fibers, such as rice fiber, rape straw fiber, bamboo fiber, and corn straw fiber, impact the mechanical, thermal insulation, water absorption, and corrosion resistance properties of concrete [81]. Previous studies have presented that the compressive strength of concrete gradually decreases upon increasing the rape straw content, and the 7-day compressive strength of concrete decreases faster than the 28-day compressive strength [82]. Subsequently, Baohua selected the sand ratio, water cement ratio, and ash content of rape straw as variables, tested the thermal conductivity of block, and observed the same trend. The author noted that this is because adding straw ash reduces the amount of cement in the concrete and reduces the hydration reaction, resulting in a reduction in the strength of concrete [83]. However, when the fiber length of rape straw is 30–40 mm, and the volume content is 0.1%, the compressive strength reaches a peak value and increases by 16.45%. When the fiber length is 20–30 mm, and the volume content is 0.2%, the splitting tensile strength and flexural strength increase by 9.12% and 6.64%, respectively [84]. When the content of rape straw ash is 10%, the dynamic bearing capacity of concrete reaches an optimum value [85]. Regarding other properties, straw concrete presents good thermal insulation performance [86].

Wood fiber-reinforced concrete is a new environmentally friendly material that can absorb and degrade carbon elements and can also reduce CO2 emission [80]. In terms of mechanical properties, According to Yang‘s investigation, the strength of concrete materials doped with sawdust under dry and saturated water absorption states shows a downward trend. However, the downward trend in the strength in saturated water absorption states is sharper. When the volumetric addition of sawdust is 3% does the strength of concrete decrease by approximately 38%, and when the volumetric addition reaches 10%, the concrete segregates [87].

Coconut shell fiber has good mechanical properties, heat, moisture, and wear resistance [88]. When the content of coconut shell fiber is 0.5 kg/m3, the 28-day flexural strength of recycled concrete can be as high as 5.79 MPa, the lowest being 4.1 MPa, with an increase of 5.13%–23.19%, achieving the conditions necessary for applications in ordinary concrete structure engineering [89,90]. The splitting tensile strength of concrete increases with the addition of coconut shell fiber. When the content of coconut shell fiber is 0.25%, and the content of nano-SiO2 is 3%, the resultant concrete has good wear resistance [91]. A study has reported that coconut shell fiber concrete materials with water-cement ratios of 0.4 have better mechanical properties. Concrete has better interfacial properties when the coconut shell fiber is woven into a network [92].

Plant fiber concrete is lightweight and environmentally friendly, has high degrees of toughness, and displays good thermal insulation performance. It has been applied to some projects with promising results. The addition of CR latex can effectively improve the strength of fiber-reinforced concrete and the viscosity of these materials [93]. However, many alkaline substances are produced during the mixing of concrete, and in alkaline environments, the problems associated with corrosion cannot be overlooked [94]. In addition, using plant fibers can result in wet concrete expansion and dry shrinkage, which can lead to changes in the plant fibers and affect their degree of bonding with the concrete [80]. An in-depth study of plant fibers may indicate that they could play a substantial role in the fabrication of recycled concrete.

Basalt fiber is a common mineral fiber, and as a new inorganic green fiber material, it has good ductility and affordability. Basalt fiber is a new material for improving the mechanical properties of recycled concrete. Many studies have displayed that basalt fiber can improve the strength of concrete [95,96], and a few studies have revealed that it can increase the strength of recycled concrete [97]. Compared with the high cost of steel fibers and the poor dispersion of polypropylene fibers, basalt fibers show high strength, high modulus, good high and low-temperature resistances, and strong acid and alkali resistances. Furthermore, they are pollution-free [98], do not generate or emit toxic substances or wastes during production, and can be easily processed with conventional processes and equipment. Without the use of any other additives during a single production process, their production costs are lower than the costs of other materials.

Basalt fiber essentially has basically the same composition as cement and the same expansion and contraction coefficient. When mixed with cement concrete, basalt fiber shows natural compatibility, is easily dispersed and has good chemical stability [99]. Studies have presented that basalt fiber has a dose-dependent reinforcement effect on a reinforced recycled aggregate and natural aggregate concrete, and there is a complementary effect between basalt fiber and recycled aggregate concrete. That is, the poor performance of recycled aggregate concrete can be offset by adding basalt fiber [100]. Adding basalt fiber improves the unstable crack propagation of concrete, effectively prevents rapid crack propagation, increases the crack resistance of concrete, and produces reinforcement, crack resistance, and toughening effects [101]. A suitable quantity of basalt fiber can also enhance the ductility of recycled concrete and improve its mechanical properties [102].

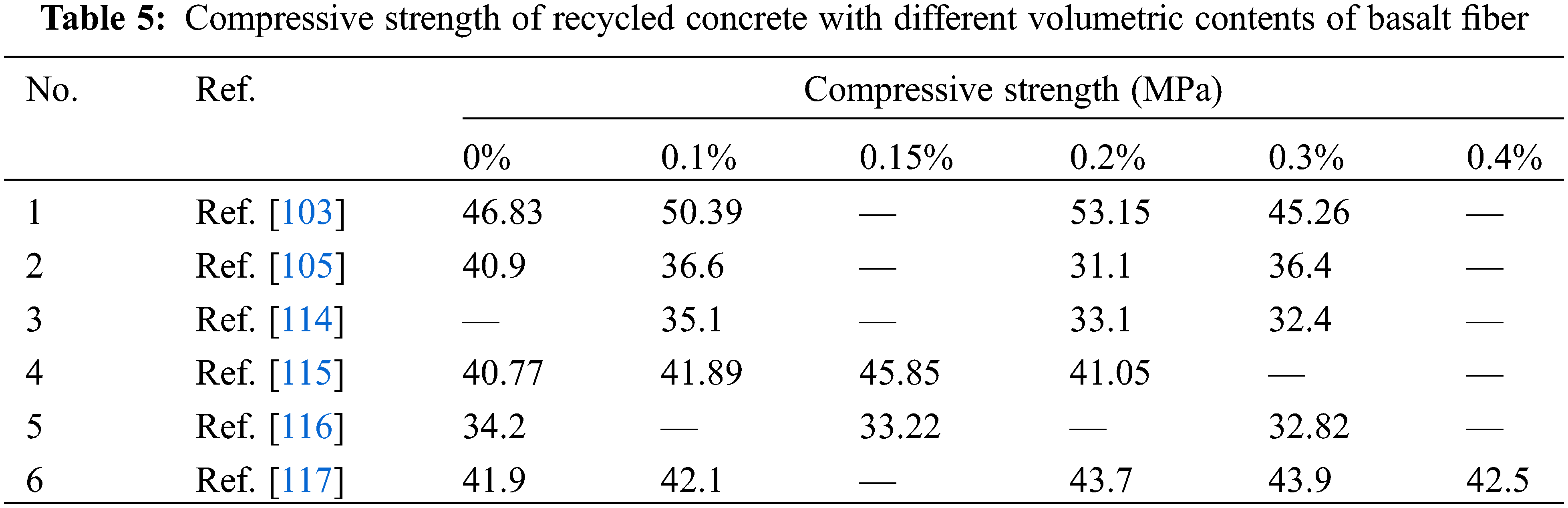

The addition of an appropriate amount of basalt fiber can increase the compressive strength [97,102–104], splitting tensile strength [102,104–107], and flexural strength [102,104] of recycled concrete to a certain extent. Scholars have conducted in-depth research on the compressive and splitting tensile properties of basalt fiber recycled concrete at volumetric contents of 0%–0.4%, among which fiber contents of 0.1%, 0.2%, and 0.3% have been the research hotspots. In general, when the content of basalt fiber increases in the range of 0%–0.15%, the compressive strength and splitting tensile strength of recycled concrete display an upward trend. In addition, studies have found that when the substitution rate is 50%, the basic mechanical properties of recycled concrete materials containing different basalt fiber contents are better than those of ordinary concrete [108]. At a fixed content, the compressive strength of recycled concrete increases upon increasing fiber length [109]. Subsequent studies have shown that the strength of recycled concrete increases upon increasing the fiber content. For three different design strength grades of concrete, when the fiber content is 1.5 kg/m3, the strength is consistent with that of ordinary concrete [97]. Furthermore, by fitting the experimental data, some scholars proposed a new conversion formula relating the mechanical indices of basalt fiber recycled concrete [110], which provides a convenient way to convert between the mechanical performance indices of basalt fiber recycled concrete.

When the content of basalt fiber is 1%, the recycled concrete achieves maximum compressive strength [104]. The compressive strength of recycled concrete has been reported to increase and decrease upon increasing the basalt fiber content [111]. Additionally, the influence of different fiber contents on the axial compressive strength of recycled concrete under different substitution rates is different [106]. A previous study has demonstrated that the compressive strength of recycled concrete has a non-significant improvement by adding basalt fiber [104]. However, at high temperatures, basalt fiber is conducive to improving recycled concrete’s compressive strength [112]. The compressive strength of recycled concrete with different basalt fiber contents (Table 5).

5.2 Splitting Tensile Strength

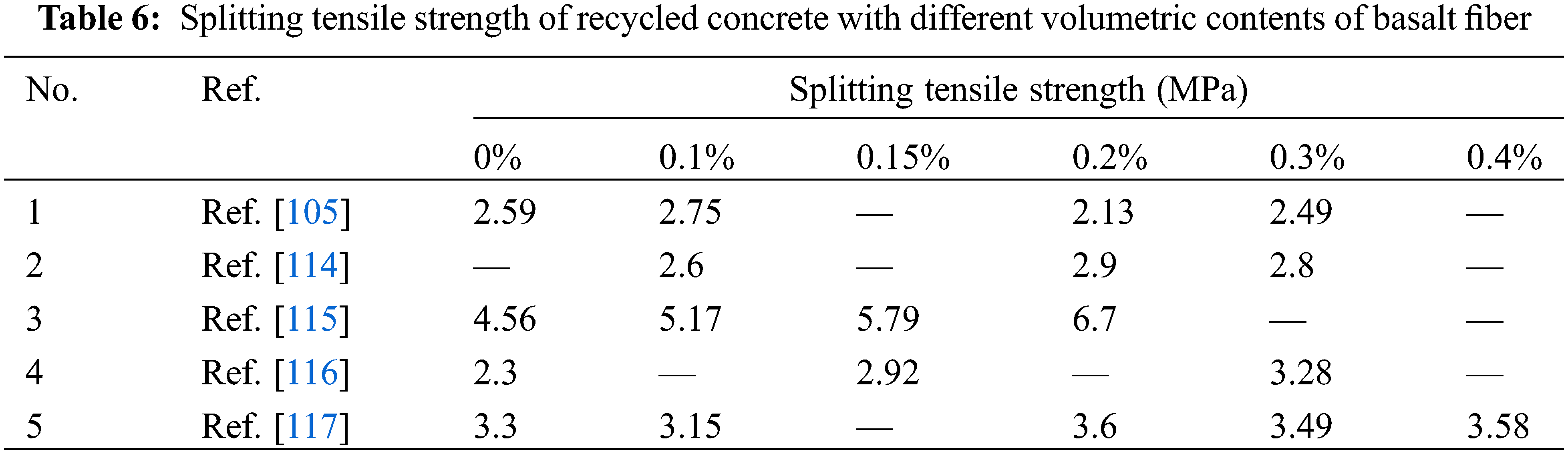

Studies have demonstrated that when the basalt fiber content is 4 kg/m3, the splitting tensile strength of recycled concrete increases by 8.3% [113]. For recycled concrete materials with a high replacement rate, the material splitting tensile strength is affected by basalt fiber, and the reinforcement effect is very significant [105]. When the content is too high, the splitting tensile strength is weakened to a certain extent. Jiangfeng investigated the physical and mechanical properties of recycled concrete reinforced with different replacement levels (0, 2, and 4 kg/m3) of recycled aggregate and observed that when the basalt fiber content was 4 kg/m3 and the substitution rate was 50%, the flexural strength and splitting tensile strength increased to their maximum values [106]. The splitting tensile strength of recycled concrete with different basalt fiber contents (Table 6).

5.3 Other Performance Parameters

The effect of basalt fiber on improving the elastic modulus of recycled concrete is somewhat ambiguous [113]. A study has revealed that the elastic modulus first decreases and then increases with increasing basalt fiber content (0%–0.2%) [118]. In addition, basalt fiber has a distinct toughening effect on rubber recycled concrete [119]. Adding basalt fiber to recycled concrete can slow down freeze-thaw damage in recycled concrete [120]. In addition, studies have displayed that adding a basalt macrofibre can improve the flexural capacity of recycled concrete beams [121]. Furthermore, adding basalt fiber can significantly improve the deformation capacity of recycled concrete, which presents potential and value for certain engineering applications [122].

Research on improving the mechanical properties of recycled concrete by fiber doping is related not only to the different fiber parameters but also to the content of fibers and their substitution rate for recycled aggregates. Most studies have presented that adding fiber can increase the mechanical properties of recycled concrete. The conclusions are as follows:

1. After adding an appropriate amount of steel fiber, the strength of recycled concrete is distinctly improved, its brittleness is reduced, and the elastic modulus of recycled concrete is improved.

2. Polypropylene fibers are suitable for replacing steel fibers in concrete and have a certain strengthening effect on recycled concrete. However, the strengthening of compressive strength is non-significant, and the fibers can reduce the elastic modulus of recycled concrete. The compressive strength and tensile strength of polypropylene fiber recycled concrete have a size effect, which has positive and negative consequences on the mechanical properties of recycled concrete.

3. Plant fiber concrete is lightweight and environmentally friendly and has high toughness and good thermal insulation performance. It has been applied to a few studies and has shown promising results. However, there is little research on its use in recycled concrete, and the corrosion problems associated with the fibers in alkaline environments cannot be ignored during mixing concrete. Plant fibers absorb water and undergo wet expansion and dry shrinkage. These problems need to be further studied.

4. Compared with other fibers, basalt fibers have many advantages, including cost savings in production. Adding these fibers to recycled concrete can improve the latter’s flexural toughness and ductility. The research shows that with a reasonable addition of basalt fiber, basalt fiber recycled concrete can achieve the strength of ordinary concrete.

Funding Statement: This work was supported by the Open Fund of Engineering Research Center of Underground Mine Construction, Ministry of Education (Anhui University of Science and Technology) (Grant No. JYBGCZX2020210), Anhui International Joint Research Center of Data Diagnosis and Smart Maintenance on Bridge Structures (Grant No. 2022AHGHYB09), Scientific Research Program of Anhui Province (Grant No. 2022AH051092).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Zhang, H. (2021). Research on the current situation of urban construction waste treatment and resource utilization. Green Environmental Protection Building, 8(12), 31–32. [Google Scholar]

2. Xiao, J. Z., Li, J. B., Lan, Y. (2003). Research on recycled aggregate concrete–A review. Concrete, 25(10), 17–20+57. [Google Scholar]

3. Sun, D. S., Li, Z. Y., Liu, K. W., Wang, A. G., Hang, W. et al. (2021). Influence of shapes and defects of recycled aggregate on drying shrinkage and mechanical properties of recycled aggregate concrete. Materials Reports, 35(11), 11027–11033+11056. [Google Scholar]

4. Zhu, H. B., Zhao, Y., Lei, X. W., Yang, Q. (2013). Current situation and suggestion on recycled concrete research. Highway Engineering, 38(1), 98–102. [Google Scholar]

5. Šeps, K., Broukalová, I., Fládr, J., Bílý, P. (2018). Study on potential of fibre reinforced concrete with recycled aggregate for applications. IOP Conference Series: Materials Science and Engineering, 379(1), 1–6. [Google Scholar]

6. Sun, Y. D., Wang, T. (2010). Influence of intensified recycled aggregate to the basic mechanical properties of recycled concrete. Sichuan Building Science, 36(4), 212–215. [Google Scholar]

7. Xiao, J. Z., Lin, Z. B., Zhu, J. (2014). Effects of recycled aggregates gradation on compressive strength of concrete. Advanced Engineering Sciences, 46(4), 154–160. [Google Scholar]

8. Wang, J., Xue, Y. F., Zhou, H. (2006). The study of compressive strength of recycled aggregate concrete. Concrete, 28(7), 47–49. [Google Scholar]

9. Cai, H. Y., Zhang, M., Dang, L. B. (2012). Experimental study on compressive strength of recycled aggregate concrete with different replacement ratios. Applied Mechanics and Materials, 1801(174–177), 1277–1280. https://doi.org/10.4028/www.scientific.net/AMM.174-177.1277 [Google Scholar] [CrossRef]

10. Ali, R., Hamid, R. (2015). Workability and compressive strength of recycled concrete waste aggregate concrete. Applied Mechanics and Materials, 3861(754–755), 417–420. https://doi.org/10.4028/www.scientific.net/AMM.754-755.417 [Google Scholar] [CrossRef]

11. Wang, P. X., Guo, H. Y., Zhou, M. (2021). Study on the mechanical properties of recycled aggregate concrete in cold region. Forest Engineering, 37(4), 102–109. [Google Scholar]

12. Chen, D. Y., Liu, H., Lu, Z. Y. (2009). Influence of polypropylene fiber content on properties of recycled concrete. China Concrete and Cement Products, 36(4), 35–37. [Google Scholar]

13. Zhou, C., He, W. C., Kong, X. Q., Zheng, Z. Y., Wang, X. Z. (2021). Study on impact behavior of steel fiber recycled concrete. Concrete, 43(5), 36–41. [Google Scholar]

14. Meesala, R. (2019). Influence of different types of fiber on the properties of recycled aggregate concrete. Structural Concrete, 20(5), 1656–1669. https://doi.org/10.1002/suco.201900052 [Google Scholar] [CrossRef]

15. Zhou, J. H., Li, T. T., Yang, G. Z. (2013). Experimental research on mechanical properties of waste fiber recycled concrete. Concrete, 34(3), 1–4. [Google Scholar]

16. Yang, R. N., Yi, J. R., Xiao, H. M., Liu, Q. F. (2006). Experimental study of steel fiber reinforced regenerated concrete’s mechanical properties. Concrete, 28(1), 27–29+42. [Google Scholar]

17. Paluri, Y., Mogili, S., Mudavath, H., Noolu, V. (2020). Effect of fibres on the strength and toughness characteristics of recycled aggregate concrete. Materials Today: Proceedings, 38, 2537–2540. https://doi.org/10.1016/j.matpr.2020.07.555 [Google Scholar] [CrossRef]

18. Wu, X. X., Zhou, J. H., Kang, T. B., Wang, F. C., Ding, X. Q. et al. (2019). Laboratory investigation on the shrinkage cracking of waste fiber-reinforced recycled aggregate concrete. Materials, 12(8), 1196. https://doi.org/10.3390/ma12081196 [Google Scholar] [PubMed] [CrossRef]

19. Jin, B. H., Zhan, D. (2014). Experimental research on mechanical properties of steel fiber recycled concrete. Concrete, 36(3), 102–105. [Google Scholar]

20. He, W. C., Kong, X. Q., Zhou, C., Wang, X. Z. (2020). Investigation on mechanical properties and microstructure of steel fiber reinforced recycled aggregate concrete. Concrete, 42(12), 44–49. [Google Scholar]

21. Fereydoon, O., Saeideh, M., Amirhosein, S. (2021). Characterization and optimization of mechanical and impact properties of steel fiber reinforced recycled concrete. International Journal of Civil Engineering, 20, 41–55. https://doi.org/10.1007/S40999-021-00656-2 [Google Scholar] [CrossRef]

22. Gao, D. Y., Gu, Z. Q., Pang, Y. Y., Yang, L. (2021). Mechanical properties of recycled fine aggregate concrete incorporating different types of fibers. Construction and Building Materials, 298, 123732. https://doi.org/10.1016/j.conbuildmat.2021.123732 [Google Scholar] [CrossRef]

23. Carneiro, J., Lima, P., Leite, M., Filho, R. (2014). Compressive stress–strain behavior of steel fiber reinforced-recycled aggregate concrete. Cement & Concrete Composites, 46, 65–72. https://doi.org/10.1016/j.cemconcomp.2013.11.006 [Google Scholar] [CrossRef]

24. Afroughsabet, V., Biolzi, M., Ozbakkaloglu, T. (2017). Influence of double hooked-end steel fibers and slag on mechanical and durability properties of high performance recycled aggregate concrete. Composite Structures, 181, 273–284. https://doi.org/10.1016/j.compstruct.2017.08.086 [Google Scholar] [CrossRef]

25. Chen, G. M., He, Y. H., Yang, H., Chen, J. F., Guo, Y. C. (2014). Compressive behavior of steel fiber reinforced recycled aggregate concrete after exposure to elevated temperatures. Construction and Building Materials, 71, 1–15. https://doi.org/10.1016/j.conbuildmat.2014.08.012 [Google Scholar] [CrossRef]

26. Gao, D. Y., Lou, Z. H., Wang, Z. Q. (2007). Experimental research on the compressive strength of steel fiber recycled concrete. Journal of Zhengzhou University (Engineering Science), 28(2), 5–10. [Google Scholar]

27. Yang, F., Chen, A. J., Wang, J., Sun, X. P. (2012). Experiments of splitting tensile and flexural strength mechanical properties of steel fiber recycled concrete. Concrete, 34(12), 11–14. [Google Scholar]

28. Xu, Z., Huang, Z. P., Liu, C. J., Deng, X. W., David, H. et al. (2021). Experimental study on mechanical properties and microstructures of steel fiber-reinforced fly ash-metakaolin geopolymer-recycled concrete. Reviews on Advanced Materials Science, 60(1), 578–590. https://doi.org/10.1515/rams-2021-0050 [Google Scholar] [CrossRef]

29. Huo, J. F., Bai, X. X., Jiang, P. F., Xue, Y. D., Song, D. T. et al. (2018). Effect of different fiber content on mechanical properties of recycled concrete. IOP Conference Series: Materials Science and Engineering, 439(4). https://doi.org/10.1088/1757-899X/439/4/042051 [Google Scholar] [CrossRef]

30. Zong, S., Liu, Z. Z., Li, S., Lu, Y. Y., Zheng, A. H. (2021). Stress-strain behaviour of steel-fibre-reinforced recycled aggregate concrete under axial tension-ScienceDirect. Journal of Cleaner Production, 278(1), 123248. [Google Scholar]

31. Zhou, C. X., Tan, Y., Zhou, J. Z., He, Q. (2021). Experimental study on strength and failure of steel fiber recycled concrete. Journal of Hubei University of Technology, 36(2), 76–80. [Google Scholar]

32. Yang, Y. S., Wang, J. (2013). Basic mechanical properties of fiber recycled concrete. Journal of Liaoning Technical University (Natural Science), 32(12), 1669–1672. [Google Scholar]

33. Zhang, Y., Liu, Q. (2017). Experimental study on recycled concrete containing recycled fibers and organic fibers. Proceedings of the 2017 6th International Conference on Energy, Environment and Sustainable Development (ICEESD 2017), Zhuhai, China. [Google Scholar]

34. Ahmadi, M., Farzin, S., Hassani, A. (2017). Mechanical properties of the concrete containing recycled fibers and aggregates. Construction and Building Materials, 144, 392–398. https://doi.org/10.1016/j.conbuildmat.2017.03.215 [Google Scholar] [CrossRef]

35. Chen, A. J., Wang, J., Yang, F. (2012). Experiments of compressive strength mechanical properties of steel fiber recycled concrete. Concrete, 34(4), 64–66. [Google Scholar]

36. Yang, F., Chen, A. J., Wang, J. (2013). The impact of different steel fibers on the basic mechanical properties of recycled concrete. New Building Materials, 40(2), 44–46. [Google Scholar]

37. Kong, X. Q., He, W. C., Zhou, C., Zheng, Z. Y., Wang, X. Z. (2020). Experimental investigation on the mechanical properties and impact resistance of steel and polypropylene hybrid fiber reinforced recycled aggregates concrete. Building Science, 36(3), 94–99. [Google Scholar]

38. Zhu, Q. (2018). Performance and calculation method of steel fiber reinforced recycled aggregate concrete (Master Thesis). Zhengzhou University, China. [Google Scholar]

39. Li, L. P., Ma, Q. H. (2017). Effect of steel fiber on mechanical properties of recycled coarse aggregate cement concrete. Journal of China & Foreign Highway, 37(3), 267–270. [Google Scholar]

40. Zhang, L. J., Gao, D. Y., Wang, L., Zhu, H. T. (2017). Experiments on shear behavior of steel fiber recycled concrete. Journal of Civil Engineering and Management, 34(2), 104–107. [Google Scholar]

41. Su, J., Qin, H. J., Shi, C. J., Fang, Z. (2021). Experimental study on scale effect of flexural strength of steel fiber reinforced recycled concrete. Journal of Hunan University (Natural Sciences), 48(7), 160–167. [Google Scholar]

42. Wang, Z. S., Tan, X. Q. (2016). Frost resistant and mechanical properties of steel fiber recycled aggregate concrete. Bulletin of the Chinese Ceramic Society, 35(4), 1184–1187. [Google Scholar]

43. Hang, W., Ge, J. J., Fang, Z. P., Zhang, Y. Y. (2020). Preparation and performance of steel fiber shrinkage-compensating recycled concrete. Bulletin of the Chinese Ceramic Society, 39(9), 2789–2794. [Google Scholar]

44. Chen, T. Z. (2015). Experimental study on mechanical properties of steel fiber and macro polypropylene fiber reinforced recycled concrete (Master Thesis). Guangdong University of Technology, China. [Google Scholar]

45. Kong, X. Q., Gao, H. D., Gang, J. M., Yuan, S. L., Liu, H. X. (2018). Study on flexural toughness of steel-polypropylene hybrid fiber recycled aggregate concrete. Bulletin of the Chinese Ceramic Society, 37(9), 2729–2736. [Google Scholar]

46. Ramesh, R., Mirza, O., Kang, W. (2019). Mechanical properties of steel fiber reinforced recycled aggregate concrete. Structural Concrete, 20(2), 745–755. https://doi.org/10.1002/suco.201800156 [Google Scholar] [CrossRef]

47. Nancy, K., Tamer, E., Hilal, E., Bilal, E. (2021). Shear behavior of steel-fiber-reinforced recycled aggregate concrete deep beams. Buildings, 11(9), 423–423. https://doi.org/10.3390/buildings11090423 [Google Scholar] [CrossRef]

48. Wang, K. (2020). Effect of polypropylene fiber on mechanical and shrinkage properties of recycled concrete. Fujian Traffic Science and Technology, 40(6), 38–41. [Google Scholar]

49. Zhang, T., Huang, W., Rong, C. (2015). Damage constitutive models of polypropylene fiber recycled concrete. Materials Reports, 29(22), 150–155. [Google Scholar]

50. Tian, L. (2020). Study on compressive and tensile size effects of polypropylene fiber recycled concrete (Master Thesis). Xi’an University of Architecture and Technology, China. [Google Scholar]

51. Syazwani, W., Sallehan, I., Abdullah, W. (2016). Properties of recycled aggregate concrete reinforced with polypropylene fibre. MATEC Web of Conferences, vol. 66. https://doi.org/10.1051/matecconf/20166600077 [Google Scholar] [CrossRef]

52. He, W. C., Kong, X. Q., Fu, Y., Zhou, C., Zheng, Z. Y. (2020). Experimental investigation on the mechanical properties and microstructure of hybrid fiber reinforced recycled aggregate concrete. Construction and Building Materials, 261. https://doi.org/10.1016/j.conbuildmat.2020.120488 [Google Scholar] [CrossRef]

53. Tobeia Sameh, B., Khattab Mustafa, M., Khlaif Hasanain, H., Ahmed Mohammed, S. (2021). Enhancing recycled aggregate concrete properties by using polymeric materials. Materials Today: Proceedings, 42, 2785–2788. [Google Scholar]

54. Yuan, C. F., Wei, Y. R., Li, S. (2021). Study on mechanical properties of polypropylene fiber mixed recycled aggregate concrete. Journal of Zhengzhou University (Engineering Science), 42(2), 49–53. [Google Scholar]

55. Kazmi, S., Munir, M., Wu, Y. F., Patnaikuni, I. (2018). Effect of macro-synthetic fibers on the fracture energy and mechanical behavior of recycled aggregate concrete. Construction and Building Materials, 189, 857–868. https://doi.org/10.1016/j.conbuildmat.2018.08.161 [Google Scholar] [CrossRef]

56. Zhu, H. B., Yao, C., Zhao, B. L., Xu, Y. Q. (2017). Experimental research on the effects of polypropylene fiber content on recycled concrete flexural fatigue performance. Sichuan Building Science, 43(5), 104–107. [Google Scholar]

57. Das, C., Dey, T., Dandapat, R., Mukharjee, B., Kumar, J. (2018). Performance evaluation of polypropylene fibre reinforced recycled aggregate concrete. Construction and Building Materials, 189, 649–659. https://doi.org/10.1016/j.conbuildmat.2018.09.036 [Google Scholar] [CrossRef]

58. Hanumesh, B. M., Harish, B. A., Ramana, N. (2018). Influence of polypropylene fibres on recycled aggregate concrete. Materials Today: Proceedings, 5(1), 1147–1155. [Google Scholar]

59. Lu, X., Yang, J., Su, H. L., Wang, F. L. (2020). Experimental investigations on performance of polypropylene fibre reinforced recycled aggregate concrete. Concrete, 42(11), 67–71+74. [Google Scholar]

60. Luo, H., Ma, F. R., Yang, Q. (2020). Experimental analysis on mechanical performance of recycled concrete made from polypropylene fiber and artificial sand. Annales de Chimie-Science des Matériaux, 44(2), 97–102. https://doi.org/10.18280/acsm [Google Scholar] [CrossRef]

61. Ahmed, T., Mohammed Ali, A., Zidan, R. (2020). Properties of high strength polypropylene fiber concrete containing recycled aggregate. Construction and Building Materials, 241, 118010. https://doi.org/10.1016/j.conbuildmat.2020.118010 [Google Scholar] [CrossRef]

62. Kumar, D., Rao, T., Madhu, T., Saroja, P., Prasad, D. (2014). An expermental study of recycled concrete with polyporpylene fiber. International Journal of Innovative Research in Advanced Engineering, 1(7), 2349–2163. [Google Scholar]

63. Zahid Hossain, F. M., Shahjalal, M., Islam, K., Tiznobaik, M., Shahria Alam, M. (2019). Mechanical properties of recycled aggregate concrete containing crumb rubber and polypropylene fiber. Construction and Building Materials, 225, 983–996. [Google Scholar]

64. Yao, Y. F. (2020). Effect of polypropylene fiber on mechanical properties and dry shrinkage of recycled concrete. Journal of Functional Materials, 51(7), 7136–7140+7147. [Google Scholar]

65. Chen, A. J., Chen, M., Wang, D. H., Hu, F. Q., Li, H. X. (2014). Research on the basic properties of the polypropylene fiber rubber recycled concrete. Concrete, 36(9), 57–60. [Google Scholar]

66. Zhang, W. J., Bao, C. C., Kong, X. Q., Qu, Y. D., Liu, H. X. (2016). Experimental study on mechanical properties of hybrid fiber basic of recycled concrete. Science Technology and Engineering, 16(13), 106–112+123. [Google Scholar]

67. Luo, H. (2016). Experimental research on mechanical properties of recycled concrete with polypropylene fiber artificial sand (Master Thesis). Guangxi University, China. [Google Scholar]

68. Wu, J. H. (2007). Experimental study on mechanics property of the polypropylene fiber recycled concrete (Master Thesis). Xiangtan University, China. [Google Scholar]

69. Wu, L. (2018). Experimental study on compressive strength of recycled aggregate concrete under cubic and axial load. Engineering and Technological Research, 41(6), 20–21. [Google Scholar]

70. Matar, P., Zéhil, G. (2019). Effects of polypropylene fibers on the physical and mechanical properties of recycled aggregate concrete. Journal of Wuhan University of Technology (Materials Science), 34(5), 1327–1344. https://doi.org/10.1007/s11595-019-2196-6 [Google Scholar] [CrossRef]

71. Zhou, J. H., Kang, T. B., Wang, F. C., Yang, J. N. (2018). Experimental study on size effect of splitting tensile strength of waste fiber recycled concrete. Journal of Shenyang Jianzhu University (Natural Science), 34(6), 1036–1044. [Google Scholar]

72. Xu, J. N., Liu, Z. X., Liu, H. X. (2018). Experimental study on bond strength of fiber recycled concrete and BFRP bar under freeze-thaw rycles. Bulletin of the Chinese Ceramic Society, 37(10), 3355–3360. [Google Scholar]

73. Yang, J. X., Lu, J. W., Xu, Y. (2009). Index and test method of synthetic fiber concrete impermeability. Concrete, 31(1), 70–72. [Google Scholar]

74. Wu, L., Li, R. M. (2007). Discussion on anti-cracking mechanism of synthetic fiber in concrete. Yangtze River, 53(4), 83–84. [Google Scholar]

75. Zhu, J. (2000). Waterproof property and its application for polypropylene fiber concrete. New Building Materials, 27(2), 38–39. [Google Scholar]

76. Gu, Z. Z., Deng, Y. M., Fan, J., Ni, M. X. (2000). The performance of synthetic fibre concrete and their engineering application. Architecture Technology, 31(1), 30–32. [Google Scholar]

77. Zhao, L. L., Du, H. H. (2017). Research status of fiber plants cement based composites. Jiangxi Building Materials, 37(8), 7–8. [Google Scholar]

78. Coutts, R. (2005). A review of Australian research into natural fibre cement composites. Cement and Concrete Composites, 27(5), 518–526. https://doi.org/10.1016/j.cemconcomp.2004.09.003 [Google Scholar] [CrossRef]

79. Pacheco-Torgal, F., Jalali, S. (2011). Cementitious building materials reinforced with vegetable fibres: A review. Construction and Building Materials, 25(2), 575–581. https://doi.org/10.1016/j.conbuildmat.2010.07.024 [Google Scholar] [CrossRef]

80. Li, C. F., Su, Y. W., Chen, G. P. (2013). Status of plant fiber concrete. Concrete, 35(5), 55–56+61. [Google Scholar]

81. Bai, S. Q. (2020). Performance study of fiber plants concrete. New Technology & New Products of China, 28(24), 73–75. [Google Scholar]

82. Liu, Q. L., Liu, B. H., Zhang, Q. (2012). Research on mechanical properties of cole straw fiber reinforced concrete. China Concrete and Cement Products, 39(12), 51–53. [Google Scholar]

83. Liu, B. H., Yi, L., Zeng, Z., Zhou, Y. (2018). Experimental research on thermal insulation properties of the rape straw ash concrete. Journal of Hunan Agricultural University (Natural Sciences), 44(3), 330–333. [Google Scholar]

84. Zeng, Z., Liu, B. H., Zhang, W. J., Fang, L. (2019). Experimental study on mechanical properties of low-volume rape straw fiber concrete. Journal of Agricultural Science and Technology, 21(6), 117–123. [Google Scholar]

85. Qi, Z., Liu, B. H., Yi, L., Zeng, Z., Zhou, Y. (2017). Dynamic mechanical properties of rape straw ash doped concrete under impact loading. Journal of Hunan Agricultural University (Natural Sciences), 43(3), 336–339. [Google Scholar]

86. Fan, J., Liu, F. S., Liu, Y., Hu, Y. Q. (2010). Experimental study on intension and thermal insulation performance of stalk fibre concrete block. Building Science, 26(8), 45–47. [Google Scholar]

87. Wen, Y., Jiang, J. H. (2016). The compressive and flexural strengths of wood-fiber concrete. Journal of the Hubei University of Technology, 31(2), 100–102. [Google Scholar]

88. Omrani, E., Menezes, P., Rohatgi, P. (2016). State of the art on tribological behavior of polymer matrix composites reinforced with natural fibers in the green materials world. Engineering Science and Technology, An International Journal, 19(2), 717–736. https://doi.org/10.1016/j.jestch.2015.10.007 [Google Scholar] [CrossRef]

89. Zhao, Y. Q., Chen, A. J., Ma, J. T., Wang, X. H. (2018). Experimental study on breaking for coconut fibres recycled concrete. Concrete, 40(2), 64–67+71. [Google Scholar]

90. Zhang, X. Y., Zhao, Y. Q. (2021). Application of double-doped technology in coconut fiber recycled concrete. Low Temperature Architecture Technology, 43(8), 26–28+33. [Google Scholar]

91. Gupta, M., Kumar, M. (2019). Effect of nano silica and coir fiber on compressive strength and abrasion resistance of concrete. Construction and Building Materials, 226, 44–50. https://doi.org/10.1016/j.conbuildmat.2019.07.232 [Google Scholar] [CrossRef]

92. Syed, H., Nerella, R., Madduru, S. (2020). Role of coconut coir fiber in concrete. Materials Today: Proceedings, 27(Pt 2), 1104–1110. [Google Scholar]

93. Zhang, Y. X., Ning, G., Xu, B., Zhang, H. X. (2016). Testing research towards the mechanical performance of the plant fiber concrete block. New Building Materials, 43(9), 43–46+76. [Google Scholar]

94. Chen, G. R., Liu, C., Wang, C. (2018). Analysis of the influence of fiber plants on concrete performance. Construction Materials & Decoration, 14(22), 197. [Google Scholar]

95. Wang, J., Ren, J. H., Guo, D. P. (2015). Size effect of basic mechanical properties of chopped basalt fiber reinforced concrete. Journal of Architecture and Civil Engineering, 32(5), 96–103. [Google Scholar]

96. Wang, H. L., Yuan, L., Song, H. (2013). Experimental study on mechanical property of chopped basalt fiber reinforced concrete. Building Structure, 43(S2), 562–564. [Google Scholar]

97. Li, S. J. (2016). Experimental study of compressive strength of basalt fiber recycled aggregate concrete. World Earthquake Engineering, 32(2), 89–92. [Google Scholar]

98. Shang, B. Y., Yang, S. B. (2011). Research progress of basalt fiber reinforced polymer composites. Chemical Industry and Engineering Progress, 30(8), 1766–1771. [Google Scholar]

99. Li, D. C., Zhao, C. X. (2020). Research on basic mechanical properties of basalt fiber reinforced concrete. Highway, 65(6), 237–241. [Google Scholar]

100. Chen, X. F., Kou, S. C., Xing, F. (2021). Mechanical and durable properties of chopped basalt fiber reinforced recycled aggregate concrete and the mathematical modeling. Construction and Building Materials, 298. https://doi.org/10.1016/j.conbuildmat.2021.123901 [Google Scholar] [CrossRef]

101. Jin, Y. F., Tao, Y., Chai, D., Xu, S. X., Li, L. H. (2022). Fracture performance of basalt fiber concrete three-point bending beam. Journal of Civil and Environmental Engineering, 66(1), 1–8. [Google Scholar]

102. Dong, T., Liao, W. J., Liu, J. J., Tang, X., Zou, F. M. et al. (2022). Effects and numerical simulation of basalt fibers on the mechanical properties of recycled aggregate concrete. Concrete, 44(1), 92–96. [Google Scholar]

103. Liu, Y., Liu, Y. Z., Guo, Y. D. (2021). Effect of basalt fiber on early cracking resistance of recycled aggregate concrete. Journal of Guangxi University (Natural Science Edition), 46(4), 814–821. [Google Scholar]

104. Katkhuda, H., Shatarat, N. (2017). Improving the mechanical properties of recycled concrete aggregate using chopped basalt fibers and acid treatment. Construction and Building Materials, 140, 328–335. https://doi.org/10.1016/j.conbuildmat.2017.02.128 [Google Scholar] [CrossRef]

105. Li, X. L., Jin, B. H., Yao, Y. F., Guo, H. W. (2017). Mechanical properties of basalt fiber reinforced recycled aggregate concrete. Journal of Hebei University (Natural Science Edition), 37(3), 225–230. https://doi.org/10.2174/1874149501711010043. [Google Scholar] [CrossRef]

106. Dong, J. F., Hou, M., Wang, Q. Y., Zhang, D. L. (2012). Mechanical properties of basalt fiber reinforced recycled aggregate concrete. Advanced Engineering Sciences, 44(S2), 9–12. [Google Scholar]

107. Tian, K. (2019). Effect of basalt fiber on mechanical properties of recycled concrete. New Building Materials, 46(6), 22–24+103. [Google Scholar]

108. Zhang, C. S., Wang, Y. Z., Zhang, X. G., Ding, Y. H., Xu, P. (2021). Mechanical properties and microstructure of basalt fiber-reinforced recycled concrete. Journal of Cleaner Production, 278. https://doi.org/10.1016/j.jclepro.2020.123252 [Google Scholar] [CrossRef]

109. Quan, X. Y., Liu, K. N., Wang, S. L., Peng, X. H. (2019). Experimental study on basic mechanical properties of basalt fiber RAC. Concrete, 41(6), 47–50. [Google Scholar]

110. Liu, H. X., Yang, J. W., Kong, X. Q., Xue, X. X. (2017). Basic mechanical properties of basalt fiber reinforced recycled aggregate concrete. The Open Civil Engineering Journal, 11(1), 43–53. https://doi.org/10.2174/1874149501711010043 [Google Scholar] [CrossRef]

111. H, M., Zhao, Y. R., Wang, H. N., Li, S. H. (2021). Mechanical properties test and strength prediction on basalt fiber reinforced recycled concrete. Advances in Civil Engineering, 2021. https://doi.org/10.1155/2021/6673416 [Google Scholar] [CrossRef]

112. Wang, Y. G., Li, S. P., Hughes, P., Fan, Y. H. (2020). Mechanical properties and microstructure of basalt fibre and nano-silica reinforced recycled concrete after exposure to elevated temperatures. Construction and Building Materials, 247(C), 118561. [Google Scholar]

113. Chen, A. J., Chen, M., Hu, F. Q., Wang, D. H., Li, H. X. (2015). Basalt fiber’s effect on the mechanical behavior of rubber recycled concrete. Concrete, 37(2), 59–62. [Google Scholar]

114. Chen, X. X., Tan, Y., Tong, Y., Zhang, W. W. (2021). Analysis of mechanical properties of basalt fiber recycled concrete based on response surface method. China Concrete and Cement Products, 48(8), 59–63. [Google Scholar]

115. Guo, R. J., Bi, Z., Wang, F., Wang, P. L., Chen, Y. (2017). Effects of different mixing methods on mechanical properties of basalt fiber reinforced concrete after high temperature. Composites Science and Engineering, (2), 88–92. [Google Scholar]

116. Gao, Y., Zong, X. (2018). The effect of easalt fiber on the basical mechanical properties of recycled aggregate concrete. Journal of Yangtze University (Natural Science Edition), 15(21), 6–10+4. [Google Scholar]

117. Ren, L. L. (2019). Study on the basic mechanical properties of fiber recycled concrete. China Concrete and Cement Products, 46(4), 49–54. [Google Scholar]

118. Fang, S. E., Hong, H. S., Zhang, P. H. (2019). Mechanical property experiments and calculation formulas of fiber-reinforced recycled aggregate concrete. Composites Science and Engineering, 46(5), 18–24+43. [Google Scholar]

119. Chen, A. J., Han, X. Y., Chen, M., Wang, X. Y., Wang, Z. H. et al. (2020). Mechanical and stress-strain behavior of basalt fiber reinforced rubberized recycled coarse aggregate concrete. Construction and Building Materials, 260(8–9). https://doi.org/10.1016/j.conbuildmat.2020.119888 [Google Scholar] [CrossRef]

120. Xie, G. L., Shen, X. D., Liu, J. Y., Zhang, B. (2021). Frost resistance and damage degradation model of basalt fiber regenerated concrete. Composites Science and Engineering, 48(4), 55–60. [Google Scholar]

121. Wael, A., Omar, A. (2019). Effect of fiber volume fraction on behavior of concrete beams made with recycled concrete aggregates. MATEC Web of Conferences, vol. 253. https://doi.org/10.1051/matecconf/201925302004 [Google Scholar] [CrossRef]

122. Li, J. Q., Li, S. X., Hu, H., Dong, J. F. (2018). Experimental study and finite element analysis on mechanical properties of FRP confined basalt fiber reinforced recycled concrete circular columns. Concrete, 45(12), 57–61. [Google Scholar]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF

Downloads

Downloads

Citation Tools

Citation Tools