| Structural Durability & Health Monitoring |  |

DOI: 10.32604/sdhm.2021.018247

REVIEW

Digital Twin-Driven Intelligent Construction: Features and Trends

1College of Civil and Architecture Engineering, Chuzhou University, Chuzhou, 23900, China

2Jiangsu Zhongji Engineering Technology Research Co., Ltd., Nantong, 226001, China

3Department of Technical Sciences, State University of Novi Pazar, Novi Pazar, 36300, Serbia

4College of Mechanics and Materials, Hohai University, Nanjing, 210098, China

*Corresponding Author: Maosen Cao. Email: cmszhy@hhu.edu.cn

Received: 01 January 2021; Accepted: 15 July 2021

Abstract: Digital twin (DT) can achieve real-time information fusion and interactive feedback between virtual space and physical space. This technology involves a digital model, real-time information management, comprehensive intelligent perception networks, etc., and it can drive the rapid conceptual development of intelligent construction (IC) such as smart factories, smart cities, and smart medical care. Nevertheless, the actual use of DT in IC is partially pending, with numerous scientific factors still not clarified. An overall survey on pending issues and unsolved scientific factors is needed for the development of DT-driven IC. To this end, this study aims to provide a comprehensive review of the state of the art and state of the use of DT-driven IC. The use of DT in planning, design, manufacturing, operation, and maintenance management of IC is demonstrated and analyzed, following which the driving functions of DT in IC are detailed from four aspects: information perception and analysis, data mining and modeling, state assessment and prediction, intelligent optimization and decision-making. Furthermore, the future direction of research, using DT in IC, is presented with some comments and suggestions. This work will help researchers gain in-depth and systematic understanding of the use of DT, and help practitioners to better promote its implementation in IC.

Keywords: Digital twin; intelligent construction; information perception and interaction; data mining and modeling; state assessment and prediction; intelligent optimization and decision; big data; virtual and physical spaces

1.1 Concept of Intelligent Construction (IC)

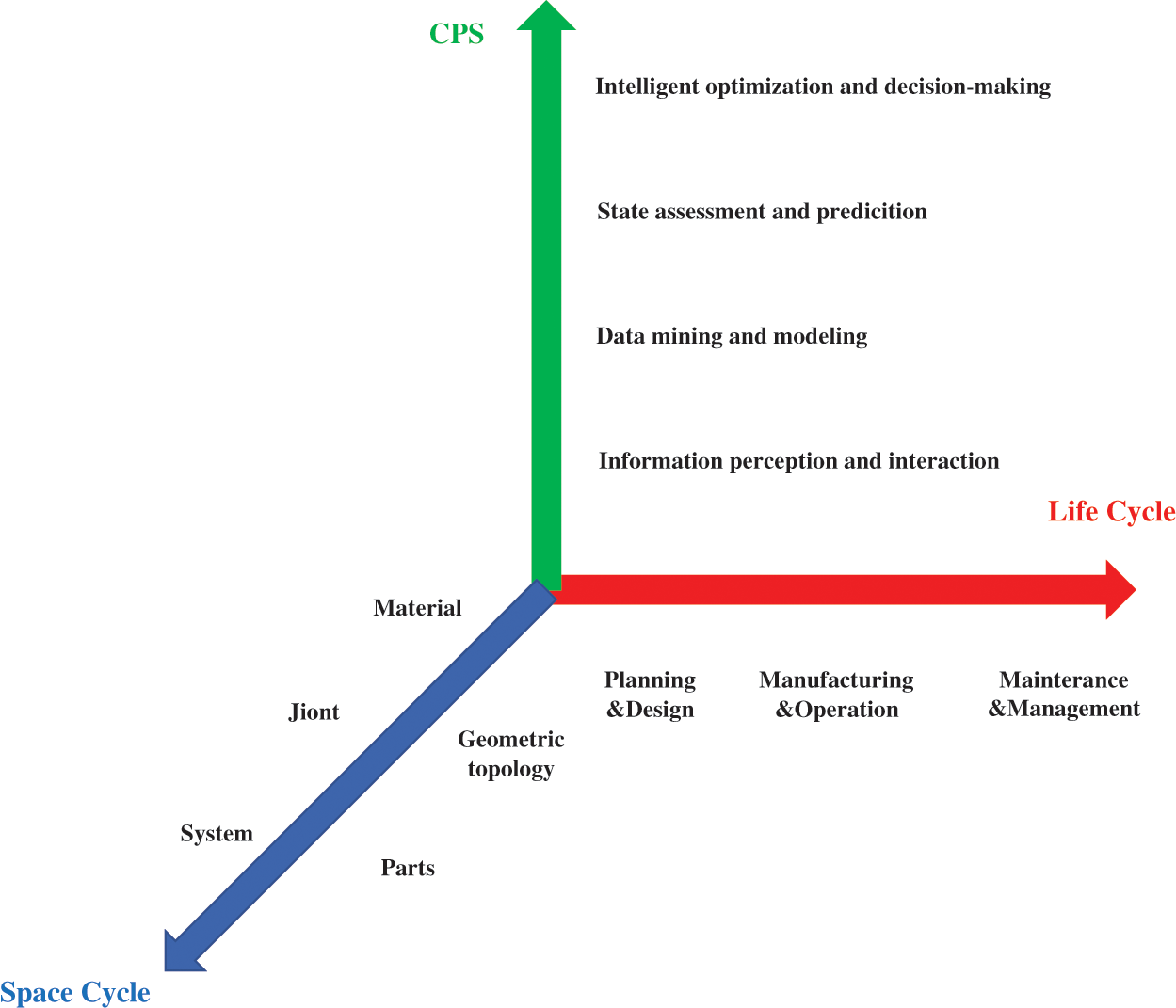

The concept of IC has been described by the Global Engineering Frontier 2018 [1], based on the integration of advanced construction technology [2–5] and information technology (IT) [6–10] with a focus on cyber-physical systems (CPS) [11–13]. Conventionally, in both industrial [14,15] and digital construction [16–19], the activities of building components, parts, and systems (i.e., physical systems) are analyzed throughout the construction life-cycle, which includes project approval, design, manufacturing, transportation, assembly, operation and maintenance, and service. Through the twin model of cyberspace [20,21], information perception and interaction, data mining and modeling, state assessment and prediction, intelligent optimization and decision are carried out according to the knowledge system of the construction of objects, processes, equipments, and systems, and promote innovation and the implementation of intelligent-sensing technology [22–24].

With increasing advances in the construction industry, Industry 4.0 proposed a new construction technology to achieve high adaptability, rapid design changes using IT, and a more flexible technical workforce training. The advanced construction technologies employed include CPS [11–13], building information modeling (BIM) [25,26], Internet of Things (IoT) [27,28], big data [29,30], and cloud computing [31,32]. In the era of Industry 4.0, IC has received increasing attention owing to the need for sustainability. As such, IC considers more intelligence in perception technology [33], data mining [34], design optimization [35], and management decisions [36], to facilitate better integration into the whole life-cycle of construction activities, to fully coordinate all participants, and to complete construction tasks in an efficient and energy-saving manner. IC has shown a diversified trend, and an increasing number of IC systems have been developed for specific tasks and applied to actual construction projects. Consequently, this has greatly improved the level of intelligence in construction [37,38].

1.2 Concept of Digital Twin (DT)

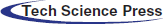

The concept of DT was described as an information-mirror model by Grieves [39], and is a digital replica of a living or non-living physical entity. It enables a seamless transfer of data by connecting the physical and virtual worlds [40], thereby allowing virtual entities to exist simultaneously with physical entities. The definition of DT has two important features. First, it emphasizes the connection between the physical model and the corresponding virtual model or counterpart. Second, a connection is established, using sensors to generate real-time data [41,42]. Tab. 1 lists some definitions of DT with their references [40,43–47]. As stated earlier, DT is a real-time digital reproduction of a physical entity. It faithfully maps physical objects, and can describe and optimize these objects based on selected models.

1.3 Relationship between DT and IC

Previously, it was a challenge to present the state of an IC system in real time. However, the emergence of DT has solved this problem [48–50]. The construction system can monitor the physical process, create DT in the physical world [51], receive real-time information from the physical world for simulation evaluation, and make smart decisions through real-time communication and cooperation with human beings. The combination of DT and IC will certainly make future construction technology more intelligent, efficient, and convenient.

This study summarizes the IC driven by DT from the perspective of sustainable development. First, we introduce the application of DT, based on five stages: planning, design, manufacture, installation, operation, and maintenance. Second, we introduce the DT-driven IC from four aspects: information perception and interaction, data mining and modeling, state assessment and prediction, intelligent optimization and decision.

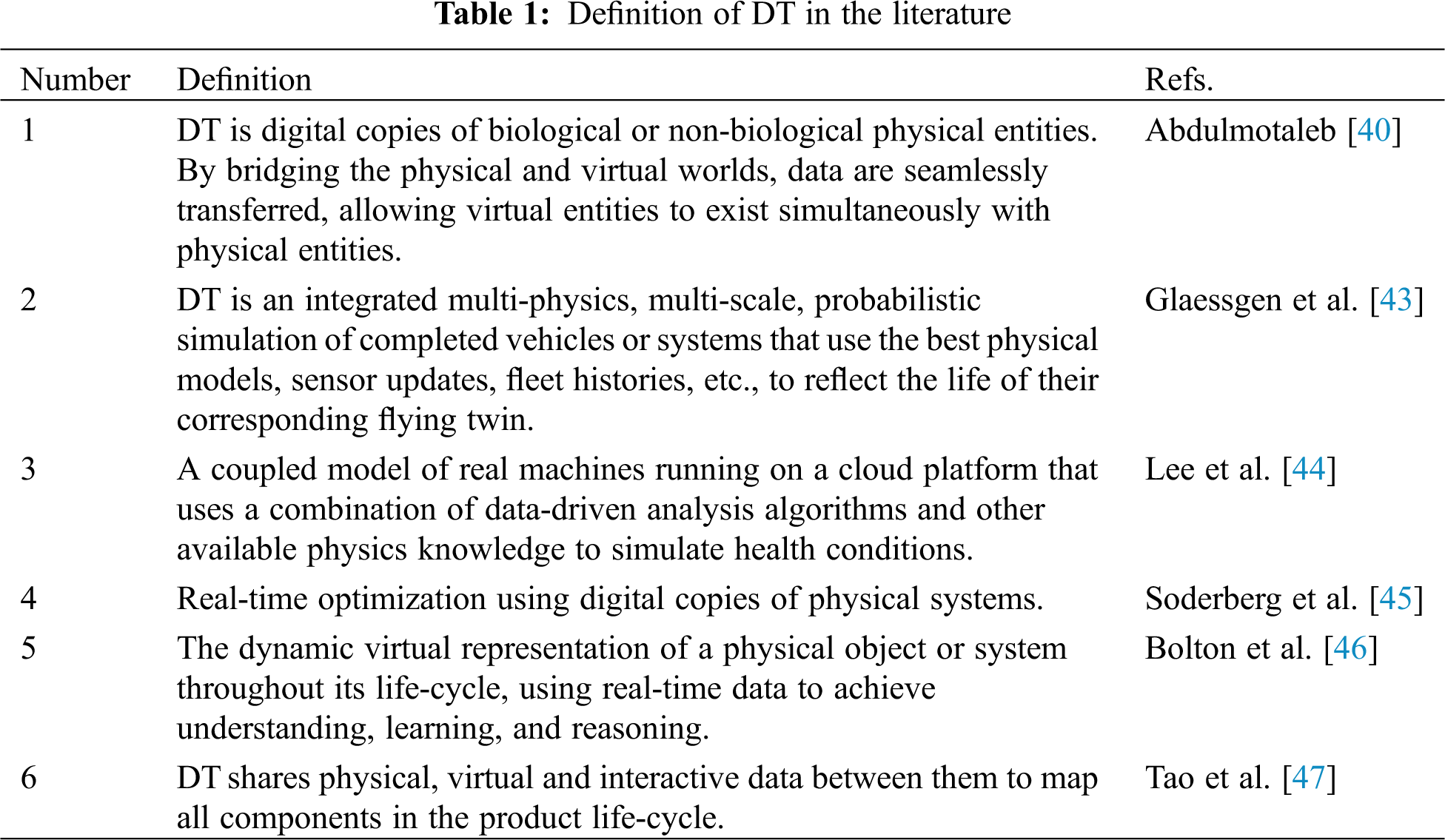

IC includes the relevant equipment, processes, and systems that support each other, as shown in Fig. 1. IC equipment is introduced in two dimensions: components and intelligent manufacturing production lines. From the perspective of the entire life-cycle of the construction link, the IC process is divided into three stages: planning and design, manufacturing and operation, and maintenance management. An IC system is introduced from five aspects: self-conscious sensing, information transformation, data mining, evaluation decision, and virtual real control. Finally, the development trend of IC is summarized in three aspects: framework, enabling technology, and application of IC. IC’s enabling technology is driven by BIM, big data, artificial intelligence (AI), and IoT.

Figure 1: Four aspects of IC

Professor Michael Grieves of the University of Michigan proposed the concept of DT in 2003. This technology was first used by NASA to simulate and analyze the flying spacecraft in the Apollo project [52]. Recently, it has received widespread attention in the field of intelligent manufacturing. The world’s most authoritative IT research and advisory firm, Gartner, chose DT as one of the top ten strategic technology trends in 2016. The Intelligent Manufacturing Academic Consortium of the China Association for Science and Technology also selected DT-driven intelligent manufacturing as one of the top ten technological advances in intelligent manufacturing in 2017. In addition to its application in the manufacturing industry, with the benefits from the development of IoT, big data, cloud computing, AI, and other new-generation IT concepts, DT has been gradually implemented in the fields of electric power, shipping, urban management, agriculture, construction, health care, environmental protection, and other industries. This section considers the application of DT in IC, based on three stages: planning and design, manufacturing and operation, and maintenance management.

The use of DT in planning and design is mainly based on the research on DT planning and design methods, which make it more efficient. This includes digital planning, design, and simulation.

Wang et al. [53] built a digital elevation model and shadow image using digital image technology, which provided effective and reasonable digital investigation tools for the planning and design of urban energy-saving buildings. Abbas et al. [54] used a geographic information system (GIS) to analyze a digital elevation model of the river basin in Canadian Fredericton and Charlottetown, and visualized extreme events and flood disasters in the two cities, to formulate urban planning policies. Franziska et al. [55] highlighted in the UK’s 2017–2018 urban planning research report that the effective use of BIM technology in public planning and consultation can provide support for new or updated public infrastructure, better resource planning, more use of public facilities, mapping, and protection of architectural historical heritage; moreover, it can achieve cost savings of 15%–25%.

In the field of construction engineering, there have been rapid advances in technology from the development of three-dimensional (3D) computer-aided design to BIM. BIM-related technology is the core technology for DT [56]. The employment of DT enables the gathering, generation, and visualization of the environment of the building of interest. All the data gathered are stored in the DT, resulting in better optimization of the building design [57]. Sacks et al. [58] proposed the concept of a single workflow of communication control in a DT structure, and defined the workflow of architectural design, as well as the extension of BIM tools combined with sensing and monitoring technology. The DT-driven design method enables researchers to quickly find design flaws and improve efficiency [59]. The concept of DT is still not clearly defined in the context of buildings and civil infrastructure. Researchers and practitioners have not reached a consensus on how the DT process and data-centric technology support design.

In the design stage, the adaptability and superiority of the simulation can be simulated using a DT model. Haag et al. [60] developed a network physical bending beam test-rig to demonstrate the concept of DT. A modular approach was studied to build a DT and make the corresponding changes to help designers quickly evaluate different designs and find any flaws [61]. Lydon et al. [62] proposed a coupled simulation of the thermal design of a heating and cooling system combined with a light roof structure, based on the DT model, which greatly shortened the product development time and cost.

2.2 DT in Manufacturing and Operation

The use of DT in construction engineering is different from that in the manufacturing industry. After establishing a virtual simulation model entity, based on a DT, it is not only applied to the processing and assembly of prefabricated components, but also used to optimize and manage the entire construction process to achieve accurate process control. It includes process simulation, digital production line, condition monitoring, and so on.

(1) Processing of assembly component

Before the processing of assembly components, the virtual simulation method can be used to carry out an in-depth design and process simulation of components, and to comprehensively analyze the rationality of assembly component design, processing rate, and efficiency. A new method was proposed for resource supply and demand-matching manufacturing, based on complex networks and the IoT, to realize intellectual perception and access to manufacturing resources [63]. Bilberg et al. [64] applied a DT to the assembly unit to create a DT model that extended the use of virtual simulation models developed during the production system’s design phase. It was used for implementation control, human and machine task-assignment, and task sequencing. Um et al. [65] proposed a universal data model, based on a DT, to support plug-and-play in modular, multi-vendor assembly lines. DT with intelligent manufacturing services were combined to produce more sensible manufacturing planning and precise production control [66].

(2) Simulation of assembly process

With the development of IT, the influence of traditional construction technology has become increasingly profound, especially with the deepening of complex construction technology. Through the CPS simulation of the DT model, the construction assembly scheme is determined and optimized to be safe, more efficient, and reasonable. Ellinger et al. [67] used DT in the design of cross-laminated timber to simulate and improve the limitation of the hybrid panel, which is mainly its unsuitability for use in long-span buildings. Using four-dimensional simulation in major capital construction projects can provide a convenient reference for project personnel and help to reduce the cost of projects [68]. Virtual commissioning is a key technology in Industry 4.0, which can deal with the issues faced by engineers during the early design phases. The process of virtual commissioning involves the creation of a DT. Such a model can be used to test and verify the control system in a simulated virtual environment to achieve rapid setup and optimization prior to physical commissioning [69].

All the elements of the production stage are integrated into a closely coordinated process through digital methods to achieve an automated production process. By means of a 3D virtual simulation model of an industrial robot, a DT model was established to control the robot for the automatic assembly of large-scale spacecraft components [70]. It was an effective way to realize the efficiency of an enterprise-resource service, by combining the basic manufacturing services with the cloud-manufacturing resource-service composition technology, based on the DT model of each stage of the product life-cycle [71]. Zhang et al. [72] proposed an image-processing method, based on a DT model, to realize the rapid individualized design of a hollow glass production line. A framework was proposed for intelligent production management and for control methods using DT, which were applied to assembly shops for complex products [73]. A method based on a DT was proposed, which combined physical system modeling and semi-physical simulation to realize a rapid and individualized design of an automatic flow-shop manufacturing system [74]. Liau et al. [75] applied a DT to the injection-molding industry, representing all stages of injection molding as virtual models to achieve a two-way control of physical processes. A DT-based manufacturing CPS was proposed to control intelligent workshops in parallel under a large-scale individualized paradigm [76]. A factory-network physical-integration framework was proposed for digital-based systems to deal with the problems faced by digital factories, and to shift the current state of digital factories to intelligent manufacturing [77].

2.2.3 Equipment Status Monitoring

The production process can be monitored visually by collecting real-time operation data of the production equipment. Abnormal equipment must be dealt with and adjusted in time to optimize the production process. Botkina et al. [78] introduced DT data formats and structures for cutting tools, information flow, and data management, and applied a DT to improve machining solutions optimized for process planning. When the DT application was applied in the production workshop, the state of the machines and products in the workshop were reflected in the virtual model in real time, thereby making the manufacturing of the product more intelligent.

2.3 DT in Maintenance Management

The use of DT in maintenance management is based on the virtual simulation model of DT. The real state of the physical model is fed back to the virtual simulation model through the signal data of the IoT devices. When the physical model fails, the virtual simulation model will synchronously produce faults. Therefore, the virtual simulation model can judge whether the physical model will produce faults according to the real-time state data, which can effectively reduce the failure rate. This part includes fault warning, maintenance, and management-scheme optimization.

By reading the real-time parameters of the sensors or control systems on the building components, a visual remote monitoring model is established to analyze the state of the building components with AI. A maintenance strategy to reduce the loss is proposed, and an early warning is given. Based on DT, fault detection and health management of different parts or areas can be realized. According to the state of the virtual model’s data, the operating mode of the building components is optimized, the safety risk is reduced, while the stability of the building structure is improved.

Combined with DT and virtual reality, a new application mode based on a DT is formed. In the manufacturing industry, Wang et al. [79] introduced an innovative investigation on prototyping a DT as the platform for human-robot interactive welding and welder behavior estimation. Uhlemann et al. [80] studied a cyber-physical production system based on DT to demonstrate the potential and advantages of real-time data acquisition, and subsequent simulation-based data processing. A low-cost manufacturing execution system (MES), based on Android devices and cloud-computing tools, had been developed and implemented by Corona [81]. Though collecting the machine data supported by MES and manufacturing technology that connects the protocol of machine tools, the DT model of the workshop was generated for production control and optimization integration. Schluse et al. [82] introduced an experimental DT system to create interactions in different application scenarios, and to provide data and communication functions for simulation-based integrated systems engineering. Macchi et al. [83] discussed the conceptual framework and potential application of an order-management-process decision-support system, based on a DT model of a manufacturing system. A conceptual framework and potential applications of a decision-support system for the order-management process were discussed, based on the DT of the manufacturing system [84].

Research progress in DT has led to continuous development in the medical, sports, and other fields. In the medical field, Groth et al. [85] used an accurate computational fluid dynamics (CFD) model generated by ANSYS soft to build a medical DT model that could reliably predict the pathological evolution and effect of surgical correction. In the sports industry, Barricelli et al. [86] established a Smart-Fit system to support trainers and coaches to monitor and manage athletes’ fitness activities and results, and produced clear suggestions that trainers could use to trigger athletes’ optimal behaviors.

Compared with other industries, the development of IT in the construction industry has been relatively slow because of the complexity of buildings. However, with the concept of digital earth, proposed by IBM, the smart city system has been incorporated into all aspects of daily city management. From the investigation of the use of DT-concept roads, the deployment of a DT box, and the feedback of real-world, real-time data flow through the IoT, equipment has become the key component for solving the problem of automatic driving vehicles (intelligent mobile devices) [87]. Gang et al. [88] proposed an information communication technology artifact, based on the dynamic source-routing framework, to optimize the functional requirements of the intelligent operation and maintenance of urban roads. Through the establishment of an urban data-evaluation model, the performance of the model and various specified baselines was compared to control urban air pollution in an economic and effective way [89].

2.3.2 Optimization of Management Decision

(1) Optimization of the production line

By analyzing the status data of the production line, the configuration parameters of manufacturing instruments are modified to ensure the performance and quality of products, as well as to optimize the production index. Tao et al. [90] proposed a DT model-driven method to improve the accuracy and efficiency of prediction and health management. Lynn et al. [91] proposed a manufacturing system based on a network and a physical system to realize process control and optimization. Luo et al. [92] established a multi-domain unified modeling method of DT machine tools to study its Computer Numerical Control (CNC) machine tools in order to make these machine tools more intelligent, optimize their operational mode, reduce the sudden failure rate, and improve the stability of machine tools.

(2) Optimization of management decision

In the context of Industry 4.0, simulation-based decision-support tools, commonly called DT [93], are increasingly being used. Using DT to carry out the intelligent management of engineering projects provides more accurate control of decision-making, reliable operation, and maintenance, and effectively improves the management and operational levels of engineering projects. Shi et al. [94] proposed the application of DT to water-conservancy project-operation management. Park et al. [95] applied DT to construct the virtual space of a micro-grid and realized the operational scheduling model of an energy-storage system, with the goal of minimizing the electricity charge. Recently, using big data, Breillat [96] summarized the role of network physical production systems, based on DTs, in facilitating corporate decision-making.

In recent years, the construction industry has been experiencing low production, high accident rates, labor shortage, and rising costs every year. With the rapid development of digital and intelligent technology, IC is considered the mainstream direction of development in the industry. However, owing to the uniqueness of construction products, the non-repeatability and fragmentation of the construction process, and the complexity of the site environment, IC still faces many difficulties in being implemented. Therefore, research on DT-driven IC has become a popular trend, and has achieved good results in intelligent design [97,98], production [99–101], logistics [102,103], and construction [104–106]. IC is a deep integration of AI technology with advanced construction technology. It is a highly integrated and collaborative construction system based on BIM, IoT, AI, cloud computing, big data, and other technologies that can adapt to changing needs in real time. IC has brought great changes to all aspects of the construction industry, enabling it to learn, produce, and use knowledge, thus realizing a balance of digitization, networking, and intelligence.

IC is not a technology oriented to a single production stage, but a highly integrated multi-link construction system (as shown in Fig. 2 for system architecture), which integrates key stages such as design, production, logistics, and construction. In an IC system, each stage can achieve a high degree of information sharing and business collaboration, which means that the IC system can quickly respond to the changing needs (for example, changes and supply) of each stage to achieve the flexibility and efficiency of the construction process. Advanced IT is the basis of IC, and its rapid development provides the necessary conditions for its implementation. BIM technology provides the underlying support for the creation, integration, management, and service of product information for IC [107,108]. The IoT technology provides the basic support for the real-time acquisition and transmission of information in the process of production, logistics, and construction [109,110], and also provides a strong guarantee for the intelligent evaluation and operation of all stages of IC [111–113].

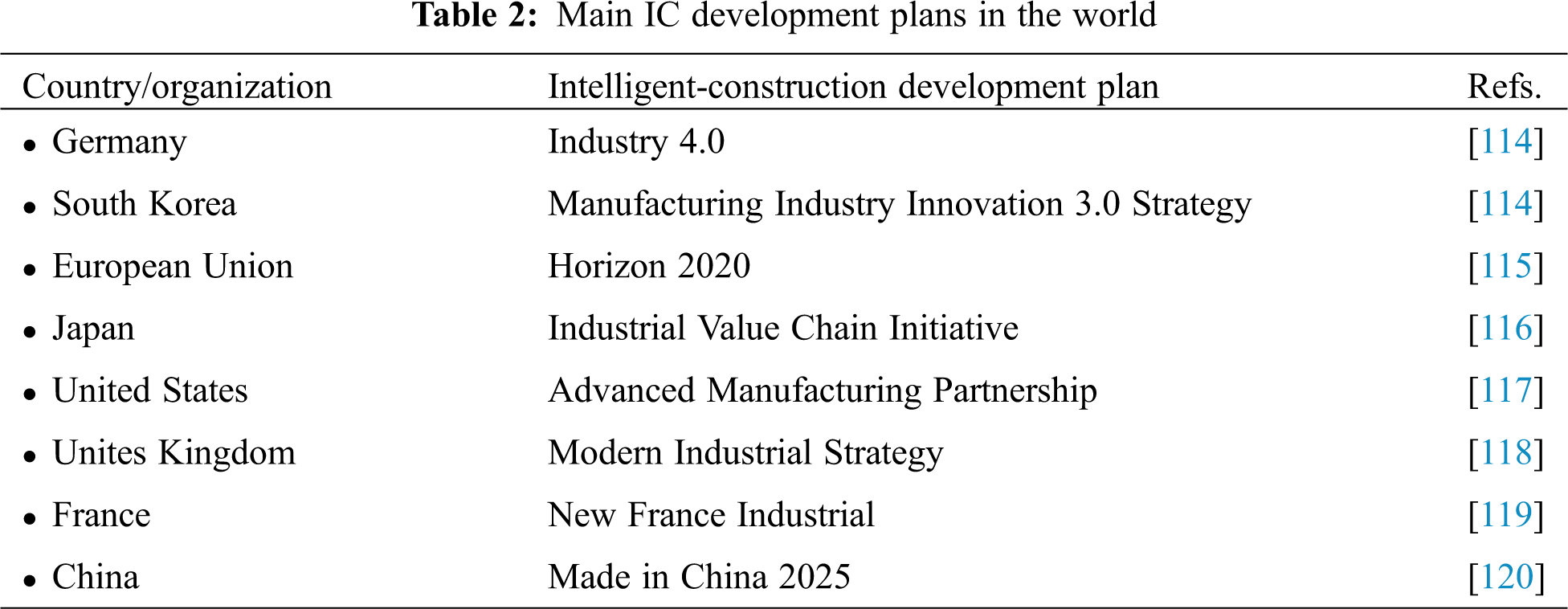

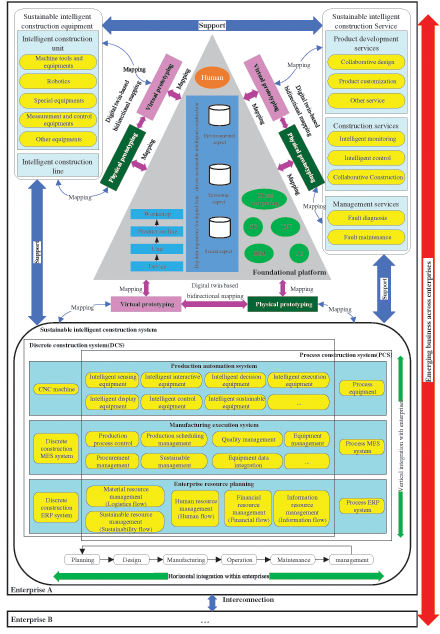

Figure 2: IC system

The construction industry’s development has evolved in stages: from human force to mechanical power construction 1.0 (prefabricated building), standardized modular assembly-line construction 2.0 (industrial building), and CAD + CNC/CAM + BIM informatization construction 3.0 (digital building). It has come to the fourth Industrial Revolution led by intelligent manufacturing in the construction industry. Therefore, the world’s traditional and emerging construction powers have proposed the development of IC planning. Tab. 2 presents the IC development plans of some countries and organizations [114–120].

In this study, the system of IC is divided into five intelligent layers: connection, analysis, network, cognition, and execution layers. The main function of the connection layer is intelligent perception—that is, the ability to obtain information and data from different parts of the construction industry at different stages through various sensors. It also includes the ability to recognize the environment, object categories, and attributes through memory, learning, judgment, reasoning, and other processes. The main function of the intelligent analysis layer and the intelligent network layer is data mining, which transforms the perceptual information into a 3D information model and uses big-data technology to mine the data needed by the collaborators. The main function of the intelligent cognitive layer is to evaluate and make decisions, that is, using the real-time state data of buildings to evaluate and make optimal decisions. The main function of the intelligent execution layer is to provide feedback-entity control, that is, to provide a feedback optimization scheme for construction equipment through an intelligent device, so as to realize automatic construction with the machinery. This section focuses on the IC system based on CPS, and introduces the development of intelligent construction from four aspects.

3.1 Information Perception and Interaction

An effective AI system is based on its perception, memory, and thinking ability, as well as learning, adaptive, and autonomous behavior abilities. With the ability of dynamic intelligent perception in complex scenes, we need to use multisource information-fusion technology to collect and fuse both similar and different types of sensor information across time and space. Only through memory, learning, judgment, and reasoning can we achieve the purpose of recognizing the environment, object categories, and attributes. On this basis, we can enable experience-based judgment and the intelligent processing of decision-making.

In the process of using information, the first step is to obtain accurate and reliable information; sensors are the main means of obtaining such information in the fields of science and production. A sensor can feel the measured information and transform it into an electrical signal or other required information output according to certain rules to meet the requirements of information transmission, processing, storage, display, recording, and control. It has the characteristics of miniaturization, digitization, intellectualization, multi-functionality, systematization, and networking [121]. In modern industrial production, especially in the process of automatic production, various sensors should be used to monitor and control various parameters in the production process, so that the equipment can work in a normal or optimal state and the product can achieve the best quality. Therefore, without excellent sensors, modern production would lose its foundation.

In basic subject research, the sensing has a more prominent position. The progress of modern science and technology has led to the development of many new fields. In addition, various kinds of extreme-technology research play an important role in deepening the understanding of materials, and in developing new energy and materials such as ultra-high and ultra-low temperatures, ultra-high pressure and vacuum, and super-strong and ultra-weak magnetic fields. Without appropriate sensors, it would be impossible to obtain significant information that cannot be directly obtained by the human senses. The first obstacle in many basic scientific studies lies in the difficulty of obtaining object information, and the emergence of new mechanisms and high-sensitivity detection sensors certainly leads to breakthroughs in this field. The development of sensing is often the pioneer of some frontier disciplines.

Sensors have already been used in many fields such as industrial production [122], space development [123], ocean exploration [124], environmental protection [125], resource investigation [126], medical diagnosis [127], bioengineering [128], and even in the protection of cultural relics [129]. Almost every modern project, in all arenas from space to the vast ocean, to all kinds of complex engineering systems, cannot proceed without the use of sensors.

Sensors are also widely used in the construction industry. Traditional applications have mainly been for structural safety monitoring [130] and in the construction process [131] to detect the quality and safety-status data of structures at various stages. With the rapid development of smart city construction and big data, IoT sensor technology has achieved innovative applications in four main aspects: machine control [132], construction-site monitoring [133], fleet management [134], and wearable device [135] applications.

The automation and intelligence of construction are inseparable from the application of industrial robots, which are widely used in all aspects of construction. As the construction industry has developed, the types and functions of industrial robots have become more diverse. With the shift from the process of traditional construction to IC, industrial robots have ushered in new and greater development.

In recent years, more and more researchers have focused on industrial robots to make them more competitive. With higher precision, fewer errors, more reasonable structure, more convenient programming, and friendlier human-computer interaction, industrial robots have become increasingly important in industrial applications. Liu et al. [136] proposed a multi-sensor combined measurement system, based on the point cloud coordinate-change method, which can improve the position accuracy of the robot by editing its kinematic parameters; the accuracy was improved by 45.8% through experimental verification. Wu et al. [137] proposed a robotic 3D measurement system, based on a multi-layer perceptron neural network. The experimental results show that a high-precision, structured light-vision sensor model can be obtained. Pérez et al. [138] studied the synergy between virtual reality and robots to create a fully immersive environment, based on virtual reality, thereby improving the efficiency of the training and simulation process and providing a cost-effective solution. However, industrial robots are inconvenient for the exchange of programming information for different processing projects, and their integration is also difficult [139]. Slavkovic et al. [140] introduced an indirect method for industrial robot-programming of machining tasks, which was designed to save machining-project information in a standardized format for the exchange of product model in the data-numerical control format, thus enabling easy exchange between different users for machining purposes.

The important technical means of modern intelligent-sensing systems is to obtain sufficient sensing information and feature information generated by the systems. The information from various sensors has different characteristics, and one of the important tasks of intelligent sensing is to extract the various characteristics of objects from various types of sensor information. The urban driving environment-collection method was developed using a road side unit camera and vehicle Global Positioning System with two sensors, and also the Dempster Shafer theory to map the credibility root to the credibility map [141]. Kirsty et al. [142] proposed a cut-invariant perception method, based on principal component analysis. This method gave the required environment information in the case of sliding, and was applied to the contour-tracking task of six objects with different curvatures.

Data mining has attracted significant attention in the information industry. The main reason is the explosion of data; there is an urgent need to transform these data into useful information and knowledge that can then be used in various applications, including business management, production control, market assessment, engineering design, and scientific exploration. Data mining uses ideas from the following areas: (1) sampling, estimation, and hypothesis-testing from statistics; (2) search algorithm, modeling technology, and learning theory of AI, pattern recognition, and machine learning. Data mining has also rapidly accepted ideas from other fields, including optimization, evolutionary computing, information theory, signal processing, visualization, and information retrieval. Some other areas, especially in database systems, need to provide effective storage, index, and query-processing support, which also play an important role.

Data mining is a popular topic in the field of AI and databases. It refers to the process of revealing hidden, previously unknown, and potentially valuable information from a large amount of data in a database. Data mining is a type of decision-making process. It is mainly based on AI, machine learning, pattern recognition, statistics, databases, visualization technology, etc. It can analyze the data of enterprises automatically, perform inductive reasoning, and extract potential patterns to help decision-makers adjust market strategies, reduce risks, and make correct decisions. The common methods of data mining include classification, regression, clustering, association rules, features, change and deviation, and web-page mining. The difference among these methods indicates the mining of data from different angles.

Classification is used to determine the common characteristics of a group of data objects in the database and to divide them into different classes according to the classification mode. Its purpose is to map the data items in the database to a given class through the classification model, which is used to predict the discrete class of data objects. Classification technology has been applied in many areas including the classification of building components, the evaluation of material properties and characteristics, structural safety assessment, and health prediction. The main classification methods are the decision tree [143], k-nearest neighbor [144], support vector machine [145], vector space model [146], Bayes [147], and neural networks [148,149].

Regression is a statistical prediction model used to describe and evaluate the relationship between dependent variables and one or more independent variables. It reflects the temporal characteristics of the attribute’s values in the transaction database, generates a function that maps data items to a real-value predictive variable, and determines the dependency relationship between the variables or attributes. The main research issues include the trend characteristics of the data series, the prediction of the data series, and the correlation among the data. The regression method has been widely used in construction engineering [150], all aspects of engineering economy [151], and can also provide a decision-making basis for building health-monitoring and early-warning systems, such as building settlement and deformation [152], and bridge anti-collision safety early-warning systems [153].

Clustering divides a group of objects into several categories according to their similarity and differences. The similarity between the objects in each category is high. However, the similarity between objects in different categories is low, which means that the difference is obvious. The difference in classification is that clustering does not rely on a given category to divide objects. The algorithm is divided into the following: (1) partition method, (2) hierarchical method, (3) density-based method, (4) grid-based method, and (5) model-based method. It can be applied to the classification of smart city management, management-background big-data decision, and management-scheme trend prediction [154,155].

Association rules describe the relationships between two data items in the database. We can infer the occurrence of another thing from the occurrence of one thing, which is the association or mutual relationship hidden in the data, so as to better understand the development law of things. In the construction industry, it can be applied to association rules for anomaly detection and reliability evaluation of intelligent devices [156].

Feature extracts feature expressions from a set of data in a database, which express the overall characteristics of the dataset. The purpose of feature selection is to extract useful information from massive amounts of data to improve the efficiency of data use. The selection and evaluation of feature validity include probability theory, mathematical statistics, and information theory. For example, in structural damage detection, prediction can be carried out according to the features [157].

Deviations are small objects in a dataset. Generally, deviation objects are called exceptions or outliers. The purpose of deviation is to identify objects that differ from most other objects. For example, by analyzing abnormal cases in the classification, abnormal mode, observation results, expected deviation, and other information [158], potential accidents can be found in the areas of structural health monitoring and early-warning systems. Therefore, it can be applied to the discovery, analysis, identification, evaluation, and early warning of various abnormal information. The causes include data from different classes, natural variation, data measurement, and collection error.

Through web mining, we can use the web to collect information about politics, the economy, policy, science and technology, finance, various markets, competitors, supply-and-demand information, customers, and so on. This study focuses on analyzing and processing information about external environment and internal operation that has significant or potentially significant impacts on an enterprise, and identifies various problems and possibilities in the process of enterprise management, according to the results. In order to identify, analyze, evaluate, and manage crises, we need to analyze and deal with the information that web mining gathers.

The construction industry has the largest amount of data at the largest scale. With the development and popularization of big data and BIM, building industrialization involves transforming the original “design-site construction” into “design-factory manufacturing-site assembly”. The construction of a building is also a product-manufacturing process. The purpose of industrialization is to make the building-construction process the manufacturing process of the manufacturing industry [159].

BIM technology provides a good technical platform for the early construction of industrialization projects, and later management and maintenance of them. Using BIM technology to establish a library of layout, the assembly component library of the industrialization building can standardize property types and components, reduce design errors, and improve drawing efficiency, especially in the processing and on-site installation of prefabricated components [160]. The dynamic visual management of the entire process of prefabricated building construction is realized in the manufacturing, transportation, and assembly process of components with a combination of radio-frequency identification (RFID) technology and BIM in the construction stage [161].

With the impact of big data, cloud computing, IoT, GIS, mobile internet, and other advances in IT the integration of social resources will be the main problem the construction industry must overcome. BIM enables the integration of cross-border resources in the construction industry, and provides a valuable tool to find the optimal resource integration. The application of the IoT, based on BIM, will give every brick and piece of rubble their own identity, and an unprecedented value in their own posts [162]. The combination of BIM with big data and cloud computing made it easy for designers to find valuable information in a huge database through data-mining technology, while the integration of BIM and GIS promoted the development of the concept of digital earth [163].

3.3 State Assessment and Prediction

State assessment is a method for estimating the internal state of a dynamic system, based on available measurement data. The data obtained by measuring a system’s input and output can only reflect its external characteristics; the dynamic law of the system needs to be described by the internal state variables (usually not measured directly). Therefore, state estimation is of great significance for understanding and controlling an IC system. Taking the 5-1 District of Shizong City as an example, a digital dual model for simulating soil resistance was established using GIS technology, and a prediction system for earthquake liquefaction and foundation-damage amplification was established, while liquefaction risk-assessment was also carried out [164].

Decision theory aims to achieve an optimal decision by assuming an ideal decision-maker has complete information, accurate calculation, and complete rationality. The practical application of this normative model is called decision, and its goal is to help people make better decisions with its tools and methodologies. Bayram [165] proposed the “best fit model” as the benchmark of Bromilow’s Time-Cost and Love et al.s’ Time-Floor models, based on 530 public building projects in Turkey, in order to fill the gap in construction-period prediction.

3.4 Intelligent Optimization and Decision

The intelligent optimization method is a very active research field, developed in recent years. Many scholars and students of systems engineering, automation, computer, management engineering, mining, machinery, and other majors have widely used intelligent optimization methods. For example, the genetic, tabu search, simulated annealing (SA), ant colony, and particle-swarm optimization have been widely used in various industries of the national economy.

In the field of construction engineering, Buitrago et al. [166] introduced a computer tool to calculate and verify the floor and support loads of cast-in-place multi-story buildings, using three AI optimization methods: random walk, descent local search, and SA. Under certain circumstances, the best solution was achieved: the cost of a support system was reduced by up to 53%; the construction time was shortened; and the conventional requirements of building construction were met.

4 Potential Research Directions

The development of IC technology will phase out traditional construction technology with its heavy environmental burden. With the increasing attention to the concept of sustainability, the sustainable development of the construction industry has been clearly positioned. This study proposes a framework of DT-driven IC, as shown in Fig. 3.

Figure 3: Framework of DT-driven IC

4.1.1 Comprehensive Sustainability

Sustainability has become an important topic [167,168]. Combining sustainable concepts with IC to achieve overall sustainability is an important future research direction. This concept can reduce emissions in the life-cycle of products, thereby achieving the requirements of both IC and comprehensive sustainability from the perspective of environmental, economic, and social aspects.

4.1.2 Upgrade Modeling and Simulation Technology

Traditional modeling and simulation technology is an indispensable tool and method for the construction industry. However, because it is only an independent unit, modeling and simulation are not suitable for an IC system. DT contains not only model simulation, but also dynamic simulation. The data interaction between digital and physical objects must be realized, so that the DT operation can add value by continuously improving industrial applications. Compared with the business environment, the interaction between uplink and downlink data needs to consider periodicity, data interface, and information modeling in order to improve efficiency.

4.1.3 IC in Life-Cycle Service

DT, based on engineering, construction, and maintenance, includes the three main components of an IC system, covering the whole building life-cycle business from product design and construction to service. From the virtual engineering design to the real construction site, and then to building operation, DT always serves every stage of the building life-cycle.

4.1.4 IC Across Blockchain Technology

Through blockchain, we can reduce logistics costs, trace the production and delivery processes of goods, and improve the efficiency of supply-chain management. Through the hierarchical structure of a scattered network connected by nodes, blockchain can realize the comprehensive transmission of information in the whole network and test the accuracy of information, which improves the convenience and intelligence of IoT transactions, to a certain extent [169].

4.1.5 IC for Environmental Protection

Significant greenhouse gas emissions have led to global warming. Environmental protection is a major concern in the global construction industry [170,171]. In the study of IC, we need to consider the impact of raw materials, processing, transportation, construction, recycling, and other aspects to guide the overall development of IC.

4.1.6 Human–Machine Collaboration

Humans and machines can interact more collaboratively in IC, which enables a human to make efficient and effective decisions.

With the implementation of IC, the accuracy of construction, component quality, and processing efficiency will continue to improve. With the help of DT and big data technology, a virtual simulation model of an entity model can be established to produce feedback for the entity state in real time. It can also be used for real-time health detection, safety diagnosis, and maintenance of structures.

IT has developed rapidly since 2000. In recent years, AI has also rapidly developed in the fields of medicine, monitoring, and interaction, thereby greatly changing people’s lifestyles. In the future, IC processes will inevitably reduce human factors. Therefore, the application of AI will be the future research direction for IC, gradually replacing the role of humans with robots.

IoT enables all objects that can perform independent functions to access the network, to achieve both interconnection and the effect of interconnection of all things. The combination of IoT and IC realizes the interconnection between prefabricated components and construction parts.

With the transformation and upgrading of the construction industry, sustainable IC has become increasingly important. The combination of IC and DT, which have intelligent sensing and simulation functions, makes the building-production process more efficient and intelligent. At the same time, it can monitor the status of the structure and prefabricated components in real time, as well as predict potential safety hazards. After introducing a DT and its application, this paper introduced four aspects of sustainable IC driven by DT: information perception and interaction, data mining and modeling, condition evaluation and prediction, and intelligent optimization and decision-making. A framework for sustainable IC, driven by a DT, was proposed. The development direction of digital dual-drive sustainable intelligent construction was also discussed.

Funding Statement: The authors are grateful for the financial support partially provided by The Quality Engineering Project of Anhui Province (2019sjjd58, 2020sxzx36), The Ministry of Education Cooperative Education Project (201901119016), The Chinese (Jiangsu)-Czech Bilateral Co-funding R&D Project (SBZ2018000220), and the Key R&D Project of Anhui Science and Technology Department (202004b11020026).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Cai, F., Ji, J. M., Jiang, Z. Q., Mu, Z. R., Wu, X. et al. (2018). Engineering fronts in 2018. Engineering, 4(6), 748–753. [Google Scholar]

2. Munoz, I., Canou, J., U Hart, M., Lombois-Burger, H., Panagiotis, S. et al. (2021). Life cycle assessment of integrated additive-subtractive concrete 3D printing. International Journal of Advanced Manufacturing Technology, 112(7), 2149–2159. [Google Scholar]

3. Ke, Y., Qiu, Y., Yang, Z. (2021). Study on the maturity of construction technology in China. IOP Conference Series: Earth and Environmental Science, 632(2), 7. DOI 10.1088/1755-1315/632/2/022053. [Google Scholar] [CrossRef]

4. Zhang, D. S. (2021). Scheme comparison and key construction technology for swivel rider cap of some super major bridge. IOP Conference Series: Earth and Environmental Science, 626, 8. DOI 10.1088/1755-1315/626/1/012010. [Google Scholar] [CrossRef]

5. Zhao, Y. M., Han, Y., Kou, Y. Y., Li, L., Du, J. H. (2021). Three-dimensional, real-time, and intelligent data acquisition of large deformation in deep tunnels. Advances in Civil Engineering, 2021(3–4), 1–11. [Google Scholar]

6. Guo, Y., Xu, J., Qiu, S., Hu, Y., Zhang, X. et al. (2021). Research on informatization construction technology based on computer statistics. IOP Conference Series: Earth and Environmental Science, 632(4), 10. DOI 10.1088/1755-1315/632/4/042058. [Google Scholar] [CrossRef]

7. Huang, M., Ninic, J., Zhang, Q. (2021). BIM, machine learning and computer vision techniques in underground construction: Current status and future perspectives. Tunnelling and Underground Space Technology, 108, 40. DOI 10.1016/j.tust.2020.103677. [Google Scholar] [CrossRef]

8. Klimova, E. V., Semeykin, A. Y., Sinebok, D. A., Yu, V. K. (2020). The modern information technologies in construction for improving occupational safety. IOP Conference Series: Materials Science and Engineering, 945(1), 8. DOI 10.1088/1757-899X/945/1/012026. [Google Scholar] [CrossRef]

9. Halttula, H., Haapasalo, H., Silvola, R. (2020). Managing data flows in infrastructure projects–the lifecycle process model. Journal of Information Technology in Construction, 25, 193–211. [Google Scholar]

10. Kuzina, O. (2020). Information technology application in the construction project life cycle. IOP Conference Series: Materials Science and Engineering, 869, 8. DOI 10.1088/1757-899X/869/6/062044. [Google Scholar] [CrossRef]

11. Javed, Y., Felemban, M., Shawly, T., Kobes, J., Ghafoor, A. (2020). A partition-driven integrated security architecture for cyberphysical systems. Computer, 53(3), 47–56. [Google Scholar]

12. Anumba, C. J., Akanmu, A., Yuan, X., Kan, C. (2020). Cyber–physical systems development for construction applications. Frontiers of Engineering Management, 8(6), 1–16. [Google Scholar]

13. Chauhan, S., Patel, P., Delicato, F. C., Chaudhary, S. (2016). A development framework for programming cyber-physical systems. 2nd International Workshop, vol. 16, pp. 47–53. IEEE. [Google Scholar]

14. Han, S. H., Lei, Z., Hermann, U., Bouferguene, A., Al-Hussein, M. (2020). 4d-based automation of heavy lift planning in industrial construction projects. Canadian Journal of Civil Engineering, 5, 37. DOI 10.1139/cjce-2019-0825. [Google Scholar] [CrossRef]

15. Dharmapala, N. V., O’Brien, W. J. (2020). Automated materials locating and tracking technology in industrial construction projects: Implementation benefits and challenges. Proceedings of the Institution of Civil Engineers-Smart Infrastructure and Construction, 171(4), 1–13. [Google Scholar]

16. Kapogiannis, G., Mlilo, A. (2019). Digital construction strategies and BIM in railway tunnelling engineering. Tunnel Engineering, 7, 1–28. [Google Scholar]

17. Maizel, I. G., Maizel, I. V., Platonov, V. V. (2020). Digital technology in the construction of Norwegian house. IOP Conference Series: Materials Science and Engineering, 962(2), 7. DOI 10.1088/1757-899X/962/2/022086. [Google Scholar] [CrossRef]

18. Popescu, M., Rippmann, M., Liew, A., Reiter, L., Block, P. (2021). Structural design, digital fabrication and construction of the cable-net and knitted formwork of the knitcandela concrete shell. Structures, 31, 1287–1299. [Google Scholar]

19. Kten, B. B., Stüner, Y. A., Akbay, R. B. (2020). Usage of information modelling and digital technologies on construction sites. 6th International Project and Construction Management Conference (e-IPCMC2020), pp. 683–691. İstanbul, Turkey. [Google Scholar]

20. Yang, X. N., Wang, W., Xu, X. F., Pang, G. R., Zhang, C. L. (2018). Research on the construction of a novel cyberspace security ecosystem. Engineering, 4(1), 47–52. [Google Scholar]

21. Zhao, X., Jia, Y., Li, A., Jiang, R., Song, Y. (2020). Multi-source knowledge fusion: A survey. World Wide Web-internet and Web Information Systems, 23(4), 2567–2592. [Google Scholar]

22. Hodge, V. J., O’Keefe, S., Weeks, M., Moulds, A. (2015). Wireless sensor networks for condition monitoring in the railway industry: A survey. IEEE Transactions on Intelligent Transportation Systems, 16(3), 1088–1106. [Google Scholar]

23. Yi, C. W., Chuang, Y. T., Nian, C. S. (2015). Toward crowdsourcing-based road pavement monitoring by mobile sensing technologies. IEEE Transactions on Intelligent Transportation Systems, 16(4), 1905–1917. [Google Scholar]

24. Chang, Y., Wu, Y. C., Price, G. (2018). A cost-effective and objective full-depth patching identification method using 3D sensing technology with automated crack detection and classification. Transportation Research Record, 2672(40), 50–58. [Google Scholar]

25. Rivera, M. L., Juan, C. V., Herrera, R. F., Jorge, C. (2019). Methodology for building information modeling (BIM) implementation in structural engineering companies (SECs). Advances in Civil Engineering, 2019, 8452461.1–8452461.16. [Google Scholar]

26. Formoso, C. T., Tzortzopoulos, P., Forgues, D. (2020). Lean and BIM meet social sciences: New perspectives in construction engineering and management. Canadian Journal of Civil Engineering, 47(2). DOI 10.1139/cjce-2019-0662. [Google Scholar] [CrossRef]

27. Riahi Sfar, A., Challal, Y., Moyal, P., Natalizio, E. (2019). A game theoretic approach for privacy preserving model in IoT-based transportation. IEEE Transactions on Intelligent Transportation Systems, 20(12), 1–10. [Google Scholar]

28. Chen, X., Shi, Q., Yang, L., Xu, J. (2018). Thriftyedge: Resource-efficient edge computing for intelligent IoT applications. IEEE Network, 32(1), 61–65. [Google Scholar]

29. Al_Janabi, S., Salman, M. A., Mohammad, M. (2018). Multi-level network construction based on intelligent big data analysis. International Conference on Big Data and Smart Digital Environment, pp. 102–118. Cham: Springer. [Google Scholar]

30. Hafiz, A., Lukumon, O., Hakeem, O., Olugbenga, A., Muhammad, B. et al. (2019). A big data analytics approach for construction firms failure prediction models. IEEE Transactions on Engineering Management, 66(4), 689–698. [Google Scholar]

31. Habibi, M., Fazli, M. A., Movaghar, A. (2019). Efficient distribution of requests in federated cloud computing environments utilizing statistical multiplexing. Future Generation Computer Systems, 90, 451–460. [Google Scholar]

32. Yan, H., Yu, P., Long, D. (2019). Study on deep unsupervised learning optimization algorithm based on cloud computing. 2019 International Conference on Intelligent Transportation, Big Data & Smart City (ICITBS), vol. 1, pp. 702–704. DOI 10.1109/ICITBS.2019.00168. [Google Scholar] [CrossRef]

33. Pachon, P., Ca Stro, R., Garcia-Macias, E., Compan, V., Puertas, E. (2018). E. Torroja’s bridge: Tailored experimental setup for SHM of a historical bridge with a reduced number of sensors. Engineering Structures, 162(1), 11–21. [Google Scholar]

34. Du, X., Xu, H., Zhu, F. (2021). A data mining method for structure design with uncertainty in design variables. Computers & Structures, 244, 24. DOI 10.1016/j.compstruc.2020.106457. [Google Scholar] [CrossRef]

35. Lin, Y., Yang, Q., Guan, G. (2019). Automatic design optimization of SWATH applying CFD and RSM model. Ocean Engineering, 172(15), 146–154. [Google Scholar]

36. Kruzhilko, O., Maystrenko, V. (2019). Management decision-making algorithm development for planning activities that reduce the production risk level. Journal of Achievements of Materials and Manufacturing Engineering, 1–2(93), 41–49. [Google Scholar]

37. Rajaee, T., Ebrahimi, H., Nourani, V. (2019). A review of the artificial intelligence methods in groundwater level modeling. Journal of Hydrology, 572, 336–351. [Google Scholar]

38. Bahmani, R., Ouarda, T. (2021). Groundwater level modeling with hybrid artificial intelligence techniques. Journal of Hydrology, 595, 13. DOI 10.1016/j.jhydrol.2020.125659. [Google Scholar] [CrossRef]

39. Grieves, M. (2015). Digital twin: Manufacturing excellence through virtual factory replication. Digital Twin White Paper, 1–7 (Online). [Google Scholar]

40. Saddik, A. E. (2018). Digital twins: The convergence of multimedia technologies. IEEE Multimedia, 25(2), 87–92. [Google Scholar]

41. Negri, E., Fumagalli, L., Macchi, M. (2017). A review of the roles of digital twin in CPS-based production systems. Procedia Manufacturing, 11, 939–948. [Google Scholar]

42. Hellyer, P. (2019). Digital methods as good as traditional construction. British Dental Journal, 227(7), 585. [Google Scholar]

43. Glaessgen, E., Stargel, D. (2012). The digital twin paradigm for future NASA and US Air Force vehicles. 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, 1–14. DOI 10.2514/6.2012-1818. [Google Scholar] [CrossRef]

44. Lee, J., Bagheri, B., Kao, H. A. (2015). A cyber-physical systems architecture for industry 4.0-based manufacturing systems. Manufacturing Letters, 3, 18–23. [Google Scholar]

45. Sderberg, R., Wrmefjord, K., Carlson, J. S., Lindkvist, L. (2017). Toward a digital twin for real-time geometry assurance in individualized production. CIRP Annals-Manufacturing Technology, 66(1), 137–140. [Google Scholar]

46. Bolton, R. N., Mccoll-Kennedy, J. R., Lilliemay, C., Andrew, G., Chiara, O. et al. (2018). Customer experience challenges: Bringing together digital, physical and social realms. Journal of Service Management, 29(1), 776–808. [Google Scholar]

47. Tao, F., Sui, F., Liu, A., Qi, Q., Zhang, M. et al. (2019). Digital twin-driven product design framework. International Journal of Production Research, 57(11–12), 3935–3953. [Google Scholar]

48. Soni, R., Tanmay, D., Twinkle, Bhatia, M. (2019). Digital twin: Intersection of mind and machine. International Journal of Computational Intelligence & IoT, 2(3), 667–670. [Google Scholar]

49. Badenko, V. L., Bolshakov, N. S., Tishchenko, E. B., Fedotov, A. A., Yadykin, V. K. (2020). Integration of digital twin and BIM technologies within factories of the future. Magazine of Civil Engineering, 10(1), 17. DOI 10.34910/MCE.101.14. [Google Scholar] [CrossRef]

50. Nikolakis, N., Alexopoulos, K., Xanthakis, E., Chryssolouris, G. (2019). The digital twin implementation for linking the virtual representation of human-based production tasks to their physical counterpart in the factory-floor. International Journal of Computer Integrated Manufacturing, 3(1,2), 1–12. [Google Scholar]

51. Wang, S., Wan, J., Zhang, D., Li, D., Zhang, C. (2016). Towards smart factory for industry 4.0: A self-organized multi-agent system with big data-based feedback and coordination. Computer Networks, 101(4), 158–168. [Google Scholar]

52. Thoms, Bergmans, Dirk, Schlemper (2018). Digital twin technology. World Cement, 49(11 Suppl.), 76–79. [Google Scholar]

53. Wang, L., Jia, D. (2017). Application of image processing technology in urban solar energy planning and design. Boletin Tecnico/Technical Bulletin, 55(9), 585–592. [Google Scholar]

54. Abbas, F., Farooque, A. A., Afzaal, H. (2020). Homogeneity in patterns of climate extremes between two cities–A potential for flood planning in relation to climate change. Water, 12(3), 782–796. [Google Scholar]

55. Allmendinger, P., Sielker, F. (2018). Centre for digital built britain mini-projects programme 2017-18 urban planning and BIM final report, 1–20. University of Cambridge. DOI 10.13140/RG.2.2.36638.64325. [Google Scholar] [CrossRef]

56. Ito, K. (2019). Change beyond building information modeling to a digital twin in architecture. Japan Architectural Review, 2(4), 391. [Google Scholar]

57. Nasaruddin, A. N., Ito, T., Tuan, T. B. (2018). Digital twin approach to building information management. The Proceedings of Manufacturing Systems Division Conference, pp. 67–68. Malaysia. [Google Scholar]

58. Sacks, R., Brilakis, I., Pikas, E., Xie, H. S., Girolami, M. (2020). Construction with digital twin information systems. Data-Centric Engineering, 1, e14. DOI 10.1017/dce.2020.16. [Google Scholar] [CrossRef]

59. He, B., Bai, K. J. (2020). Digital twin-based sustainable intelligent manufacturing: A review. Advances in Manufacturing, 9, 1–21. [Google Scholar]

60. Haag, S., Anderl, R. (2018). Digital twin–proof of concept. Manufacturing Letters, 15, 64–66. [Google Scholar]

61. Guo, J., Zhao, N., Lin, S., Zhang, S. (2018). Modular based flexible digital twin for factory design. Journal of Ambient Intelligence and Humanized Computing, 10(3), 1189–1200. [Google Scholar]

62. Lydon, G. P., Caranovic, S., Hischier, I., Schlueter, A. (2019). Coupled simulation of thermally active building systems to support a digital twin. Energy and Buildings, 202, 109298.1–109298.19. [Google Scholar]

63. Cheng, Y., Tao, F., Xu, L., Zhao, D. (2016). Advanced manufacturing systems: Supply-demand matching of manufacturing resource based on complex networks and Internet of Things. Enterprise Information Systems, 12, 780–797. [Google Scholar]

64. Bilberg, A., Malik, A. A. (2019). Digital twin driven human-robot collaborative assembly. CIRP Annals-Manufacturing Technology, 68(1), 499–502. [Google Scholar]

65. Um, J., Weyer, S., Quint, F. (2017). Plug-and-simulate within modular assembly line enabled by digital twins and the use of automationML. IFAC PapersOnLine, 50(1), 15904–15909. [Google Scholar]

66. Qi, Q., Tao, F., Zuo, Y., Zhao, D. (2018). Digital twin service towards smart manufacturing. Procedia CIRP, 72, 237–242. [Google Scholar]

67. Ellinger, J., Beorkrem, C., Dodson, C. (2019). Computationally derived cross-laminated timber reinforcement and construction: Innovative techniques of representation in architectural design. Digital wood design, pp. 1135–1150. Springer. DOI 10.1007/978-3-030-03676-8_46. [Google Scholar] [CrossRef]

68. Guevremont, M., Hammad, A. (2019). Defining levels of development for 4D simulation of major capital construction projects: Proceedings of the 35th CIB W78 2018 Conference: IT in design, construction, and management. Advances in Informatics and Computing in Civil and Construction Engineering, 77–83. [Google Scholar]

69. Mykoniatis, K., Harris, G. A. (2021). A digital twin emulator of a modular production system using a data-driven hybrid modeling and simulation approach. Journal of Intelligent Manufacturing, 5, 1–13. [Google Scholar]

70. Meng, S., Tang, S., Zhu, Y., Chen, C. (2019). Digital twin-driven control method for robotic automatic assembly system. IOP Conference Series: Materials Science and Engineering, 493, 6. DOI 10.1088/1757-899X/493/1/012128. [Google Scholar] [CrossRef]

71. Xiang, F., Zhi, Z., Jiang, G. Z. (2018). Digital twins technology and its data fusion in iron and steel product life cycle. 2018 IEEE 15th International Conference on Networking, Sensing and Control (ICNSC), pp. 1–5. IEEE. DOI 10.1109/ICNSC.2018.8361293. [Google Scholar] [CrossRef]

72. Zhang, H., Liu, Q., Chen, X., Zhang, D., Leng, J. (2017). A digital twin-based approach for designing and multi-objective optimization of hollow glass production line. IEEE Access, 5, 26901–26911. [Google Scholar]

73. Zhuang, C., Liu, J., Xiong, H. (2018). Digital twin-based smart production management and control framework for the complex product assembly shop-floor. International Journal of Advanced Manufacturing Technology, 96, 1149–1163. [Google Scholar]

74. Liu, Q., Zhang, H., Leng, J., Chen, X. (2019). Digital twin-driven rapid individualised designing of automated flow-shop manufacturing system. International Journal of Production Research, 57, 3903–3919. [Google Scholar]

75. Liau, Y., Lee, H., Ryu, K. (2018). Digital Twin concept for smart injection molding. IOP Conference Series: Materials Science and Engineering, 324(1), 6. DOI 10.1088/1757-899X/324/1/012077. [Google Scholar] [CrossRef]

76. Leng, J., Zhang, H., Yan, D., Qiang, L., Chen, X. et al. (2019). Digital twin-driven manufacturing cyber-physical system for parallel controlling of smart workshop. Journal of Ambient Intelligence and Humanized Computing, 10, 1155–1166. [Google Scholar]

77. Cheng, Y., Zhang, Y., Ji, P., Xu, W., Zhou, Z. et al. (2018). Cyber-physical integration for moving digital factories forward towards smart manufacturing: A survey. International Journal of Advanced Manufacturing Technology, 97, 1209–1221. [Google Scholar]

78. Botkina, D., Hedlind, M., Olsson, B., Henser, J., Lundholm, T. (2018). Digital twin of a cutting tool. Procedia CIRP, 72, 215–218. [Google Scholar]

79. Wang, Q., Jiao, W., Wang, P., Zhang, Y. M. (2020). Digital twin for human-robot interactive welding and welder behavior analysis. IEEE/CAA Journal of Automatica Sinica, 99, 1–10. [Google Scholar]

80. Uhlemann, H. J., Schock, C., Lehmann, C., Freiberger, S., Steinhilper, R. (2017). The digital twin: Demonstrating the potential of real time data acquisition in production systems. Procedia Manufacturing, 9, 113–120. [Google Scholar]

81. Urbina Coronado, P. D., Lynn, R., Louhichi, W., Parto, M., Wescoat, E. et al. (2018). Part data integration in the shop floor digital twin: Mobile and cloud technologies to enable a manufacturing execution system. Journal of Manufacturing Systems, 48(C), 25–33. [Google Scholar]

82. Schluse, M., Priggemeyer, M., Atorf, L., Rossmann, J. (2018). Experimentable digital twins—streamlining simulation-based systems engineering for industry 4.0. IEEE Transactions on Industrial Informatics, 14(4), 1722–1731. [Google Scholar]

83. Macchi, M., Roda, I., Negri, E., Fumagalli, L. (2018). Exploring the role of digital twin for asset lifecycle management. IFAC–PapersOnLine, 51(11), 790–795. [Google Scholar]

84. Kunath, M., Winkler, H. (2019). Untersuchung des Status quo betrieblicher Entscheidungsunterstützungssysteme im Zuge der fortschreitenden Digitalisierung. BTU Cottbus-Senftenberg, Lehrstuhl für Produktionswirtschaft, 1–83. DOI 10.26127/BTUOpen-4822. [Google Scholar] [CrossRef]

85. Groth, C., Porziani, S., Biancolini, M. E., Costa, E., Morgenthaler, V. (2018). The medical digital twin assisted by Reduced Order Models and Mesh Morphing. International CAE Conference, pp. 10. [Google Scholar]

86. Barricelli, B. R., Casiraghi, E., Gliozzo, J., Petrini, A., Valtolina, S. (2020). Human digital twin for fitness management. IEEE Access, 8, 26637–26664. [Google Scholar]

87. Marai, O. E., Taleb, T., Song, J. S. (2020). Roads infrastructure digital twin: A step toward smarter cities realization. IEEE Network, 99, 1–8. [Google Scholar]

88. Gang, Y., Yi, W., Min, H., Lsa, B., Zma, B. et al. (2021). RIOMS: An intelligent system for operation and maintenance of urban roads using spatiotemporal data in smart cities. Future Generation Computer Systems, 115, 583–609. [Google Scholar]

89. Reza, H. A., Ashkan, S. (2018). Towards sustainable smart city by particulate matter prediction using urban big data, excluding expensive air pollution infrastructures. Big Data Research, 17, 1–10. DOI 10.1016/j.bdr.2018.05.006. [Google Scholar] [CrossRef]

90. Tao, F., Zhang, M., Liu, Y., Nee, A. (2018). Digital twin driven prognostics and health management for complex equipment. Cirp Annals, 67(1), 169–172. [Google Scholar]

91. Lynn, R., Chen, A., Locks, S., Nath, C., Kurfess, T. (2015). Intelligent and accessible data flow architectures for manufacturing system optimization. Advances in Production Management Systems: Innovative Production Management Towards Sustainable Growth, pp. 27–35. [Google Scholar]

92. Luo, W., Hu, T., Zhang, C., Wei, Y. (2018). Digital twin for cnc machine tool: Modeling and using strategy. Journal of Ambient Intelligence and Humanized Computing, 10(3), 1129–1140. [Google Scholar]

93. Bécue, A., Maia, E., Feeken, L., Borchers, P., Praa, I. (2020). A new concept of digital twin supporting optimization and resilience of factories of the future. Applied Sciences, 10(13), 31. DOI 10.3390/app10134482. [Google Scholar] [CrossRef]

94. Shi, Y., Xu, J., Du, W. (2019). Discussion on the new operation management mode of hydraulic engineering based on the digital twin technique. Journal of Physics: Conference Series, 1168(2), 5. DOI 10.1088/1742-6596/1168/2/022044. [Google Scholar] [CrossRef]

95. Park, H. A., Byeon, G., Son, W., Jo, H. C., Kim, S. (2020). Digital twin for operation of microgrid: optimal scheduling in virtual space of digital twin. Energies, 13(20), 15. DOI 10.3390/en13205504. [Google Scholar] [CrossRef]

96. Breillat, R. (2020). Industrial artificial intelligence, Internet of Things smart devices, and big data-driven decision-making in digital-twin-based cyber-physical production systems. Economics Management and Financial Markets, 15(1), 47–53. [Google Scholar]

97. Zhang, S., Liu, T., Zhu, G., Wang, C. (2019). Research and application of intelligent design of three-dimensional parameterization in long-distance water diversion engineering based on BIM. Journal of Water Resources and Water Engineering, 30(3), 139–145. [Google Scholar]

98. Dehghanbanadaki, A. (2020). Intelligent modelling and design of soft soil improved with floating column-like elements as a road subgrade. Transportation Geotechnics, 26(3), 15. DOI 10.1016/j.trgeo.2020.100428. [Google Scholar] [CrossRef]

99. Carvalho, N., Chaim, O., Cazarini, E., Gerolamo, M. (2018). Manufacturing in the fourth industrial revolution: A positive prospect in sustainable manufacturing. Procedia Manufacturing, 21, 671–678. [Google Scholar]

100. Stoycheva, S., Marchese, D., Paul, C., Padoan, S., Juhmani, A. S. et al. (2018). Multi-criteria decision analysis framework for sustainable manufacturing in automotive industry. Journal of Cleaner Production, 187, 257–272. [Google Scholar]

101. Gath, H., Herzog, G. (2015). Intelligent logistics 2.0. German Research, 37(1), 26–29. [Google Scholar]

102. Bergmans, T. (2014). Intelligent logistics. International Cement Review, 11, 91–92. [Google Scholar]

103. Liu, C., Feng, Y., Lin, D., Wu, L., Guo, M. (2020). IoT based laundry services: An application of big data analytics, intelligent logistics management, and machine learning techniques. International Journal of Production Research, 58(3), 1–19. [Google Scholar]

104. Lu, C., Liu, J., Liu, Y., Liu, Y. (2019). Intelligent construction technology of railway engineering in China. Frontiers of Engineering Management, 6(4), 503–516. [Google Scholar]

105. Mohamed, Y., Abourizk, S. M. (2005). Framework for building intelligent simulation models of construction operations. Journal of Computing in Civil Engineering, 19(3), 277–291. [Google Scholar]

106. Ranaweera, K., Ruwanpura, J., Fernando, S. (2013). Automated real-time monitoring system to measure shift production of tunnel construction projects. Journal of Computing in Civil Engineering, 27(1), 68–77. [Google Scholar]

107. Wang, L. J., Huang, X., Zheng, R. Y. (2012). The application of BIM in intelligent construction. Applied Mechanics & Materials, 188, 236–241. [Google Scholar]

108. Ma, Z., Liu, Z. (2014). BIM-based intelligent acquisition of construction information for cost estimation of building projects. Procedia Engineering, 85, 358–367. [Google Scholar]

109. Zhao, L., Liu, Z., Mbachu, J. (2019). Development of intelligent prefabs using IoT technology to improve the performance of prefabricated construction projects. Sensors, 19(19), 30. DOI 10.3390/s19194131. [Google Scholar] [CrossRef]

110. Berouine, A., Lachhab, F., Malek, Y. N., Bakhouya, M., Ouladsine, R. (2017). A smart metering platform using big data and IoT technologies. International Conference of Cloud Computing Technologies & Applications, vol. 1, pp. 1–6. [Google Scholar]

111. Lakmazaheri, S. (2010). Intelligent geometric modeling of standard bridges. Computer-Aided Civil & Infrastructure Engineering, 11(6), 367–379. [Google Scholar]

112. Snya, B., Lcc, A., Fjc, B. (2019). AI-based design of urban stormwater detention facilities accounting for carryover storage. Journal of Hydrology, 575, 1111–1122. [Google Scholar]

113. Lv, Z., Lou, R., Singh, A. K. (2020). AI empowered communication systems for intelligent transportation systems. IEEE Transactions on Intelligent Transportation Systems, 99, 1–9. [Google Scholar]

114. Kang, H. S., Lee, J. Y., Choi, S. S., Kim, H., Park, J. H. et al. (2016). Smart manufacturing: Past research, present findings, and future directions. International Journal of Precision Engineering and Manufacturing–Green Technology, 3(1), 111–128. [Google Scholar]

115. Walshe, K., Mckee, M., Mccarthy, M., Groenewegen, P., Hansen, J. et al. (2013). Health systems and policy research in Europe: Horizon 2020. Lancet, 382(9893), 668–669. [Google Scholar]

116. Zhong, R. Y., Xun, X., Klotz, E., Newman, S. T. (2017). Intelligent manufacturing in the context of industry 4.0: A review. Engineering, 3(5), 616–630. [Google Scholar]

117. Hemphill, T. A. (2014). Policy debate: The us advanced manufacturing initiative: Will it be implemented as an innovation–or industrial–policy? Innovation Management Policy & Practice, 16(1), 67–70. [Google Scholar]

118. Lewis, P., Bell, K. (2019). Understanding the UK’s productivity problems: new technological solutions or a case for the renewal of old institutions? Employee Relations: The International Journal, 41(2), 296–312. [Google Scholar]

119. Radanliev, P., Roure, D. D., Kleek, M. V., Santos, O., Ani, U. (2019). Artificial intelligence in cyber physical systems. AI & Society, 19, 1–9. [Google Scholar]

120. Yeung, G. (2018). ‘Made in China 2025’: The development of a new energy vehicle industry in China. Area Development and Policy, 4(2), 1–21. [Google Scholar]

121. António, B., Joan, C., Sergi, V. (2016). A review of distributed optical fiber sensors for civil engineering applications. Sensors, 16(5), 748. DOI 10.3390/s16050748. [Google Scholar] [CrossRef]

122. Li, L., Hu, H., Qin, Y., Tang, K. (2019). Digital approach to rotational speed measurement using an electrostatic sensor. Sensors, 19(11), 2540. DOI 10.3390/s19112540. [Google Scholar] [CrossRef]

123. Benkstein, K. D., Rogers, P. H., Montgomery, C. B., Jin, C., Raman, B. et al. (2014). Analytical capabilities of chemiresistive microsensor arrays in a simulated Martian atmosphere. Sensors & Actuators: B Chemical, 197, 280–291. [Google Scholar]

124. Li, N., José-Fernán, M., Juan, M. C., Martina, E. (2016). A survey on underwater acoustic sensor network routing protocols. Sensors, 16(3), 414. DOI 10.3390/s16030414. [Google Scholar] [CrossRef]

125. Girei, S. H., Hong, N. L., Ahmad, M. Z., Mahdi, M. A., Yaacob, M. H. (2020). High sensitivity microfiber interferometer sensor in aqueous solution. Sensors, 20(17), 4713. DOI 10.3390/s20174713. [Google Scholar] [CrossRef]

126. Jeong, S., Yoo, G., Yoo, M., Yeom, I., Woo, H. (2019). Resource-efficient sensor data management for autonomous systems using deep reinforcement learning. Sensors, 19(20), 4410. DOI 10.3390/s19204410. [Google Scholar] [CrossRef]

127. Tabatabaee, R. S., Golmohammadi, H., Ahmadi, S. H. (2019). Easy diagnosis of jaundice: A smartphone-based nanosensor bioplatform using photoluminescent bacterial nanopaper for point-of-care diagnosis of hyperbilirubinemia. ACS Sensors, 4(4), 1063–1071. [Google Scholar]

128. Wood, A. J., Basuray, S., Bok, S., Gangopadhyay, K., Gangopadhyay, S. et al. (2016). Enhanced DNA detection through the incorporation of nanocones and cavities into a plasmonic grating sensor platform. IEEE Sensors Journal, 16(10), 3403–3408. [Google Scholar]

129. Xiao, C., Chen, N., Li, D., You, L., Gong, J. (2017). Scrms: An RFID and sensor web-enabled smart cultural relics management system. Sensors, 17(1), 60. DOI 10.3390/s17010060. [Google Scholar] [CrossRef]

130. Yan, J., Downey, J., Cancelli, A., Laflamme, A., Chen, S. et al. (2019). Concrete crack detection and monitoring using a capacitive dense sensor array. Sensors, 19(8), 1843. DOI 10.3390/s19081843. [Google Scholar] [CrossRef]

131. Zhong, D., Lv, H., Han, J., Wei, Q. (2014). A practical application combining wireless sensor networks and Internet of Things: Safety management system for tower crane groups. Sensors, 14(8), 13794–13814. [Google Scholar]

132. Tang, K., Yuan, H. W., Lv, J. X., Chen, F. C. (2020). Developing an intelligent monitoring technology for airport stone column machines. Sensors, 20(11), 3050–3061. [Google Scholar]

133. Weng-Fong, C., Lin, T. H., Lin, Y. C. (2018). A real-time construction safety monitoring system for hazardous gas integrating wireless sensor network and building information modeling technologies. Sensors, 18(2), 436–459. DOI 10.3390/s18020436. [Google Scholar] [CrossRef]

134. Chen, L. W., Peng, Y. H., Tseng, Y. C., Tsai, M. F. (2018). Cooperative sensing data collection and distribution with packet collision avoidance in mobile long-thin networks. Sensors, 18(10), 3588. DOI 10.3390/s18103588. [Google Scholar] [CrossRef]

135. Liu, G., Ho, C., Slappey, N., Zhou, Z., Snelgrove, S. E. et al. (2016). A wearable conductivity sensor for wireless real-time sweat monitoring. Sensors and Actuators B: Chemical, 227, 35–42. [Google Scholar]

136. Liu, B., Zhang, F., Qu, X., Shi, X. (2016). A rapid coordinate transformation method applied in industrial robot calibration based on characteristic line coincidence. Sensors, 16(2), 239. DOI 10.3390/s16020239. [Google Scholar] [CrossRef]