| Phyton-International Journal of Experimental Botany |  |

DOI: 10.32604/phyton.2022.018485

ARTICLE

Effects of Different Irrigation Management on the Textural Properties of Double-Cropping Late Indica Rice in South China

1Ministry of Education and Jiangxi Key Laboratory of Crop Physiology, Ecology and Genetic Breeding, Jiangxi Agricultural University, Nanchang, 330045, China

2Institute of Crop Sciences, Chinese Academy of Agricultural Sciences, Beijing, 100081, China

*Corresponding Author: Yanhua Zeng. Email: zyh74049501@163.com

Received: 28 July 2021; Accepted: 26 October 2021

Abstract: In order to investigate the effects of different irrigation management on the textural properties of two different double-cropping late indica rice, the effects of three irrigation management including conventional irrigation (CK), constant irrigation (CI) and alternate wetting and drying (AWD) on textural properties has been researched under field conditions of two years. The results indicated that the firmness, cohesiveness and chewiness were decreased under AWD treatment, and the stickiness was increased compared with CK, while the textural properties under CI treatment showed the opposite trend with AWD treatment. Additionally, AWD treatment significantly improved the springiness of TY871 compared with CK and CI treatment, but had no significant effect in RYHZ, suggesting improvement of the cooking and eating quality of TY871 under AWD treatment. Correlation analysis showed that the chewiness was positively correlated with the firmness and cohesiveness, and the cohesiveness was positively correlated with the firmness. AWD could promote the textural properties of high-quality late indica rice in South China whereas CI treatment has shown the disadvantage of the textural properties, which will provide useful information for the improvement of cooking and eating quality of rice.

Keywords: Indica rice; alternate wetting and drying; textural properties; correlation analysis

Rice is one of the most important food crops and feeds more than half of the population in China [1]. The cooking and eating quality (CEQ) of rice has been given more and more attention with the improvement of people’s living standards [2]. It is difficult to evaluate the CEQ of rice because of the different taste preference of people in different regions [3,4]. However, in recent years, the proposed textural properties of rice have solved the problem [5]. The main principle of texture analyzer is to simulate the mechanical movement such as chewing and squeezing the rice and then obtaining the indexes of textural properties in computer analysis software [6]. Previous studies have shown that textural properties can well reflect the palatability of rice [7]. Stickiness was considered to be the most important index of textural properties because it was significantly correlated with the molecular structure of amylopectin and negatively correlated with the amylose content [8]. Li et al. [6] found that small molecules such as amylopectin short chains would exudate from rice surface during cooking, thus stickiness was positively correlated with the content of amylopectin short chains (DP ≤ 36). In addition, previous studies reported that gluten content was positively correlated with firmness and negatively correlated with stickiness in rice [9,10].

Traditional constant irrigation (CI) was gradually replaced by alternate wetting and drying (AWD) because it inhibits root respiration and significantly decreased water use efficiency [11]. Compared with CI, AWD could significantly save irrigation water consumption and increase rice yield (soil water potential ≤−15 kPa) [2,11]. In our previous study, AWD could significantly improve the processing quality, decrease the protein content, and improve the gelatinization properties of indica rice cultivar [2]. However, there was a lack of research on rice textural properties under different irrigation management. In addition, in recent years, the high-quality late indica rice cultivars were gradually replacing the previous common-quality rice cultivars in the double-cropping indica rice regions of South China [12]. Therefore, the purpose of this study was to compare the textural properties of two different grain quality indica rice cultivars under different irrigation management. This research could provide a theoretical basis for improving the CEQ of indica rice under different water irrigation conditions in the double-cropping indica rice regions of South China.

We conducted a field experiment under three irrigation managements and established in a split-plot design (length, 5 m; width, 5 m; three replications) at the Shanggao Experimental Base of Jiangxi Agricultural University (114°97′E, 28°23′N, and 93.4 m altitude). Three are two indica rice cultivars, one high-quality indica rice cultivars with lower amylose content (TY 871) and a common-quality indica rice cultivars with higher amylose content (RYHZ), which were provided by Jiangxi Modern Seed Industry Co. Ltd., China. In 2019, the seeds were sown on June 22, the seedlings were transplanted on July 20 and the rice was mature on November 01; in 2020, the seeds were sown on June 27, the seedlings were transplanted on July 25, and the rice was mature on November 10. The rice seeding amount was 30 kg·ha−1, rice seedling was transplanted by an artificial simulator, and the distance between row and hill was 25 cm × 14 cm. The total N applied in late-season rice was 165 kg · N · ha−1, N: P2O5: K2O = 1:0.5:1, nitrogen fertilizer was applied at transplanting stage (40%), tillering stage (20%), and panicle initiation stage (40%), phosphate fertilizer was applied at transplanting stage (100%), potassium fertilizer was applied at transplanting stage (50%) and panicle initiation stage (50%). Other cultivation measures were carried out in accordance with local high yield cultivation requirements. The soil developed from quaternary red clay is classified as a typic stagnic anthrosol [13]. The soil properties of 0–20 cm layer were 5.41 of pH, 31.2 g·kg−1 of soil organic matter, 1.42 g·kg−1 of total nitrogen (N), 173.8 mg·kg−1 of alkaline hydrolyzable N, 14.7 mg·kg−1 of available phosphorus (P), and 69.5 mg·kg−1 of available potassium (K).

The three water irrigation management are as follows. (i) Conventional irrigation (CK): In the whole growth period, the flooded layer was maintained at 2–4 cm, and the irrigation management was stopped one week before harvest, except for the field draining in the middle stage (when the population tiller number reached 80% of the expected panicle number); (ii) constant irrigation (CI): The water layer of 2–5 cm was maintained throughout the whole growth period, and the soil water potential remained 0 MPa, the constant irrigation was stopped one week before harvest; (iii) alternate wetting and drying (AWD): The shallow water layer was maintained from the transplanting period to the turning green period, and the alternate wetting and drying irrigation was repeated after the turning green period. When the shallow water layer draining naturally until the soil water potential was about −15 kPa, the field water layer was carried out to 1–2 cm, in addition, the field draining was carried out in the late tillering period. Continuous monitoring of soil water potential throughout the growth period by negative pressure pot device (TRS-II, Guangzhou Hangxin Scientific Instrument, Ltd., China). The soil water potential was shown in Xiong et al. [2].

The preparation method of rice refers to the GB/T 15682-2008 National Standard of the People’s Republic of China. The textural properties were evaluated using a texture analyzer (TVT 6700, Perten, Stockholm, Sweden) with 36 mm cylindrical probe using a two-cycle compression program. The supporting software Texcalc 5 was used for textural properties index analysis. Take 10 g of milled rice and cook for 30 min. Then three cooked-rice with the same integrity were selected for each measurement and repeated 10 times. Then a maximum value and a minimum value were excluded, and the average value of the final 8 replicates was taken as the final value of a measurement. The specific parameters are as follows: the compression ratio of 80%, the test speed of 1.0 mm/s, the retraction speed of 2.0 mm/s, the triggering force of 5 g, and the data collection frequency of 333 pps. The textural properties included firmness, stickiness, springiness, cohesiveness and chewiness. Firmness, stickiness and chewiness were recorded as gram (g).

Data in this study were the average value of each treatment with three replications. The mean and standard deviations were performed with SPSS 22.0 statistical software (SPSS Inc., Chicago, USA) to determine the least significant difference (LSD) at P < 0.05 levels. Multivariate analyses of variance (MANOVA) were conducted to determine the effects of year, cultivars, and irrigation management (as independent variables) as well as their interaction effects on the textural properties of rice (as dependent variables) at a significance level of 0.05 and 0.01. Additionally, Pearson’s correlation analysis was used to analyze the correlations among the textural properties of the two cultivars at a significance level of 0.05 and 0.01.

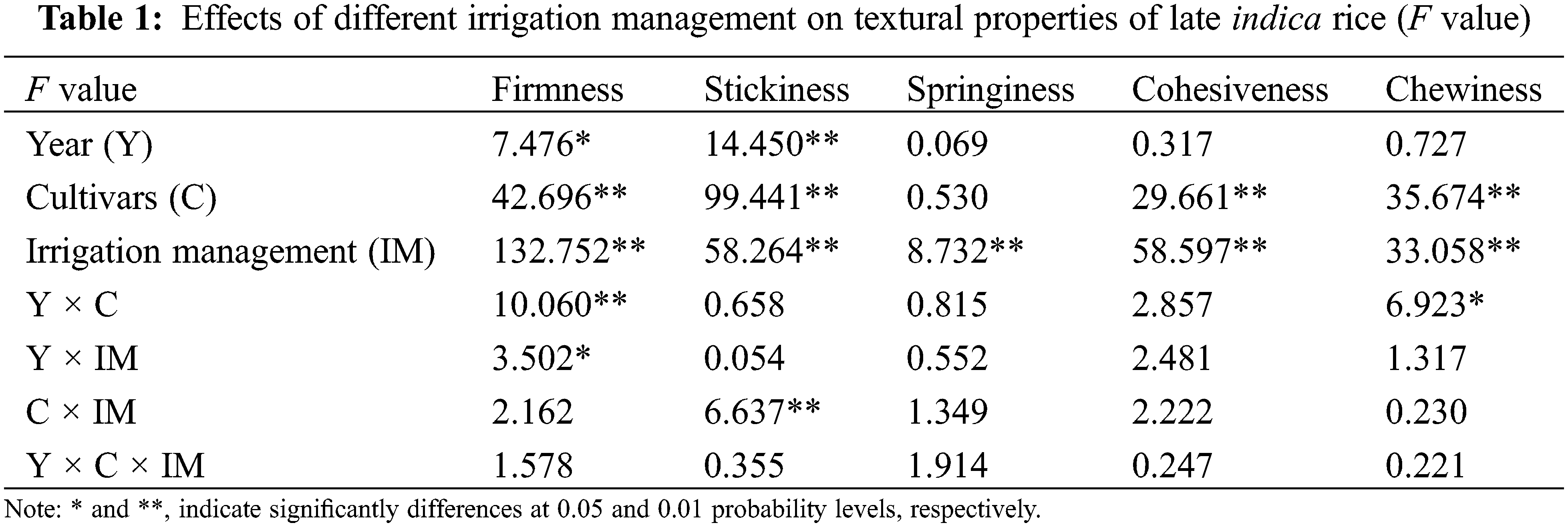

Irrigation management (IM) has a significant effect on texture properties (Table 1). Firmness, stickiness, cohesiveness and chewiness on different cultivars (C) were significantly different. In addition, only firmness and stickiness showed significant differences between two years (Y). However, Y × C had a significant effect on firmness and chewiness, and Y × IM only had a significant effect on firmness, and stickiness was significantly different under C × IM.

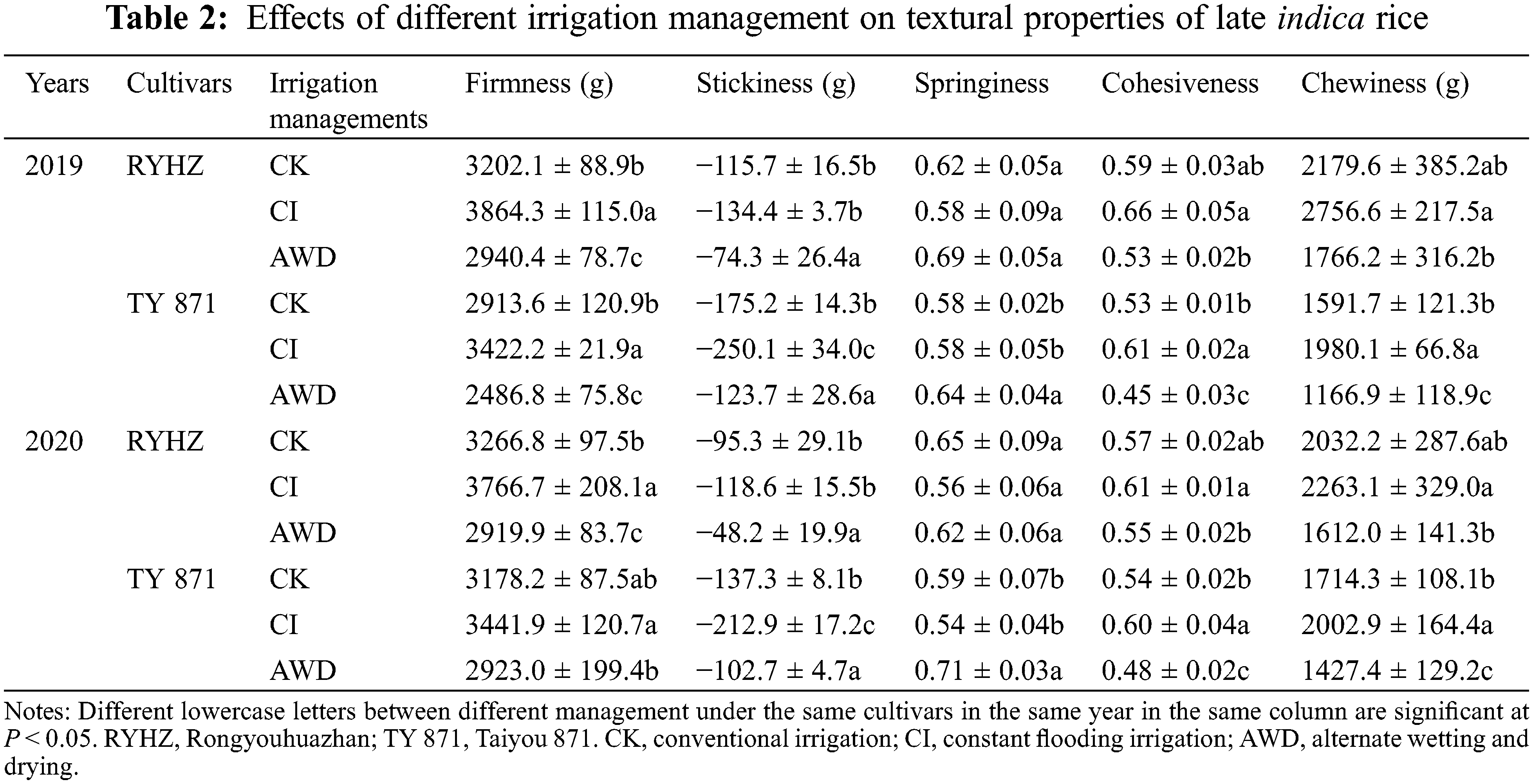

Under different irrigation management, compared with CK, CI treatment tended to increase the values of firmness, cohesiveness and chewiness, but significantly decrease stickiness in TY 871 cultivars, however, CI treatment had no significant effect on springiness (Table 2). Compared with CK, AWD treatment tended to decrease firmness and significantly increase stickiness in the two cultivars; but only significantly increased springiness and decreased cohesiveness, chewiness in TY 871, and those had no significant effects in RYHZ. In addition, AWD treatment significantly decreased firmness, cohesiveness and chewiness, whereas significantly increased stickiness compared with CI treatment in the two cultivars. Springiness significantly increased only in TY 871 under AWD.

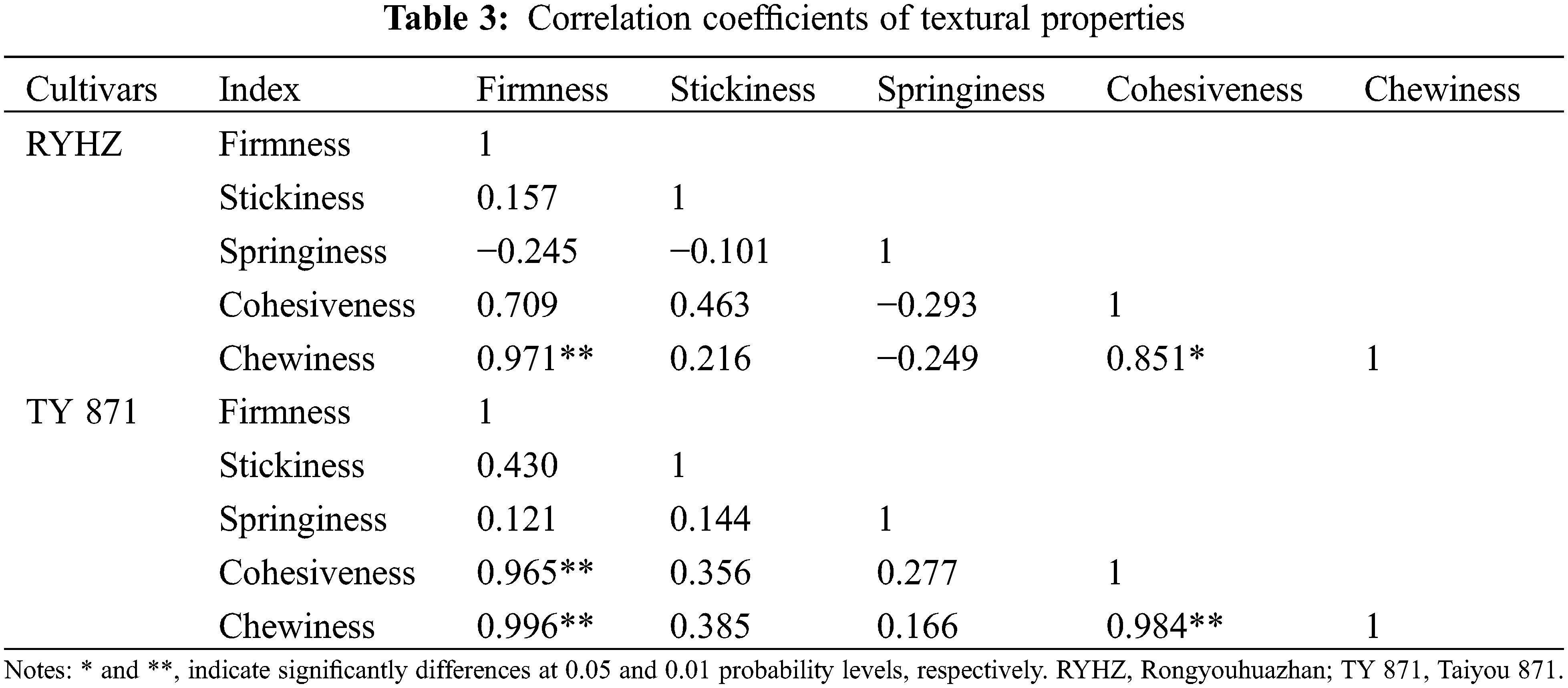

3.2 Correlation Coefficients of Textural Properties

There has a certain correlation among the textural properties of the two cultivars (Table 3). The chewiness was significantly positively correlated with firmness and cohesiveness in the two cultivars; however, cohesiveness was only significantly positively correlated with firmness in TY 871.

4.1 Irrigation Management has Changed the Textural Properties of the Late Indica Rice

Rice cooking is essentially the process of qualitative change of rice components such as starch, protein and lipid in the process of cooking rice under the action of water and heat [14]. Water migrates from the surface of rice to the inner layer of the rice and then starch gelatinization, causing the expansion of rice [14]. The probe of texture analyzer compresses the cooked rice led the internal material leached to the surface, the different extracts showed different textural properties [15].

The firmness is peak pressure when the rice was first squeezed by the probe of the texture analyzer [14]. The significant increase of firmness under CI treatment might be attributed to the decrease of amylose content and the increase of protein content [16]. High protein content easily forms complexes with lipids to prevent starch gelatinization, resulting in a significant increase of firmness [17]. Meanwhile, the protein content decreased significantly under AWD treatment in the two cultivars, which might be the main reason for the decrease in rice firmness. In addition, there was a significant interaction between Y and C, Y and IM on firmness, and there was no obvious change of firmness under each treatment, indicating that firmness of high-quality indica rice was not only related to irrigation management but also affected by inter-annual environmental changes and cultivar types [2].

After the first stamping is completed, the interval formed during the probe recovery process is the value of stickiness [14]. Previous research showed that stickiness was greatly affected by the genetic type of rice cultivars and protein content [3]. This study also reached a similar conclusion that there was a significant interaction effect of stickiness between cultivars and irrigation management, indicating that rice cultivars type (different amylose content) might be the reason why stickiness responded differently to water irrigation management [2]. Stickiness had a significant difference under CI treatment in TY 871, but had no significant effect in RYHZ, due to the different genetic factors. Otherwise, the decrease of firmness and the increase of stickiness under AWD treatment will contribute to making the rice CEQ better [18].

Springiness is the degree of “bounce” of the rice grain itself after deformation during the first extrusion process [14]. Irrigation management has no significant effect on the springiness in RYHZ, which might be caused by the genetic characteristics of the cultivars. However, AWD significantly increased springiness in TY 871, which might be attributed to the intermittent irrigation promoted grain filling by increasing grain-filling enzyme activity such as granule-bound starch synthase and starch branching enzyme, preventing the senescence of rice and finally making starch crystalline and granule structure orderly, thus increasing the resilience of cooked rice after extrusion [19].

Cohesiveness is the ability of rice to resist squeezing and whether it can be broken during squeezing [14]. A significant decrease of cohesiveness under AWD treatment might be attributed to starch fine structure, especially the increase of amylopectin short & middle chains [20]. The structure of starch was alternately arranged by crystalline regions and amorphous regions, the increase of amylopectin short & middle chains was not conducive to the formation of starch crystalline regions, the resist squeezing ability was weakened led to the decrease of cohesiveness [16].

The chewiness is the comprehensive expression of firmness, stickiness and springiness, and refers to the energy required to chew rice into a stable state when cooked rice is swallowed [14]. Therefore, the significant increase in stickiness and significant decrease in firmness were the main reason for the significant decrease in chewiness in the two cultivars under AWD treatment. There was also a significant interaction between Y and C in this study. Compared with 2019, the chewiness of RYHZ showed a decreasing trend in 2020, while the chewiness of TY 871 showed an increasing trend in 2020. Previous studies have indicated that rice with long-chain amylopectin tended to have a higher chewiness, while rice with short-chain amylopectin tended to have a lower chewiness [16,20]. Therefore, this might be caused by the increase of amylopectin medium & long chains for TY 871 in 2020, while the decrease of amylopectin medium & large chains for RYHZ.

4.2 The Relationships among the Textural Properties of the Late Indica Rice under Different Irrigation Management

Previous studies have indicated that the firmness and chewiness are positively correlated with the protein content, the stickiness is negatively correlated with the protein content, and the firmness is also positively correlated with the lipid content [21]. In addition, firmness and chewiness were significantly positively correlated with the amylose content [22]. All the above research showed the relationship between textural properties and physicochemical properties under different rice cultivars. However, the relationship between rice texture characteristics under different irrigation management has not been reported yet. Finally, the results of our research showed that chewiness was significantly positively correlated with firmness and cohesiveness, and cohesiveness was significantly positively correlated with firmness.

In conclusion, the textural properties of rice were caused by the different components and structures of the internal materials, especially starch and protein [14,17]. The higher amylose and amylopectin medium & long chains will increase rice crystallinity regions and starch granule gelatinization temperature eventually leading to the increase of firmness and chewiness [23]. Meanwhile, the increase of protein content and lipids will prevent rice gelatinization and eventually lead to the increase of firmness [24]. In addition, lipid content was negatively correlated with firmness and stickiness and positively correlated with springiness and cohesiveness [25].

The results of our study showed that the AWD treatment had great influences on textural properties in the two indica rice cultivars. Compared with CK, the firmness under AWD treatment has decreased significantly, stickiness increased significantly, while the result of CI treatment was opposite to that of AWD treatment. For high-quality cultivar TY 871, AWD treatment has significantly increased springiness and significantly decreased cohesiveness and chewiness but those have no effect in common-quality cultivar RYHZ. In addition, chewiness was positively correlated with firmness and cohesiveness, and cohesiveness was positively correlated with firmness. The results could provide some useful information for the improvement of the cooking and eating of rice.

Funding Statement: The study was supported by the Key Project of Jiangxi Provincial Natural Science Foundation (20202ACBL215004), the National Natural Science Foundation of China (32071950), the National Key Research & Development Project of China (2016YFD0300501), and the Key Research of & Development Project Jiangxi Province, China (20171BBF60030). We also like to thank those who have been at the forefront of the fight against the COVID-19 epidemic for allowing us to concentrate on writing this paper securely.

Conflicts of Interest: The authors declare that they have no conflicts of interests to report regarding the present study.

1. Li, Y. X., Zhang, W. F., Ma, L., Wu, L. Q., Shen, J. B. et al. (2014). An analysis of China’s grain production: Looking back and looking forward. Food and Energy Security, 3(1), 19–32. DOI 10.1002/fes3.41. [Google Scholar] [CrossRef]

2. Xiong, R. Y., Xie, J. X., Tan, X. M., Yang, T. T., Pan, X. H. et al. (2021). Effects of irrigation management on grain yield and quality of high-quality eating late-season indica rice in South China. Scientia Agricultural Sinica, 54(7), 1512–1524. DOI 10.3864/j.issn.0578-1752.2021.07.015. [Google Scholar] [CrossRef]

3. Zhang, Z., Min, L., Fang, Y., Liu, F., Yue, L. et al. (2012). Diversification of the waxy gene is closely related to variations in rice eating and cooking quality. Plant Molecular Biology Reporter, 30(2), 462–469. DOI 10.1007/s11105-011-0362-x. [Google Scholar] [CrossRef]

4. Haider, Z., Mahmood, A. (2016). Effect of transplanting dates on cooking, milling and eating quality parameters of some fine and coarse grain rice lines. Journal of Nutrition & Food Sciences, 6(5), 1–5. DOI 10.4172/2155-9600.1000552. [Google Scholar] [CrossRef]

5. Siaw, M. O., Wang, Y. J., McClung, A. M., Mauromoustakos, A. (2021). Porosity and hardness of long-grain brown rice kernels in relation to their chemical compositions. LWT-Food Science and Technology, 144, 111243. DOI 10.1016/j.lwt.2021.111243. [Google Scholar] [CrossRef]

6. Li, H. Y., Xu, M. H., Chen, Z. J., Li, J., Wen, Y. Y. (2021). Effects of the degree of milling on starch leaching characteristics and its relation to rice stickiness. Journal of Cereal Science, 98, 103163. DOI 10.1016/j.jcs.2021.103163. [Google Scholar] [CrossRef]

7. Puhin, K., Fukuoka, M., Ratanasumawong, S. (2021). Effect of starch and non-starch components on water migration, microstructure, starch retrogradation and texture of flat rice noodles made from different rice varieties. International Journal of Food Science and Technology, 56(7), 3344–3354. DOI 10.1111/ijfs.14957. [Google Scholar] [CrossRef]

8. Ramesh, M., Ali, S. Z., Bhattacharya, K. (1999). Structure of rice starch and its relation to cooked-rice texture. Carbohydrate Polymers, 38(4), 337–347. DOI 10.1016/S0144-8617(98)00125-8. [Google Scholar] [CrossRef]

9. Baxter, G., Blanchard, C., Zhao, J. (2014). Effects of glutelin and globulin on the physicochemical properties of rice starch and flour. Journal of Cereal Science, 60(2), 414–420. DOI 10.1016/j.jcs.2014.05.002. [Google Scholar] [CrossRef]

10. Kojima, T. I., Horigane, A. K., Nakajima, H., Yoshida, M., Nagasawa, A. (2004). T2 map, moisture distribution, and texture of boiled Japanese noodles prepared from different types of flour. Cereal Chemistry, 81(6), 746–751. DOI 10.1094/CCHEM.2004.81.6.746. [Google Scholar] [CrossRef]

11. Xiao, M. H., Li, Y. Y., Wang, J. W., Hu, X. J., Wang, L. et al. (2019). Study on the law of nitrogen transfer and conversion and use of fertilizer nitrogen in paddy fields under water-saving irrigation mode. Water, 11(2), 218. DOI 10.3390/w11020218. [Google Scholar] [CrossRef]

12. Zhang, C. X., Xiao, J. X., Ye, Q., Yang, X. G., Guo, J. P. (2016). Variation characteristics of climate suitability for late rice in southern China from 1951 to 2010. Acta Agriculturae Universitatis Jiangxiensis, 38(4), 792–804. DOI 10.13836/j.jjau.2016113. [Google Scholar] [CrossRef]

13. IUSS Working Group, WRB (2006). World reference base for soil resources 2006. World Soil Resources Reports, No. 103. FAO, Rome. http://refhun.elsevier.com/S0378-4290(17)31810-5/sbref0095. [Google Scholar]

14. Jin, L. C., Geng, Z. M., Li, J. Z., Wang, P., Chen, F. et al. (2011). Correlation between components and molecule structure of rice starch and eating quality. Jiangsu Journal of Agricultural Sciences, 27(1), 13–18. DOI 10.3969/j.issn.1000-4440.2011.01.003. [Google Scholar] [CrossRef]

15. Toyoshima, H., Okadome, H., Yoshizaki, S., Kimura, T., Ohtsubo, K. I. (1999). Evaluation of textural and chemical properties of newly bred characteristic rice grains. Nippon Shokuhin Kagaku Kogaku Kaishi, 46(3), 123–130. DOI 10.3136/nskkk.46.123. [Google Scholar] [CrossRef]

16. Xiong, R. Y., Xie, J. X., Chen, L. M., Yang, T. T., Tan, X. M. et al. (2021). Water irrigation management affects starch structure and physicochemical properties of indica rice with different grain quality. Food Chemistry, 347(3), 129045. DOI 10.1016/j.foodchem.2021.129045. [Google Scholar] [CrossRef]

17. Putseys, J. A., Derde, L. J., Lamberts, L., Ostman, E., Bjorck, I. M. et al. (2010). Functionality of short chain amylose-lipid complexes in starch-water systems and their impact on in vitro starch degradation. Journal of Agricultural and Food Chemistry, 58(3), 1939–1945. DOI 10.1021/jf903523h. [Google Scholar] [CrossRef]

18. Cameron, D. K., Wang, Y. (2005). A better understanding of factors that affect the hardness and stickiness of long-grain rice. Cereal Chemistry, 82(2), 113–119. DOI 10.1094/cc-82-0113. [Google Scholar] [CrossRef]

19. Li, Z., Zhong, L., Puleng, L., Hong, Z., Zhang, Z. et al. (2018). A positive response of rice rhizosphere to alternate moderate wetting and drying irrigation at grain filling stage. Agricultural Water Management, 207(93), 26–36. DOI 10.1016/j.agwat.2018.05.022. [Google Scholar] [CrossRef]

20. Seetapan, N., Limparyoon, N., Gamonpilas, C., Methacanon, P., Fuongfuchat, A. (2015). Effect of cryogenic freezing on textural properties and microstructure of rice flour/tapioca starch blend gel. Journal of Food Engineering, 151, 51–59. DOI 10.1016/j.jfoodeng.2014.11.025. [Google Scholar] [CrossRef]

21. Zhou, X. Q., Ren, H. L., Zhang, Y. R., Wang, J. F. (2012). Correlation between mouthfeel property of cooked rice and main quality properties of rice. Journal of Henan University of Technology, 33(5), 22–24. DOI 10.16433/j.cnki.issn1673-2383.2012.05.016. [Google Scholar] [CrossRef]

22. Singh, N., Kaur, L., Sodhi, N. S., Sekhon, K. S. (2005). Physicochemical, cooking and textural properties of milled rice from different Indian rice cultivars. Food Chemistry, 89(2), 253–259. DOI 10.1016/j.foodchem.2004.02.032. [Google Scholar] [CrossRef]

23. Cai, C., Wei, C. (2013). In situ observation of crystallinity disruption patterns during starch gelatinization. Carbohydrate Polymers, 92(1), 469–478. DOI 10.1016/j.carbpol.2012.09.073. [Google Scholar] [CrossRef]

24. Zhan, Q., Ye, X. T., Zhang, Y., Kong, X. L., Bao, J. S. et al. (2020). Starch granule-associated proteins affect the physicochemical properties of rice starch. Food Hydrocolloids, 101(1), 105504. DOI 10.1016/j.foodhyd.2019.105504. [Google Scholar] [CrossRef]

25. Derycke, V., Vandeputte, G. E., Vermeylen, R., Man, W. D., Goderis, B. et al. (2005). Starch gelatinization and amylose-lipid interactions during rice parboiling investigated by temperature resolved wide angle X-ray scattering and differential scanning calorimetry. Journal of Cereal Science, 42(3), 334–343. DOI 10.1016/j.jcs.2005.05.002. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |