International Journal of

Experimental Botany

| Phyton- International Journal of Experimental Botany |  |

DOI: 10.32604/phyton.2021.014637

ARTICLE

Amylose Content, Morphology, Crystal Structure, and Thermal Properties of Starch Grains in Main and Ratoon Rice Crops

College of Agronomy, Hunan Agricultural University, Changsha, 410128, China

*Corresponding Author: Qiyuan Tang. Email: qytang@hunau.edu.cn

Received: 14 October 2020; Accepted: 29 January 2021

Abstract: Rice ratooning, or the production of a second rice crop from stubble after the harvest of the main crop, is considered to be a green and resource-efficient rice production system. The present study was conducted to examine variance in amylose content (AC), grain morphology, crystal structure, and thermal properties of starch between main- and ratoon-season rice of seven varieties. Ratoon-season rice grains had higher ACs and significantly lower transition gelatinization temperatures (To, Tp, and Tc) than did main-season rice grains. The relative crystallinity and lamellar peak intensity of ratoon-season rice starch were 7.89% and 20.38% lower, respectively, than those of main-season rice starch. In addition, smaller granules with smoother surfaces and lower thermal parameters were observed in the starch of ratoon-season rice. The relative crystallinity and lamellar peak intensity of starch correlated negatively with the AC and positively with transition gelatinization temperatures. These results suggest that the superior cooking quality of ratoon-season rice is attributable to the moderate increase of grain AC, which reduces the relative crystallinity, weakens the crystal structure, and lead to a decrease in the gelatinization temperature.

Keywords: Ratooning rice; starch; amylose content; crystal structure; thermal property

Rice feeds half of the world’s population and is grown in more than 95 countries. China is the principal producer of rice (representing >28% of global production) and plays a key role in global food security [1]. Economic conditions and quality improvement programs have increased the demand for sustainable green agriculture. However, the overuse of commercial fertilizers, pesticides, and heavy machinery has negatively affected the environment and increased production costs [2]. Rice ratooning, or the production of a second rice crop from stubble after the harvest of the main crop, is considered to be a green and resource-efficient rice production system. Rice ratooning is associated with significantly larger net energy and cost–benefit ratios, as well as a substantially lower global warming potential, than are middle- and double-season rice cultivation techniques [2]. In recent years, the ratoon cultivation system has drawn much attention and has been practiced widely by farmers in regions where light and temperature resources are sufficient for one seasonal crop, but insufficient for two seasonal crops [3].

Ratoon rice is characterized by high grain quality, which could be a determinant factor for farmers’ economic returns. Compared with those of main-season rice (MR), the chalky rice rate and chalkiness of ratoon-season rice (RR) are significantly lower and the appearance quality is better [4]. The improvement of the cooking and eating qualities of ratoon crops is reflected mainly by a decrease in the gelatinization temperature [5]. Huang et al. [6] reported that the head rice yields of the superior and inferior grains of RR are significantly higher than those of main crops. The quality of RR has been reported to be generally better than that of MR, but differences in starch structure and properties between MR and RR remain poorly understood.

The starch in rice endosperm accounts for about 90% of the dry weight of rice grains [7], and it is the major determinant of rice quality. With higher amylose content (AC), the water absorption of starch is reduced, and the hardness of starch gel is increased [8]. Furthermore, the AC and granular structure have been suggested to affect rice starch pasting properties (e.g., gelatinization temperature), which correlate strongly with rice cooking quality and functionality [9]. The particle size distribution of starch is related to its rheological and gelatinizing properties, as well as starch granule size, which in turn affects starch composition and crystallinity [10]. The gelatinization characteristics of rice starch are governed by its granularity (ratio of crystalline and amorphous regions) [11]. The crystallinity of starch granules correlates positively with the gelatinization temperature and negatively with the AC [12,13]. Starch thermal properties, as revealed by differential scanning calorimetry (DSC) analysis, include gelatinization enthalpy and temperature. Cai et al. [14] reported a positive correlation between the gelatinization enthalpy of rice starch and the AC. However, Kong et al. [9] found a negative correlation between these properties and Park et al. [15] detected no correlation. The structure and properties of starch are related closely to the cooking quality of rice. Although several studies have indicated that the quality of RR is better than that of MR, the differences between MR and RR in starch characteristics and their possible correlations with grain quality have rarely been explored. Thus, the present study was conducted to evaluate the variance in AC, grain morphology, crystal structure, and thermal properties of rice starch between MR and RR of seven varieties. Our data will facilitate the sustainable development of green agriculture and production of high-quality rice.

We obtained samples of seven rice cultivars from a field experiment. Field trials (three replications) were performed in 2017 in the Datonghu district of Yiyang (29°08’N, 112°26’E), Hunan Province, China. The region is a typical alluvial plain of Dongting Lake, and the soil parent materials are river and lake sediments. It lies within the continental monsoon humid climate zone, within the transition from the subtropical zone to the north subtropical zone. The annual average temperature is 16.5°C, the frost-free period is 264 days, the average annual precipitation is 1240.8 mm, the average annual duration of sunshine is 1643.3 h, and the average annual total solar radiation is 439.3 J/cm2. Field management was identical for all cultivars. The cultivars were four hybrid indica rice varieties [Wanxiangyouhuazhan (WXYHZ), Chuankangyou 308 (CKY 308), Chuankanghuazhan (CKHZ), and Chuankangsimiao (CKSM)] and three conventional indica rice varieties [Meixiangzhan 2 (MXZ 2), Xiangyaxiangzhan (XYXZ), and Meixiangxinzhan (MXXZ)]. Each cultivar was planted in three plots, each with an area of 4 × 5 m2. Two seedlings of each cultivar were transplanted with a spacing of 20 × 20 cm per hill. Additionally, 180 kg/hm2 pure nitrogen was applied to the MR. The N:P:K fertilization ratio was 1:0.5:0.8. The base:tiller:ear nitrogen fertilizer ratio was 5:2:3. Tillering fertilizer was applied about 10 days after transplanting, and ear fertilizer was applied at the third stage of young panicle differentiation. Twenty days after the full heading of MR crops, 150 kg/hm2 urea and 75 kg/hm2 KCl were applied to each plot as germination-promoting fertilizer. The MR crops were harvested artificially, and the stubble height was 30 cm. Shallow irrigation was applied 1–2 days after harvesting in the first season, and 225 kg/hm2 hair and seedling fertilizer was applied. In the mature stage, timely harvesting and threshing were performed, and the samples were stored for 3 months. All grain samples were mechanically dehulled and polished.

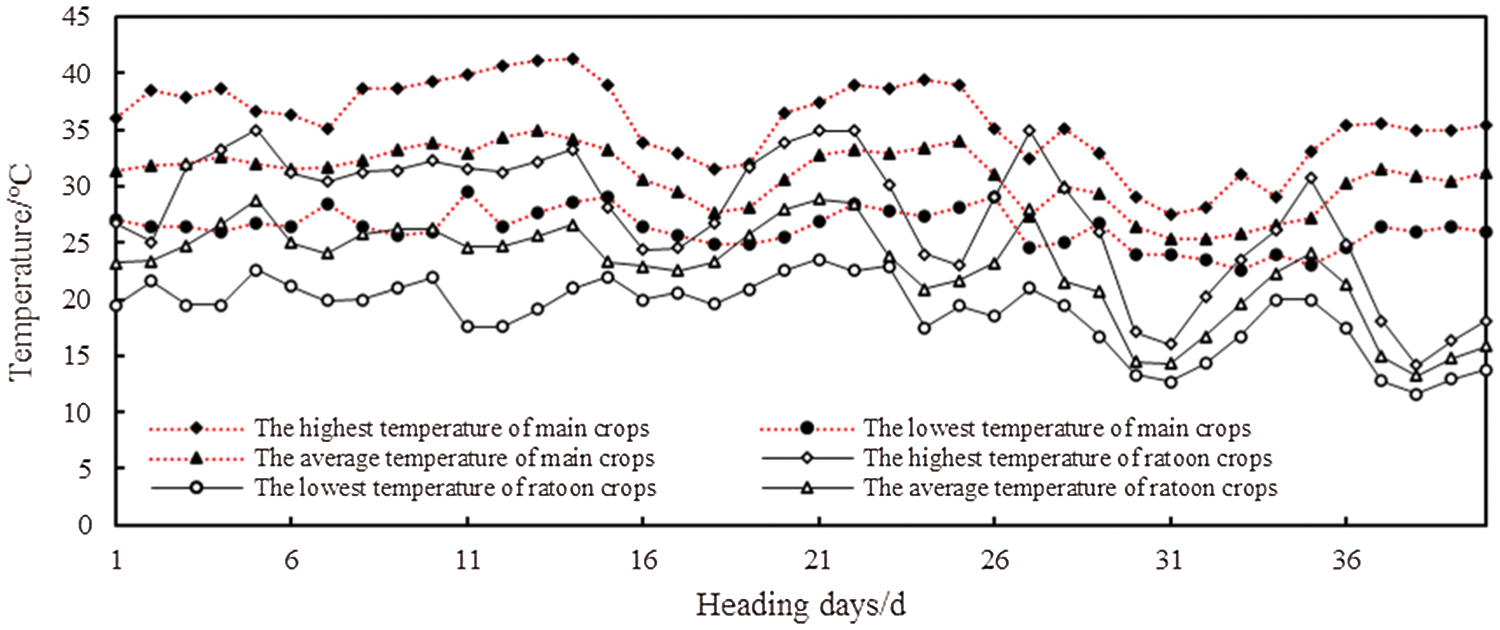

The temperature during ripening differed significantly between the MR and RR (Fig. 1). The daily average temperatures in the 20 days after full heading for MR and RR were 27.6–34.9°C and 20.9–28.9°C, respectively. The temperature peaks in the main and ratoon seasons were 41.3°C and 34.9°C, respectively, with 19 and 0 respective high-temperature (>35°C) days. The minimum temperatures in the 20 days after full heading for MR and RR were 24.9°C and 17.5°C, respectively.

Figure 1: Temperature curves after heading of the main and ratoon rice crops

2.3 Measurement of Amylose Content

The percentage of amylose was measured using a simplified amylose assay procedure and the spectrophotometric method [14].

2.4 Isolation of Starch Granules

Milled rice (25 g) was soaked overnight at 4°C in ultrapure water, washed and ground, and then passed through four layers of gauze. The slurry was filtered through 200- and 400-mesh sieves and then centrifuged (3,000 × g) for 10 min. The supernatant was discarded, and the precipitate was resuspended in 0.4% (w/v) NaOH solution. The resulting slurry was placed in a constant-temperature (25°C) shaker (THZ-320; Shanghai Jing Hong Laboratory Co., Ltd., Shanghai, China) for 4 h and then centrifuged (3,000 × g) for 20 min. The precipitate was suspended in water and neutralized with 1 M hydrochloric acid, followed by centrifugation (3,000 × g) for 10 min. The supernatant and top protein layer were discarded. The lower starch layer was resuspended in ultrapure water and centrifuged as described above; this procedure was repeated twice. The material was dehydrated via successive precipitation with anhydrous ethanol. The final purified starch was dried in an electro-thermostatic blast oven at 40°C for 48 h, ground to an extent allowing passage through a 100-mesh sieve, and then stored in an airtight container.

2.5 Scanning Electron Microscopy

Granule morphology was evaluated via scanning electron microscopy (JSM-6380LV; Joel Ltd., Tokyo, Japan). Starch samples were placed using a conductive adhesive, coated with gold, and photographed under accelerating voltages in multiples of 20 kV. Granules were displayed at 5,000× magnification.

2.6 Starch Powder Particle Size

The particle size of starch powder was measured using a laser particle size analyzer (LS-POP6; OMEC Instruments Co., Ltd., Guangzhou, China). The average particle size in starch samples was termed the D (50) value. The refractive indexes of the starch samples and water were 1.6 and 1.33, respectively.

Relative starch crystallinity was determined using an X-ray diffractometer (XRD-6100; Shimadzu Co., Kyoto, Japan) delivering Cu-Kα radiation (40 kV, 30 mA), following the method of Kong et al. [9].

2.8 Small-Angle X-Ray Scattering

Small-angle X-ray scattering (SAXS; NanoSTAR; Bruker-Axs, Karlsruhe, Germany) data were obtained as described by Cai et al. [14].

2.9 Fourier-Transform Infrared Spectroscopy

Fourier-transform infrared (FT-IR) spectra of samples embedded in KBr pellets were obtained using an FT-IR Spectrum65 spectrometer (PerkinElmer Inc., Beaconsfield, UK), employing the method of Li et al. [16].

The thermal properties of starch granules were measured by DSC (200-F3; Netzsch, Selb, Germany), as described by Kong et al. [9].

The data were subjected to analysis of variance using Statistix Ver. 8.0 (Analytical Software, Tallahassee, FL, USA). Multiple comparisons were made using Fisher’s protected least-significant difference test at the 0.05 probability level. We also derived Pearson correlation coefficients.

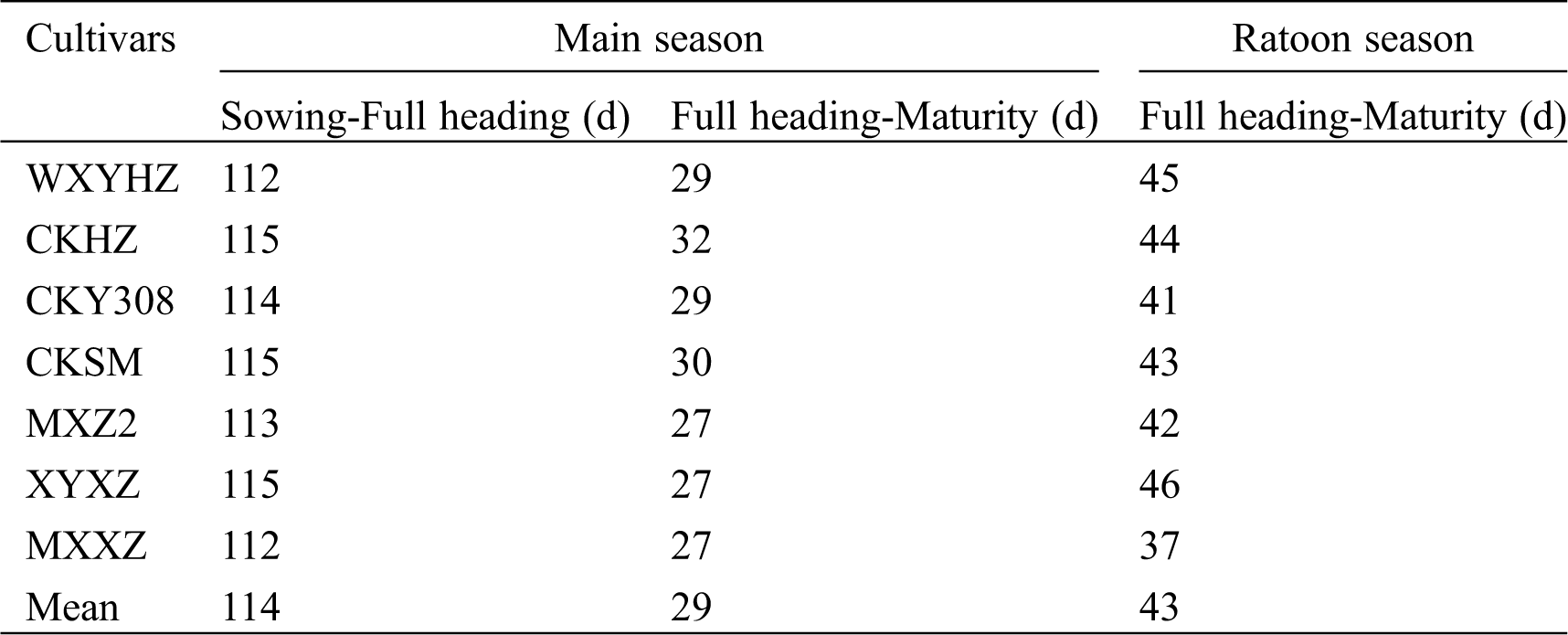

3.1 Growth Periods of Main and Ratoon Rice Crop Varieties

The time from full heading to maturity (and thus the filling period) was longer for RR than for MR (Tab. 1). The time from sowing to full heading differed among the tested varieties; it was longest (115 days) for CKHZ, CKSM, and XYXZ, and shortest (112 days) for WXYHZ and MXXZ. The time from heading to maturity was longer for all RR varieties than for MR varieties.

Table 1: Growth period of varieties of main and ratoon rice crops

The AC was, on average, 0.96% greater for RR than for MR grains (Tab. 2). It was slightly lower for RR than for MR of the XYXZ variety, and slightly higher for RR than for MR of the WXYHZ, CKHZ, CKY308, CKSM, MXZ2, and MXXZ varieties.

Table 2: Amylose content in main and ratoon rice crops

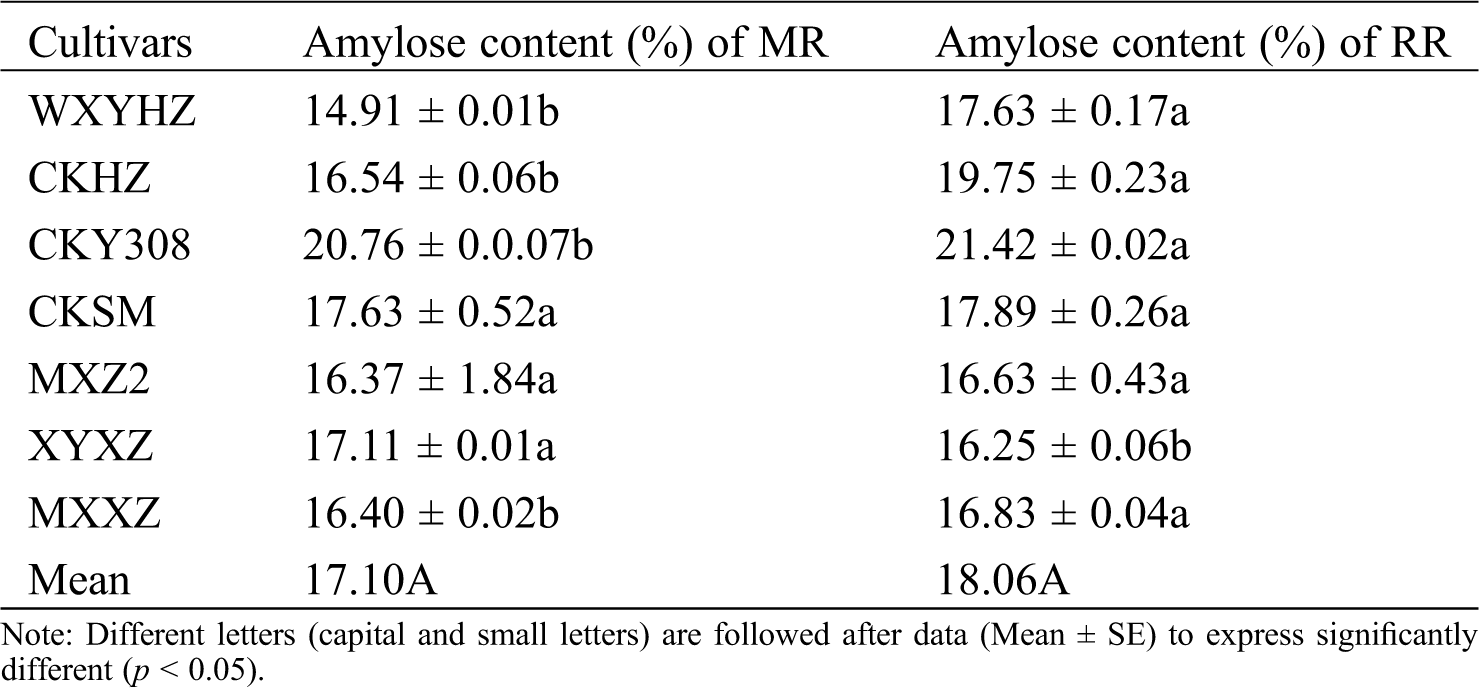

3.3 Rice Starch Morphology and Granule Size

The starch granules were tightly packed, with well-defined edges and relatively smooth (sometimes concave) surfaces (Fig. 2). However, some differences were found between MR and RR starch granules. The major difference was that MR starch granules were pitted and had uneven surfaces, whereas RR granules had smooth surfaces.

Figure 2: Microscopic images of starch granules from rice varieties of Wanxiangyouhuazhan (1), Chuankangyou 308 (2), Chuankanghuazhan (3), Chuankangsimiao (4), Meixiangzhan 2 (5), Xiangyaxiangzhan (6), Meixiangxinzhan (7); A: Main season rice. B: Ratoon season rice

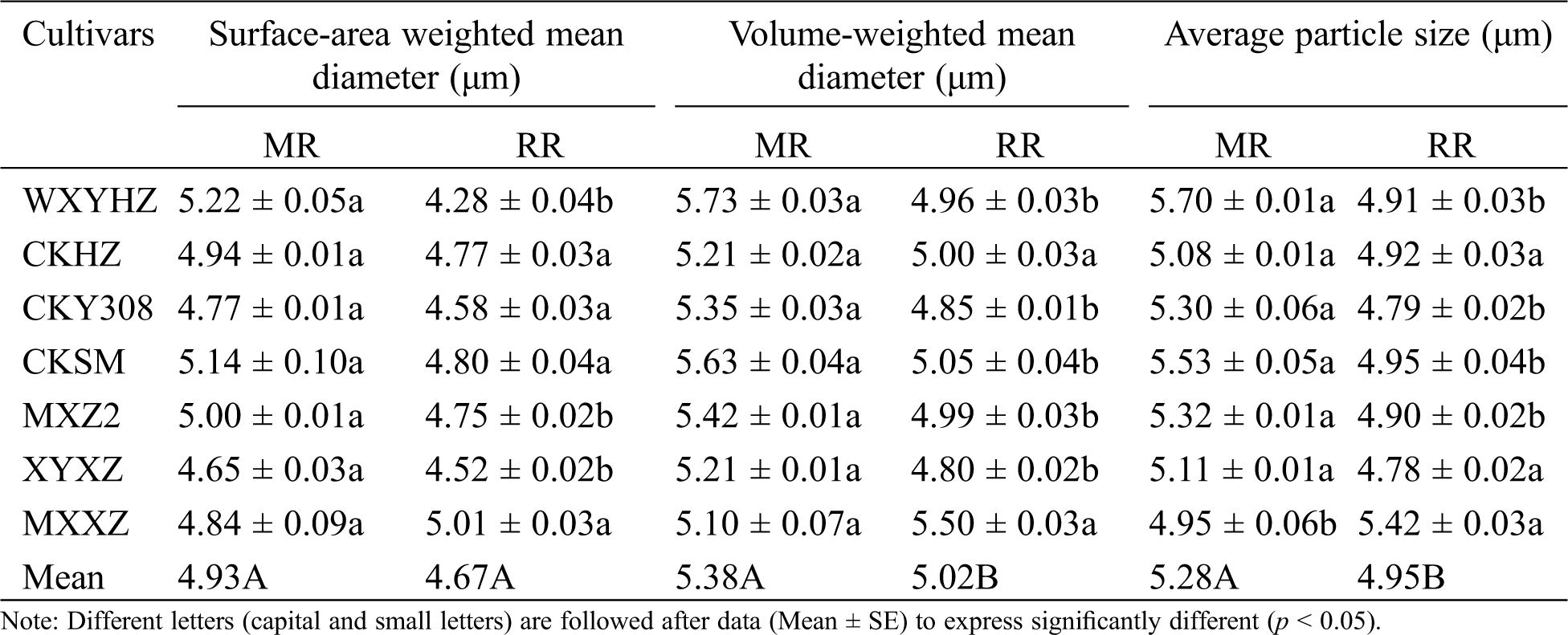

Starch grain size also differed significantly between MR and RR (Tab. 3). The volume-weighted mean diameter and average particle size of RR were significantly lesser than those of MR. The surface area–weighted mean diameter of RR starch was lesser than that of MR, but the difference was not significant. The surface area–weighted mean diameter was significantly lesser for RR than for MR starch of the WXYHZ, MXZ2, and XYXZ varieties, with no significant difference observed for the other varieties. For the WXYHZ, CKY308, CKSM, MXZ2, and XYXZ varieties, volume-weighted mean diameters were 13.4%, 9.3%, 10.2%, 7.9%, and 7.9%, lesser, respectively, for RR than for MR. For the WXYHZ, CKY 308, CKSM, and MXZ 2 varieties, average particle sizes were significantly lesser (by 13.9%, 9.6%, 10.5%, and 7.9%, respectively) for RR than for MR. However, the average RR starch particle size was greater than that of MR for the MXXZ variety.

Table 3: Diameters of starch granule

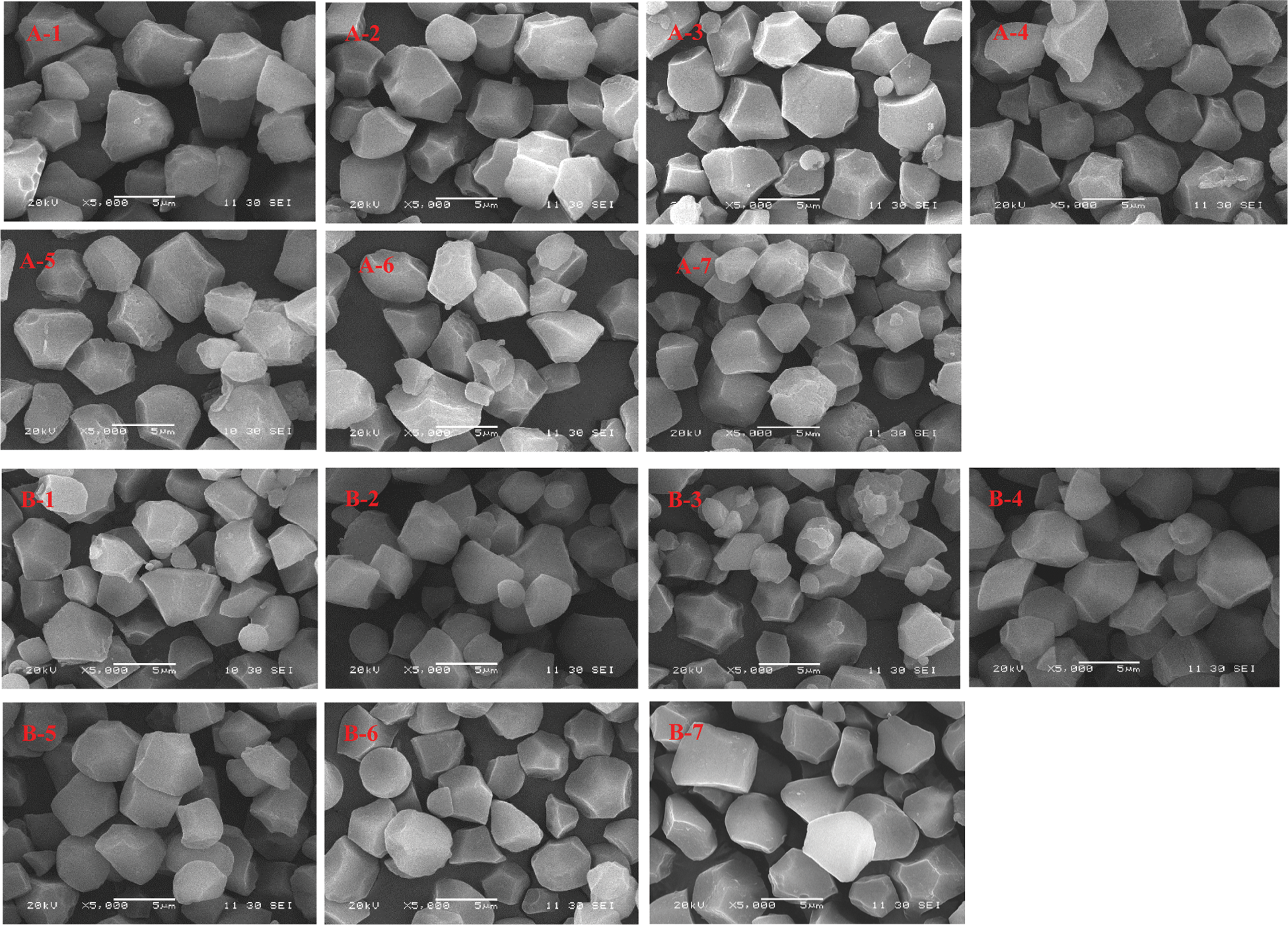

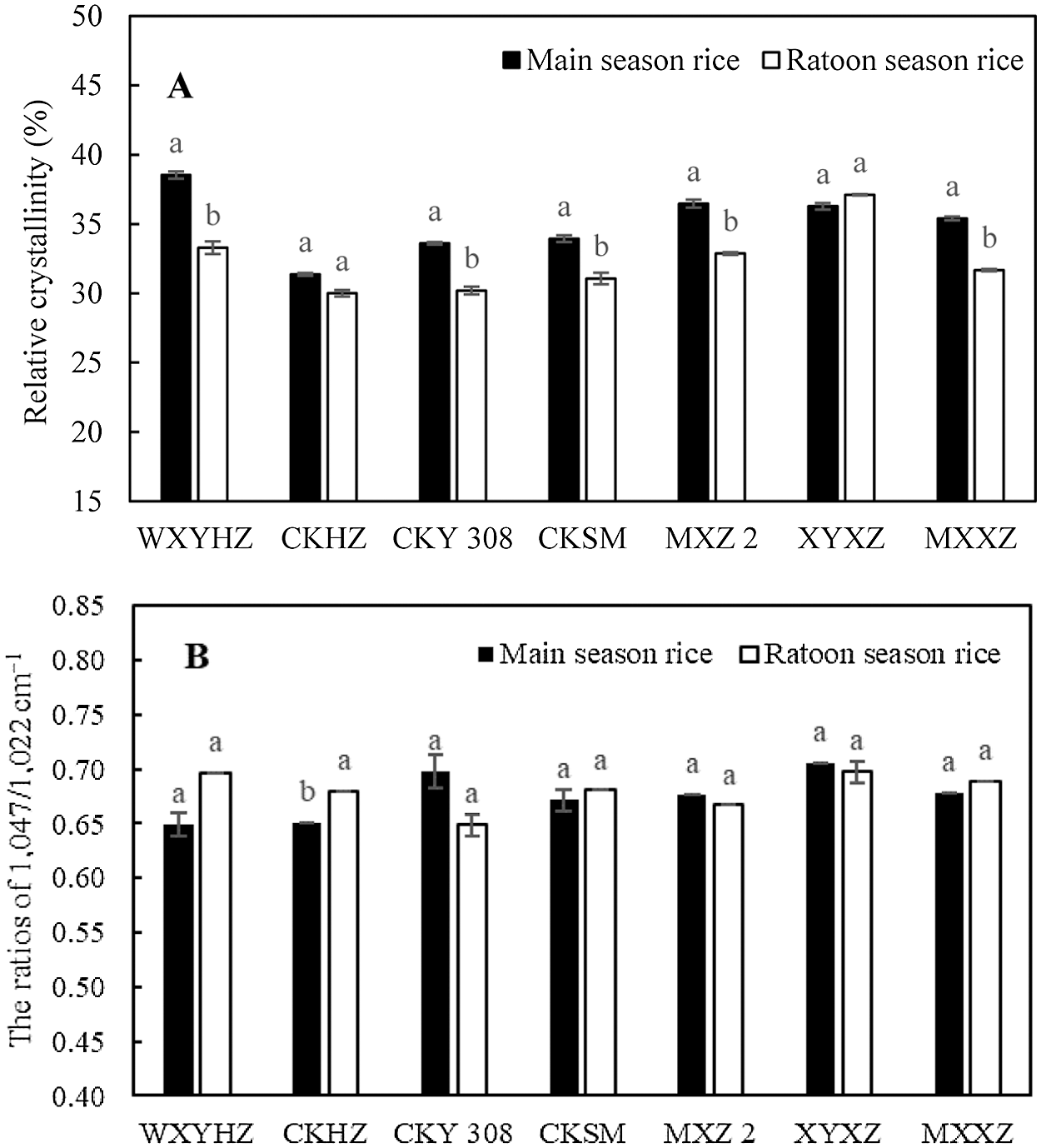

MR and RR starches exhibited the typical A-type crystal structure. The average relative crystallinities of MR and RR differed significantly (35.09% and 32.32%, respectively). Among the seven varieties studied, the RRs of five varieties had significantly reduced relative crystallinities relative to those of the MRs (the exceptions were CKHZ and XYXZ; Fig. 3A). The values for the WXYHZ, CKY308, CKSM, MXZ2, and MXXZ cultivars were lower by 5.23%, 3.41%, 2.88%, 3.59%, and 3.73%, respectively.

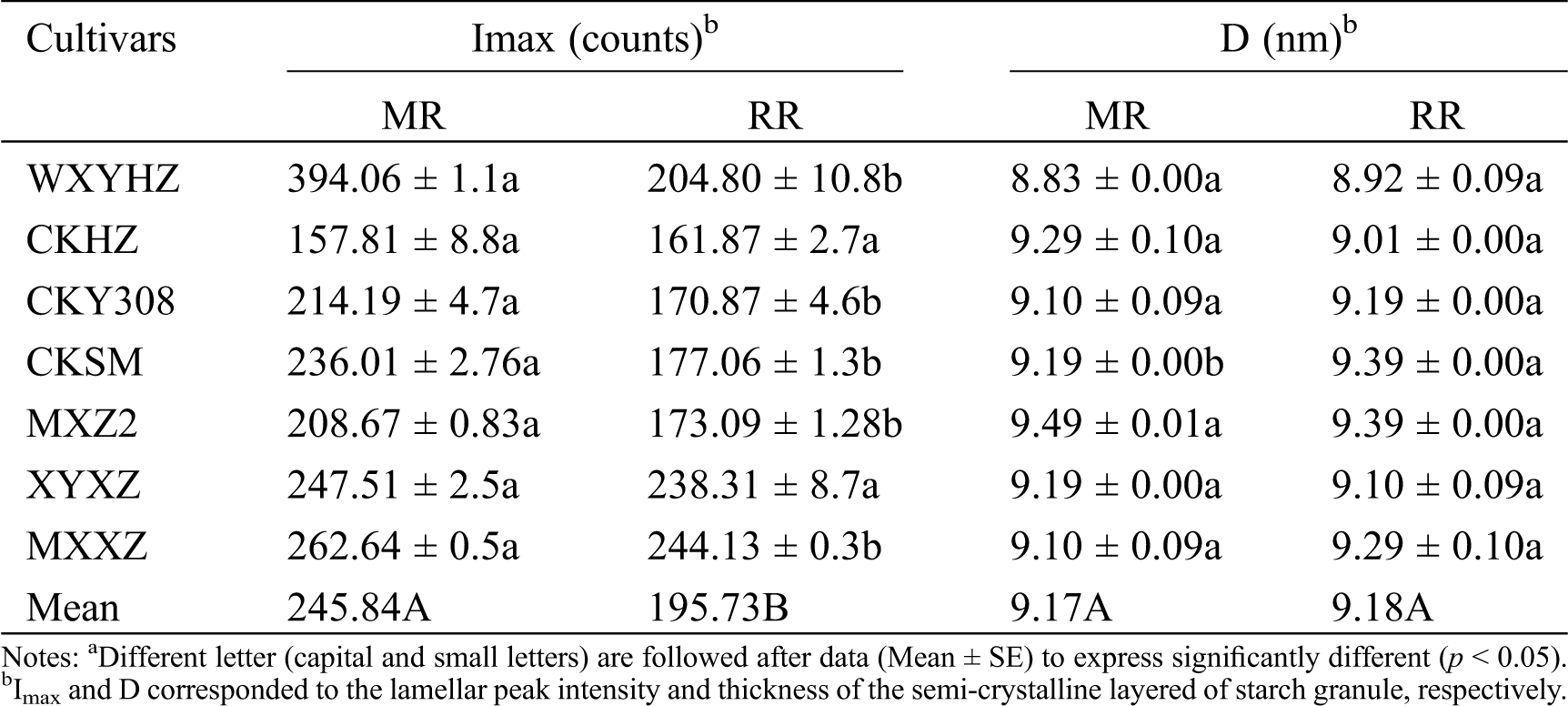

The SAXS maximum peak intensities (Imax values) of the lamellae and the thicknesses (D values) of the semi-crystalline layered structures are listed in Tab. 4. The Imax of RR was significantly lower than that of MR. However, the thicknesses of the semi-crystalline layered structures did not differ significantly between the MR and RR starch granules. Except for CKHZ and XYXZ, the Imax values for the rice varieties were significantly decreased in RR, with the largest difference (48%) observed for WXYHZ. The D value of RR CKSM was significantly higher than that of MR; no significant difference between RR and MR was observed for the other varieties.

Table 4: SAXS parameters of rice starchesa

The deconvoluted FT-IR spectra and starch absorbance ratios (1,047/1,022 cm−1) were similar for both crops (Fig. 3B). Starch infrared spectra exhibit three characteristic peaks at 1,047, 1,022, and 995 cm−1. The first two peaks reflect the ordered and amorphous structural components, and the peak at 995 cm−1 reflects between-molecule hydrogen bonding [17]. The 1,047/1,022 cm−1 absorbance ratio reflects the extent of molecular order, with higher ratios indicating greater order. For the WXYHZ variety, the 1,047/1,022 cm−1 ratio was significantly higher for RR than for MR; no significant difference was observed between RR and MR for the other varieties.

Figure 3: Relative crystallinity (A) and the ratios of 1,047/1,022 cm−1 (B) of the MR and RR starches

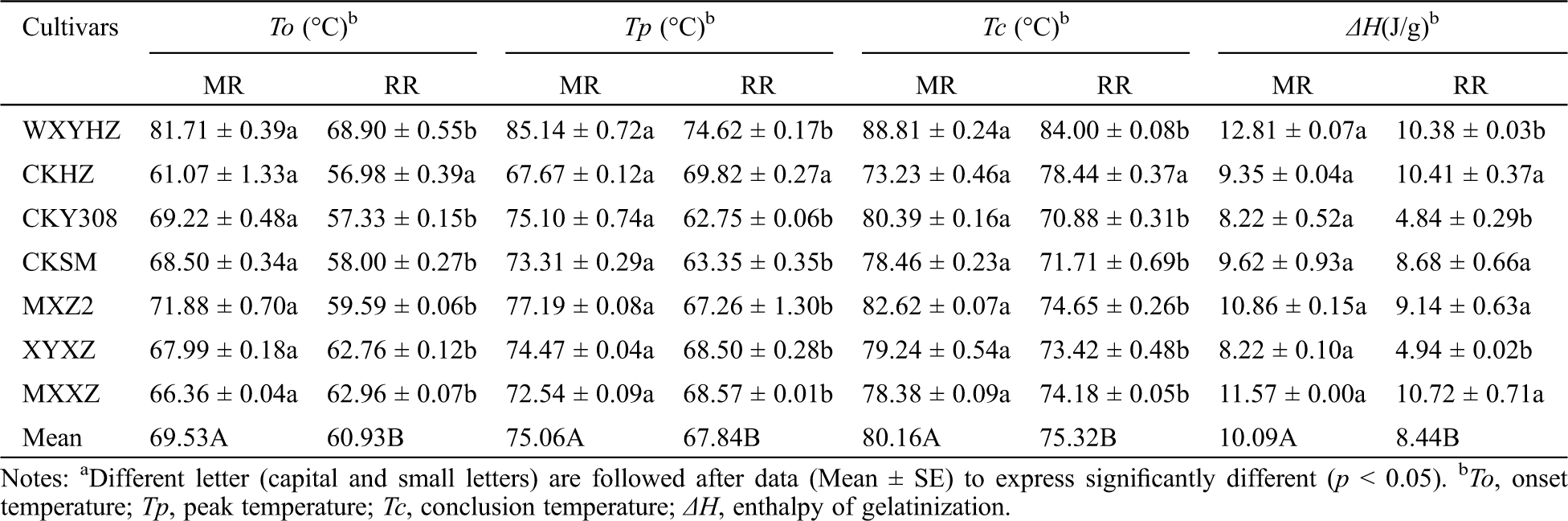

The thermal properties of the starches of MR and RR (as revealed by DSC) differed significantly. The starches of RR showed significantly lesser gelatinization enthalpy (ΔH, 8.44 J/g) and gelatinization temperatures [onset temperature (To), 60.93°C; peak temperature (Tp), 67.84°C; conclusion temperature (Tc), 75.32°C]. The To, Tp, and Tc of WXYHZ, CKY308, CKSM, MXZ2, XYXZ, and MXXZ were significantly lower in RR (Tab. 5). In addition, the rice varieties (except CKHZ) had decreased ΔH values for RR; differences were significant for WXYHZ, CKY308, and XYXZ.

Table 5: DSC parameters of rice starchesa

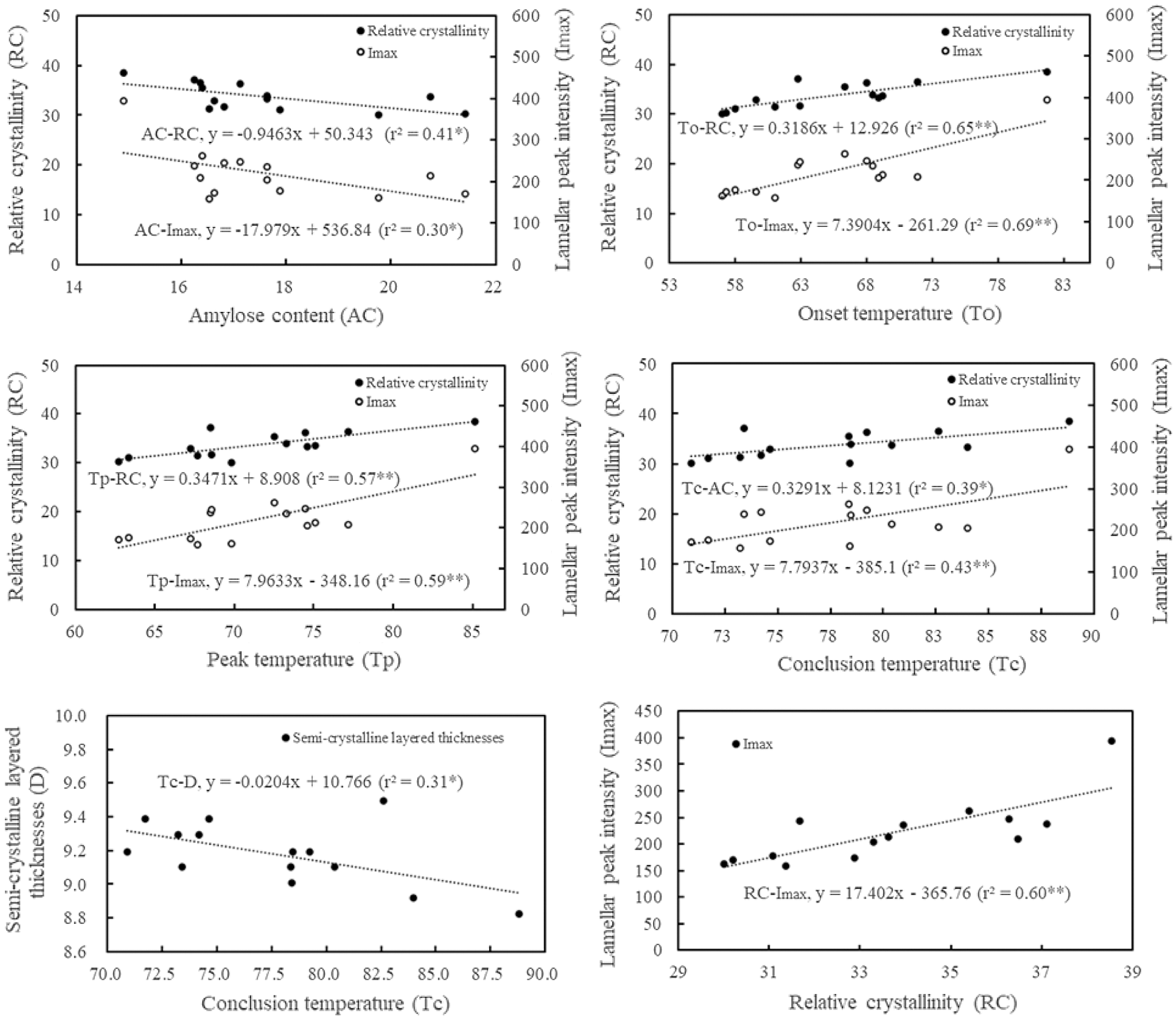

The relative crystallinity and lamellar peak intensity correlated negatively with the AC and positively correlated with To, Tp, and Tc (Fig. 4); The semi-crystalline layered thickness correlated negatively with Tc, and the relative crystallinity correlated positively with the lamellar peak intensity.

Figure 4: Relationship between amylose content, crystal structure and thermal properties.

The AC is an important index of rice cooking and eating quality. In the present study, the AC of RR was greater than that of MR. Further analysis revealed that the temperature at the grain-filling stage was higher for MR than for RR, which may have contributed to the greater AC of RR. High temperatures during the grain-filling period significantly reduced the MR grain size and AC [18], increased its chalkiness [19], and affected enzyme activities essential for consistent and regular synthesis of amylose and amylopectin [20]. Under the same field temperatures and sunlight conditions, the activities of enzymes related to starch synthesis differed significantly between MR and RR [6], which may also have contributed to the difference in AC. Previously, rice quality was suggested to correlate strongly with the temperature during grain filling, rather than with solar radiation [4,21]. For RR, overly high temperatures accelerate grain filling, potentially reducing rice quality [21]. Moreover, high temperatures at the grain-filling stage could enhance α-amylase activity, resulting in pitted and uneven starch granule surfaces, which may be the main reason for the differences in starch morphological structure and particle size observed between MR and RR in this study [22]. Grain filling initiated earlier, lasted longer, and proceeded more steadily in the early and middle grain-filling stages in RR crops [6], which was conducive to increases in the proportions of medium and small starch grains and promoted the close arrangement of starch grains, thereby reducing the occurrence of chalkiness and improving the appearance quality.

The present results suggest that the crystal structure of RR starch granules would be weakened by an increase in the AC. X-ray diffraction showed that MR and RR starch grains were A-type crystals, and that the relative crystallinity was significantly lesser for RR than for MR. This difference could be attributed to differences in AC and amylopectin chain-length distributions. Fan et al. [23] reported that a high temperature did not change the starch crystal type. Amylopectin with short-branched chains is generally considered to be responsible for the crystalline structure of starch granules, whereas amylose can disrupt the crystalline packing of amylopectin [24]. Thus, the relative crystallinity correlates negatively with the AC. However, the effect of amylopectin on the crystallinity of RR starch was not examined in this study; we will examine it in future research. RR also had a lower lamellar peak intensity, confirming the difference in crystal structure between MR and RR. Rice starch granules exhibit semi-crystalline and amorphous growth rings, and SAXS can be used to measure the thickness of the semi-crystalline layer. The location of the scattering peak depends on the lamellar size, and the peak area and intensity principally reflect the extent of ordering of the semi-crystalline regions [25]. The scattering intensity depends on the extent of the ordered semi-crystalline structure, and on differences in electron density between crystalline and amorphous lamellae against an amorphous background [26]. Correlation analysis showed that the Imax gradually decreased with increasing AC, in agreement with the findings reported by Cai et al. [14]. This relationship may reflect the decrease in electron density between the crystalline and amorphous lamellae that occurs with increasing AC. In addition, MR and RR starch infrared spectra were similar, indicating similar (A-type) starch crystal forms, for the different rice varieties. This result was consistent with the X-ray diffraction results. The 1047/1022 cm−1 ratio did not differ between MR and RR, indicating that the degree of cross-linking between starch molecules did not change significantly.

The differences in starch grain size and crystal structure would result in differences in gelatinization temperatures and enthalpy between MR and RR. The lower gelatinization temperatures (To, Tp, and Tc) of RR starch may be attributed to its smaller molecular size and weaker crystal structure. Various studies have suggested that the functional properties of rice starch are influenced by its morphology and crystalline structure [27,28]. Differences in gelatinization temperature among cultivars have been reported to be influenced by variations in starch granule morphology [29]. The interior structure of large starch granules is more rigid than that of small ones. Additionally, more energy is required for the gelatinization of large starch granules [30]. ΔH is known to be an indicator of the loss of double-helical and crystalline structures in starch granules. The lesser relative crystallinity and semi-crystalline structure ordering of RR could reduce the gelatinization temperature and energy. For more-crystalline rice starch, the crystal structure density, energy required to destroy the crystal structure, and initial temperature at which the starch becomes paste would be greater [12].

Significant differences in crystal structure and starch thermal properties between MR and RR were related closely to the temperature during ripening. Lower temperatures at the grain-filling stage of RR led to increased AC, which weakened the crystal structure of the starch granules. Additionally, the starch granules of RR were neater and smaller than those of MR. Thus, RR starches exhibited lower thermal parameters (To, Tp, Tc, and ΔH) than did MR starches. The AC correlated negatively with the relative crystallinity and lamellar peak intensity of starch, and the relative crystallinity and Imax correlated positively, significantly or extremely significantly, with transition gelatinization temperatures (To, Tp, and Tc). Whether ratooning affects starch structure and properties requires further study.

Acknowledgement: We want to acknowledge Dr. Weiqin Wang and other members of our research group, College of agronomy, Hunan Agricultural University, China, for them unconditional help during the entire research period.

Funding Statement: This research was supported by the National Key R&D Program of China (No. 2018YFD0301002), and the Earmarked Fund for China Agriculture Research System (No. CARS-01-26).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Liu, H. Y., Hussain, S., Zheng, M. M., Peng, S. B., Huang, J. L. et al. (2015). Dry direct-seeded rice as an alternative to transplanted-flooded rice in Central China. Agronomy for Sustainable Development, 35(1), 285–294. DOI 10.1007/s13593-014-0239-0. [Google Scholar] [CrossRef]

2. Yuan, S., Cassman, K. G., Huang, J. L., Peng, S. B., Grassini, P. (2019). Can ratoon cropping improve resource use efficiencies and profitability of rice in Central China? Field Crops Research, 234, 66–72. DOI 10.1016/j.fcr.2019.02.004. [Google Scholar] [CrossRef]

3. Lin, W. X. (2019). Developmental status and problems of rice ratooning. Journal of Integrative Agriculture, 18(1), 246–247. DOI 10.1016/S2095-3119(19)62568-2. [Google Scholar] [CrossRef]

4. Wang, H., Liu, X. C., Zhang, Q., Yu, G. L., Zhang, W. D. et al. (2020). Differences in grain yield and quality in main and ratoon rice in southern Henan province. Chinese Journal of Rice Science, 34, 425–434. DOI 10.16819/j.1001-7216.2020.0106. [Google Scholar] [CrossRef]

5. Alizadeh, M. R., Habibi, F. (2016). A comparative study on the quality of the main and ratoon rice crops. Journal of Food Quality, 39(6), 669–674. DOI 10.1111/jfq.12250. [Google Scholar] [CrossRef]

6. Huang, J. W., Pan, Y. P., Chen, H. F., Zhang, Z. X., Fang, C. X. et al. (2020). Physiochemical mechanisms involved in the improvement of grain-filling; rice quality mediated by related enzyme activities in the ratoon cultivation system. Field Crops Research, 258(3), 107962. DOI 10.1016/j.fcr.2020.107962. [Google Scholar] [CrossRef]

7. Li, H. Y., Lei, N. Y., Yan, S., Yang, J. Y., Wen, Y. Y. et al. (2019). The importance of amylopectin molecular size in determining the viscoelasticity of rice starch gels. Carbohydrate Polymers, 212(4), 112–118. DOI 10.1016/j.carbpol.2019.02.043. [Google Scholar] [CrossRef]

8. Bao, J. S., Shen, S. Q., Sun, M., Corke, H. (2006). Analysis of genotypic diversity in the starch physicochemical properties of nonwaxy rice: Apparent amylose content, pasting viscosity and gel texture. Starch-Stärke, 58(6), 259–267. DOI 10.1002/star.200500469. [Google Scholar] [CrossRef]

9. Kong, X. L., Zhu, P., Sui, Z. Q., Bao, J. S. (2015). Physicochemical properties of starches from diverse rice cultivars varying in apparent amylose content and gelatinization temperature combinations. Food Chemistry, 172, 433–440. DOI 10.1016/j.foodchem.2014.09.085. [Google Scholar] [CrossRef]

10. Lindeboom, N., Chang, P. R., Tyler, R. T. (2004). Analytical, biochemical and physicochemical aspects of starch granule size, with emphasis on small granule starches: A review. Starch-Stärke, 56(34), 89–99. DOI 10.1002/star.200300218. [Google Scholar] [CrossRef]

11. Cooke, D., Gidley, M. J. (1992). Loss of crystalline and molecular order during starch gelatinization: Origin of the enthalpic transition. Carbohydrate Research, 227, 103–112. DOI 10.1016/0008-6215(92)85063-6. [Google Scholar] [CrossRef]

12. Han, W. F., Xiong, S. B., Li, J. T., Zhao, S. M., Mo, Z. M. (2015). Crystallinity and pasting properties of glutinous rice starches. Journal of the Chinese Cereals and Oils Association, 30, 48–53. DOI 10.3969/j.issn.1003-0174.2015.08.009. [Google Scholar] [CrossRef]

13. Lopez-Rubio, A., Flanagan, B. M., Gilbert, E. P., Gidley, M. J. (2008). A novel approach for calculating starch crystallinity and its correlation with double helix content: A combined XRD and NMR study. Biopolymers, 89(9), 761–768. DOI 10.1002/bip.21005. [Google Scholar] [CrossRef]

14. Cai, J. W., Man, J. M., Huang, J., Liu, Q. Q., Wei, W. X. et al. (2015). Relationship between structure and functional properties of normal rice starches with different amylose contents. Carbohydrate Polymers, 125(4), 35–44. DOI 10.1016/j.carbpol.2015.02.067. [Google Scholar] [CrossRef]

15. Park, I. M., Ibáñez, A. M., Zhong, F., Shoemaker, C. F. (2007). Gelatinization and pasting properties of waxy and non-waxy rice starches. Starch-Stärke, 59(8), 388–396. DOI 10.1002/star.200600570. [Google Scholar] [CrossRef]

16. Li, S. N., Li, C., Yang, Y. Z., He, X. W., Zhang, B. et al. (2019). Starch granules as Pickering emulsifiers: Role of octenylsuccinylation and particle size. Food Chemistry, 283(8), 437–444. DOI 10.1016/j.foodchem.2019.01.020. [Google Scholar] [CrossRef]

17. Zhang, Y. F., Chen, C., Chen, Y., Chen, Ye (2019). Effect of rice protein on the water mobility, water migration and microstructure of rice starch during retrogradation. Food Hydrocolloids, 91(1), 136–142. DOI 10.1016/j.foodhyd.2019.01.015. [Google Scholar] [CrossRef]

18. Yamakawa, H., Hirose, T., Kuroda, M., Yamaguchi, T. (2007). Comprehensive expression profiling of rice grain filling-related genes under high temperature using DNA microarray. Plant Physiology, 144(1), 258–277. DOI 10.1104/pp.107.098665. [Google Scholar] [CrossRef]

19. Liu, Q., Wu, X., Ma, J., Li, T., Zhou, X. et al. (2013). Effects of high air temperature on rice grain quality and yield under field condition. Agronomy Journal, 105(2), 446–454. DOI 10.2134/agronj2012.0164. [Google Scholar] [CrossRef]

20. Fan, X. L., Li, Y. Q., Lu, Y., Zhang, C. Q., Li, E. P. et al. (2019). The interaction between amylose and amylopectin synthesis in rice endosperm grown at high temperature. Food Chemistry, 301(11), 125258. DOI 10.1016/j.foodchem.2019.125258. [Google Scholar] [CrossRef]

21. Gong, J. L., Zhang, H. C., Hu, Y. J., Long, H. Y., Chang, Y. et al. (2013). Effects of air temperature during rice grain-filling period on the formation of rice grain yield and its quality. Chinese Journal of Ecology, 32, 482–491. DOI 10.13292/j.1000-4890.2013.0131. [Google Scholar] [CrossRef]

22. Li, C. Y., Fu, K. Y., Zhang, R. Q., Xu, F. F., Shi, X. Y. et al. (2015). Effect of high temperature post anthesis on the development of starch granules in winter wheat. Journal of Triticeae Crops, 35, 1395–1402. DOI 10.7606/j.issn.1009-1041.2015.10.11. [Google Scholar] [CrossRef]

23. Fan, X. L., Li, Y. Q., Lu, Y., Zhang, C. Q., Li, E. P. et al. (2019). The interaction between amylose and amylopectin synthesis in rice endosperm grown at high temperature. Food Chemistry, 301(11), 125258. DOI 10.1016/j.foodchem.2019.125258. [Google Scholar] [CrossRef]

24. Cheetham, N. W. H., Tao, L. P. (1998). Variation in crystalline type with amylose content in maize starch granules: An X-ray powder diffraction study. Carbohydrate Polymers, 36(4), 277–284. DOI 10.1016/S0144-8617(98)00007-1. [Google Scholar] [CrossRef]

25. Blazek, J., Gilbert, E. P. (2011). Application of small-angle X-ray and neutron scattering techniques to the characterisation of starch structure: A review. Carbohydrate Polymers, 85(2), 281–293. DOI 10.1016/j.carbpol.2011.02.041. [Google Scholar] [CrossRef]

26. Yuryev, V. P., Krivandin, A. V., Kiseleva, V. I., Wasserman, L. A., Genkina, N. K. et al. (2004). Structural parameters of amylopectin clusters and semi-crystalline growth rings in wheat starches with different amylose content. Carbohydrate Research, 339(16), 2683–2691. DOI 10.1016/j.carres.2004.09.005. [Google Scholar] [CrossRef]

27. Tao, H., Yan, J., Zhao, J. W., Tian, Y. Q. (2015). Effect of multiple freezing/thawing cycles on the structural and functional properties of waxy rice starch. PLoS One, 10(5), e0127138. DOI 10.1371/journal.pone.0127138. [Google Scholar] [CrossRef]

28. Dhital, S., Butardo, V. M., Jobling, S. A., Gidley, M. J. (2015). Rice starch granule amylolysis–differentiating effects of particle size, morphology, thermal properties and crystalline polymorph. Carbohydrate Polymers, 115(2), 305–316. DOI 10.1016/j.carbpol.2014.08.091. [Google Scholar] [CrossRef]

29. Kaur, M., Singh, N. (2005). Studies on functional, thermal and pasting properties of flours from different chickpea (Cicer arietinum L.) cultivars. Food Chemistry, 91(3), 403–411. DOI 10.1016/j.foodchem.2004.06.015. [Google Scholar] [CrossRef]

30. Vandeputte, G. E., Delcour, J. A. (2004). From sucrose to starch granule to starch physical behaviour: A focus on rice starch. Carbohydrate Polymers, 58(3), 245–266. DOI 10.1016/j.carbpol.2004.06.003. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |