| Phyton-International Journal of Experimental Botany |  |

DOI: 10.32604/phyton.2021.012903

ARTICLE

Effects of Exogenous α-Ketoglutaric Acid on 2-Acetyl-1-Pyrroline, Yield Formation and Grain Quality Characters of Aromatic Rice

1College of Agriculture, Yangtze University, Jingzhou, 434023, China

2National Selenium-Rich Product Quality Supervision and Inspection Center, Enshi, 434023, China

3Institute of Crop Science, Chinese Academy of Agricultural Sciences, Beijing, 100081, China

*Corresponding Authors: Jianlong Xu. Email: xujianlong@caas.cn; Jianqiang Zhu. Email: 200572@yangtzeu.edu.cn

Received: 17 July 2020; Accepted: 25 August 2020

Abstract: The improvement of grain quality in aromatic rice is very important for farmer to increase their income. Present study was conducted with a two-year field experiment and three aromatic rice cultivars in order to study the effects of exogenous α-ketoglutaric acid on yield formation, grain quality characters and the biosynthesis of 2-acetyl-1-pyrroline (2-AP, key component of aromatic rice’s fragrance) in aromatic rice. At heading stage, 0.50 mmol L–1 (T1) and 1.00 mmol L–1 (T2) α-ketoglutaric acid solutions were overhead sprinkle to aromatic rice plants, respectively while the treatment which was overhead sprinkled with distilled water was set as control (CK). The results showed that 17.34%–33.04% and 21.39%–34.74% higher grain 2-AP contents were recorded in T1 and T2 treatments, respectively. Compared with CK, T1 and T2 treatments significantly reduced the transcript level of gene BADH2 which is related to the 2-AP biosynthesis in aromatic rice. 3.86%–7.51% higher grain protein contents and 1.15%–3.37% higher head rice rates were also recorded in α-ketoglutaric acid treatments than CK. Moreover, T1 and T2 treatments remarkably decreased the chalky rice rate, chalkiness and grain amylose content. However, there was no remarkable difference in grain yield and related trails (effective panicle number, grain number per panicle, seed-setting rate and 1000-grain weight) among CK, T1 and T2 treatments. In conclusion, application of exogenous α-ketoglutaric acid enhanced 2-AP biosynthesis and improved grain quality of aromatic rice.

Keywords: α-ketoglutaric acid; aromatic rice; chalkiness; protein; 2-acetyl-1-pyrroline

As a special type of rice for special aroma and great quality, aromatic rice is popular by people around the world. The compounds of the aroma in aromatic rice are very complicated and many studies have been conducted to identify them in the past. For example, Maraval et al. [1] determinated more than 100 volatile compounds in the aroma of aromatic rice. The research of Yang et al. [2] indicated that there might be 13 volatile compounds which contribute to the differences in aromatic rice aroma. In recent years, it has been established that 2-acetyl-1-pyrroline (2-AP) is the main flavour compound in aromatic rice cultivars which endows the characteristic roasted popcorn-like flavour [3].

The grain quality characters including milling, appearance, nutrient, smell and taste are the points get attention in aromatic rice production because they directly influence the price, popularity and economy. Therefore, Numerous studies were conducted to explore how to improve the grain quality of aromatic rice. Recently, Luo et al. [4] showed that the foliar application of selenite in aromatic rice production was able to increase the grain protein content and decreased both chalky rice rate and chalkiness of aromatic rice. The study of Mo et al. [5] revealed that interaction between water management and nitrogen application would induce the regulation in both yield formation and grain 2-AP biosynthesis in aromatic rice. The research of Li et al. [6] also showed that exogenous manganese significantly affected the yield formation, grain quality characters and rice aroma of aromatic rice.

α-ketoglutaric acid is one of two keto derivatives of glutaric acid while it is also an important intermediate product in plant tricarboxylic acid cycle and a key node connecting carbon and nitrogen metabolism in cells, and the position of α-ketoglutaric acid in the tricarboxylic acid cycle is after isocitrate and before succinyl coenzyme A [7]. Although α-ketoglutaric acid has potential to be a plant regulator in rice production, there was no more study about the effect of exogenous α-ketoglutaric acid on the growth and development of rice especially aromatic rice.

Hence, present study was conducted with a two-year field experiment in order to investigate the effects of exogenous α-ketoglutaric acid on 2-acetyl-1-pyrroline, yield formation and grain quality characters of aromatic rice cultivars.

Field experiment was conducted at Experimental Research Farm, Feng village, Zengcheng (23°13′N, 113°81′E, altitude 11 m), China between July and November in 2018 and repeated in 2019. The experimental site enjoys a subtropical-monsoon climate. Three aromatic rice cultivars, “Guangliangxiangyou-66” (GLXY-66), “Exiang-1” (EX-1) and “Wangeng-505” (WG-505), were used in present study. At heading stage of each aromatic rice cultivar, 0.50 mmol L–1 and 1.00 mmol L–1 α-ketoglutaric acid solution were overhead sprinkled respectively and those treatments were named as T1 and T2. Another treatment which was overhead sprinkled with distilled water was set as control (CK). The treatments were arranged in randomized complete block design (RCBD) in triplicate in each year with net plot size of 20 m2. At grain filling stage (ten days of receiving α-ketoglutaric acid treatment), fresh leaves from each treatment were separated from the main plant and stored at −80°C till physio-biochemical analysis. At maturity, fresh grains from each treatment were collected and stored at −80°C till physio-biochemical analysis.

2.2 Estimation of Yield and Related Attributes

At the maturity stage, the rice grains were harvested from six-unit sampling area (1 m2) in each plot and threshed by machine. Then after sun drying, the grain yield was determined on basis of the dry weight. Average effective panicle number per area (1 m2) was calculated form six-unit sampling area (1 m2) in each plot. Then six representative hills of rice plants from each plot were taken to determine the other yield- related traits including seed-setting rate, 1000-grain weight and grain number per panicle.

2.3 Estimation of Grain 2-AP Content

The determination of 2AP content in grains was determinated based on the method of synchronization distillation and extraction method (SDE) combined with GCMS-QP 2010 Plus (Shimadzu Corporation) [8].

2.4 Estimation of Grain Quality

The dried grains of each aromatic rice cultivar from each treatment was taken from storage and then brown rice rate was estimated using a rice huller (Jiangsu, China) while milled rice and head rice recovery rates were calculated by using a Jingmi testing rice grader (Zhejiang, China). Grains with chalkiness and chalkiness degree were estimated by using an SDE-A light box (Guangzhou, China) while an Infratec-1241 grain analyzer (FOSS-TECATOR) was used to determine the grain amylose and protein contents.

2.5 Estimation of Malondiadehyde (MDA) Content and Antioxidant Enzymes Activities

The content of MDA and activities of antioxidant enzymes including superoxide (SOD, EC 1.15.1.1), peroxidase (POD EC 1.11.1.7) and catalase (CAT, EC 1.11.1.6) were determinated according to the methods described by Kong et al. [9]. After reacting with thiobarbituric acid, the absorbance was read at the 532, 600 and 450 nm while the MDA content was expressed as μmol g–1 FW. POD (EC 1.11.1.7) activity was estimated after the reaction in the solution including enzyme extract, H2O2, guaiacol and sodium phosphate buffer (SPB, pH 7.0). One POD unit of enzyme activity was expressed as the absorbance increase by 0.01 (U g–1 FW) due to guaiacol oxidation. SOD (EC 1.15.1.1) activity was measured by using nitro blue tetrazolium (NBT). In brief, 0.05 ml of an enzyme extract was added into the reaction mixture which contained SPB (pH 7.8), methionine buffer, NBT buffer, ethylene diamine tetraacetic acid (EDTA)-2Na buffer and lactoflavin. After the reaction, the absorbance was recorded at 560 nm. One unit of SOD activity was equal to the volume of the extract needed to cause 50% inhibition of the color reaction. CAT (EC 1.11.1.6) activity was estimated by adding an aliquot of enzyme extract to the reaction solution containing 0.3% H2O2 and SPB and then the absorbance was read at 240 nm. One CAT unit of enzyme activity was defined as the absorbance decrease by 0.01 (U g–1 FW).

The experiment data was analyzed using the statistical software ‘Statistix 8.1’ (Analytical Software, Tallahassee, FL, USA) and differences among means were separated by using the least significant difference (LSD) test at the 5% probability level. Graphical representation was performed via Sigma Plot 14.0 (Systat Software Inc., California, USA).

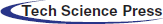

As shown in Fig. 1, exogenous α-ketoglutaric acid treatments (T1 and T2) significantly increased the grain 2-AP content compared with CK. There was no significant difference between two applied concentrations of α-ketoglutaric acid. For GLXY-66, compared with CK, α-ketoglutaric acid treatments significantly increased grain 2-AP content by 23.14%–32.22% in 2018 and by 34.74%–26.58% in 2019; For EX-1, T1 and T2 treatments significantly increased 2-AP content by 33.04%, 28.38% in 2018 and 29.12%, 23.60% in 2019 compared with CK respectively; For WG-505, compared with CK, T1 and T2 treatments significantly increased 2-AP content by 18.01%, 21.39% in 2018 and 17.34%, 24.49% in 2019, respectively.

Figure 1: Effects of exogenous α-ketoglutaric acid on grain 2-AP content of aromatic rice. Capped bars represent S.E. of three replicates. Means sharing a common letter do not differ significantly at (P ≤ 0.05) according to least significant difference (LSD) test for both the years. The same as below

3.2 Transcript Level of Gene BADH2

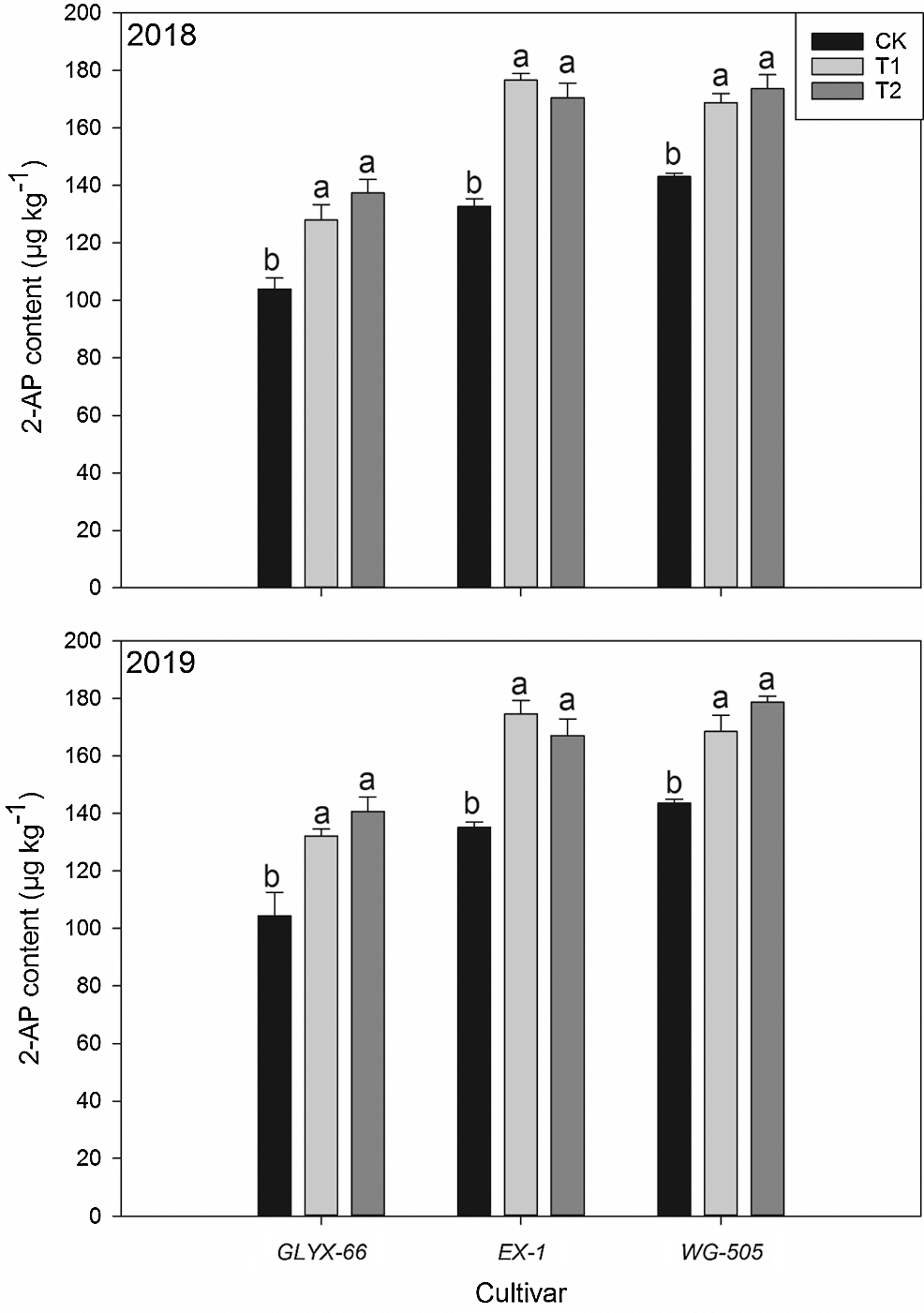

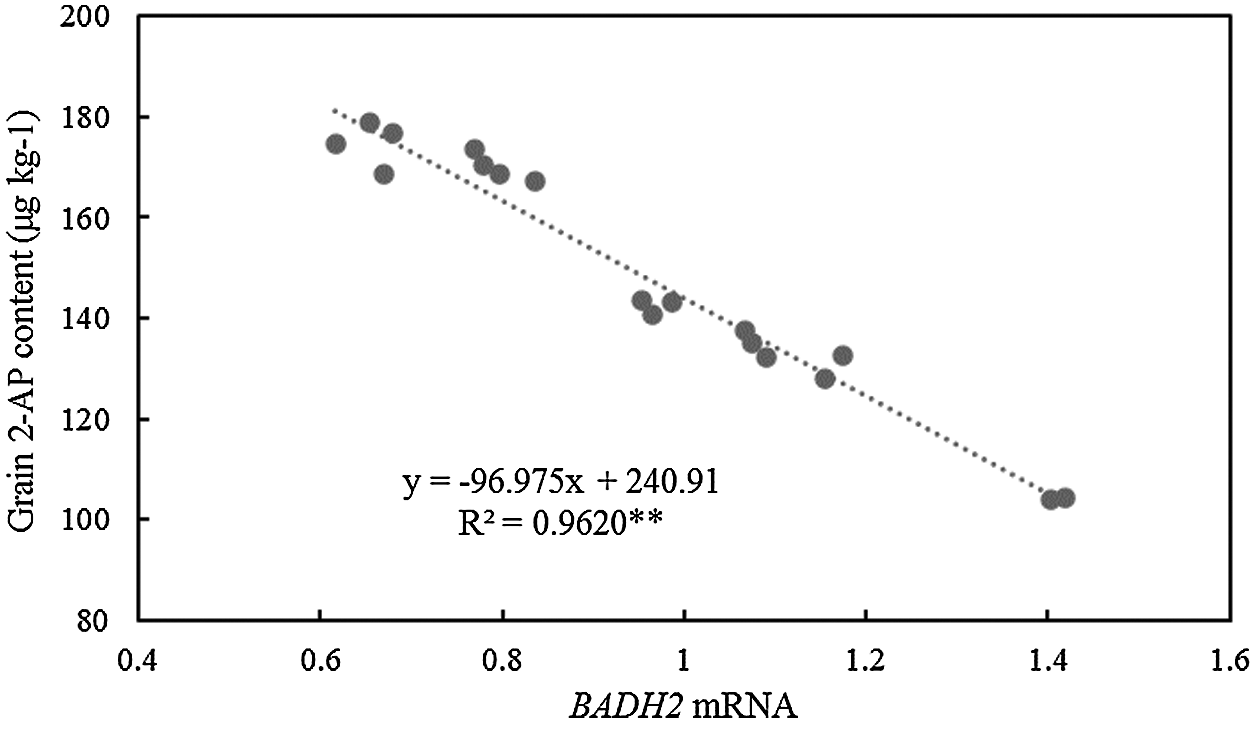

As shown in Fig. 2, lower transcript levels of gene BADH2 were recorded in T1 and T2 treatments than CK. For GLXY-66, compared with CK, T1 and T2 treatments reduced the transcript level of BADH2 by 17.82%, 24.05% in 2018 and 23.07%, 31.90% in 2019, respectively; For EX-1, compared with CK, T1 and T2 treatments decreased the transcript level of BADH2 by 42.13%, 33.58% in 2018 and 24.08%, 22.31% in 2019, respectively; For WG-505, compared with CK, T1 and T2 treatments reduced the transcript level of BADH2 by 19.29%, 22.08% in 2018 and 29.61%, 31.26% in 2019, respectively. Further, we observed that there was a significant and positive correlation between grain 2-AP content and transcript level of gene BADH2 (Fig. 3).

Figure 2: Effects of exogenous α-ketoglutaric acid on transcript level of gene BADH2 in aromatic rice

Figure 3: Correlation analyses between grain 2-AP content and transcript level of gene BADH2. Significant correlations at *P < 0.05 and **P < 0.01

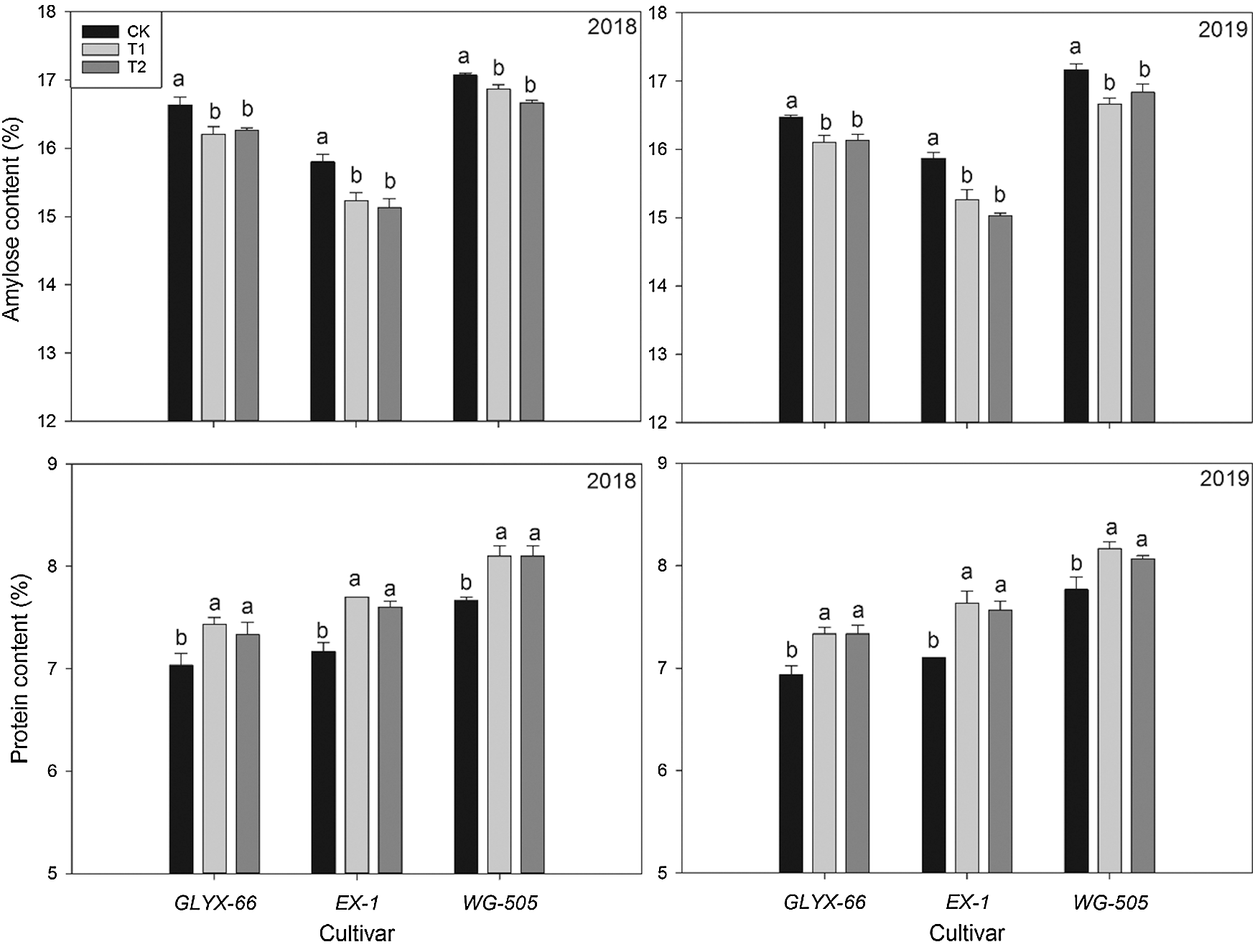

3.3 Grain Protein and Amylose Contents

As shown in Fig. 4, exogenous α-ketoglutaric acid significantly increased the grain protein content and decreased grain amylose content of aromatic rice cultivars. In 2018, compared with CK, 1.17%–4.22% lower grain amylose contents and 4.27%–7.44% higher grain protein contents were recorded in α-ketoglutaric acid treatments; In 2019, 1.94%–5.25% lower grain amylose contents and 3.86%–7.51% higher grain protein contents were recorded in α-ketoglutaric acid treatments than CK.

Figure 4: Effects of exogenous α-ketoglutaric acid on grain protein and amylose content of aromatic rice

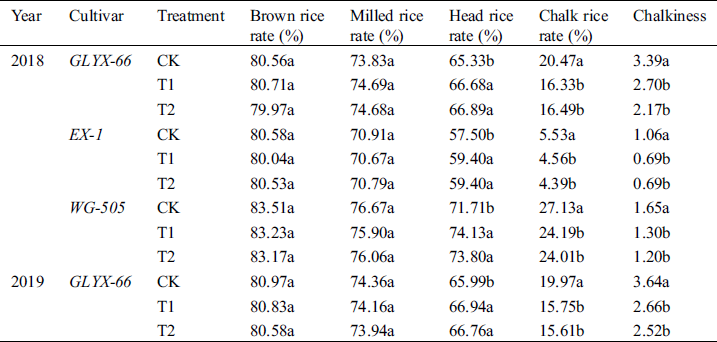

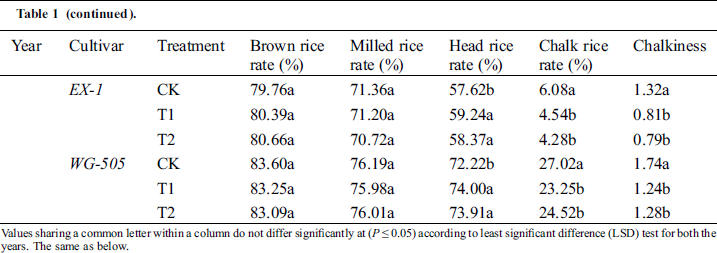

3.4 Grain Milling and Appearance Quality

Exogenous α-ketoglutaric acid treatments significantly influenced the grain milling and appearance quality characters of aromatic rice (Tab. 1). Compared with CK, both T1 and T2 treatments significantly increased the head rice rate for GLYX-66, EX-1, WG-505 in both years but there was no significant difference among CK, T1 and T2 treatments in brown rice rate and milled rice rate for three aromatic rice cultivars. On the other hand, lower chalk rice rates and chalkiness were both recorded in T1 and T2 than CK for all aromatic rice cultivars in 2018 while the similar trends were also observed in 2019.

Table 1: Effects of exogenous α-ketoglutaric acid on grain milling and appearance quality of aromatic rice

Values sharing a common letter within a column do not differ significantly at (P ≤ 0.05) according to least significant difference (LSD) test for both the years. The same as below.

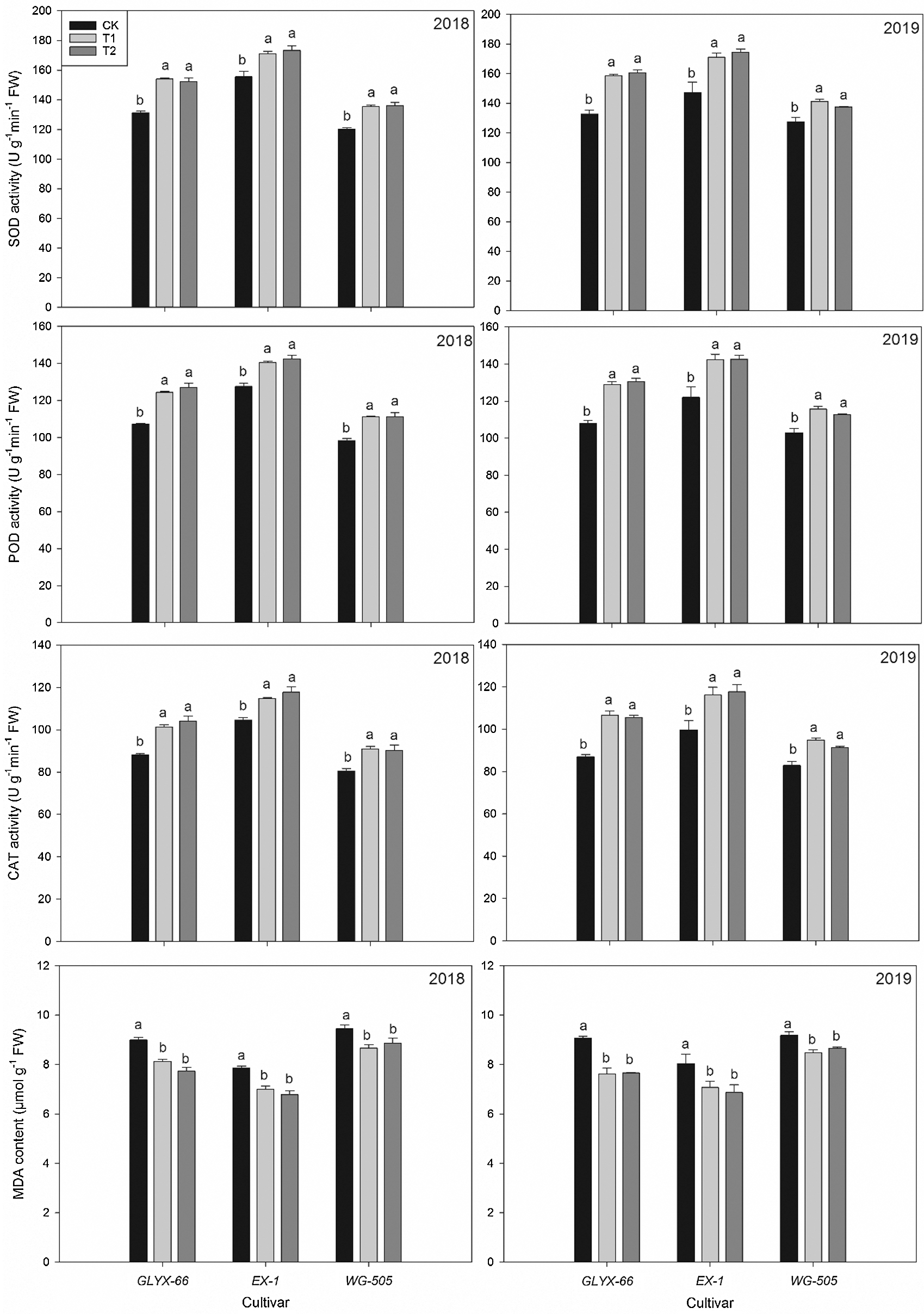

3.5 MDA Contents and Antioxidant Responses

Exogenousα-ketoglutaric acid regulated the antioxidative enzymatic activities in terms of SOD, POD and CAT and lowered lipid peroxidation (MDA production) as shown in Fig. 5. Compared with CK, T1 and T2 treatments significantly enhanced the POD activities for all aromatic rice cultivars in both years. Higher SOD and CAT activities were also recorded in T1 and T2 treatments than CK. There was no remarkable difference between T1 and T2 in POD, SOD and CAT activities. Meanwhile, MDA contents significantly decreased under T1 and T2 treatments compared with CK.

Figure 5: Effects of exogenous α-ketoglutaric acid on MDA content and activities of antioxidant enzymes including SOD, POD and CAT

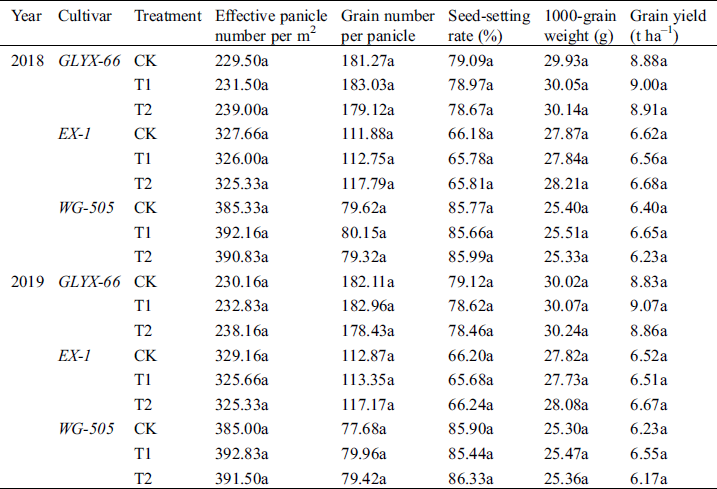

3.6 Yield and Related Attributes

As shown in Tab. 2, exogenous α-ketoglutaric acid did not have significant effects on yield and related attributes of aromatic rice cultivars. There was no remarkable difference among CK, T1 and T2 treatments in grain yield for three aromatic rice cultivars in both 2018 and 2019. Similar trends were also observed in effective panicle number, grain number per panicle and seed-setting rate as well as 1000-grain weight.

Table 2: Effects of exogenous α-ketoglutaric acid on yield and related attributes

Present study revealed that the effects of exogenous α-ketoglutaric acid on yield formation, grain quality and grain 2-AP content of three aromatic rice cultivars. According to the results, the application of α-ketoglutaric acid improved the appearance, nutrient, taste quality as well as aroma although didn’t have significant influences on the grain yield of aromatic rice. As far as the aroma of aromatic rice was concerned, 2-AP is the key compound and the level of 2-AP represents the intensity of the aroma which would significant affected the price of aromatic rice in international market [10]. In our study, grain 2-AP contents of three aromatic rice cultivars all increased under exogenous α-ketoglutaric acid treatments. The biosynthesis of 2-AP in aromatic rice is a very complicated phenomenon which involves many enzymes and substances whilst in recent years, it has been identified that the 2-AP production in aromatic rice is mainly controlled by the expression of gene BADH2 for encoding the betaine aldehyde dehydrogenase to inhibit the 2-AP biosynthesis [11]. The results showed that application of α-ketoglutaric acid at heading stage substantially reduced the transcript level of BADH2 while the grain 2-AP concentration was significantly increased. Our results agreed with the study of Bao et al. [11] which showed that lower expression of BADH2 led to the higher content of 2-AP in aromatic rice.

Rice is an important protein source for human. Normally, most farmers would choose to apply more nitrogen fertilizer to increase grain protein content of rice [12,13], however, the use of large amounts of nitrogen fertilizer not only increased greenhouse gas emissions, but also caused surface water eutrophication and soil acidification [14]. The results of present study showed that the foliar application of α-ketoglutaric acid in rice production was able to achieve the goal to increase grain protein content. Meanwhile, because α-ketoglutaric acid is an organic matter and the lower dosage applied, less environment pollution would be caused during the application process. On the other hand, present study showed that exogenous α-ketoglutaric acid significantly decreased the grain amylose content which affects the texture of cooked rice, increases hardness and reduces stickiness of rice [15–17]. Lower content of amylose in grain means better texture with less harness and stickiness. Therefore, the application of α-ketoglutaric acid would improve the nutrient and texture of aromatic rice.

In addition, we observed that exogenous α-ketoglutaric acid improved the appearance of aromatic rice for significantly decreasing both chalk rice rate and chalkiness. Chalkiness refers to the white opaque part of rice endosperm formed by the loose tissue. As one of the important characters to measure rice quality, Chalkiness directly affects the appearance quality, commodity circulation and processing quality of rice [18]. The chalky area of rice grain is caused by the accumulation of starch and protein grains in endosperm and easy to be broken during processing [19]. The main reason of the decreased chalkiness might relate to the antioxidative system of aromatic rice during the grain-filling stage. The study of Kong et al. [19] revealed that the conditions of antioxidant system and lipid peroxidation significantly affected the appearance quality of aromatic rice. Normally, because the paddy environment is very complicated, the rice plant would face many and different degrees stress such as unsuitable air or soil temperature, strong wind, pest bite, large temperature difference, unsuitable soil pH and so on during the growth and development while the MDA content is an important indicator of oxidative stress [20–22]. In our study, lower MDA contents was observed in α-ketoglutaric acid treatments than CK. Less MDA means less lipid peroxidation and this might be attributed to the enhanced activities SOD, POD and CAT. Previous studies has revealed that SOD, POD and CAT are the antioxidant enzymes in rice and play significant roles in maintaining cellular structures and functions and protect the rice plant from abiotic stresses [23]. For example, SOD dismutases superoxide radical whereas POD and CAT involved in scavenging H2O2. The higher antioxidative enzymatic activities under α-ketoglutaric acid treatments would be beneficial for the grain-filling process and it also could be the reason for the higher head rice rate in present study.

Moreover, there was no remarkable difference between two applied concentrations of α-ketoglutaric acid on aromatic rice performances. Considered the cost, the optimum applied concentration of α-ketoglutaric acid in aromatic rice production might be 0.50 mmol L–1 and more studies should be done in the physiological and molecular level to reveal the metabolism of how α-ketoglutaric acid affecting the 2-AP concentration of aromatic rice in the future.

Foliar applications of α-ketoglutaric acid not only significantly improved the head rice rate, protein content and 2-AP content, but also significantly decreased the amylose content, chalk rice rate and chalkiness of aromatic rice. But α-ketoglutaric acid applications had no significant influence on grain yield and related attributes of aromatic rice.

Funding Statement: This work is supported by Hubei special fund for agricultural science and technology innovation (2018skjcx01) and the Engineering Research Center of Ecology and Agricultural Use of Wetland, Ministry of Education (KFT201904).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Maraval, I., Mestres, C., Pernin, K., Ribeyre, F., Boulanger, R. et al. (2008). Odor-active compounds in cooked rice cultivars from Camargue (France) analyzed by GC-O and GC-MS. Journal of Agricultural & Food Chemistry, 56(13), 5291–5298. DOI 10.1021/jf7037373. [Google Scholar] [CrossRef]

2. Yang, D. S., Shewfelt, R. L., Lee, K. S., Kays, S. J. (2008). Comparison of odor-active compounds from six distinctly different rice flavor types. Journal of Agriculture & Food Chemistry, 56(8), 2780–2787. DOI 10.1021/jf072685t. [Google Scholar] [CrossRef]

3. Poonlaphdecha, J., Gantet, P., Maraval, I., Sauvage, F. O., Menut, C. et al. (2016). Biosynthesis of 2-acetyl-1-pyrroline in rice calli cultures: Demonstration of 1-pyrroline as a limiting substrate. Food Chemistry, 197, 965–971. DOI 10.1016/j.foodchem.2015.11.060. [Google Scholar] [CrossRef]

4. Luo, H. W., He, L. X., Du, B., Wang, Z. M., Zheng, A. X. et al. (2019). Foliar application of selenium (Se) at heading stage induces regulation of photosynthesis, yield formation, and quality characteristics in fragrant rice. Photosynthetica, 57(4), 1007–1014. DOI 10.32615/ps.2019.114. [Google Scholar] [CrossRef]

5. Mo, Z. W., Li, Y. H., Nie, J., He, L. X., Tang, X. R. (2019). Nitrogen application and different water regimes at booting stage improved yield and 2-acetyl-1-pyrroline (2AP) formation in fragrant rice. Rice, 12(1), 77. DOI 10.1186/s12284-019-0335-5. [Google Scholar] [CrossRef]

6. Li, M. J., Ashraf, U., Tian, H., Mo, Z. W., Pan, S. G. et al. (2016). Manganese-induced regulations in growth, yield formation, quality characters, rice aroma and enzyme involved in 2-acetyl-1-pyrroline biosynthesis in fragrant rice. Plant Physiology & Biochemistry, 103, 167–175. DOI 10.1016/j.plaphy.2016.03.009. [Google Scholar] [CrossRef]

7. Chernyavskaya, O. G., Shishkanova, N. V., Il’Chenko, A. P., Finogenova, T. V. (2000). Synthesis of alpha-ketoglutaric acid by Yarrowia lipolytica yeast grown on ethanol. Applied Microbiology & Biotechnology, 53(2), 152–158. DOI 10.1007/s002530050002. [Google Scholar] [CrossRef]

8. Xie, W. J., Ashraf, U., Zhong, D., Lin, R. B., Xian, P. Q. et al. (2019). Application of γ-aminobutyric acid (GABA) and nitrogen regulates aroma biochemistry in fragrant rice. Food Science & Nutrition, 7(11), 3784–3796. DOI 10.1002/fsn3.1240. [Google Scholar] [CrossRef]

9. Kong, L. L., Ashraf, U., Cheng, S. R., Rao, G. S., Tang, X. R. (2017). Short-term water management at early filling stage improves early-season rice performance under high temperature stress in South China. European Journal of Agronomy, 90, 117–126. DOI 10.1016/j.eja.2017.07.006. [Google Scholar] [CrossRef]

10. Bao, G. G., Ashraf, U., Wang, C. L., He, L. X., Wei, X. S. et al. (2018). Molecular basis for increased 2-acetyl-1-pyrroline contents under alternate wetting and drying (AWD) conditions in fragrant rice. Plant Physiology & Biochemistry, 133, 149–157. DOI 10.1016/j.plaphy.2018.10.032. [Google Scholar] [CrossRef]

11. Chen, S. H., Yang, Y., Shi, W. W., Ji, Q., He, F. et al. (2008). Badh2, encoding betaine aldehyde dehydrogenase, inhibits the biosynthesis of 2-acetyl-1-pyrroline, a major component in rice fragrance. Plant Cell, 20(7), 1850–1861. DOI 10.1105/tpc.108.058917. [Google Scholar] [CrossRef]

12. Deng, Q. Q., Ashraf, U., Cheng, S. R., Sabir, S. R., Mo, Z. W. et al. (2018). Mild drought in interaction with additional nitrogen dose at grain filling stage modulates 2-acetyl-1-pyrroline biosynthesis and grain yield in fragrant rice. Applied Ecology & Environmental Research, 16(6), 7741–7758. DOI 10.15666/aeer/1606_77417758. [Google Scholar] [CrossRef]

13. Xie, W. J., Ashraf, U., Zhong, D. T., Lin, R. B., Xian, P. Q. et al. (2019). Application of γ-aminobutyric acid (GABA) and nitrogen regulates aroma biochemistry in fragrant rice. Food Science & Nutrition, 7(11), 3784–3796. DOI 10.1002/fsn3.1240. [Google Scholar] [CrossRef]

14. Huang, M., Chen, J., Cao, F., Zou, Y. B. (2018). Increased hill density can compensate for yield loss from reduced nitrogen input in machine-transplanted double-cropped rice. Field Crops Research, 221, 333–338. DOI 10.1016/j.fcr.2017.06.028. [Google Scholar] [CrossRef]

15. Ando, I., Sato, H., Aoki, N., Suzuki, Y., Takeuchi, Y. (2010). Genetic analysis of the low-amylose characteristics of rice cultivars Oborozuki and Hokkai-PL9. Breeding Science, 60(3), 187–194. DOI 10.1270/jsbbs.60.187. [Google Scholar] [CrossRef]

16. Yoon, M. R., Koh, H. J., Kang, M. Y. (2009). Pasting and amylose component characteristics of seven rice cultivars. Journal of the Korean Society for Applied Biological Chemistry, 52(1), 63–69. DOI 10.3839/jksabc.2009.011. [Google Scholar] [CrossRef]

17. Umemoto, T., Terashima, K. (2002). Research note: Activity of granule-bound starch synthase is an important determinant of amylose content in rice endosperm. Functional Plant Biology, 29(9), 1121–1124. DOI 10.1071/PP01145. [Google Scholar] [CrossRef]

18. Dai, L. P., Lan, W., Leng, Y. J., Yang, Y. L., Zeng, D. L. (2016). Quantitative trait loci mapping for appearance quality in short-grain rice. Crop Science, 56(4), 1484–1492. DOI 10.2135/cropsci2015.07.0404. [Google Scholar] [CrossRef]

19. Chen, J. L., Tang, L., Shi, P. H., Yang, B. H., Zhu, Y. (2016). Effects of short-term high temperature on grain quality and starch granules of rice (Oryza sativa L.) at post-anthesis stage. Protoplasma, 254(2), 935–943. DOI 10.1007/s00709-016-1002-y. [Google Scholar] [CrossRef]

20. Liu, K., Deng, J., Lu, J., Wang, X. Y., Lu, B. L. et al. (2019). High nitrogen levels alleviate yield loss of super hybrid rice caused by high temperatures during the flowering stage. Frontiers in Plant Science, 10, 122. DOI 10.3389/fpls.2019.00357. [Google Scholar] [CrossRef]

21. Rao, G. S., Ashraf, U., Kong, L. L., Mo, Z. M., Xiao, L. Z. et al. (2019). Low soil temperature and drought stress conditions at flowering stage affect physiology and pollen traits of rice. Journal of Integrative Agriculture, 18(8), 1859–1870. DOI 10.1016/S2095-3119(18)62067-2. [Google Scholar] [CrossRef]

22. Liu, K., Yang, R., Lu, J., Wang, X. Y., Lu, B. L. et al. (2019). Radiation use efficiency and source-sink changes of super hybrid rice under shade stress during grain-filling stage. Agronomy Journal, 111(4), 1788–1798. DOI 10.2134/agronj2018.10.0662. [Google Scholar] [CrossRef]

23. Luo, H. W., Du, B., Zheng, A. X., Lai, R. F., You, Z. S. et al. (2018). Flooding treatment restrains volunteer rice germination and seedling growth. Applied Ecology & Environmental Research, 16(5), 7231–7242. DOI 10.15666/aeer/1605_72317242. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |