Open Access

Open Access

ARTICLE

Recycling of Mud Derived from Backwash Wastewater Coagulation as Magnetic Sodalite Sphere for Zn2+Adsorption

1 School of Environment, Northeast Normal University, Changchun, 130024, China

2 School of Environmental Science & Engineering, Huazhong University of Science and Technology, Wuhan, 430074, China

* Corresponding Author: Hongbin Yu. Email:

(This article belongs to the Special Issue: Current Advances in Green Nanomaterials Applications)

Journal of Renewable Materials 2021, 9(9), 1599-1607. https://doi.org/10.32604/jrm.2021.015189

Received 29 November 2020; Accepted 29 January 2021; Issue published 23 April 2021

Abstract

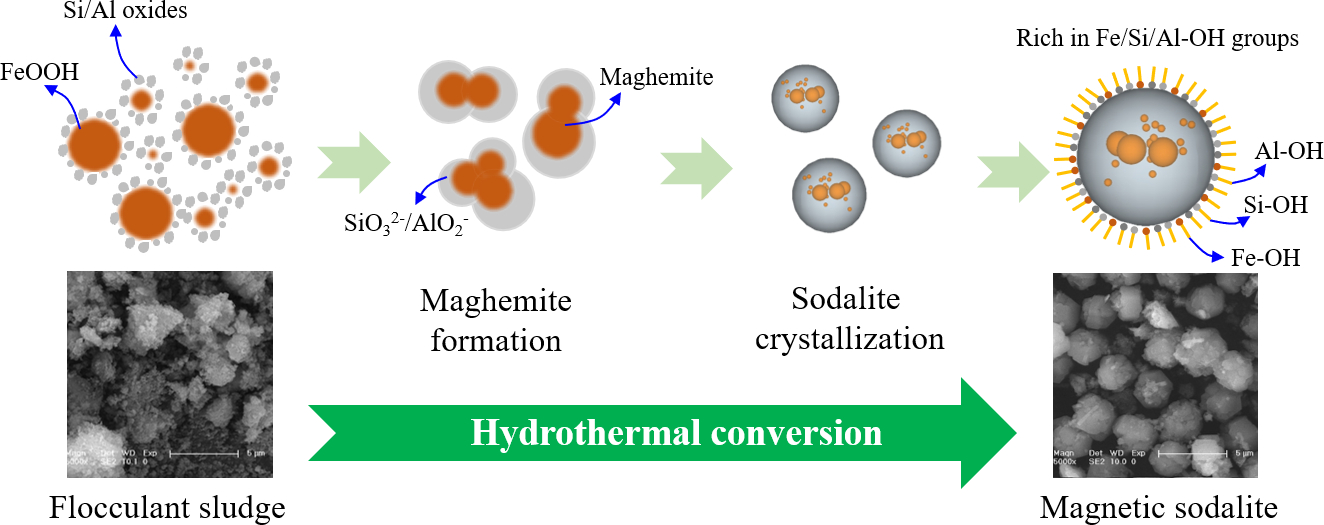

Herein, we reported a method to prepare magnetic sodalite sphere by using the mud from backwash wastewater after polyaluminum chloride (PAC) coagulation. The results showed that approximately 100% of Fe in the wastewater was precipitated as flocculent iron mud (FM) by adding PAC. FM was converted to spherical magnetic sodalite (FMP) with a diameter of 3 μm via a facile alkali hydrothermal method without adding Al/Si resources or reductant. The product FMP had the saturated magnetization of 10.9 emu g−1 and high Zn2+ adsorption capacity of 50.6 mg g−1. Without coagulation with PAC, the removal rate of Fe from the wastewater was only 92.7%, and the precipitated mud (RM) was converted to irregular particles (RMP), which had weak magnetic response and low capacity of Zn2+ adsorption comparing with FMP. With the method, the Fe in backwash wastewater was effectively recycled, and the generated sludge was converted to well-formed sodalite sphere without generating any secondary waste.

Graphic Abstract

Keywords

Cite This Article

Copyright © 2021 The Author(s). Published by Tech Science Press.

Copyright © 2021 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools