| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2021.015003

ARTICLE

Improving the Unconfined Compressive Strength of Red Clay by Combining Biopolymers with Fibers

1School of Construction Engineering, Yunnan Agricultural University, Kunming, 650201, China

2Powerchina Kunming Engineering Corporation Limited, Kunming, 650051, China

3South-West Survey and Design Group Company Limited, Kunming, 650200, China

*Corresponding Author: Lina Wang. Email: wlnyongji@126.com

Received: 16 November 2020; Accepted: 22 December 2020

Abstract: To explore an environmentally friendly improvement measure for red clay, the function and mechanism of xanthan gum biopolymer and polypropylene fibers on the strength properties of red clay were investigated by unconfined compressive strength and scanning electron microscopy tests. The test results demonstrated that the contents and curing ages of xanthan gum had significant influences on the unconfined compressive strength of red clay. Compared with untreated soil, 1.5% xanthan gum content was the optimal ratio in which the strength increment was between 41.52 kPa and 64.73 kPa. On the other hand, the strength of xanthan gum-treated red clay increased, whereas the ductility decreased with the increase in curing ages, indicating that the xanthan gum-treated red clay started to gradually consolidate after 3 days of curing and stiffness significantly improved between 7 and 28 days of curing. The results also showed that the synergistic consolidation effects of the xanthan gum–polypropylene fibers could not only effectively enhance the strength of red clay but also reduce the brittle failure phenomenon. The strengths of soil treated with 2.0% xanthan gum-polypropylene fibers were 1.9–2.41 and 1.12–1.47 times than that of red clay and 1.5% xanthan gum-treated clay, respectively. The results of study provide the related methods and experiences for the field of ecological soil treatment.

Keywords: Biopolymer; xanthan gum; polypropylene fiber; red clay; micro–mechanism; unconfined compressive strength

Red clay is a type of high-plastic clay mainly formed from carbonate rocks through intense chemical weathering and lateritization. It is widely distributed approximately at 1.08 million km2 in Yunnan, Guangxi, Guizhou, and other provinces in China, which accounts for one ninth of the Chinese land areas. As a type of special soil, red clay has high water content, high porosity, high liquid limit (50%–80%), poor water stability, expansibility, and other undesirable engineering properties. Therefore, the soil reinforcement methods of red clay are important research topics in geotechnical engineering. In actual engineering, red clay structure will be easily damaged due to the action of external environmental factors. Moreover, the untreated red clay layer for infrastructure construction is likely to induce ground subsidence, uneven settlement, slope instability, and other engineering hazards. Although, traditional inorganic reinforcement materials (e.g., lime, cement, and fly ash) that are used for red clay could improve the mechanical properties of soil, these materials can potentially influence the ecological development due to the high stiffness, low permeability, and presence of residual inorganic materials in soils. Also, the production of cement and its industrial by-products will emit large amounts of greenhouse gases, such as carbon dioxide and nitrogen oxides [1]. In addition, the application of chemical additives (e.g., epoxy resins, polyurethanes and glass water) in ground treatment can lead to a number of environmental problems, such as surface runoff pollution and ecosystem damage [2]. Therefore, there are growing appeals for exploring environmentally materials to improve the engineering properties of special soils and to respond to greenhouse gas reduction strategies.

Xanthan gum is a polysaccharide fermented from glucose or sucrose by xanthomonas campestris [3]. The merits of xanthan gum include antioxidation, antienzymolysis, and high stability under a wide range of temperatures (28°C–80°C) and acid–base (pH = 1–11). Moreover, the well-known characteristics of xanthan gum are pseudo–plasticity and high shear stability even at low concentrations [4]. Because of these excellent properties, xanthan gum has found a wide range of applications in the cosmetics industry, oil production, pharmaceuticals industry, and food processing (e.g., for use as gelling, thickening, or suspending agents) [5]. Some previous studies have revealed that xanthan gum, as an environmentally renewable material, gradually becomes a type of organic binder in bio–geotechnical engineering due to the advantages of material characteristic [6]. Chang et al. [7] investigated the effect of xanthan gum on soil consolidation in different types of soils and showed that xanthan gum preferentially formed a strong biopolymer matrix through hydrogen bonding in the presence of clay particles; xanthan gum also had better treatment effect on soils with preferable particle grading. Ayeldeen et al. [8] showed that the shear strength of sand and silt soil was considerably increased after treatment with biopolymers (i.e., xanthan gum and gellan gum). Latifi et al. [9] found that the addition of a small amount of xanthan gum in the presence of clay particles could produce meaningful reinforcement. Lee et al. [10] showed that xanthan gum could be used for soil treatment under low restriction levels or shallow conditions. The addition of xanthan gum to the residual soil by Rashid et al. [11] markedly enhanced the soil strength within 28 days. Therefore, the xanthan gum biopolymer is expected to significantly improve the engineering mechanical properties of soil and is suitable for the ecological treatment of red clay.

Additionally, the phenomenon of shrinkage and desiccation crack will generally occur in red clay due to water loss by evaporation, which directly or indirectly influences the mechanical and hydraulic properties of soil [12]. Although, the traditional improvement measure utilizes lime and cement to improve the soil strength and cracking resistance, these chemical additives could not completely limit the cracking of red clay when the initial water content was high. Kaniraj et al. [13] studied the individual and combined effects of fiber inclusion and cement stabilization on soil, indicating that fiber inclusion obviously changed the brittle to ductile behavior. The application of fiber-reinforced soil can reduce the usage of cement-treated soil and contribute to restore the degraded ecosystems [14,15]. The free dispersion of fibers in the soil can also produce the effect of flexible reinforcement to soil, which not only improves the soil stability but is also beneficial for providing a stable growth environment before the plant root formation [16]. Polypropylene fiber as an environmental reinforcement material has some specific advantages of high strength, easy mixing, low creep shrinkage and rain erosion resistance [17]. Certain studies have shown that polypropylene fiber has significant advantages in improving the soil engineering performance and compensating for the porosity, dispersibility, and brittleness. Plé et al. [18] added polypropylene fibers to the clay and found that the composite material becomes more and more rigid as the fiber incorporation increased in compression, and also exhibits beneficial effects in ductility under direct tensile tests. Polypropylene fibers could improve the residual strength and fracture toughness, while constraining the deformation of soil to improve the integrity. Malekzadeh et al. [19] investigated that polypropylene fiber–reinforced soil can effectively reduce swell-shrink movement of expansive soils. In particular, the shrinkage of reinforced soil reduced considerably upon desiccation, as the shrinkage limit increased by more than 50%. Divya et al. [20] simulated the cracking characteristics of fiber clay under uneven settlements by using the centrifugal model test and showed that the fiber length-to-diameter ratio and content could effectively control the crack formation. Thus, the incorporation of polypropylene fibers could not affect the soil environment and also causes a potential improvement on the engineering properties of red clay by restraining deformation, improving strength, and controlling the crack formation.

The present study mainly aims to purpose an environmentally friendly improvement measure for red clay using xanthan gum and polypropylene fibers through experimental investigations in which some essential influencing factors (e.g., xanthan gum content, curing ages, and polypropylene fiber content) are considered. Scanning electron microscopy (SEM) tests are also performed to further realize the mechanism of the red clay treated with xanthan gum and investigate the synergistic consolidation effects of xanthan gum and fibers.

In the present study, red clay was sampled from a foundation pit at 3 m–5 m depth in Kunming, Yunnan, China. The latitude and longitude coordinate of the sampling site is 102° 42′ 31″ E and 25° 02′ 11″ N, respectively. Yunnan red clay is rich in iron and aluminum ions. Moreover, it has low density but high strength and liquid limit. The coefficient of uniformity (Cu) and the coefficient of gradation (Cc) were 7.27 and 0.65, respectively. Its specific gravity is 2.82. Tab. 1 includes the basic physical properties of red clay. The particle size distribution of red clay is shown in Fig. 1.

Figure 1: Particle size distribution of red clay

Table 1: Basic physical properties of red clay

The main component of biopolymer is polysaccharides [6], which means that biopolymers are environmentally renewable materials. The biopolymer used in this study was an industrial-grade xanthan gum. The solid form of the xanthan gum is white powder having high hydrophilic property when dissolved in water. When mixed properly with water, it forms the stable viscous gels even at low concentrations [21]. This anionic polysaccharide is composed of D-uronic acid, D-mannose, pyruvylated mannose, 6-O-acetyl D-mannose, and 1,4-linked glucan. The glucose main chain of xanthan gum is linked with a trisaccharide side chain, which is aligned with the main chain and provides stability and overall conformation through hydrogen bonding [22]. Its anionic and hydrophilic surface characteristics facilitate interactions with cations inducing a stronger gelation.

Short polypropylene fiber was selected as the reinforcement material of red clay owing to its good ductility, fineness, and dispersion. Also, polypropylene fiber is a hydrophobic and chemically inert material which does not absorb and react with the soil moisture. The length of the monofilament fiber was 9 mm. The basic physical parameters of polypropylene fiber are given in Tab. 2.

Table 2: Basic physical properties of polypropylene fiber

2.2 Sample Preparation and Test Methods

2.2.1 Unconfined Compressive Strength Test

Unconfined compressive strength tests were performed by using a UTM device. To reasonably evaluate the strength properties of treated red clay on different contents and curing ages, three parallel specimens for each set of conditions (e.g., a total of 144 specimens) were prepared. In addition, the three measurements were averaged and selected to minimize the experimental errors. Tab. 3 lists test groups and results.

Table 3: Groups and results of the unconfined compressive strength test

The specimens were prepared by strictly adhering to the GB/T50123-2019 procedures. First, the representative red clay was dried naturally, crushed, and passed through a 2-mm sieve. Then, the samples were prepared with specific amounts (0.5%, 1.0%, 1.5%, 2.0%, and 2.5% of soil mass weight ratio) of xanthan gum and 9 mm polypropylene fibers (1.0% of the soil mass weight ratio) by using an automatic rotator to completely mix with red clay. Next, the optimum moisture content (

2.2.2 Scanning Electron Microscope Test

SEM tests were conducted with the FlexSEM1000 equipment, which was applied to objectively observe the characteristics of the microscopic structure and confirm the interactions between the xanthan gum, polypropylene fibers, and particles. The test samples were selected from pure red clay, soil treated with 1.5% xanthan gum, and soil treated with 2.0% xanthan gum-polypropylene fiber after curing for 28 days. The specimen size was 1 mm thick and 10 mm in diameter. In addition, the 1.5% (liquid/solid ratio in the mass) xanthan gum solution and glass beads (1–2 mm particle size) were mixed together for modeling so as to make the structural form between the xanthan gum and soil particles more visual.

3.1 Unconfined Compressive Strength Test

3.1.1 Effect of Xanthan Gum Content on the UCS of Xanthan Gum-Treated Soil

Figs. 2a and 2b show the stress–strain curves for the soil treated with xanthan gum at 7 days and 28 days of curing age, respectively. Clearly, the axial stress of the specimens showed an inverted V-shaped trend, which described that the stress first increased and then declined with the increasing axial strain. During the rising stage of the curves, red clay and soil modified by xanthan gum showed the similar trends in the growth of strength. However, with the substantial increase in xanthan gum content, the time for the modified soil to reach the peak stress gradually lengthened, and the peak stress first increased and then decreased. In the decreasing stage of the curves, as the content of xanthan gum increases, the decline in the curve increases moderately, whereas the increase in the curing ages also leads to the reduction of soil ductility.

Figure 2: Stress–strain curves of the soil modified by xanthan gum for the (a) 7 and (b) 28 days curing

For the curing age of 7 days, the unconfined compressive strength of the control group (red clay) was 70.49 kPa, whereas the 0.5% xanthan gum-modified soil increased only by 27.74%. The strength of the soil treated with 1.0%, 1.5%, 2.0%, and 2.5% of xanthan gum increased significantly by 50.33%, 67.46%, 58.90%, and 57.04%, respectively. For the curing age of 28 days, the strength of red clay was 96.34 kPa whereas those of the red clay modified by 0.5%, 1.0%, 1.5%, 2.0%, and 2.5% of xanthan gum were 120.88 kPa, 131.90 kPa, 161.07 kPa, 155.63 kPa, and 148.86 kPa, which increased by 24.47%, 36.91%, 67.19%, 61.54%, and 54.51%, respectively. The strength improvement could be the result of the dehydration of xanthan gum through the hydrogel to form a strong biopolymer–clay matrix, which enhances the bonding characteristics between the particles [7] and has a significant soil–solidifying effect. When the xanthan gum content exceeds 1.5%, the excess xanthan gum monomers adsorb water to form large cementation lumps in the clay, which fills the pore space of the clay particles and increases the connection among local particles [23]. Therefore, local weak points were formed in the process of the force deformation of the specimen, which causes the strength to be gradually attenuated.

The results showed that the xanthan gum content had different effects on the treatment of Yunnan red clay. In particular, 0.5% of the xanthan gum content had limited reinforcing effect; the addition of 1.5% xanthan gum content had the most noticeable enhancement on soil consolidation, and the effects of the strength enhancement tended to be steady after the xanthan gum content exceeded 1.5%. Therefore, 1.5% xanthan gum was the optimal content required to improve the unconfined compressive strength of Yunnan red clay. Considering the economic cost, the effective content of xanthan gum was 1.0% to 1.5% for strengthening the Yunnan red clay.

3.1.2 Effect of Curing Ages on the UCS of Soil Modified by Xanthan Gum

Fig. 3 shows the influential pattern of different curing ages on the unconfined compressive strength of the red clay treated with xanthan gum. As shown in Fig. 3a, the strength of the specimens increased to varying degrees with the increase of curing ages. The strength values of the modified soil were all significantly greater than that of the red clay. The strength of the modified soil with different xanthan gum contents showed different states with curing ages. For each curing age, the soil modified by 0.5% xanthan gum had the least tendency to increase in strength with increasing curing age. The strength of the soil treated with 1.5% xanthan gum showed the greatest increase, which was 52.26 kPa for curing ages ranging from 3 days to 28 days. The red clay treated with 2.0% and 2.5% xanthan gum still showed a large increase in the strength with the increasing curing ages. The difference in the strength values between the 2.5% xanthan–red clay and 1.0% admixture was small for curing ages of 3 days, 7 days, and 14 days until obviously changing after 14 days.

Figure 3: Effect of curing ages on the unconfined compressive strength of soil modified by xanthan gum: (a) Variation curve; (b) Strength increment

Fig. 3b shows the strength increment of the specimens at different curing ages. Clearly, the strength of the modified soil increased gradually with increasing curing ages and improved rapidly after curing 14 days. The strength increment of the control group (red clay) was 32.20 kPa from 3 to 28 days, which was significantly less than the soil modified by 1.5% xanthan gum. In addition, compared to the red clay, the strength of the 1.5% xanthan gum-treated soil increased by 44.67 kPa, 47.55 kPa, 49.64 kPa, and 64.73 kPa after curing 3, 7, 14, and 28 days, respectively. This result implied that the soil treated with xanthan gum could gradually start the soil consolidation phenomenon after curing for three days, and the strength grew rapidly between 7 days and 28 days. Moreover, the treatment soil was slightly brittle due to the water loss and the shrinkage of the xanthan gum matrices.

3.1.3 Effect of Xanthan Gum Content on the UCS of Soil Treated by Xanthan Gum and Polypropylene Fiber

Fig. 4 shows the stress–strain curves of the soil treated with xanthan gum and polypropylene fibers at 7 days and 28 days of curing ages, respectively. As shown in Fig. 4, the axial stress of the treatment soil showed a tendency to first increase and then decrease with the increasing axial strain. During the upward curve phase, the red clay showed a rapid upward trend and reached the peak stress first, whereas the soil reinforced by polypropylene fibers and xanthan gum-polypropylene fiber rose slowly. As the xanthan gum content increased, the time taken for the soil modified by xanthan gum and polypropylene fibers to reach the peak stress gradually increased. In the decreasing stage of the curve, the strength of the red clay dropped sharply and showed the brittle failure phenomenon, whereas the soil treated with xanthan gum-polypropylene fiber and polypropylene fibers showed a slow declining trend with high ductility and residual strength.

Figure 4: Stress–strain curves of soils modified by xanthan gum and polypropylene fiber for curing ages of (a) 7 days; (b) 28 days

At the curing age of 7 days, red clay and the soil reinforced with 1.0% polypropylene fibers were used as the control groups (strengths of 70.49 kPa and 86.49 kPa, respectively). The strength increments of the soil treated with 0.5% xanthan gum-polypropylene fiber were 26.3 kPa and 10.3 kPa. The 2.0% xanthan gum-polypropylene fiber treated soil reached a maximum peak stress of 154.19 kPa with the increments of 83.7 kPa and 67.7 kPa. The improvement effect showed a decaying trend when the blending amount was 2.5%, and the peak stress was 137.66 kPa. At the curing age of 28 days, the strengths of red clay and 1.0% polypropylene fibers-reinforced soil were 96.34 kPa and 118.91 kPa, respectively. However, the strength of the soil treated with 0.5%, 1.0%, 1.5%, 2.0%, and 2.5% xanthan gum–polypropylene fibers were 127.03 kPa, 169.67 kPa, 190.61 kPa, 231.70 kPa, and 196.59 kPa, respectively. These values showed an increase of 31.86%, 76.12%, 97.85%, 117.07%, and 104.06% than that of red clay, and 6.83%, 42.69%, 60.30%, 94.85%, and 65.33% compared to that of the soil reinforced with polypropylene fibers. The synergistic consolidation effects of xanthan gum and polypropylene fibers result from the ability of the xanthan gum to adsorb clay particles to form firmly biopolymer–clay matrices that tightly wrap the three-dimensional fiber structure. This phenomenon significantly enhanced the tensile strength and expanded the force range of the fibers to place better constraints on the displacement and deformation of soil.

On comparing Figs. 2 and 4, it was found that 1.0% polypropylene fiber-reinforced soil could improve the strength and ductility of red clay; however, its enhancement effect on the strength properties was less than that of the soil treated with xanthan gum. Although, the soil treated with xanthan gum can improve the strength of red clay, this treatment also reduces the residual strength and slightly induces the brittle failure phenomenon. The synergistic consolidation effects of biopolymer and fibers could better make up for those shortcomings. Moreover, the effective content range of xanthan gum could be extended (up to 2.0%) after adding the fibers.

3.1.4 Effect of Curing Age on the UCS of Soil Treated with Xanthan Gum and Polypropylene Fiber

Fig. 5 shows the effect of different curing ages on the soil treated with xanthan gum and polypropylene fibers. From Fig. 5, it can be observed that with the increase of the curing ages, the strength of both the modified soil and red clay rose to varying degrees. Actually, the unconfined compressive strength of the soil treated with xanthan gum and polypropylene fibers was always higher than that of red clay and the soil reinforced with polypropylene fibers. At 3 days of curing, the strength of the soil reinforced with polypropylene fibers was 79.59 kPa and that of the soil modified by 0.5% xanthan gum-polypropylene fiber was 82.98 kPa. However, with the increase of the curing ages, the strength of the soil modified by 0.5% xanthan gum-polypropylene fiber was moderately greater than that of the soil reinforced by polypropylene fibers. At each curing age, the strengths of the soil modified with 1.0%, 1.5%, 2.0%, and 2.5% admixtures of xanthan gum-polypropylene fiber were significantly higher than those of the fiber-reinforced soil and red clay. With increasing curing ages, 2.0% xanthan gum content had the greatest improvement on the strength properties. The strength growth trend of the soil treated with 2.5% xanthan gum-polypropylene fibers was similar to that of the soil treated with the 1.5% xanthan gum.

Figure 5: Effect of curing age on the UCS of the xanthan gum-polypropylene fiber treated soil

Fig. 6 shows the strength increment of specimens at different curing ages. Clearly, the strength increment of the modified soil gradually increased with increasing curing ages. During the curing age ranging from 3 to 28 days, the strength increment of red clay was 32.20 kPa, whereas that of the soil modified by 1.5% xanthan gum was 52.26 kPa. In addition, the strength of the soil modified by 2.0% xanthan gum-polypropylene fiber increased by 57.76 kPa, 83.7 kPa, 110.84 kPa, and 135.36 kPa as compared with red clay for the curing ages of 3 days, 7 days, 14 days, and 28 days, respectively. Moreover, the strength of the soil modified by 2.0% xanthan gum-polypropylene fiber increased by 13.09 kPa, 36.15 kPa, 61.2 kPa, and 70.63 kPa compared with the 1.5% xanthan gum-treated soil on each curing age. As compared with the soil modified by xanthan gum and the soil modified by both xanthan gum and polypropylene fibers, the treatment samples needed some time to produce consolidation to improve the strength properties after the xanthan gum was mixed into the soil. In addition, both treated samples exhibited similar trends in the enhancement of strength in the curing period.

Figure 6: Change in the unconfined compressive strength increment with curing ages

The model of xanthan gum and glass beads referenced the experimental design methods of Chang et al. [24]. Fig. 7 shows the SEM images of the model of 1.5% xanthan gum-glass beads. It was observed that xanthan gum formed the thin biopolymer coating on the surface of glass beads and expanded the area of the contact point between the particles in Fig. 7a. For distant particles that were not in direct contact, Fig. 7b shows that a bridging structure was formed between the particles through the adsorption and pulling action of the xanthan solution [24]. The xanthan gum formed the film coating on the surface of uncharged glass beads, which was similar to the interaction between xanthan gum and sand particles [25]. In contrast, Fig. 8 shows a 12,000× SEM image of xanthan gum-treated red clay. The morphology of the xanthan gum was a flake crystal structure in the red clay. In addition, the xanthan gum and clay particles were tightly clustered into the sheets and groups.

Figure 7: Model of the xanthan gum and glass beads

Figure 8: SEM image of the crystals of the xanthan gum in red clay

Fig. 9a presents the SEM image of the red clay cured for 28 days. The red clay particles showed obvious looseness, large pore spaces, weak connecting and unstable overall structure. Fig. 9b depicts the SEM image of 1.5% xanthan gum-treated soil at 28 curing days. As could be clearly seen in Fig. 9b, the loose clay particles were tightly cemented together. In addition, the xanthan gum and particles formed continuous smooth sheets of clay that fill the pore spaces such that the visible pores were very small compared to the original soil. This phenomenon could be explained by the xanthan gum monomers that induced the hydrogen bonding of water molecules and rendered the monomers hydrophilic through the hydroxyl groups on their surfaces, which directly bonded to the surface of clay particles and increased the contact areas between the particles, which altered the alignment properties of particles [26]. In addition, xanthan gum could interact indirectly with alkaline metal ions (i.e., Na+, Mg2+, and Ca2+) in clay to form ionic bonds [27]. Xanthan gum forms biopolymer–clay matrices through both direct and indirect ways [28]. The strengthening mechanism of xanthan gum in red clay could be included in the formation of firmly biopolymer matrices and the combination of bonding properties between xanthan gum and clay particles [24–28].

Figure 9: SEM images of (a) Red clay; (b) Soil treated with 1.5% xanthan gum

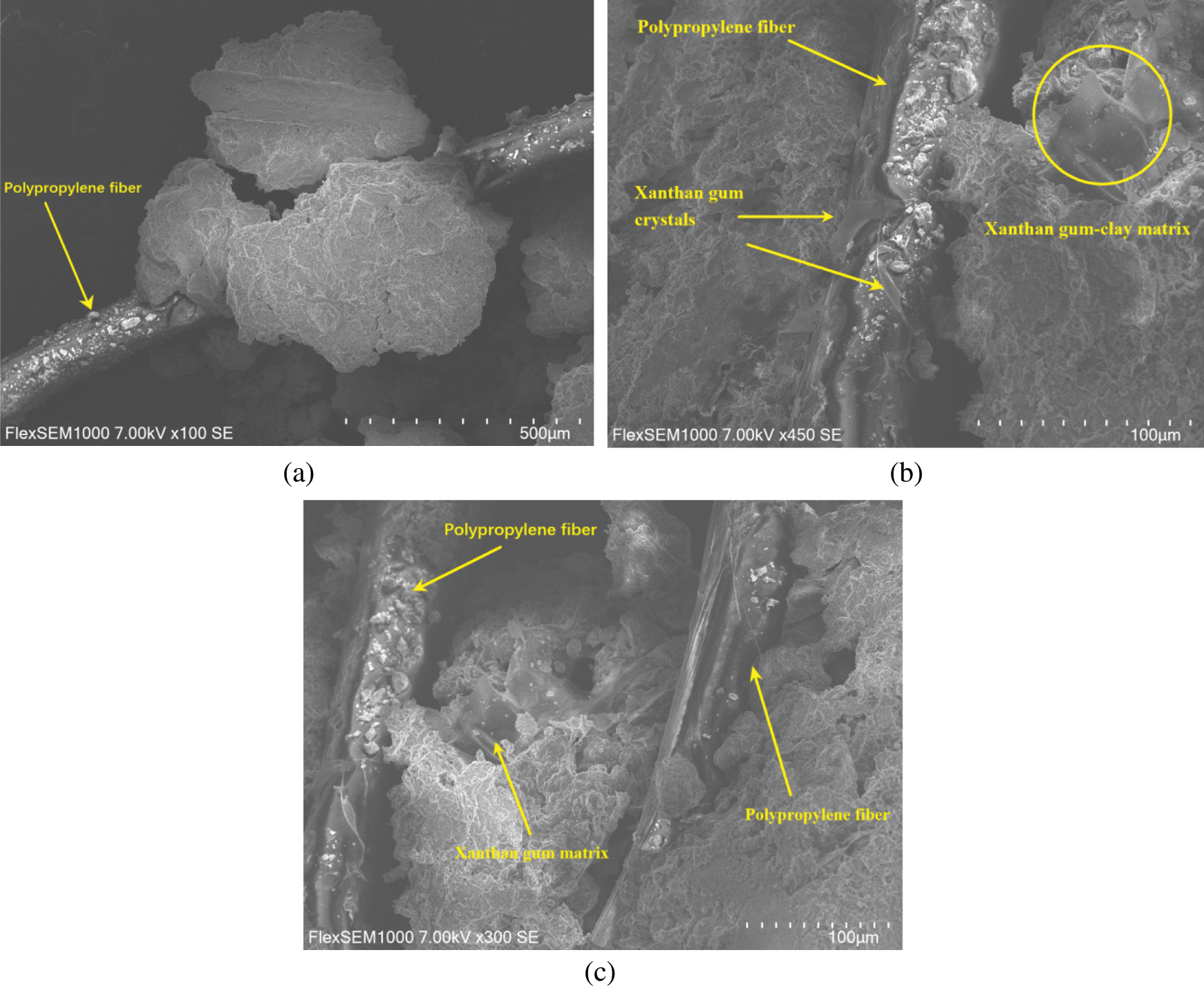

Figs. 10a–10c are the SEM images of red clay treated with polypropylene fibers and xanthan gum, respectively. Fig. 10a showed the state of a single polypropylene fiber in the soil. It was observed that the single polypropylene fiber was embedded in the loose soil. When the soil treated with polypropylene fiber was subjected to external loads, the inconsistency of the deformation between the fiber and soil could lead to mutual dislocation trend due to the higher elastic modulus of polypropylene fiber [29]. The fiber was pulled to produce interfacial forces, which limited the relative sliding of the fiber, and also made it sustain sustain tensile stress to share the external loads. This strengthening mechanism is based on the function of one-dimensional tensile reinforcement of discrete fiber. However, Figs. 10b and 10c clearly show the surfaces of the polypropylene fiber are covered with clay particles and xanthan gum–clay matrices. This was due to the ionic bonding between the xanthan gum and clay particles, which accumulated the particles around the xanthan gum and fibers to form biopolymer–fiber clay matrices. Fig. 10c clearly shows that the fibers were randomly distributed and interwoven in the soil. The other fibers could be influenced to sustain the forces together when one of the fibers was pulled, so as to form a three-dimensional stress network. This kind of reinforcement mechanism is mainly based on three-dimensional fibers network. Thus, the interfacial forces between the polypropylene fibers, xanthan gum-clay matrices, and soil particles can more effectively constrain the relative sliding of the fibers so that the fibers could withstand greater tensile stresses and expand the load ranges [30], thereby further limiting soil deformation and improving soil integrity. Tab. 4 shows the schematic summary of interaction between the xanthan gum biopolymer, polypropylene fibers, and red clay particles.

Figure 10: SEM images of (a) polypropylene fiber-treated clay and (b–c) soil treated by 2.0% xanthan gum-polypropylene fiber

Table 4: Schematic model of the microstructure of soil treated with xanthan gum and polypropylene fibers indicating specific polymerization behavior

In this study, the effects of xanthan gum and polypropylene fibers on the strength properties of red clay using the unconfined compressive strength and scanning electron microscope tests were revealed. The following conclusions can be drawn:

1. The strength of the xanthan gum-modified red clay showed an obvious nonlinear increase with the increase of xanthan gum contents. In particular, 1.5% xanthan gum content was the optimal ratio in which the strength increment was between 41.52 kPa and 64.73 kPa compared with the untreated red clay. When the xanthan gum content exceeded 1.5%, the enhancement effect was gradually stable and the strength values were slightly attenuated. As for the curing ages, the soil treated with xanthan gum gradually produced soil consolidation after curing 3 days, whereas the stiffness improved significantly after curing 7 to 28 days.

2. The synergistic consolidation effects of xanthan gum and polypropylene fibers could more effectively enhance the unconfined compressive strength and residual strength of red clay and also reduce the brittle failure phenomenon of the red clay and xanthan gum-treated soil. In particular, the strength of xanthan gum-polypropylene fiber treated soil was 1.9–2.41 and 1.12–1.47 times, respectively, of the xanthan gum-treated soil and the soil reinforced with polypropylene fibers.

3. The mechanism of xanthan gum on red clay results from the interactions between xanthan gum and the charged surface of clay particles at the microscopic scale, which directly and indirectly interacts with hydrogen ions and alkaline metal ions to change the alignment characteristic of soil particles, so as to form firmly biopolymer–clay matrices. In addition, the synergistic consolidation effects of xanthan gum and polypropylene fibers originate from the existence of xanthan gum which could adsorb the clay particles and tightly wrap the polypropylene fibers together to form biopolymer–fiber clay matrices, thereby effectively expanding the force range of fibers and restraining the deformation and displacement of soil.

The present study analyzed the improvement mechanism of xanthan gum-treated red clay and also investigated the biopolymer–fiber synergistic consolidation effects on the red clay. However, the durability of biopolymer, the construction process of biopolymer–fiber reinforcement, and the economic cost still needs to be systematically studied using practical projects in future.

Acknowledgement: The authors thank Prof. Biyu Rao (College of Civil and Architectural Engineering, Yunnan Agricultural University, Kunming, Yunnan, China) for her helpful suggestions and comments on experiments.

Funding Statement: This study was supported by the State Key Laboratory Project of China (Grant No. KF2020-12) and the Yunnan Education Department Project of China (Grant Nos. 2020Y0175 and 2020J0240).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Ilhan, C., Jooyoung, I., Gye-Chun, C. (2016). Introduction of microbial biopolymers in soil treatment for future environmentally-friendly and sustainable geotechnical engineering. Sustainability, 8(3), 251. DOI 10.3390/su8030251. [Google Scholar] [CrossRef]

2. Kapur, A., Oss, H. G. V., Keoleian, G., Kendall, K. A. (2009). The contemporary cement cycle of the united states. Journal of Material Cycles and Waste Management, 11(2), 155–165. DOI 10.1007/s10163-008-0229-x. [Google Scholar] [CrossRef]

3. Carignatto, C. R. R., Oliveira, K. S. M., de Lima, V. M. G., Neto, P. D. O. (2011). New culture medium to xanthan production by xanthomonas campestris pv. Indian Journal of Microbiology, 51(3), 283–288. DOI 10.1007/s12088-011-0171-9. [Google Scholar] [CrossRef]

4. Rosalam, S., England, R. (2006). Review of xanthan gum production from unmodified starches by Xanthomonas comprestris sp. Enzyme and Microbial Technology, 39(2), 197–207. DOI 10.1016/j.enzmictec.2005.10.019. [Google Scholar] [CrossRef]

5. Singh, S. P., Das, R. (2019). Geo-engineering properties of expansive soil treated with xanthan gum biopolymer. Geomechanics & Geoengineering, 2019(2), 1–16. [Google Scholar]

6. Chen, C., Wu, L., Perdjon, M., Huang, X., Peng, Y. (2019). The drying effect on xanthan gum biopolymer treated sandy soil shear strength. Construction and Building Materials, 197, 271–279. DOI 10.1016/j.conbuildmat.2018.11.120. [Google Scholar] [CrossRef]

7. Chang, I., Im, J., Prasidhi, A. K., Cho, G. C. (2015). Effects of xanthan gum biopolymer on soil strengthening. Construction and Building Materials, 74, 65–72. DOI 10.1016/j.conbuildmat.2014.10.026. [Google Scholar] [CrossRef]

8. Ayeldeen, M., Negm, A., El-Sawwaf, M., Kitazume, M. (2017). Enhancing the behavior of collapsible soil using biopolymers. Journal of Rock Mechanics and Geotechnical Engineering, 9(2), 329–339. DOI 10.1016/j.jrmge.2016.11.007. [Google Scholar] [CrossRef]

9. Latifi, N., Horpibulsuk, S., Meehan, C. L., Abd Majid, M. Z., Tahir, M. M. et al. (2016). Improvement of problematic soils with biopolymer-an environmentally friendly soil stabilizer. Journal of Materials in Civil Engineering, 29(2), 04016204.1–04016204.11. [Google Scholar]

10. Lee, S., Im, J., Cho, G. C., Chang, I. (2019). Laboratory triaxial test behavior of xanthan gum biopolymer-treated sands. Geomechanics and Engineering, 17(5), 445–452. [Google Scholar]

11. Rashid, A. S. A., Latifi, N., Meehan, C. L., Manahiloh, K. N. (2017). Sustainable improvement of tropical residual soil using an environmentally friendly additive. Geotechnical and Geological Engineering, 35(6), 2613–2623. DOI 10.1007/s10706-017-0265-1. [Google Scholar] [CrossRef]

12. Tang, C. S., Shi, B., Cui, Y. J., Liu, C., Gu, K. (2012). Desiccation cracking behaviour of polypropylene fiber-reinforced clayey soil. Canadian Geotechnical Journal, 49(9), 1088–1101. DOI 10.1139/t2012-067. [Google Scholar] [CrossRef]

13. Kaniraj, S. R., Havanagi, V. G. (2001). Behavior of cement-stabilized fiber-reinforced fly ash-soil mixtures. Journal of Geotechnical and Geoenvironmental Engineering, 127(7), 574–584. DOI 10.1061/(ASCE)1090-0241(2001)127:7(574). [Google Scholar] [CrossRef]

14. Luo, Y., Zhou, D., Zhang, J. (2012). Experiments on a new material for the ecological protection of rock slopes. Energy Procedia, 16(Part A), 272–277. DOI 10.1016/j.egypro.2012.01.045. [Google Scholar] [CrossRef]

15. Kumar, A., Walia, B. S., Mohan, J. (2006). Compressive strength of fiber reinforced highly compressible clay. Construction and Building Materials, 20(10), 1063–1068. DOI 10.1016/j.conbuildmat.2005.02.027. [Google Scholar] [CrossRef]

16. Loades, K. W., Bengough, A. G., Bransby, M. F. (2010). Planting density influence on fibrous root reinforcement of soils. Ecological Engineering, 36(3), 276–284. DOI 10.1016/j.ecoleng.2009.02.005. [Google Scholar] [CrossRef]

17. Jiang, H., Cai, Y., Liu, J. (2010). Engineering properties of soils reinforced by short discrete polypropylene fiber. Journal of Materials in Civil Engineering, 22(12), 1315–1322. DOI 10.1061/(ASCE)MT.1943-5533.0000129. [Google Scholar] [CrossRef]

18. Plé, O., Lê, T. N. H. (2012). Effect of polypropylene fiber-reinforcement on the mechanical behavior of silty clay. Geotextiles and Geomembranes, 32, 111–116. DOI 10.1016/j.geotexmem.2011.11.004. [Google Scholar] [CrossRef]

19. Malekzadeh, M., Bilsel, H. (2014). Hydro-mechanical behavior of polypropylene fiber reinforced expansive soils. KSCE Journal of Civil Engineering, 18(7), 2028–2033. DOI 10.1007/s12205-014-0389-2. [Google Scholar] [CrossRef]

20. Divya, P. V., Viswanadham, B. V. S., Gourc, J. P. (2014). Evaluation of tensile strength-strain characteristics of fiber-reinforced soil through laboratory tests. Journal of Materials in Civil Engineering, 26(1), 14–23. DOI 10.1061/(ASCE)MT.1943-5533.0000772. [Google Scholar] [CrossRef]

21. Petri, D. F. S. (2015). Xanthan gum: A versatile biopolymer for biomedical and technological applications. Journal of Applied Polymer Science, 132(23), 42035. DOI 10.1002/app.42035. [Google Scholar] [CrossRef]

22. Cadmus, M. C., Jackson, L. K., Burton, K. A., Plattner, R. D., Slodki, M. E. (1982). Biodegradation of xanthan gum by bacillus sp. Applied & Environmental Microbiology, 44(1), 5–11. DOI 10.1128/AEM.44.1.5-11.1982. [Google Scholar] [CrossRef]

23. Whitcomb, P. J. (1978). Rheology of xanthan gum. Journal of Rheology, 22(5), 493–505. DOI 10.1122/1.549485. [Google Scholar] [CrossRef]

24. Chang, I., Cho, G. C. (2012). Strengthening of Korean residual soil with β-1,3/1,6-glucan biopolymer. Construction and Building Materials, 30, 30–35. DOI 10.1016/j.conbuildmat.2011.11.030. [Google Scholar] [CrossRef]

25. Cabalar, A. F., Wiszniewski, M., Skutnik, Z. (2017). Effects of xanthan gum biopolymer on the permeability, odometer, unconfined compressive and triaxial shear behavior of a sand. Soil Mechanics and Foundation Engineering, 54(5), 356–361. DOI 10.1007/s11204-017-9481-1. [Google Scholar] [CrossRef]

26. Nugent, R., Zhang, G., Gambrell, R. (2009). Effect of exopolymers on the liquid limit of clays and its engineering implications. Transportation Research Record: Journal of the Transportation Research Board, 2101(1), 34–43. DOI 10.3141/2101-05. [Google Scholar] [CrossRef]

27. Khatami, H. R., O’Kelly, B. C. (2013). Improving mechanical properties of sand using biopolymers. Journal of Geotechnical and Geoenvironmental Engineering, 139(8), 1402–1406. DOI 10.1061/(ASCE)GT.1943-5606.0000861. [Google Scholar] [CrossRef]

28. Chang, I., Prasidhi, A. K., Im, J., Cho, G. C. (2015). Soil strengthening using thermo-gelation biopolymers. Construction and Building Materials, 77, 430–438. DOI 10.1016/j.conbuildmat.2014.12.116. [Google Scholar] [CrossRef]

29. Tang, C. S., Shi, B., Gao, F., Cai, Y. (2007). Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotextiles and Geomembranes, 25(3), 194–202. DOI 10.1016/j.geotexmem.2006.11.002. [Google Scholar] [CrossRef]

30. Tang, C. S., Shi, B., Zhao, L. Z. (2010). Interfacial shear strength of fiber reinforced soil. Geotextiles and Geomembranes, 28(1), 54–62. DOI 10.1016/j.geotexmem.2009.10.001. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |