| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2021.014987

ARTICLE

Fiber Loading of Date Palm and Kenaf Reinforced Epoxy Composites: Tensile, Impact and Morphological Properties

1Department of Mechanical Engineering, Acharya Nagarjuna University-College of Engineering and Technology, Guntur, Andhra Pradesh, India

2Department of Mechanical Engineering, RVR & JC College of Engineering and Technology, Guntur, Andhra Pradesh, India

*Corresponding Author: Syed Waheedullah Ghori. Email: waheedullahghori@gmail.com

Received: 14 November 2020; Accepted: 23 January 2021

Abstract: Date palm fiber (DPF) and kenaf fiber were reinforced in epoxy having various fiber loading 40%, 50%, and 60% by weight. These hybrid samples were manufactured by hot press technique and then characterized for tensile, impact, and morphological behavior to evaluate the ratio of fibers in the hybrid composites; the addition of kenaf improved the tensile properties, Scanning Electron Microscopy (SEM) revealed the interfacial bonding of fiber/matrix, and dispersion and void content in composites. Impact test studies reflected the effect of natural fiber with epoxy, level of stress transfer from matrix to reinforced material, and reinforced material’s role in absorbing the impacts. It showed that 50% of DPF had the best shock-absorbing capacity. The obtained results indicated that 30% DPF in hybrid composite showed improved tensile properties and homogeneous distribution of fiber without void content; however, 50% DPF loading in hybrid composites had the best impact properties.

Keywords: Date palm fibre; kenaf fibre; epoxy resin; tensile properties; impact strength and scan electron microscopy

The limited resources of petroleum-based polymers and increasing cost due to limited supply of crude oil is an issue for the synthetic polymers industries. These synthetic polymers also affect the environment negatively, due to their non-degradable characteristics. A study on the production of synthetic polymers in 2015 found that 8300 million metric tonnes polymers such as resin, fiber and additives have been produced for various applications by only eight big industrial sectors [1]. Out of total polymers, nearly 75% are used in the production of plastics. Among these, only 9% are used for recycling, 12% for incinerated and the remaining portion are used for landfill, which takes centuries to degrade [2]. From the aspect of biodegradability, lignocellulosic-based materials can replace the portion of these polymers up to 50% and produce half biodegradable material, capable of reducing the cost and maintaining sustainability and waste management of by-products of the industries [3]. Several polymer nanocomposites with minimal addition of nanofillers such as multiwalled carbon nanotubes [4], nano alumina [5], graphene nanosheets [6] have been developed by researchers for biomedical and gearing applications but these composites have high energy footprint and exhibit problems of agglomeration and inhomogeneity. Such nanocomposites are not environment friendly.

Many fibers are extracted from plants such as bast, core, seeds, leaves, fruits etc. However, some plants give specific type of fibers such as jute core and bast fiber, leaf fiber from pineapple [7] fruit bunch fibers from oil palm fruits [8], several types of fibers from a date palm tree, sugar palm [9] coconut trees [10] etc. Trees from palm family are most widely planted in Asia and Africa. Date palm alone produces a very high amount of fiber which is 42% higher than coir, 10% more than sisal and 20% more than hemp [11]. The anatomical structure of each palm fibers found polygonal to round when the cross-section is visible. Bundles of multicellular fibers structure the DPF, and the center of fibers are hollow called lacuna [12].

Natural fibers have been used for engineering purposes from long ago such as cotton fibers for insulation foam, and wood fiber reinforced phenolic composites for clutch disk [13,14]. The reinforcement of natural fiber in polymers reduced the energy production, renewability, biodegradability, weight reduction, and enhanced acoustic behaviour and thermal insulation of materials. In various properties, natural fiber revealed comparative similar specific properties to the synthetic fibers. Several companies, such as Mercedes Benz used natural fiber reinforced composites for door panels [15,16]. Natural fibers with concrete increase the flexural properties [17], moisture resistance capacity, reduces the maintenance costs, increases durability and above all they are ecofriendly materials [18,19].

Among the thermoset polymers, epoxy is one of the versatile and established resins with epoxide groups and very promising for the polymeric structure consisting of two atoms of carbon and one atom of oxygen [20]. The epoxy resins have been used in various applications such as electronic components, automotive mobile, lightweight building construction materials, circuit board lamination, surface coatings (as moisture barrier), handicraft potting, different types of adhesives, marine structural purposes and several advanced composites on a worldwide scale. Some demerits in the high-performance areas limited the use of epoxy such as delimitation of bonding, fracture toughness, inherent brittleness, micro-cracks, or void content [21], and low impact absorption properties [22]. These disadvantages can be eliminated using appropriate reinforcement and additives, to improve thermal, dynamic, mechanical, morphological and electrical properties [23,24]. Date palm is a highly cultivated plant near the equator and southern hemisphere, especially in arid and semi-arid areas yielding high volume of fibers [25,26].

Basic studies on DPF are investigated to predict properties of thermoset and thermoplastic composites such as single tensile properties, chemical compositions, morphological studies, anatomical structure, and thermal properties [7,12]. Gheith et al. [27] studied the flexural and thermal properties of composite made from epoxy reinforced with DPF fiber and found flexural properties and thermal properties improved significantly at 50% fiber loading. A recent study by [28] based on the DPF revealed that it has thermal insulation properties because of its anatomical structure and thermal stability. Other research work showed that DPF could be used as insulation material due to its morphology, the thermal degradation starts at 232°C and the Differential Scanning Calorimetry indicated the endothermic transition from 243°C –382°C with a peak at 369°C. Asim et al. [2] developed DPF reinforced phenolic composites and investigated the mechanical, thermal and morphological properties. They found that 50% fiber loading improved some mechanical properties (tensile modulus and impact properties) and reduced tensile strength, flexural strength and modulus. SEM analysis revealed the fiber and matrix bonding of composites, and the DMA showed that 50% of DPF reinforced composites showed highest storage modulus.

DPF may be used with other fiber to improve the mechanical strength and compatibility within the matrix. Kenaf fiber is an industrial crop, known for its good mechanical properties when it is reinforced in the polymer matrices. This fiber has attracted the researchers due to its high performance in polymer composites [29,30]. Kenaf fiber reinforcements are used in polymer composites for several applications such as automotive, sports equipment, food and beverage, packaging, and furniture [31].

By using hybridization technique, composites’ properties such as mechanical, thermal, physical and moisture absorption can be designed and enhanced by better fiber/matrix bonding [32,33].

Many other studies have investigated the hybridization effect of the physical, thermal and mechanical properties of the composites [33,34]. Research based on coir fibers and pineapple leaf fibers hybrid composites were analyzed for mechanical, morphological, thermal and physical properties. Hybrid composites improved impact properties. SEM studies reveal the behaviour of fibers and matrix relationship. The thermal properties improved due to the higher content of lignin in Coir fiber.

In this study, DPF and kenaf fibers reinforced epoxy composites are developed using hand lay-up process to derive the benefits of both the reinforcing fibers in improving the tensile properties and impact resistance. SEM studies employed to analyze fiber/matrix bonding in the composites.

The epoxy resin was used as a matrix and hardener (Jointmine 905–3S) purchased from Tazdiq Engineering Sdn. Bhd., Malaysia. Date palm fibers were extracted from date palm trees in Saudi Arabia and imported to Malaysia. The chemical composition of DPF was studied and mentioned in previous research [27]. Kenaf fiber is a native natural fiber of Malaysia, the chemical composition of kenaf have been reported in a previous study [35].

In this study, DPF and kenaf are the reinforcement material used for the fabrication of DPF/K/Epoxy hybrid composites. In these hybrid composites, the matrix content is fixed at 50%, and natural fibers are also fixed at 50%. But, there are 2 types are fibers, so the ratio of fiber in composites was varied. There were three compositions of fibers, shown in Tab. 1. Natural fibers have been ground into 0.5 to 1 mm in using a grinder, the moisture content was maintained between 6%–8%. These samples were prepared using hand layup and then hot pressing for fast curing and avoiding the void content to maintain uniform density. Samples were cut for tensile and impact testing as per ASTM test standards.

Table 1: Formulation of composites

Tensile Test

The samples were cut as per ASTM standard D3039 in size of 120 mm × 20 mm × 3 mm [23]. All specimens were placed for conditioning at 25°C with the humidity of 50% for 48 h before the testing operated. The testing was conducted by using a 5 kN Blue hill INSTRON Universal Testing Machine. Then tensile strength and modulus were calculated over the average results of six samples.

Scanning Electron Microscopy (SEM)

The fracture cross-section of spent tensile test specimens were examined under optical and scanning electron microscopes. Scanning Electron Microscope (SEM) Model HITACHI S-3400N was used for the microscopic structure. For sample preparation, it needs to be coated with gold then placed in SEM machine at the distance of 6.2 mm from the lens, and emission current was 58 μA and the acceleration voltage of 5.0 kV. SEM helps to examine the morphology and fibers and voids.

Impact test

All samples were cut and prepared according to ASTM D256 into 6 replica of dimension 70 mm × 15 mm × 8 mm, then conditioned at 22°C with the humidity of 50% for 48 h before the testing operated. For impact test, Izod Impact machine Zwick/Roell HIT5OP was used.

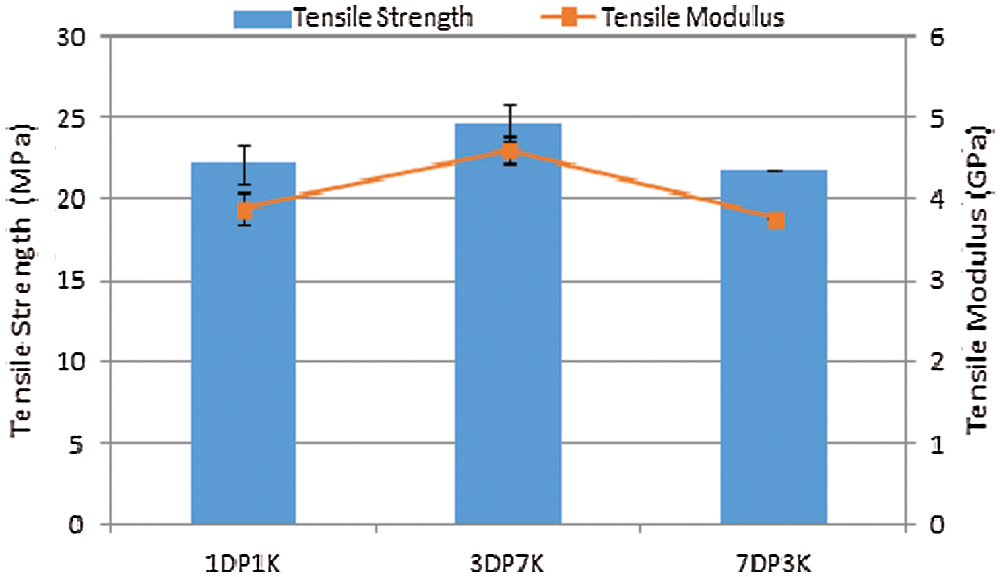

The tensile properties of kenaf and DPF reinforced hybrid composites have been illustrated in Fig. 1. The reinforced fibers used in various ratios to assume that tensile strength and modulus of the hybrid composites will be enhanced after adding a certain amount of kenaf fiber with DPF in epoxy composites. Among all hybrid composites, 3DP7K hybrid composite revealed the highest tensile strength and modulus 24.66 MPa and 4.61 GPa, respectively. The tensile strength and modulus of the 1DP1K showed 22.12 MPa and 3.88 GPa respectively, and the 1DP1K showed lower tensile strength and modulus by 89.72% and 84.22%, respectively. Another hybrid composite, 7DP3K, showed tensile strength and modulus 21.71 MPa and 3.765 GPa, respectively, and the 7DP3K showed lower tensile strength and modulus by 88.04% and 81.59%, respectively.

Figure 1: Effect of DPF/kenaf loading on tensile strength of epoxy hybrid composites

It is observed that 1DP1K and 7DP3K values are very close to each other composites. However, among all composites, it is observed that a higher ratio of kenaf fiber enhanced the mechanical properties. The reinforced materials decide the thermal, mechanical and physical properties of a hybrid composite [36]. Comparative study of both kenaf fiber and DPF showed that kenaf fiber has better mechanical properties and interfacial bonding [12,37]. The previous studies show that DPF composites depicted lower mechanical properties [27,38] than kenaf fiber reinforced epoxy composites [39,40]. When the load is applied to natural fiber reinforced composites, the reinforcement resists the failure. Kenaf fibers have high tensile strength and good interfacial bonding with epoxy. As a reinforced material to delay the failure during the tensile test, Kenaf fibre increases the tensile strength, and modulus. Asim et al. [41] studied the effect of fiber on tensile fracture in hybrid composites. They found that weaker fiber in hybrid composite break first when the force is applied, but the stronger fibers hold for a long time. Sometimes if bonding with fiber and matrix is strong, it holds the matrix and other fibers together, making hybrid composites stiffer. The enhancement of tensile properties of 3DP7K can be explained based on the theory of load transfer, the matrix transferred its load to the fibres, and kenaf fiber bear it effectively [32,42]. Another configuration 1DP1K and 7DP3K showed lower tensile properties; there could be several reasons; an appropriate ratio of fibers in hybrid composites, proper dispersion of fiber in composites, density or morphology of fibers, the surface area of fiber and presence of void content in composites [9,43,44]. Another research found that a lower quantity of fiber cannot spread homogeneously in the polymer, which provides poor stress transfer to fibers from matrix [45]. The DPF and kenaf reinforced hybrid composites showed better tensile properties though some ratios did not work such as 1DP1K and7DP3K, because less kenaf fiber could not bear the matrix’s stress. Similar works have been reported on mechanical properties of hybridization of two types of fiber, banana and sisal fiber having ratio 4:1 improved the tensile strength [46], jute and banana reinforced hybrid composites [47] and pineapple and kenaf hybrid composite improved the mechanical properties [41].

Scanning Electron Microscopy (SEM)

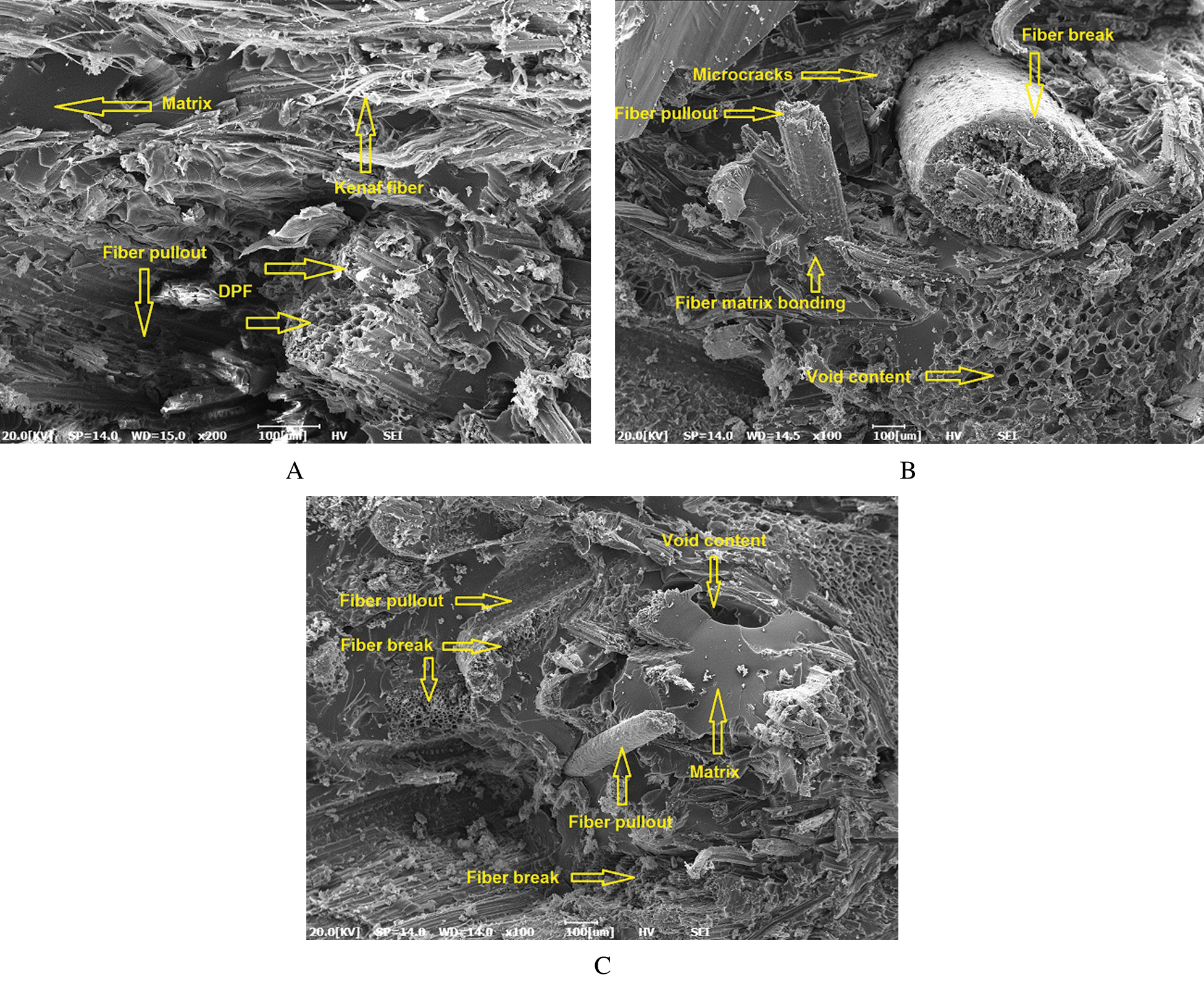

In Fig. 2, the fiber distribution has been clearly seen throughout the sample, the behaviour of fiber with matrix has also been explained. In Fig. 2A, it can be easily seen the presence of fibers, the fiber breakdown, and fiber pullout. Some areas are unattended by fibers, but there is no void content present at the fractured area. In Fig. 2B, there are hairline cracks at joint of fibers and matrix, which showed poor interfacial bonding, though at the same time fiber break showed resistance of slippage from the matrix, which means. Other fiber showed strong connected with the matrix, which indicates good fiber/matrix interfacial bonding. Some void content revealed the fractured surface, but it could be fractured DPF fiber because the cross-section of DPF resembles this area [48] or the outer layer of DPF is dotted outside reveal impression on matrix.

Figure 2: SEM of tensile tested samples (A) 1DP1K, (B) 3DP7K and (C) 7DP3K

In Fig. 2, the void content has clearly revealed some places. Unattended matrix also presented close to the void areas. Fiber pullout is shown with the dotted impression of the outer surface of DPF. The fiber break also clearly visible from fracture samples cross section, which showed several hollow spots. The fiber break without micro cracks showed that the fiber/matrix bonding is strong. Improper fiber distribution in matrix cause poor stress transfer from matrix to fibers, consequently poor tensile strength [30], 3DP7K showed homogeneous fiber distribution. This is one reason for higher tensile properties. SEM micrograph revealed the fiber pull out means bonding between fiber and matrix is weak [49] through the symptoms of better interfacial bonding is fiber break [50], which is shown in all samples. 1DP1K and 7DP3K revealed poor mechanical properties (tensile strength and modulus) because of micro voids in composites that open the gateway for fiber pullout and cause pre-rupturing of fibers to provide poor mechanical composites [38].

Impact Strength

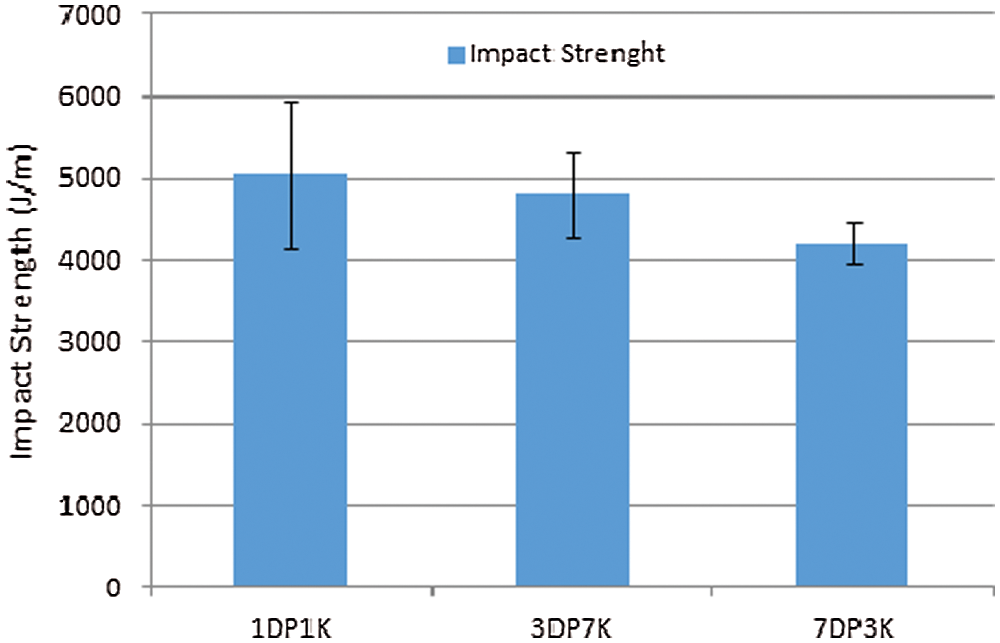

Fig. 3 illustrates the impact strength of DPF/kenaf reinforced epoxy composites. 1DP1K showed the highest impact strength than the rest of composites, which showed that 50% DPF and 50% kenaf fiber with epoxy composites have the best combination for impact properties.

The impact-resistant properties of DPF reinforced composites showed better than other fibers due to the anatomical structure of DPF. This DPF is hollow from the center, which helps to absorb impact and stabilize the structure of fiber and composites [12], but the impact properties decline after increasing the DPF and decreasing the DPF. The interfacial bonding plays a vital role in impact properties, and morphology of DPF makes superior fibers for impact properties.

Figure 3: Effect of DPF/kenaf loading on impact strength of epoxy hybrid composites

As we know from the literature kenaf has better interfacial bonding than the DPF, and the impact properties matrix transfers the stress to the reinforced fibers to absorb the energy. Still, if interfacial bonding is weak, it hinders the transfer of stress, resulting in lower impact strength. In 7DP3K, the bonding is weak; due to this impact, strength is weak. In another case, strong interfacial bonding provide better interfacial bonding [51], 3DP7K has better interfacial bonding, but DPF is very less that could be the reason for lower impact properties. Several other reasons make natural fibre-reinforced composites weaker impact strength; debonding, pullout, and fractures of the fibers are the three basic mechanisms of energy absorption during impact test [2,52]. It is also assumed that the strain energy is due to fiber debonding, and fiber fracture is proportional to the debonded length [53].

This research investigated the mechanical and morphological properties of kenaf and DPF reinforced epoxy hybrid composites and confirmed that kenaf fibers loading improves the tensile properties of the DPF/Epoxy composites. It also shows that composites with DPF 30% display better mechanical properties as compared with other composites. The morphology of both fibers has huge differences such as density, anatomy, and chemical constituents, so the ratio is essential to optimize and found 30% DPF is the best fiber loading used to hybridize with kenaf fiber to fabricate hybrid composites. In SEM, 3DP7K did not show the void content and agglomeration of fibers; however, other fiber loading revealed the untouched matrix, which means fibers were agglomerated and there were void contents. The Impact properties of 1DP1K showed the highest shock absorbing composites which revealed that DPF worked as impact-resistant efficiently, the 7DP3K did not work well it may be due to the weaker interfacial bonding of the fiber and matrix of the composites, and 3DP7K showed lower impact strength despite better interfacial strength, is lower DPF content in composites. This composite can be used as a false wall, sound absorbing wall and false ceiling.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Geyer, R., Jambeck, J. R., Law, K. L. (2017). Production, use, and fate of all plastics ever made. Science Advances, 3(7), e1700782. DOI 10.1126/sciadv.1700782. [Google Scholar] [CrossRef]

2. Asim, M., Jawaid, M., Khan, A., Asiri, A. M., Malik, M. A. (2020). Effects of Date Palm fibres loading on mechanical, and thermal properties of Date Palm reinforced phenolic composites. Journal of Materials Research and Technology, 9(3), 3614–3621. DOI 10.1016/j.jmrt.2020.01.099. [Google Scholar] [CrossRef]

3. Liu, R., Peng, Y., Cao, J., Chen, Y. (2014). Comparison on properties of lignocellulosic flour/polymer composites by using wood, cellulose, and lignin flours as fillers. Composites Science and Technology, 103, 1–7. DOI 10.1016/j.compscitech.2014.08.005. [Google Scholar] [CrossRef]

4. Dabees, S., Kamel, B. M., Tirth, V., Alshalakny, A. B. (2020). Experimental design of AL2O3/MWCNT/HDPE hybrid nanocomposites for hip joint replacement. Bioengineeered, 11, 672–692. [Google Scholar]

5. Dabees, S., Tirth, V., Mohamed, A., Kamel, B. M. (2020). Wear performance and mechanical properties of MWCNT/HDPE nanocomposites for gearing applications. Journal of Materials Research and Technology, 1–13. DOI 10.1016/j.jmrt.2020.09.129. [Google Scholar] [CrossRef]

6. Mohamed, A., Tirth, V., Kamel, B. M. (2020). Tribological characterization and rheology of hybrid calcium grease with graphene nanosheets and multi-walled carbon nanotubes as additives. Journal of Materials Research and Technology, 9(3), 6178–6185. DOI 10.1016/j.jmrt.2020.04.020. [Google Scholar] [CrossRef]

7. Asim, M., Paridah, M. T., Chandrasekar, M., Shahroze, R. M., Jawaid, M. et al. (2020). Thermal stability of natural fibers and their polymer composites. Iranian Polymer Journal, 29, 625–648. [Google Scholar]

8. Jawaid, M., Khalil, H. A., Bakar, A. A., Hassan, A., Dungani, R. (2012). Effect of jute fibre loading on the mechanical and thermal properties of oil palm-epoxy composites. Journal of Composite Materials, 47(13), 1633–1641. DOI 10.1177/0021998312450305. [Google Scholar] [CrossRef]

9. Shahroze, R. M., Ishak, M. R., Salit, M. S., Leman, Z., Chandrasekar, M. et al. (2020). Sugar palm fiber/polyester nanocomposites: Influence of adding nanoclay fillers on thermal, dynamic mechanical, and physical properties. Journal of Vinyl and Additive Technology, 26(3), 236–243. DOI 10.1002/vnl.21736. [Google Scholar] [CrossRef]

10. Siakeng, R., Jawaid, M., Ariffin, H., Sapuan, S. (2018). Thermal properties of coir and pineapple leaf fibre reinforced polylactic acid hybrid composites. IOP Conference Series: Materials Science and Engineering, Selangor, Malaysia, 368, 012019. [Google Scholar]

11. Rout, J., Misra, M., Tripathy, S., Nayak, S., Mohanty, A. (2002). Surface modification of coir fibers. II. Cu (II)-IO initiated graft copolymerization of acrylonitrile onto chemically modified coir fibers. Journal of Applied Polymer Science, 84(1), 75–82. DOI 10.1002/app.10221. [Google Scholar] [CrossRef]

12. Ghori, W., Saba, N., Jawaid, M., Asim, M. (2018). A review on date palm (phoenix dactylifera) fibers and its polymer composites. IOP Conference Series: Materials Science and Engineering, Selangor, Malaysia, 368, 012009. [Google Scholar]

13. Mahdi, E., Sahari, B., Hamouda, A., Khalid, Y. (2001). An experimental investigation into crushing behaviour of filament-wound laminated cone-cone intersection composite shell. Composite Structures, 51(3), 211–219. DOI 10.1016/S0263-8223(00)00132-X. [Google Scholar] [CrossRef]

14. Goda, K., Sreekala, M., Gomes, A., Kaji, T., Ohgi, J. (2006). Improvement of plant based natural fibers for toughening green composites—Effect of load application during mercerization of ramie fibers. Composites Part A: Applied Science and Manufacturing, 37(12), 2213–2220. DOI 10.1016/j.compositesa.2005.12.014. [Google Scholar] [CrossRef]

15. Mahdi, E., Hamouda, A., Sahari, B., Khalid, Y. (2003). Effect of hybridisation on crushing behaviour of carbon/glass fibre/epoxy circular-cylindrical shells. Journal of Materials Processing Technology, 132(1–3), 49–57. DOI 10.1016/S0924-0136(02)00260-1. [Google Scholar] [CrossRef]

16. Mahdi, E., Hamouda, A., Sahari, B., Khalid, Y. (2003). Effect of residual stresses in a filament wound laminated conical shell. Journal of Materials Processing Technology, 138(1–3), 291–296. DOI 10.1016/S0924-0136(03)00087-6. [Google Scholar] [CrossRef]

17. Mahdi, E., Hamouda, A., Mokhtar, A., Majid, D. (2005). Many aspects to improve damage tolerance of collapsible composite energy absorber devices. Composite Structures, 67(2), 175–187. DOI 10.1016/j.compstruct.2004.09.010. [Google Scholar] [CrossRef]

18. Mahdi, E., Hamouda, A. (2012). Energy absorption capability of composite hexagonal ring systems. Materials & Design, 34(3), 201–210. DOI 10.1016/j.matdes.2011.07.070. [Google Scholar] [CrossRef]

19. Mahdi, E., Ochoa, D., Vaziri, A., Eltai, E. (2019). Energy absorption capability of date palm leaf fiber reinforced epoxy composites rectangular tubes. Composite Structures, 224(3), 111004. DOI 10.1016/j.compstruct.2019.111004. [Google Scholar] [CrossRef]

20. Mgbemena, C. O., Li, D., Lin, M. F., Liddel, P. D., Katnam, K. B. et al. (2018). Accelerated microwave curing of fibre-reinforced thermoset polymer composites for structural applications: A review of scientific challenges. Composites Part A: Applied Science and Manufacturing, 115(1), 88–103. DOI 10.1016/j.compositesa.2018.09.012. [Google Scholar] [CrossRef]

21. Nezhad, H. Y., Thakur, V. K. (2018). Effect of morphological changes due to increasing carbon nanoparticles content on the quasi-static mechanical response of epoxy resin. Polymers, 10(10), 1106. DOI 10.3390/polym10101106. [Google Scholar] [CrossRef]

22. Saba, N., Jawaid, M., Alothman, O. Y., Paridah, M., Hassan, A. (2015). Recent advances in epoxy resin, natural fiber-reinforced epoxy composites and their applications. Journal of Reinforced Plastics and Composites, 35(6), 447–470. DOI 10.1177/0731684415618459. [Google Scholar] [CrossRef]

23. Matykiewicz, D., Barczewski, M., Knapski, D., Skórczewska, K. (2017). Hybrid effects of basalt fibers and basalt powder on thermomechanical properties of epoxy composites. Composites Part B: Engineering, 125(6), 157–164. DOI 10.1016/j.compositesb.2017.05.060. [Google Scholar] [CrossRef]

24. Chruściel, J. J., Leśniak, E. (2015). Modification of epoxy resins with functional silanes, polysiloxanes, silsesquioxanes, silica and silicates. Progress in Polymer Science, 41, 67–121. DOI 10.1016/j.progpolymsci.2014.08.001. [Google Scholar] [CrossRef]

25. Abid, W., Magdich, S., Mahmoud, I. B., Medhioub, K., Ammar, E. (2018). Date palm wastes co-composted product: An efficient substrate for tomato (Solanum lycopercicum L.) seedling production. Waste and Biomass Valorization, 9(1), 45–55. DOI 10.1007/s12649-016-9767-y. [Google Scholar] [CrossRef]

26. Alsaeed, T., Yousif, B., Ku, H. (2013). The potential of using date palm fibres as reinforcement for polymeric composites. Materials & Design, 43(6), 177–184. DOI 10.1016/j.matdes.2012.06.061. [Google Scholar] [CrossRef]

27. Gheith, M. H., Aziz, M. A., Ghori, W., Saba, N., Asim, M. et al. (2019). Flexural, thermal and dynamic mechanical properties of date palm fibres reinforced epoxy composites. Journal of Materials Research and Technology, 8(1), 853–860. DOI 10.1016/j.jmrt.2018.06.013. [Google Scholar] [CrossRef]

28. Ali, M. E., Alabdulkarem, A. (2017). On thermal characteristics and microstructure of a new insulation material extracted from date palm trees surface fibers. Construction and Building Materials, 138(1), 276–284. DOI 10.1016/j.conbuildmat.2017.02.012. [Google Scholar] [CrossRef]

29. Malingam, S. D., Ng, L. F., Chan, K. H., Subramaniam, K., Selamat, M. Z. et al. (2018). The static and dynamic mechanical properties of kenaf/glass fibre reinforced hybrid composites. Materials Research Express, 5(9), 095304. DOI 10.1088/2053-1591/aad58e. [Google Scholar] [CrossRef]

30. Asim, M., Jawaid, M., Abdan, K., Ishak, M. (2018). The effect of silane treated fibre loading on mechanical properties of pineapple leaf/kenaf fibre filler phenolic composites. Journal of Polymers and the Environment, 26(4), 1520–1527. DOI 10.1007/s10924-017-1060-z. [Google Scholar] [CrossRef]

31. Bambach, M. (2017). Compression strength of natural fibre composite plates and sections of flax, jute and hemp. Thin-Walled Structures, 119(5), 103–113. DOI 10.1016/j.tws.2017.05.034. [Google Scholar] [CrossRef]

32. Asim, M., Jawaid, M., Saba, N., Nasir, M., Sultan, M. T. H. (2017). Processing of hybrid polymer composites—A review. Hybrid polymer composite materials, pp. 1–22. Elsevier. [Google Scholar]

33. Yusoff, R. B., Takagi, H., Nakagaito, A. N. (2016). Tensile and flexural properties of polylactic acid-based hybrid green composites reinforced by kenaf, bamboo and coir fibers. Industrial Crops and Products, 94, 562–573. DOI 10.1016/j.indcrop.2016.09.017. [Google Scholar] [CrossRef]

34. Shahroze, R. M., Ishak, M. R., Salit, M. S., Leman, Z., Asim, M. et al. (2018). Effect of organo-modified nanoclay on the mechanical properties of sugar palm fiber-reinforced polyester composites. BioResources, 13(4), 7430–7444. DOI 10.15376/biores.13.4.7430-7444. [Google Scholar] [CrossRef]

35. Asim, M., Jawaid, M., Abdan, K., Ishak, M. (2017). Effect of pineapple leaf fibre and kenaf fibre treatment on mechanical performance of phenolic hybrid composites. Fibers and Polymers, 18(5), 940–947. DOI 10.1007/s12221-017-1236-0. [Google Scholar] [CrossRef]

36. Agrebi, F., Hammami, H., Asim, M., Jawaid, M., Kallel, A. (2020). Impact of silane treatment on the dielectric properties of pineapple leaf/kenaf fiber reinforced phenolic composites. Journal of Composite Materials, 54(7), 937–946. DOI 10.1177/0021998319871351. [Google Scholar] [CrossRef]

37. Asim, M., Jawaid, M., Abdan, K., Ishak, M. R. (2016). Effect of alkali and silane treatments on mechanical and fibre-matrix bond strength of kenaf and pineapple leaf fibres. Journal of Bionic Engineering, 13(3), 426–435. DOI 10.1016/S1672-6529(16)60315-3. [Google Scholar] [CrossRef]

38. Saba, N., Alothman, O. Y., Almutairi, Z., Jawaid, M., Ghori, W. (2019). Date palm reinforced epoxy composites: Tensile, impact and morphological properties. Journal of Materials Research and Technology, 8(5), 3959–3969. DOI 10.1016/j.jmrt.2019.07.004. [Google Scholar] [CrossRef]

39. Jaafar, C. A., Zainol, I., Rizal, M. M., Sultan, U. (2018). Preparation and characterisation of epoxy/silica/kenaf composite using hand lay-up method. Proceedings of the 27th Scientific Conference of the Microscopy Society Malaysia (27th SCMSM 2018pp. 2–6. Melaka, Malaysia. [Google Scholar]

40. Saba, N., Paridah, M., Jawaid, M. (2015). Mechanical properties of kenaf fibre reinforced polymer composite: A review. Construction and Building Materials, 76, 87–96. DOI 10.1016/j.conbuildmat.2014.11.043. [Google Scholar] [CrossRef]

41. Asim, M., Jawaid, M., Abdan, K., Ishak, M., Alothman, O. (2018). Effect of hybridization on the mechanical properties of pineapple leaf fiber/kenaf phenolic hybrid composites. Journal of Renewable Materials, 6(1), 38–46. DOI 10.7569/JRM.2017.634148. [Google Scholar] [CrossRef]

42. Asim, M., Saba, N., Jawaid, M., Nasir, M. (2018). Potential of natural fiber/biomass filler-reinforced polymer composites in aerospace applications. Sustainable composites for aerospace applications, pp. 253–268. Elsevier. [Google Scholar]

43. Yahaya, R., Sapuan, S., Jawaid, M., Leman, Z., Zainudin, E. (2015). Effects of kenaf contents and fiber orientation on physical, mechanical, and morphological properties of hybrid laminated composites for vehicle spall liners. Polymer Composites, 36(8), 1469–1476. DOI 10.1002/pc.23053. [Google Scholar] [CrossRef]

44. Uma Devi, L., Bhagawan, S. S., Thomas, S. (2012). Polyester composites of short pineapple fiber and glass fiber: Tensile and impact properties. Polymer Composites, 33(7), 1064–1070. DOI 10.1002/pc.22217. [Google Scholar] [CrossRef]

45. Asim, M., Paridah, M., Jawaid, M., Nasir, M., Siakeng, R. (2019). Effects of nanoclay on tensile and flexural properties of pineapple leaf fibre reinforced phenolic composite. International Journal of Recent Technology and Engineering, 8, 473–476. [Google Scholar]

46. Idicula, M., Neelakantan, N., Oommen, Z., Joseph, K., Thomas, S. (2005). A study of the mechanical properties of randomly oriented short banana and sisal hybrid fiber reinforced polyester composites. Journal of Applied Polymer Science, 96(5), 1699–1709. DOI 10.1002/app.21636. [Google Scholar] [CrossRef]

47. Boopalan, M., Niranjanaa, M., Umapathy, M. (2013). Study on the mechanical properties and thermal properties of jute and banana fiber reinforced epoxy hybrid composites. Composites Part B: Engineering, 51(16), 54–57. DOI 10.1016/j.compositesb.2013.02.033. [Google Scholar] [CrossRef]

48. Agoudjil, B., Benchabane, A., Boudenne, A., Ibos, L., Fois, M. (2011). Renewable materials to reduce building heat loss: Characterization of date palm wood. Energy and Buildings, 43(2–3), 491–497. DOI 10.1016/j.enbuild.2010.10.014. [Google Scholar] [CrossRef]

49. Siakeng, R., Jawaid, M., Ariffin, H., Sapuan, S., Asim, M. et al. (2019). Natural fiber reinforced polylactic acid composites: A review. Polymer Composites, 40(2), 446–463. DOI 10.1002/pc.24747. [Google Scholar] [CrossRef]

50. Siakeng, R., Jawaid, M., Tahir, P. M., Siengchin, S., Asim, M. (2020). Improving the properties of pineapple leaf fibres by chemical treatments. Pineapple leaf fibers, pp. 55–71. Springer. [Google Scholar]

51. Manikandan, V., Jappes, J. W., Kumar, S. S., Amuthakkannan, P. (2012). Investigation of the effect of surface modifications on the mechanical properties of basalt fibre reinforced polymer composites. Composites Part B: Engineering, 43(2), 812–818. DOI 10.1016/j.compositesb.2011.11.009. [Google Scholar] [CrossRef]

52. Siakeng, R., Jawaid, M., Asim, M., Saba, N., Sanjay, M. et al. (2020). Alkali treated coir/pineapple leaf fibres reinforced PLA hybrid composites: Evaluation of mechanical, morphological, thermal and physical properties. Express Polymer Letters, 14(8), 717–730. DOI 10.3144/expresspolymlett.2020.59. [Google Scholar] [CrossRef]

53. Bax, B., Müssig, J. (2008). Impact and tensile properties of PLA/Cordenka and PLA/flax composites. Composites Science and Technology, 68(7–8), 1601–1607. DOI 10.1016/j.compscitech.2008.01.004. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |