Open Access

Open Access

ARTICLE

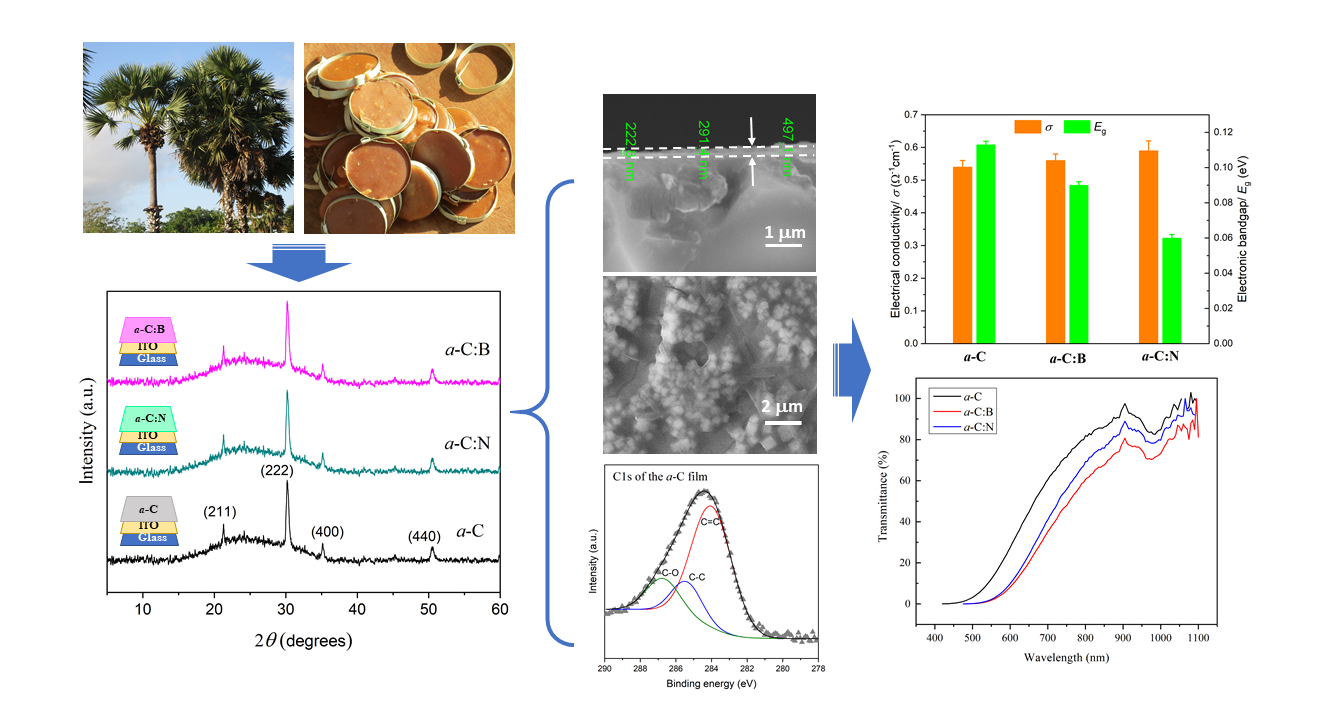

Hydrogenated Amorphous Carbon Films from Palmyra Sugar

1 Department of Physics, Faculty of Science and Data Analytics, Institut Teknologi Sepuluh Nopember, Kampus ITS Sukolilo, Surabaya, 60111, Indonesia

2 Departement of Electronic Engineering, Faculty of Engineering, Universitas Muhammadiyah Malang, Malang, Indonesia

3 Departement of Electronic Engineering, Faculty of Industrial Technology, Institut Teknologi Nasional Malang, Malang, Indonesia

4 Synchrotron Light Research Institute, Nakhon Ratchasima, 3000, Thailand

* Corresponding Authors: Budhi Priyanto. Email: ; Darminto. Email:

(This article belongs to the Special Issue: New Trends in Sustainable Materials for Energy Conversion, CO2 Capture and Pollution Control)

Journal of Renewable Materials 2021, 9(6), 1087-1098. https://doi.org/10.32604/jrm.2021.014466

Received 29 September 2020; Accepted 27 January 2021; Issue published 11 March 2021

Abstract

A simple, highly reproducible, and environmentally friendly method is a considered approach in generating renewable energy materials. Here, hydrogenated amorphous carbon (a-C) films have been successfully prepared from palmyra liquid sugar, employing spin-coating and spraying methods. Compared with the former method, the latter shows a significance in producing a better homogeneity in particle size and film thickness. The obtained films have a thickness of approximately 1000 to 100 nm and contain an sp2 hexagonal structure (~70%) and sp3 tetrahedral configuration (~30%) of carbons. The introduction of boron (B) and nitrogen (N) as dopants has created the local structural modification of bonding, inducing a slight change of electrical conductivity, electronic energy bandgap, and optical transparency near-infrared region. The obtained a-C film features a “green” semiconducting material.Graphic Abstract

Keywords

Cite This Article

Copyright © 2021 The Author(s). Published by Tech Science Press.

Copyright © 2021 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools