| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2021.014344

ARTICLE

Use of Scrapped Rubber Tires for Sustainable Construction of Manhole Covers

1Department of Urban and Infrastructure Engineering, NED University of Engineering and Technology, Karachi, 75270, Pakistan

2Department of Civil Engineering, NED University of Engineering and Technology, Karachi, 75270, Pakistan

*Corresponding Author: Afzal Ahmed. Email: afzalahmed@neduet.edu.pk

Received: 18 September 2020; Accepted: 25 November 2020

Abstract: Scrapped tires from vehicles are produced in large quantities. Despite numerous existing uses of scrapped tires, a large quantity ends up at the landfill sites, which contributes to environmental degradation. The development of more applications of scrapped tire usage can reduce the disposal of tires at landfill sites. This research proposes a novel use of scrapped tires by using the strips taken from scrapped tires in replacement of steel bars as reinforcement. Manhole covers were produced using scrapped tires by completely replacing the steel with scrapped tires. Four different samples of manhole covers were prepared and tested. The highest bearing capacity of 25.5 kN was recorded with a sample of 100 mm thickness made with cementitious composite, which is 2.25 times higher than the bearing capacity of a conventional reinforced-concrete manhole cover. The use of manhole covers made with scrapped tires can effectively address the theft issue of manhole covers. The lifecycle cost analysis shows that the manhole cover made with scrapped tires is 3.4 times more cost-effective in comparison with the conventional manhole cover. This research shows a new avenue of the potential use of scrapped tires as reinforcement in structures, which can improve sustainable construction practices.

Keywords: Scrapped tires; sustainability; manhole cover; waste management; recycling

Access to a personal vehicle is becoming a necessity. It is estimated that more than one billion passenger cars travel on the roads around the globe [1]. According to the US Bureau of Transportation Statistics, the total number of highway registered vehicles in the US in 2017 was 272 million vehicles [1]. 98.1 million vehicles were manufactured during 2018 around the world [2]. Tires are one of the essential parts of a motor vehicle and need replacement after a particular time. In 2019, the production of tires was estimated at 19.25 million tons, and it is expected to grow at 3.4% compound annual growth to 22.75 million tons by the end of 2024 [3].

Generally, the lifecycle of tires is classified into five main stages: Extraction, production, consumption, collection, and waste management of dislocated tires [4]. The necessary materials used in the modern methods of production of tires are rubber, steel, and fabric, along with other chemical compounds. The composition and production of tires are based on the vehicle for which tires are manufactured [5]. Continuous research is being carried out to improve the strength, durability, and recycling/ reuse of tires [6]

The continuous replacement of tires generates a large amount of scrapped tires globally. Around one billion worn-out tires reach the end of their life annually [7]. According to the Rubber Manufacturing Association (RMA), about 300 million scrap tires are produced annually in the United States. Out of these 300 million scrap tires, 40% tires are used in tire-derived-fuel (TDF), 26% are used in crumb rubber products, 5.5% are used for civil engineering applications, and 13% are dumped in landfills [3]. Civil engineering applications were the third-largest market for scrap tires in the US, consuming roughly 19 million tires in 2017, which is 14.9% higher than the consumption in 2015. In 2017, China had about 380 million waste tires, and this number increases by 6%–8% each year [8]. During 2013–2014, the total weight of waste tires in Australia was about 408,000 tons [9]. Presently in Australia, 20 million tires are disposed off each year and end up in landfill [10]. The United Kingdom produces around 55 million waste tires in a year [11]. Tens of millions of tires are wasted across the Middle East every year [12].

Among developing countries, India manufactures 650,000 tires and removes 275,000 tires from vehicles every day. It is estimated that every year about 300,000 tons of tires are imported into India for recycling and disposal [13]. In Bangladesh, 90,000 tons of waste tires are generated every year, which makes a significant part of the total wastes [14]. Approximately 400,000–600,000 tons of waste tires are generated each year in Thailand [15]. In South Africa, more than 300,000 tons of tires attain the end-of-life each year. Less than 20% are reprocessed, with 60 million kept at prohibited storage sites, where they pose a fire exposure and a breeding ground for mosquitos [16]. In Pakistan, around 300 tons of scrap rubber, including tires, are produced per month. Most of this trash is dumped into landfill sites. The trash is thrown away on the ground at landfill sites, which is not only hazardous for humans but also poses a severe risk to the environment [17]. According to the latest report, the solid waste generation increases by 2.4% each year in Pakistan [18].

As an outcome of increasing vehicle ownership, coupled with the growing road infrastructure in Pakistan, the tire market is expected to witness steady growth [19]. Pakistan’s rubber tire market size was valued at $272.1 million in 2017, and it is predicted to reach $1,592.9 million by 2025. In 2017, the highest contributor to the market was the radial type design segment, accounting for $207.7 million, and its value is expected to reach $1,196.4 million by 2025 [20].

Despite a lot of available applications of scrapped tires, most of the used tires are still dumped into landfill sites, especially in developing countries [21]. By the year 2030, around 1200 million overrun tires will be generated yearly [22]. This highlights the need to develop more applications to utilize the scrapped tires so that the burden on landfill sites may be reduced while increasing the use of recycled material in construction activities [23]. The sustainable construction practices have been the prime focus of policymakers around the globe, which requires minimum consumption of natural resources and considers the development of practices based on environmental and economic sustainability. Utilization of scrapped tires in new applications will contribute to the existing share of recycling and re-utilization of scrapped tires, which will reduce the burden on the landfill sites and reduce dependency on raw material [24].

Nowadays, using scrap tires as construction materials in civil engineering is of increasing interest. Tires can be classified as low weight, relatively compressible with low thermal conductivity, and can be easily chopped into small pieces, which make tires suitable for various civil engineering applications. Complete scrap tires have been used as culverts, retaining walls, and for slope and beach stabilization. The shredded tires have been used as highway embankments, horizontal drains, ravine crossings, lightweight backfill, and roadbed support [25]. Other applications of used tires include rubber modified asphalt pavements, rubberized Portland cement concrete, crash barriers, lightweight fillers, bumpers, and artificial reefs [26].

Extensive research has been carried out to study the use of crumb rubber obtained from scrap tires in concrete, construction materials, and other civil engineering applications. Sgobba et al. [27] used rubber particles from recycled tires waste in place of crushed stones, which are used as fillers in the concrete mixture. The study concluded that the rubber aggregates from scrapped tires could be used in the replacement of crushed stones, which also resulted in lightweight concrete and ultimately reduced the dead weight of the structure. Thomas et al. [22] studied the effect of adding rubber crumb derived from scrap tires as partial replacement of natural fine aggregates. The study concluded that the compressive strength, flexural tensile strength, and pull-off strength of rubber-modified concrete were less than the control mix. Guo et al. [28] further highlighted that the use of crumb rubber particles from scrap tires might result in the loss of compressive strength of concrete due to stiffness and the problems arising due to the bonding of cement paste with rubber crumbs. The study suggested the treatment of rubber crumb with a particular chemical improves the strength of rubber-modified concrete. The study also concluded that the use of rubber-modified concrete reduces thermal conductivity and noise transmission, which improves the energy efficiency of the building [28]. Youssf et al. [29] used rubber modified concrete made by replacing sand with rubber crumbs derived from scrapped tires and concluded that the use of crumb rubber concrete along with fibre-reinforced polymers neutralizes the loss of strength due to adding rubber crumbs. Yilmaz et al. [30] explored the possibility of using tire rubber crumbs with fly ash and cement. The effect of using rubber crumbs in different proportions was studied along with varying proportions of fly ash. Various other studies have also explored the properties of rubber crumb concrete [31−36]. Strukar et al. [37] provide a comprehensive overview of studies published on rubber-modified concrete till 2019. Liu et al. [38] evaluated the engineering properties and environmental impacts of adding recycled rubber tires to improve the geotechnical properties of the rubber-sand mixture. The thermal conductivity of sand-rubber mixture is affected by adding rubber particles [39]. The addition of recycled rubber grains in rubber-sand mixture reduces its modulus of compression [40]. The review of studies on rubber-modified concrete concludes that the use of rubber in concrete improves the ductility and energy absorption of concrete, which makes it more useful for earthquake resistant structures.

Rubber crumbs derived from scrap tires are also used in asphalt pavements and road construction. Heitzman [41] described the procedure and framework for using rubber crumbs in asphalt pavement. Junior et al. [42] suggested that scrap tire rubber has the potential to replace styrene-butadiene-styrene (SBS), which is one of the most commonly used materials in asphalt roads. Another study suggested using microwave treated crumb rubber, which improves the properties of rubber-asphalt blend [43]. Numerous other studies have also studied the possibility of using rubber crumbs from scraped tires in road construction [44−48].

Sewerage manholes are one of the essential components of urban infrastructure, which are usually provided along the roadsides. Open manholes are among the problems faced by the commuters and municipal authorities in various developing countries, including Pakistan. The open manhole affects the flow of traffic and road safety of commuters. Furthermore, manholes without a cover on local streets pose a severe threat to pedestrians and kids playing on the streets. In different cities of Pakistan, various incidents involving children and other pedestrians have been reported when the victim fell in the open manhole causing deaths or severe injuries. The problem gets even worse during the rainy season, as the roads fill up with murky water, and pedestrians are unable to see the open manholes [49]. In India, due to fall in pits and open manholes, five people die every day [50]. More than 70 injuries or deaths were reported in China due to open or damaged manhole covers during 2017–19, which motivated authorities to introduce the death penalty for stealing or damaging a manhole cover [51]. The theft of manhole covers is one of the primary reasons resulting in open manholes.

Theft of manhole covers is a global problem, and the practice can be noticed in several megacities such as Mumbai, Chicago, and many others. The stolen manhole covers are sold in the market due to the scrap value of these covers. A single manhole cover with frame is a heavyweight iron material and can be sold for cash in the scrap market. The theft of manhole covers can be reduced by the replacement of steel with a material that reduces its scrap value [52]. Therefore, one of the main objectives and contribution of this research is to prepare manhole cover with the least scrap value along with improving sustainable construction practices and reducing the burden of scrapped tires on landfill sites. This research paper proposes a new application of utilizing strips of scrapped rubber tires as a replacement of steel in casting manhole covers, which can be extended to other structural applications.

Different types of manhole cover available around the globe include manhole covers made from cast iron, ductile cast iron (high strength), plastic, fibre-reinforced plastic, steel fibre reinforced concrete, and composite manhole covers [53]. The selection of a particular manhole cover type depends on various factors, including usage, expected loading on the manhole cover, drainage requirement, and the type of land use/road. Most of the manhole covers used in Pakistan are Reinforced Concrete (RC), which use concrete and steel as the sole materials.

In this study, various tests on the performance of scrapped rubber tires as replacement of steel are carried out to determine the strength, ductility, and behaviour when subjected to load. This information is then applied to produce manhole covers using concrete as a compression member and scrap rubber tire strips and pieces as tension members instead of steel reinforcements. In contrast to the existing literature, this research proposed new use of scrap tires by replacing steel in manhole covers with strips made from scrap tires, which will have the following benefits:

• The salvage value of manhole cover will be reduced, thus preventing its theft.

• Sustainable construction practice will be encouraged by inventing a new application of scrapped tire usage.

• The impact of scrapped tires on landfill sites and the environment may be reduced by more utilization of scrapped tires in making manhole covers.

• This research opens a new avenue of research applications of scrapped tires in replacement of steel bar reinforcements. Various other products can be made using the procedure described in this paper.

2 Materials and Their Proportions

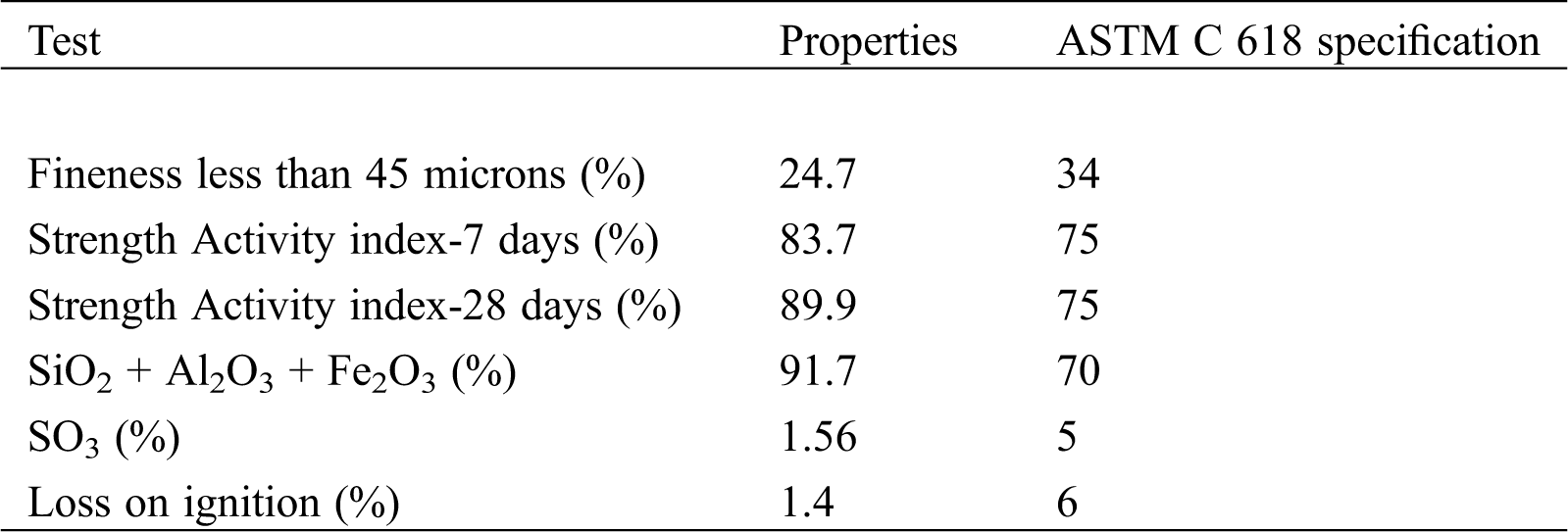

The experimental program is based on the investigation of materials suitable the casting and testing of the manhole cover. Ordinary Portland cement qualifying the ASTM Type I specification [54] was used for the casting of the manhole cover. Pozzocrete 40 (P40) fly ash was used. The physical and chemical properties of P40 fly ash are given in Tab. 1, which conforms to ASTM C 618 Class F fly ash [55] as a partial cement replacing the material.

Table 1: Physical and chemical properties of P40 fly ash (source matrixx Co.)

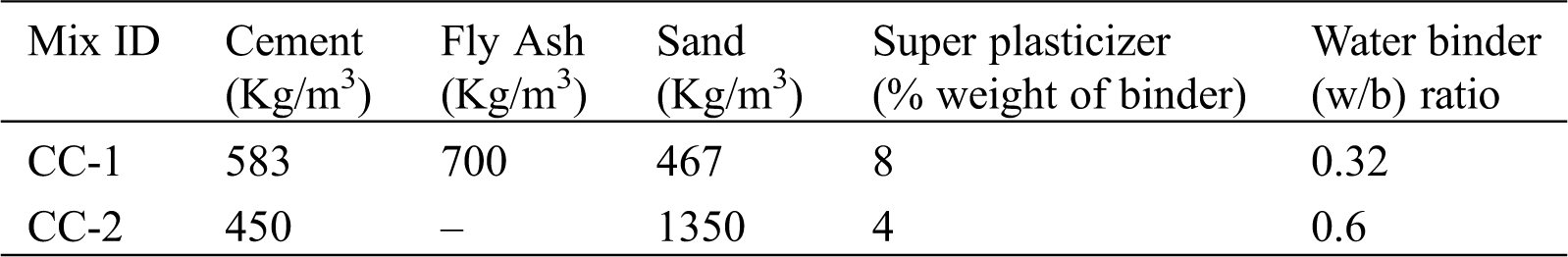

Sand passing through #50 sieve and retained on #200 sieve was utilized. The finer sand was used to ensure the homogeneous cement paste, which is needed to improve the bonding of the rubber with cement paste. The homogeneous cement paste with finer sand was required so that it can flow through the gaps between rubber strips. Two different mix proportions were explored, as shown in Tab. 2. One of the mixes (CC-1) has higher binder content, while the other mix (CC-2) has a lesser binder. The reason was to ensure higher economy by minimizing the use of cement and good bonding of rubber with the cement paste.

Table 2: Mix proportions of cement-sand mortars

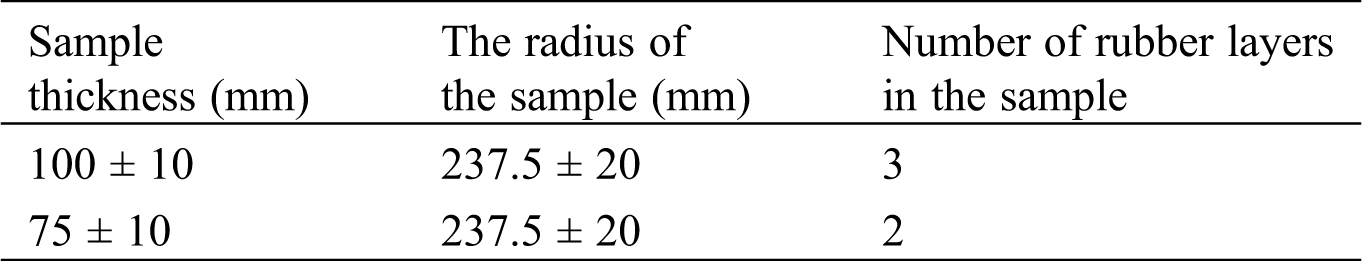

The rubber tires strips were used to replace the steel reinforcements in manhole covers. Eight manhole cover molds were prepared for casting. Four of the manhole covers were 100 mm thick, while the other four were 75 mm in thickness. Two samples of 100 mm and two from 75 mm thickness were cast with cement-sand mortar. The dimension of each type of sample was calculated, as shown in Tab. 3.

Table 3: Manhole cover specimens size

3 Preparation of Mold Frame and Rubber Strips

This section describes the procedure employed in this research to use scrape rubber tire in a manhole cover.

3.1 Tensile Strength of Strips from the Tire

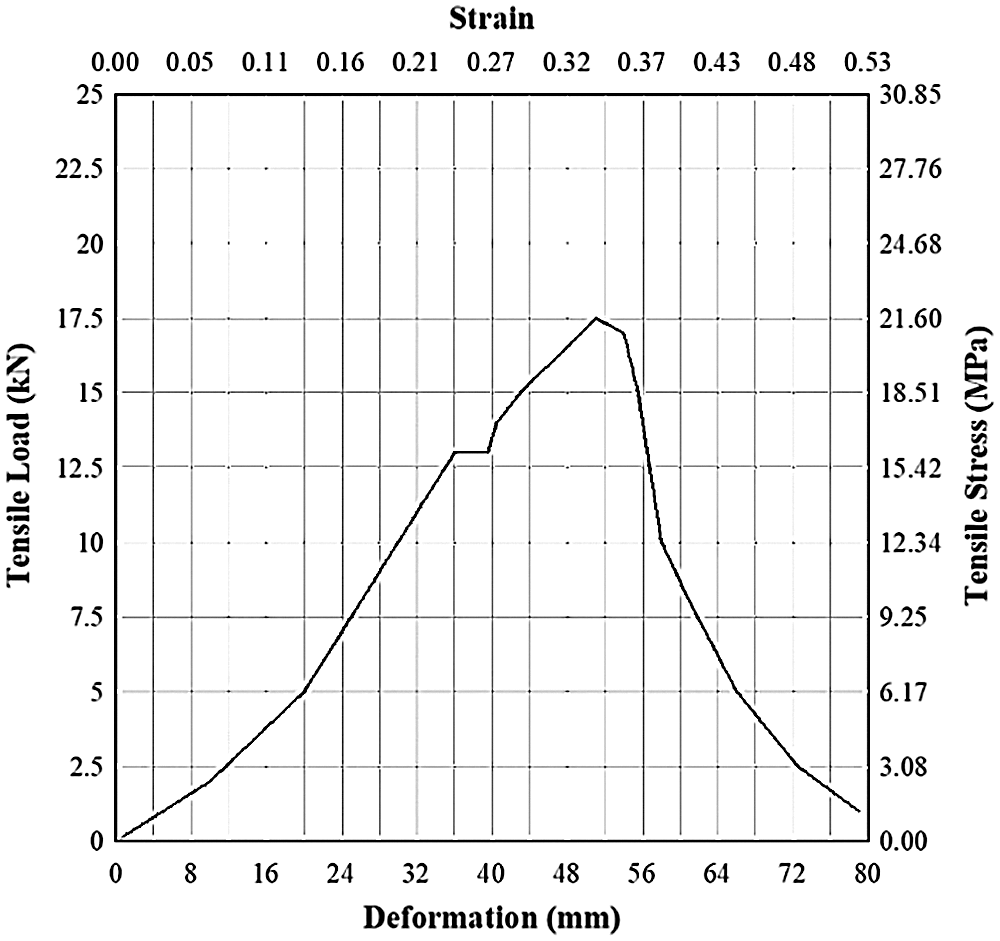

Longitudinal strips from scrap tires are used in the replacement of steel bars. Therefore, it was essential to test the tensile strength of the strips. For this purpose, a rectangular strip of 300 × 60 × 12 mm was sliced from the tread portion of a rubber tire and was tested in Universal Testing Machine (UTM) under tension. The sample is shown in Fig. 1.

Figure 1: Tread sample for tensile strength test

The rectangular sample was placed in the loading unit of Universal Testing Machine by attaching one end of it to the upper crosshead while the other end to the lower crosshead. Once the sample was clamped between the crossheads, the tensile load was applied from the control unit at a speed of 1 kN/min. The crossheads kept pulling the sample from both sides until signs of cracks were shown on the sample’s surface. The load-deformation and stress-strain response under direct tension are shown in Fig. 2. The tread sample kept on bearing tensile load and was able to bear a tensile load of 17.38 kN (20.5 MPa) until cracks started appearing on the surface, and the clamps of UTM start marking scratches on the sample ends.

Figure 2: Load-deformation response of scrapped tire under tension

The value of tensile strength obtained from the test shows that the strips from tire have significantly lower values than the tensile strength of the ordinary steel reinforcement, which is at least 280 MPa of yield strength. Therefore, it was concluded that more quantity of tire strips than the number of steel bars would be used. Thus, more than one layer of strips from rubber tires are required to achieve the strength required in the manhole cover. However, this will not increase the cost of manhole cover, as the strips from scrap tires are very cheap.

3.2 The Frame of a Manhole Cover

The diameter of the conventional manholes in Pakistan is usually sized from 450 mm to 500 mm. The use of car tires as frame is a feasible option, as car tire has the same outer diameter as the manhole of common streets in Pakistan and other countries. The tires of larger or smaller size can be used to fit the size of different manhole diameter by cutting the tire tread and adding the required length from another tire to obtain the required diameter. The conventional manhole covers are made in a steel frame with steel bars. The manhole cover prepared in this research was with the aim that the steel is completely removed. Therefore, the frame of the manhole cover was also made with a scrapped tire that can fit inside a 500 mm manhole. For this purpose, a tubeless tire with an internal diameter of 300 mm was selected, as its external diameter is around 500 mm. A tire has three different material components in it, which are tread, sidewall, and beads, as shown in Fig. 3. Tread is the contact part of a tire, which provides traction and bears the entire load applied to it. It is made of hard synthetic rubber embedded with thin steel wires to form the basic structure of it. This part, due to being the toughest one, was utilized to be arranged in different formats to place in a manhole cover as the reinforcement.

Figure 3: Tire composition [56]

The entire experiment was conducted at the Material Testing Laboratory under the supervision of authors. Tubeless tires, because of steel wires and steel belts in their layers, are hard materials to cut. So, an electric disc grinder having an equally strong blade was used for this purpose. Since the tread of the selected car tire has a width of 150 mm, whereas the required height of the mold frame has to be between 75–100 mm. Therefore, the tread portion of the tire was reduced to frames of two different sizes, one 75 mm and the other 100 mm to make the mold frame. In addition to making a mold frame, the strips are also extracted from the tire. The reinforcement strips were obtained by cutting long strips from the tread part of the scrapped tire. The steps followed for making the mold, and rubber strips are shown in Fig. 4.

Figure 4: Preparation of rubber strips and rubber mold frame for the casting of a manhole cover (a) Cutting of tire for separating tire tread (b) Tire tread (c) Cutting of tread through a grinder for rubber strips (d) Rubber strip used (e) Rubber tire mold for manhole with rubber strips (f) Orthogonal/Hash orientation of rubber strips in the mold

After cutting of tires into molds and strips, the next step was the placement of strips in the mold. For this purpose, a hash pattern was used to place the strips in the tire frame, as shown in Fig. 4. The longitudinal strips were placed in multiple layers, to provide the cover with maximum strength, as the strips from scrapped materials do not cost any significant amount. Five strips were placed in a layer. The mold frame with 100 mm height could afford three layers of tire strips, and the mold with 75 mm could take two layers of strips, as shown in Figs. 4e and 4f. After placing the strips in a hash pattern in the mold frame, the holes were made on both ends of the strips as well as on the edges of the mold frame through a drill machine. Thin steel wires were used to connect strips to the mold by passing the wires through the strips and mold. The strips were connected and placed in such a way that some gap was left between each layer and among consecutive strips so that cement-sand paste can be poured into the frame.

As shown in Figs. 4e and 4f, the strips in the mold occupy a lot of space, leaving very little room for concrete to be poured. Due to this lack of space between layers, it was necessary to use cement sand mortar without the coarse aggregates. In addition, self-compacting behaviour was also required to ensure that the mortar is adequately filled all around the rubber strips. The materials and their proportion used for cement sand mortar are discussed in the following section.

4 Mixing, Casting, and Curing of Specimens

This research followed IS 12592 standard for the casting of manhole cover [57]. All the dry ingredients were mixed in a pan mixer, as shown in Fig. 5. A pan mixer homogeneously combines cement, aggregate, and water to form mortar paste. The cauldron rotates horizontally around its axis inside the mixer to combine the components. Before pouring the mortar into the mold, scrap plastic was placed at the bottom surface and on the edges of the mold, as shown in Fig. 5c. The wrapping was done with the help of duct tape to avoid leakage of mortar while pouring. After these arrangements, the mortar mix was then poured into the mold with scrap rubber tire to cast a manhole cover, as shown in Fig. 5d. Along with the Manhole cover, three cylinders of 100 mm diameter and 200 mm length were also cast to check the compressive strength of cement-sand mortar as per ASTM C39 [58]. After 24 h of casting, specimens were cured in an open water tank for 28 days. Once the curing period was completed, both ends of the cylinders were capped with the sulfur compound to ensure the uniform distribution of the compressive load between cylinder and machine, as recommended in ASTM C 469 [59]. The details of the tests performed, and their results are as follows:

Figure 5: Mixing, casting and curing of specimens (a) All ingredients and mold for manhole cover (b) Pan mixer used (c) Inverted mold showing plastic for casting (d) Manhole cover sample after casting (e) Cylinder specimens (f) Curing of specimen

The response of cylinder specimens under compression was carried by using Universal Testing Machine (UTM) as per ASTM C39 [57] with a loading rate of 0.5 mm/min. The testing setup of the cylinder is shown in Fig. 6. The deformation under load was measured through a linear variable differential transducer (LVDT) on the gauge length of 100 mm. Two LVDTs, one to check horizontal deformation and the other for vertical deformation, were placed. The stress-strain curves of cylinders were acquired, and the maximum compressive stress and corresponding strain values were determined.

Figure 6: Cylinders tested under compression

After the casting and curing, the samples were tested for their strength and load capacity in Universal Testing Machine. A supporting frame was designed to provide support to the samples of manhole covers during the testing using UTM, as shown in Fig. 7. The frame served as a support for the samples, providing space underneath the sample and holding it from the edges only. The frame was designed, keeping in view the dimensions of the manhole covers. The dimensions of the steel frame used in the test are also shown in Fig. 7. The steel frame was inserted inside the UTM after placing the specimen of the manhole cover. A concentrated point load was applied at the centre of the cover by the upper crosshair of the UTM with a speed of 0.5 kN/min until the sample failed. The conventional manhole covers were also tested for their load capacity. The load capacity of conventional manhole covers made with steel reinforcements was compared with the load capacity of the cover made with scrapped tires.

Figure 7: Supporting frame and testing of the manhole cover

6.1 The Response of Cylinders under Compression

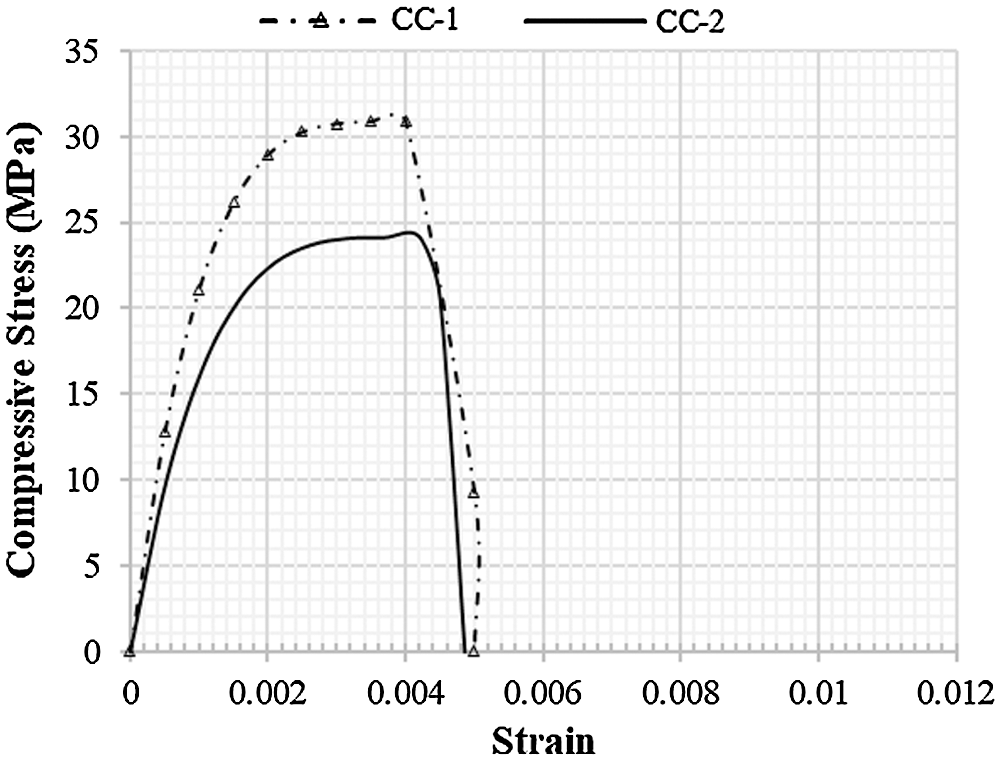

The stress-strain response under compression of mix CC-1 and CC-2 is shown in Fig. 8. The compressive strength of CC-1 and CC-2 is 31.2 MPa and 24.3 MPa, respectively, which is evident as the cement content was high in the mix CC-1. The strain at peak stress is almost the same, which is approximately equal to 0.004, which is slightly higher than the ordinary concrete.

Figure 8: Stress Strain response under compression

6.2 The Response of Manhole Covers under Bending

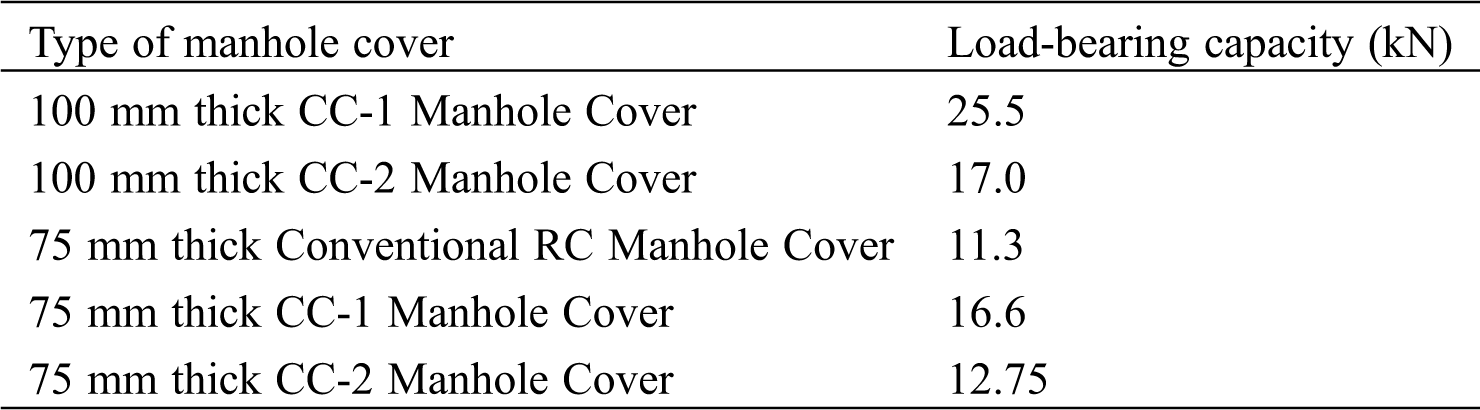

The load-deformation responses of all manhole covers under bending were recorded, and the responses were plotted, as shown in Fig. 9. The maximum load of 25.5 kN was observed to be sustained by the manhole cover of 100 mm thickness, which was made of mix CC-1 having three layers of rubber strips. Other than this manhole cover, the rest of the samples could sustain the load in the range of 12.75 to 17 kN. The maximum load taken by all different test samples is shown in Tab. 4. A conventional RC manhole cover purchased from the market was also tested to compare the performance of manhole covers made with scrapped tires. The load-deformation response of the conventional manhole covers is also shown in Fig. 9, which shows that RC manhole cover could take a maximum load of 11.3 kN.

Figure 9: Load-deformation response of manhole covers under bending

Table 4: Comparison between load-bearing capacities of manhole covers

The comparison of the load-bearing capacity of various manhole covers made with the scrapped tire shows that the load-bearing capacities of all the manhole covers made with scrapped tires were higher than the RC-based conventional manhole cover. The load-bearing capacity of RC conventional manhole covers was 11.3 kN, whereas, the least load-bearing capacity of the manhole cover made with scrapped tires was 12.76, which is 10% higher than the conventional RC manhole cover. The highest load-bearing capacity was observed for the manhole cover sample of 100 mm thick and cast with CC-1 mix, which is 2.25 times higher than the conventional RC cover.

The above load test results show that the use of scrap rubber tires in manhole cover is a workable option to replace steel reinforcement because the load-bearing capacities of the manhole covers made with scrapped tires are significantly higher than the RC manhole cover. Thus, all the options that were explored in this study can be used in the replacement of conventional RC manhole covers.

This research study introduces the promising reuse of scrap rubber tires for sustainable and feasible construction practice. In addition, the problem of open manhole and theft of RC manhole covers can also be addressed by manhole cover reinforced with scrap rubber tires. This is one of the solutions to addressing the theft of RC manhole cover and metal covers as the load-carrying capacity of scrap rubber tire cover is significantly higher. Theft problem of a conventional manhole cover is due to the steel rebar used as the reinforcement, which has the salvage value. The proposed manhole cover has scrapped rubber tire as reinforcement, and thus no salvage value. The proposed manhole cover is easily distinguished by rubber tire at the outer circumferential surface of the cover. Furthermore, the proposed covers once used on a large scale will diminish the theft problem with the awareness of the fact that there is no steel reinforcement inside. Thus, the solution of the epidemic of stealing manhole covers using alternative materials to metal such as scrap tire and concrete composite is proving to be a solution. The gases generated from the municipal drains, specifically hydrogen sulfide (H2S) is poisonous and can cause a health risk when exposed to these gases through open manholes. These gases also cause deterioration of metal covers and the corrosion to the embedded steel in RC manhole covers that consequently require replacement with new cover after a certain period. Additionally, the manhole covers are also exposed to water and sewerage water ponding due to inadequate drainage facilities and overflow of sewage. The exposure of conventional RC manhole covers to water and sewage also reduces the life of cover due to corrosion of steel [60]. This is not going to be an issue with scrap tire and concrete composite cover.

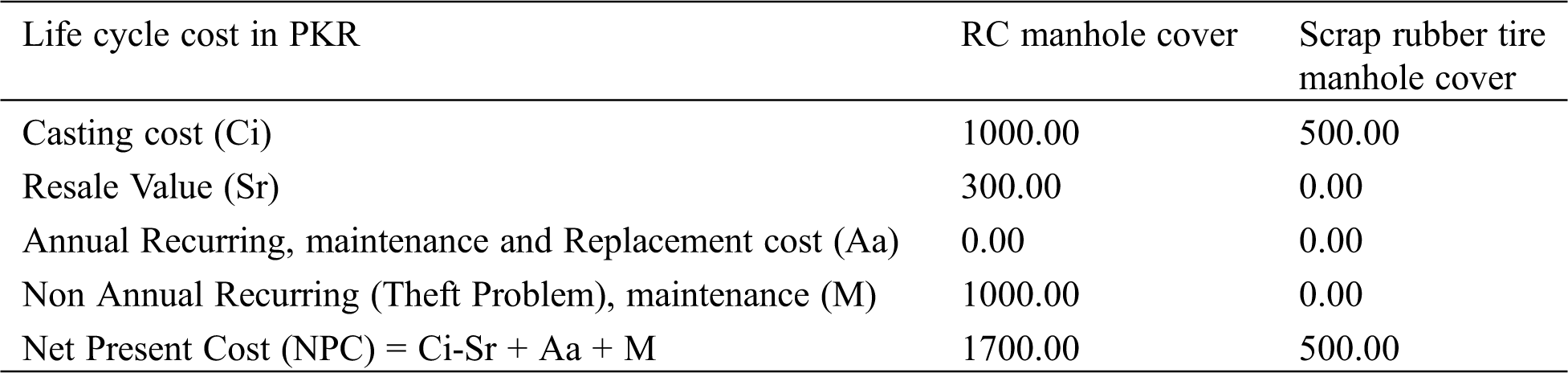

Tab. 5 shows the assessment of the life cycle cost of RC manhole cover and scrap rubber tire manhole cover based on the net present value method, which is one of the widely used methods for economic evaluation [61]. The life cycle cost analysis presented in Tab. 5 assumes a life of 10-years for both types of manhole covers. Furthermore, it is assumed that the manhole cover made with scrapped tires will not be stolen, whereas the RC manhole cover is stolen once in its life cycle on average. The analysis shows that the net present cost of scrap rubber tire manhole cover is PKR 500, which is 3.4 times lower than the conventional covers.

Table 5: Comparison of life cycle cost

7 Conclusions and Recommendations

This research proposes a novel use of scrapped rubber tires and adds a unique application of using scrapped rubber tires in sustainable construction practices. In contrast to the existing use of tires in construction, which is mainly used as rubber crumbs (filler in place of natural aggregates), this research proposes the use of tire strips as tension members in replacement of steel bars. This research opens a new avenue in the domain of sustainable construction practices by showcasing a novel application of scrapped rubber tires. The strips taken from scrapped tires taken from cars were tested for tensile strength, which was observed as 17.38 kN. The strips taken from scrapped tires can be used in other products and applications.

The theft of manhole covers is a significant problem, which results in open manholes on the streets. The manhole covers are stolen due to the salvage value of frame and rebars of steel in the conventional RC manhole covers. This research proposed to completely replace the steel frame and bars in the process of casting manhole covers with the frame made of tire’s tread portion and strips also taken from tread portion of a tire. The use of scrapped rubber tires in place of steel in manhole covers reduces the salvage value of the manhole covers, thus tackling the theft issue of manhole covers.

The manhole covers were prepared with two different depths (75 mm and 100 mm) using two different mixes (CC-1 and CC-2). The manholes covers were tested for their bearing load capacity. The 100 mm manhole cover prepared with CC-1 mixture was recorded with the highest laod-bearing capacity of 25.5 kN. A conventional RC manhole cover was also tested using UTM. The RC manhole cover could take a load of 11.3 kN. The comparison of load-bearing capacities of the conventionally used RC manhole cover with the manhole covers made with scrapped tires shows that the manhole covers prepared with the scrapped tires have the potential of replacing conventional RC manhole covers. The comparison of the lifecycle cost analysis of RC manhole cover with the scrapped tire based manhole cover shows that the scrapped tire based manhole cover costs 3.4 times lesser than the RC manhole cover. Thus, the scrap tire based manhole covers are economical and viable replacement of the conventional manhole covers.

This research is first of its nature to propose the use of scrap tires as tensile members in structures. This study is mainly focused on the strength of materials and load-bearing capacity of manhole cover prepared using scrap tires. However, long-term studies, such as fatigue and durability, are recommended for future endeavours. More extensive tests can be carried out to find out the tensile strengths of different types of scrapped tires. The type and quality of material used in a tire may also affect the tensile strength of the strips taken from a scrapped tire, which needs further investigation. Furthermore, the time for which a tire is used in a vehicle and the condition of the tire when it is taken out from the vehicle may also affect the strength achieved from the scrapped tire, which can be further studied in detail. Furthermore, the resistance to environmental conditions of scrap tires based manhole covers can be tested in future.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Woldometer. (2020). Cars produced this year. https://www.worldometers.info/cars/. [Google Scholar]

2. Number of U.S. Aircraft, Vehicles, Vessels, and Other Conveyances. (2020). https://www.bts.gov/content/number-us-aircraft-vehicles-vessels-and-other-conveyances. [Google Scholar]

3. EVANS, R. (2019). Global tire manufacturing output to grow 3.4% year-on-year. https://www.tiretechnologyinternational.com/news/business/global-tire-manufacturing-output-to-grow-3-4-year-on-year.html. [Google Scholar]

4. Presti, D. L. (2013). Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Construction and Building Materials, 49, 863–881. DOI 10.1016/j.conbuildmat.2013.09.007. [Google Scholar] [CrossRef]

5. Ganjian, E., Khorami, M., Maghsoudi, A. A. (2009). Scrap-tyre-rubber replacement for aggregate and filler in concrete. Construction and Building Materials, 23(5), 1828–1836. DOI 10.1016/j.conbuildmat.2008.09.020. [Google Scholar] [CrossRef]

6. End-of-Life Tires (ELTs) (2019). A framework for effective management systems. https://www.etrma.org/wp-content/uploads/2019/09/appendices-a-framework-for-effective-elt-management-systems-final-25.6.10.pdf. [Google Scholar]

7. Leblanc, R. (2018). The importance of tire recycling. https://www.thebalancesmb.com/the-importance-of-tire-recycling-2878127. [Google Scholar]

8. Scott, E. (2019). Chinese tyre group doublestar invests in smart pyrolysis plant. https://www.tyreandrubberrecycling.com/latest-news/posts/2019/march/doublestar-invests-in-pyrolysis/. [Google Scholar]

9. Mountjoy, E., Hasthanayake, D., Freeman, T. (2015). Stocks & fate of end of life tyres-2013-14 study. National Environmental Protection Council, Melbourne, Australia. [Google Scholar]

10. Thackray, L. (2019). Recycling plant gains environmental approval to give end-of-road tyres new life as oil, steel and carbon. https://www.abc.net.au/news/2019-06-02/recycling-australias-tyre-piles/11169386. [Google Scholar]

11. 2010 to 2015 Government Policy: Waste and Recycling. (2015). https://www.gov.uk/government/publications/2010-to-2015-government-policy-waste-and-recycling/2010-to-2015-government-policy-waste-and-recycling. [Google Scholar]

12. Zafar, S. (2019). Tire recycling in Middle East (Disposal of Waste Tires). https://www.ecomena.org/tag/tire-recycling-in-middle-east/. [Google Scholar]

13. Aggarwal, M. (2019). Control import of waste tyres into India, NGT tells pollution board. [Google Scholar]

14. Aziz, M. A., Rahman, M., Molla, H. (2019). Design, fabrication and performance test of a fixed bed batch type pyrolysis plant with scrap tire in Bangladesh. Journal of Radiation Research and Applied Sciences, 11(4), 311–316. DOI 10.1016/j.jrras.2018.05.001. [Google Scholar] [CrossRef]

15. Connor, K., Cortesa, S., Issagaliyeva, S., Meunier, A., Bijaisoradat, O. et al. (2013). Developing a sustainable waste tire management strategy for Thailand. Worcester, Massachusetts: Worcester Polytechnic Institute. [Google Scholar]

16. Linnenkoper, K. (2019). South Africa invests in tyre tech from Down Under. https://recyclinginternational.com/rubber/south-africa-invests-in-tyre-tech-from-down-under/28041/. [Google Scholar]

17. Wahid, W. (2019). Change waste to wealth. https://nation.com.pk/30-Jul-2019/change-waste-to-wealth. [Google Scholar]

18. Malik, S. (2019). Pakistan’s waste problem is a recycling industry waiting to be found. https://www.dawn.com/news/1505436. [Google Scholar]

19. Pakistan Tyre Market Forecast and Opportunities, 2020. (2015). https://www.techsciresearch.com/report/pakistan-tyre-market-forecast-and-opportunities-2020/180.html. [Google Scholar]

20. Pakistan Rubber Tyre Market Report 2019: Opportunity Analysis & Industry Forecast, 2018–2025. (2019). https://www.businesswire.com/news/home/20190930005514/en/Pakistan-Rubber-Tyre-Market-Report-2019-Opportunity. [Google Scholar]

21. Krunk, K. (2016). Top 20 countries that are used as dumping grounds of the world’s trash. http://www.atchuup.com/countries-used-as-dumping-grounds-of-worlds-trash/. [Google Scholar]

22. Thomas, B. S., Gupta, R. C. (2016). Properties of high strength concrete containing scrap tire rubber. Journal of Cleaner Production, 113, 86–92. DOI 10.1016/j.jclepro.2015.11.019. [Google Scholar] [CrossRef]

23. Kordoghli, S., Paraschiv, M., Kuncser, R., Tazerout, M., Prisecaru, M. et al. (2016). Managing the environmental hazards of waste tires. Journal of Engineering Studies and Research, 20(4), 1–11. DOI 10.29081/jesr.v20i4.52. [Google Scholar] [CrossRef]

24. Sommerville, S. J. (2014). Viability of using recycled automotive tyre rubber as aggregate in concrete. Bachelor of Engineering (4th Year Project). Charles Darwin University. [Google Scholar]

25. Yang, S. (1999). Use of scrap tires in civil engineering applications. Retrospective Theses and Dissertations. [Google Scholar]

26. Shu, X., Huang, B. (2014). Recycling of waste tire rubber in asphalt and portland cement concrete: An overview. Construction and Building Materials, 67, 217–224. DOI 10.1016/j.conbuildmat.2013.11.027. [Google Scholar] [CrossRef]

27. Sgobba, S., Marano, G. C., Borsa, M., Molfetta, M. (2010). Use of rubber particles from recycled tires as concrete aggregate for engineering applications. 2nd International Conference on Sustainable Construction Materials and Technologies. Ancona, Itlay. [Google Scholar]

28. Guo, S., Dai, Q., Si, R., Sun, X., Lu, C. (2017). Evaluation of properties and performance of rubber-modified concrete for recycling of waste scrap tire. Journal of Cleaner Production, 148, 681–689. DOI 10.1016/j.jclepro.2017.02.046. [Google Scholar] [CrossRef]

29. Youssf, O., Hassanli, R., Mills, J. E. (2017). Mechanical performance of FRP-confined and unconfined crumb rubber concrete containing high rubber content. Journal of Building Engineering, 11, 115–126. DOI 10.1016/j.jobe.2017.04.011. [Google Scholar] [CrossRef]

30. Yilmaz, A., Degirmenci, N. (2009). Possibility of using waste tire rubber and fly ash with Portland cement as construction materials. Waste Management, 29(5), 1541–1546. DOI 10.1016/j.wasman.2008.11.002. [Google Scholar] [CrossRef]

31. Wang, J., Dai, Q., Si, R., Guo, S. (2019). Mechanical, durability, and microstructural properties of macro synthetic polypropylene (PP) fiber-reinforced rubber concrete. Journal of Cleaner Production, 234, 1351–1364. DOI 10.1016/j.jclepro.2019.06.272. [Google Scholar] [CrossRef]

32. Záleská, M., Pavlík, Z., Čítek, D., Jankovský, O., Pavlíková, M. (2019). Eco-friendly concrete with scrap-tyre-rubber-based aggregate–Properties and thermal stability. Construction and Building Materials, 225, 709–722. DOI 10.1016/j.conbuildmat.2019.07.168.

33. Gerges, N. N., Issa, C. A., Fawaz, S. A. (2018). Rubber concrete: Mechanical and dynamical properties. Case Studies in Construction Materials, 9, e00184. DOI 10.1016/j.cscm.2018.e00184.

34. He, L., Ma, Y., Liu, Q., Mu, Y. (2016). Surface modification of crumb rubber and its influence on the mechanical properties of rubber-cement concrete. Construction and Building Materials, 120, 403–407. DOI 10.1016/j.conbuildmat.2016.05.025.

35. Xie, J., Fang, C., Lu, Z., Li, Z., Li, L. (2018). Effects of the addition of silica fume and rubber particles on the compressive behaviour of recycled aggregate concrete with steel fibres. Journal of Cleaner Production, 197, 656–667. DOI 10.1016/j.jclepro.2018.06.237.

36. Asutkar, P., Shinde, S., Patel, R. (2017). Study on the behaviour of rubber aggregates concrete beams using analytical approach. Engineering Science and Technology, an International Journal, 20(1), 151–159. DOI 10.1016/j.jestch.2016.07.007. [Google Scholar] [CrossRef]

37. Strukar K., Kalman Šipoš T., Miličević I., Bušić R. (2019). Potential use of rubber as aggregate in structural reinforced concrete element–A review. Engineering Structures, 188, 452–468. DOI 10.1016/j.engstruct.2019.03.031. [Google Scholar] [CrossRef]

38. Liu, L., Cai, G., Zhang, J., Liu, X., Liu, K. (2020). Evaluation of engineering properties and environmental effect of recycled waste tire-sand/soil in geotechnical engineering: A compressive review. Renewable and Sustainable Energy Reviews, 126, 109831. DOI 10.1016/j.rser.2020.109831. [Google Scholar] [CrossRef]

39. Liu, L., Cai, G., Liu, X. (2020). Investigation of thermal conductivity and prediction model of recycled tire rubber-sand mixtures as lightweight backfill. Construction and Building Materials, 248, 118657. DOI 10.1016/j.conbuildmat.2020.118657. [Google Scholar] [CrossRef]

40. Liu, L., Cai, G., Liu, S. (2018). Compression properties and micro-mechanisms of rubber-sand particle mixtures considering grain breakage. Construction and Building Materials, 187, 1061–1072. DOI 10.1016/j.conbuildmat.2018.08.051. [Google Scholar] [CrossRef]

41. Heitzman, M. (1992). Design and construction of asphalt paving materials with crumb rubber modifier. Transportation Research Record. 1339, 1–8. [Google Scholar]

42. de Almeida Júnior, A. F., Battistelle, R. A., Bezerra, B. S., de Castro, R. (2012). Use of scrap tire rubber in place of SBS in modified asphalt as an environmentally correct alternative for Brazil. Journal of Cleaner Production, 33, 236–238. DOI 10.1016/j.jclepro.2012.03.039. [Google Scholar] [CrossRef]

43. Yu, G. X., Li, Z. M., Zhou, X. L., Li, C. L. (2011). Crumb rubber–modified asphalt: microwave treatment effects. Petroleum Science and Technology, 29(4), 411–417. DOI 10.1080/10916460903394102. [Google Scholar] [CrossRef]

44. Wang, H., You, Z., Mills-Beale, J., Hao, P. (2012). Laboratory evaluation on high temperature viscosity and low temperature stiffness of asphalt binder with high percent scrap tire rubber. Construction and Building Materials, 26(1), 583–590. DOI 10.1016/j.conbuildmat.2011.06.061. [Google Scholar] [CrossRef]

45. Ding, X., Ma, T., Zhang, W., Zhang, D. (2017). Experimental study of stable crumb rubber asphalt and asphalt mixture. Construction and Building Materials, 157, 975–981. DOI 10.1016/j.conbuildmat.2017.09.164.

46. Wang, Q. Z., Wang, N. N., Tseng, M. L., Huang, Y. M., Li, N. L. (2020). Waste tire recycling assessment: Road application potential and carbon emissions reduction analysis of crumb rubber modified asphalt in China. Journal of Cleaner Production, 249, 119411. DOI 10.1016/j.jclepro.2019.119411.

47. Gong, F., Guo, S., Chen, S., You, Z., Liu, Y. et al. (2019). Strength and durability of dry-processed stone matrix asphalt containing cement pre-coated scrap tire rubber particles. Construction and Building Materials, 214, 475–483. DOI 10.1016/j.conbuildmat.2019.04.151.

48. Zhang, J., Xu, G., Gong, M., Yang, J. (2018). Laboratory research on fatty acid based biobinder as an addition for crumb rubber modified asphalt. Transportation Research Congress 2016: Innovations in Transportation Research Infrastructure, pp. 127–140. Reston, VA: American Society of Civil Engineers. [Google Scholar]

49. Karim, B. M. (2019). Missing manhole covers. https://tribune.com.pk/letter/2006149/6-missing-manhole-covers. [Google Scholar]

50. Dash, D. K. (2012). Five die every day due to fall in pits, manholes. http://toi.in/Y3g9mb/a24gk. [Google Scholar]

51. Allen, K. (2020). Manhole cover thieves ’may get death sentences’ in China. BBC News. https://www.bbc.com/news/blogs-news-from-elsewhere-52400235. [Google Scholar]

52. Raza, A. (2018). Wasa to place fiberglass manhole covers to stop theft. https://www.thenews.com.pk/print/339759-wasa-to-place-fiberglass-manhole-covers-to-stop-theft. [Google Scholar]

53. Rahman, F. U. (2019). Materials used for manhole construction. https://theconstructor.org/practical-guide/how-to-construct-manhole/40241/. [Google Scholar]

54. C150/C150M. (2001). Standard specification for Portland cement. Annual book of ASTM standards. Philadelphia, PA: ASTM. [Google Scholar]

55. ASTM. (2000). Standard specification for coal fly ash and raw or calcined natural pozzolan for use as a mineral admixture in concrete. ASTM International, USA. [Google Scholar]

56. Nakao, Y., Yamamoto, K. (2002). Waste tire recycle and its collection system. Nippon Steel Technical Report, (86), 21–24. [Google Scholar]

57. Standard, I. (2002). Precast Concrete Manhole Cover and Frame—Specification. IS 12592: 2002. [Google Scholar]

58. ASTM. (2012). Standard test method for compressive strength of cylindrical concrete specimens, pp. 20−24. ASTM, USA. [Google Scholar]

59. ASTM. (2001). Standard test method for static modulus of elasticity and Poisson’s ratio of concrete in compression. ASTM, USA. [Google Scholar]

60. Delaunois, F., Tosar, F., Vitry, V. (2014). Corrosion behaviour and biocorrosion of galvanized steel water distribution systems. Bioelectrochemistry, 97, 110–119. DOI 10.1016/j.bioelechem.2014.01.003. [Google Scholar] [CrossRef]

61. El-Nashar, W. Y. (2017). Effect of drains coverings on environment by using value engineering. Alexandria Engineering Journal, 56(3), 327–332. DOI 10.1016/j.aej.2017.05.013. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |