Journal of Renewable Materials

Journal of Renewable Materials

Journal of Renewable Materials Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2021.014610

ARTICLE

Test and Analysis of the Sound Insulation Performance of Four Types of Timber Structure Floors under Jumping Excitation

1College of Materials Science and Engineering, Nanjing Forestry University, Nanjing, 210037, China

2College of Mechanical and Electronic Engineering, Nanjing Forestry University, Nanjing, 210037, China

3College of Civil Engineering, Tongji University, Shanghai, 200092, China

4College of Civil Engineering, Nanjing Forestry University, Nanjing, 210037, China

*Corresponding Author: Zheng Wang. Email: wangzheng63258@163.com

Received: 12 October 2020; Accepted: 04 December 2020

Abstract: To improve the impact sound insulation performance of building floors and meet the objective requirements for living comfort of residents, in this article, three kinds of elastic cushion materials, Portuguese cork board, BGL insulation sound insulation foam board, and EPP polypropylene plastic foam board, are applied to the sound insulation of a light frame wood floor structure of the same bedroom and compared to the ordinary floor. This study uses the transfer function method and transient excitation method to measure the sound insulation, damping ratio, and elastic modulus of materials, as well as the sound insulation of the floor under the jumping excitation method of daily behavior. Through comparative analysis, the results and factors of improving the sound insulation performance of the floor are obtained, according to which three types of elastic cushion materials and the floor covering composed of them have higher vibration and noise reduction performance. Among them, the overall sound insulation performance of BGL board floor is the highest, followed by EPP board and cork board floor, and ordinary OSB floor is the lowest. Under the jumping excitation method, three floating floors can improve the impact sound insulation performance of the middle and low-frequency bands.

Keywords: Timber floor structure; elastic cushion material; damping ratio; elastic modulus; jumping excitation method of daily behavior; testing and comparative analysis

The optimal design of floor sound insulation for light wood frame structures is the key to ensuring the comfort of the upper and lower floors of the building, as well as an important factor for measuring the healthy lifestyle of residents and ensuring the quality of life. In terms of experimental research on building floor materials and structures, foreign experts and scholars have made abundant research on floor sound insulation [1−4]. At the same time, it is easy to cause contradictions between neighboring households, directly affect people’s mental state, and seriously affect people’s physical and mental health [5]. Sang et al. [6] uses two standardised impact sources (tapping machine and impact ball) and six real sound sources (the footsteps of adults and children and the dropping of objects) measured sound pressure levels on four different lightweight floor configurations. In the AcuWood project, different noise sources were recorded in different field situations and subjectively evaluated by performing laboratory listening tests [7]. However, studies have shown that the physiological response of noise to the human body has nothing to do with the type of noise source [8]. Since the frequency, damping ratio, and other dynamic characteristics of materials are closely related to the impact sound insulation performance of the floor structure, and the damping effect of the glued material is provided by glue. New materials such as cork board, graphite molded polystyrene board (BGL), and expanded polypropylene board (EPP) are widely used and favored by many industries such as construction and indoor decoration. At present, the largest and second main production areas of the world’s cork resources are Portugal and Qinling area in China, and in 2019 alone, the sales volume of Portuguese cork in China reached nearly 50,000 m2. The cork, which is commonly used for wine bottle corks, is formed by a hexagonal stacking of its cell structure. It has the following qualities such as light weight, sound insulation, heat insulation, moisture resistance, flame retardancy, high dimensional stability, no formaldehyde, renewability, recyclability, and many other advantages of natural materials. It can also improve comfort and beauty on a practical basis. As sustainability becomes one of the major priorities in architecture, engineering and construction (AEC) sector, renewable materials like timber, bamboo and other bio-composite materials are widely used in various fields [9]. Over the past decade, an enormous research has been done and new trends, such as fiber reinforced polymer-to-wood (FRP-to-wood) connections [10] and steel timber composite (STC) connection systems [9], have been developed and studied to provide a reference for sustainable engineering applications. Recently, bamboo has also become one of the main materials in structural applications, and its performance is also very good [9,11,12]. Various types of engineered bamboo materials, such as scrimber [11] and laminated bamboo [9], have been investigated and have better mechanical performance compared with other green building materials. According to the latest research, renewable cork materials have shown excellent sound insulation properties [13,14]. And oriented strand board (OSB) has been proved that it was an effective technical member to improve the flexural bearing capacity of wood truss used to the floor [15]. In 1999, Carvalho et al. [16] conducted on-site measurement experiments on the impact sound insulation performance of cork polymer materials placed under linoleum, ceramic tiles, and wooden floors based on the concrete floor structure. The research has shown that adding a cork layer can increase the standardized impact sound pressure level of floor weighting by 18–25 dB, and a prediction formula determined by statistical analysis is given. In 2015, the National Research Centre of Testing Techniques for Building Materials measured the air sound insulation of Portuguese AMORIM cork board with a size of 500 mm × 1000 mm × 30 mm, and its weighted sound insulation reached 20 dB. As a simple, practical, and effective measure to improve the sound insulation of floors, floating floors have been used in residential buildings that require high sound insulation. In the floating floor structure, the elastic cushion material includes mineral wool felt, rubber sheet, glass fiberboard, etc.; there are also new foaming materials such as BGL board, EPP board, etc., which can effectively reduce the transmission of impact noise energy in the floor. For example, in 2014, Yoo et al. [17] used the finite element (FEM) method and field measurement method to study the impact of elastic vibration isolators and viscoelastic damping materials on reducing the heavyweight ground impact sound of reinforced concrete structures. And in 2019, Qiu Wei studied the reinforced concrete floating floor with BGL thermal and sound insulation system. By analyzing the causes of cracks on the concrete protective layer, the overall sound insulation performance of the floor was improved. Damping is the structure material to absorb the vibration energy emitted by the seismic source, especially to prevent the internal structure resonance effect caused by the vibration wave, and thus achieve the vibration reduction effect. However, the elastic modulus reflects one of the most important and characteristic mechanical properties of elastic materials and is an indicator of the ability of materials to resist elastic deformation.

For this reason, according to ISO 10534-2 and ISO 140-7, this article intends to apply elastic cushion materials from Portuguese cork board, BGL board, EPP board, in the design of three types of sound insulation of the floor structures in the same bedroom of a light wood frame construction. And the sound insulation performance of the ordinary OSB floor covering is compared. By carrying out dynamic tests on the damping ratio and elastic modulus parameters of related materials, as well as the sound insulation test and analysis of the floor under the jumping excitation method of daily behavior, it is possible to promote the application of new elastic cushion materials in the timber structure industry. It is expected that this study will provide a reference for improving the optimization design and application of the sound insulation structure of the light frame wood floor systems.

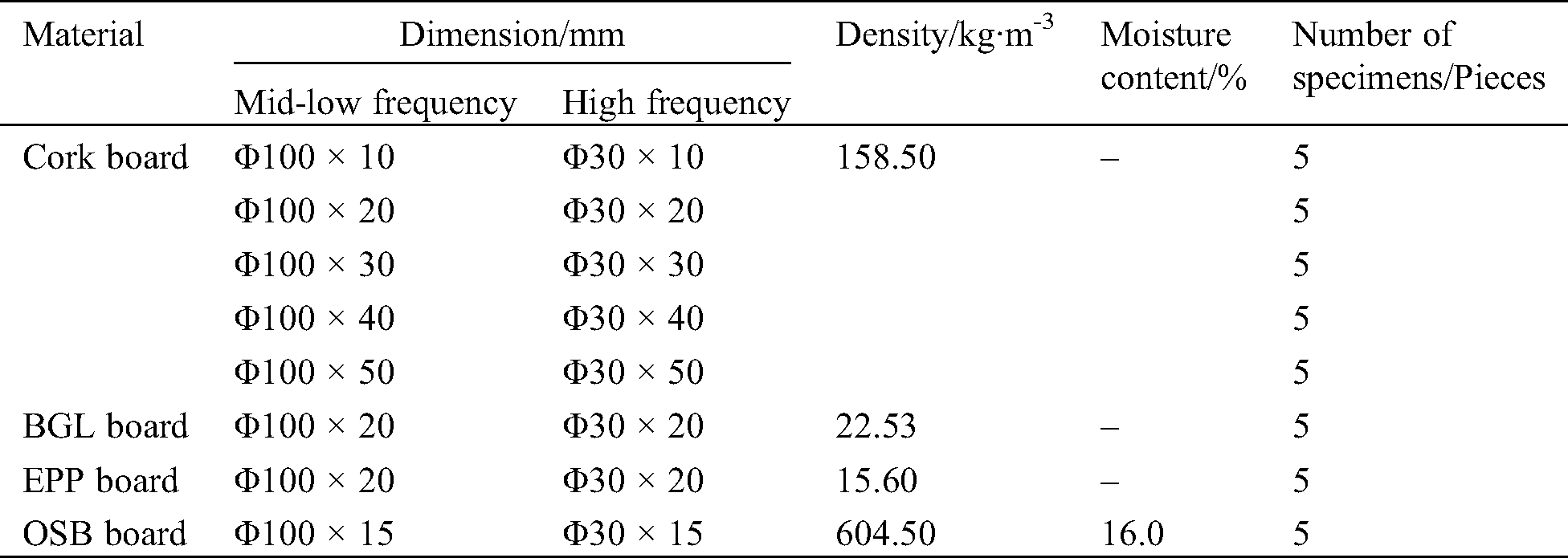

2.1.1 Specimens for Sound Insulation Test

Table 1: Basic parameters of the specimens

Three elastic cushion materials used in the structure of the floor and OSB material are taken as test specimens with a diameter of 100 mm for the mid-low frequency (below 1600 Hz) range; the specimens with a diameter of 30 mm are used for the high frequency (1600–6300 Hz) range. Basic parameters of the specimens are shown in Tab. 1.

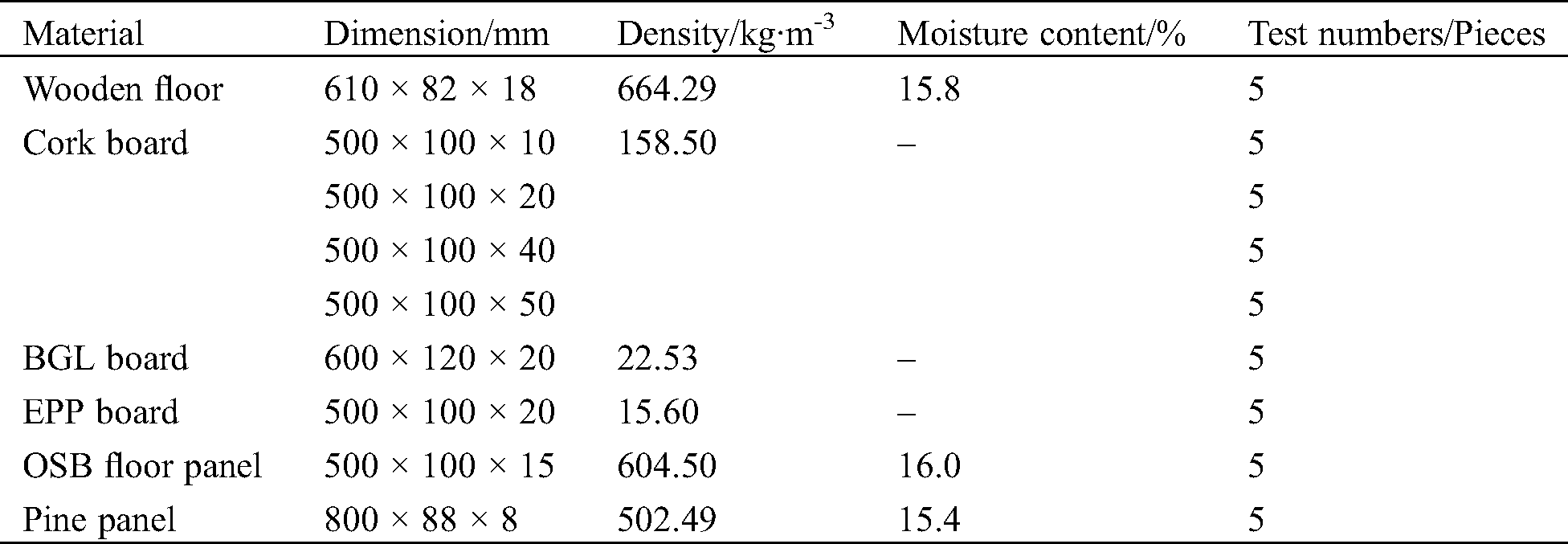

2.1.2 Specimens for Determining the Material Damping Ratio and Elastic Modulus Parameters

Specifications of the structural material specimens are shown in Tab. 2.

Table 2: Specifications of the structural material specimens

2.1.3 Four Types of Floor Structures Have Been Developed to Test the Sound Insulation under the Jumping Excitation Method of Daily Behavior

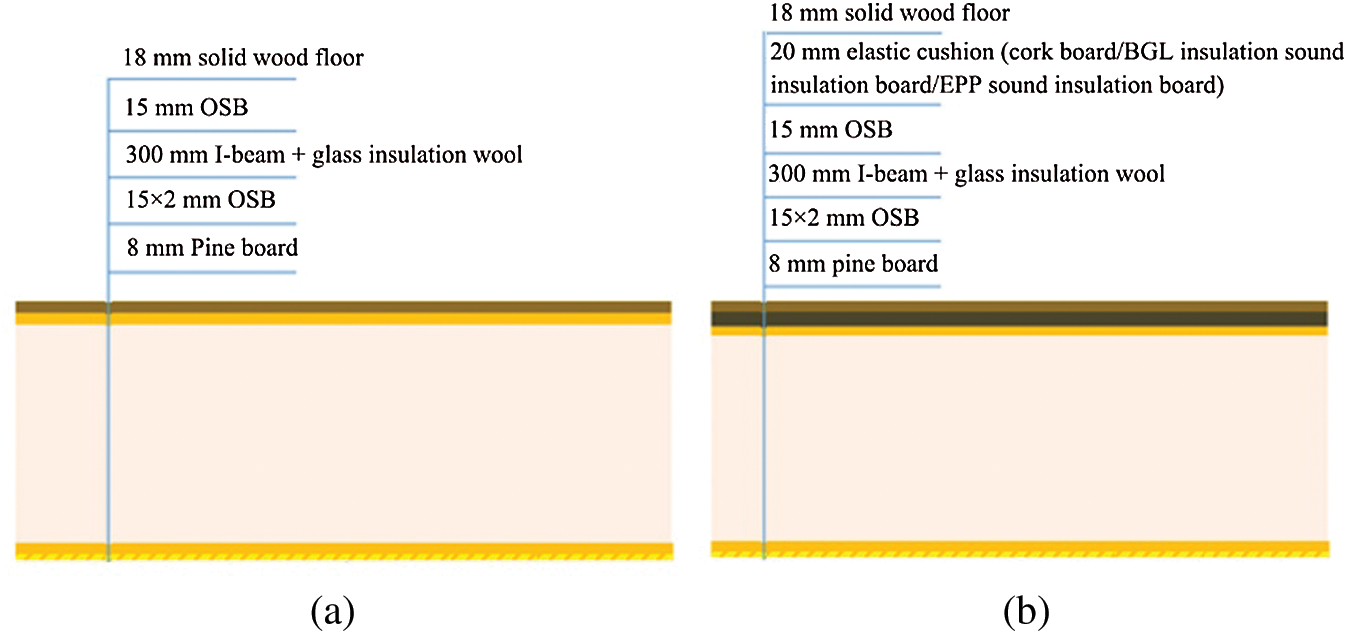

The object of this research is a two-story light wood frame construction with a 9 m2 bedroom on the second floor. The four types of floor structures include one type of ordinary floor and three types of a floating floor. The three types of floating floor are constructed by adding three different elastic cushions between the floor slab and the floor covering. They are cork board floating floor, BGL board floating floor, and EPP board floating floor. The floor structure is shown in Fig. 1.

Figure 1: Schematic diagram of four types of light wood framing floor structures (a) Ordinary floor (b) Floating floor

BSWA SW422 510045 impedance tube. The large and small pipe diameters 100 mm and 30 mm, which are used for medium and low-frequency and high-frequency tests, respectively. Supporting equipment include sound level channel calibrator, digital-to-analog converter, BSWA TECH power amplifier, BSWA TECH signal generator, signal receiver, and VA-Lab test and analysis system; DYM3 barometer, indoor thermometer, and hygrometer; CRAS vibration and dynamic signal acquisition and analysis system; CA YD-125 piezoelectric acceleration sensor; TES1350B sound level meter; AWA6221A sound level calibrator; HK 30 wood moisture tester; TG328B electro-optical analytical balance (0.1 g); bench vise; rubber hammer; steel tape measure (0–5 m); vernier caliper (0–150 mm).

2.3 Testing Principle and Main Steps

2.3.1 Material Sound Insulation Test

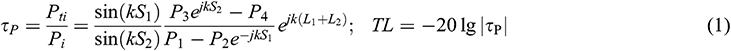

The test was carried out in the laboratory. According to ISO 10534-2, the four-microphone method based on transfer function theory is used to measure the sound insulation of cork board, BGL board, EPP board, and OSB board [15−17]. The test principle diagram is shown in Fig. 1. The P1 and P2 measured in channel 1 and channel 2 are represented by incident sound pressure Pi and reflected sound pressure Pr, respectively, and the material sound insulation, sound pressure transmission coefficient, and transmission sound pressure are represented by  ,

,  and Pti, respectively.

and Pti, respectively.

Figure 2: Principle of sound insulation measurement based on the four-microphone method

The main test steps: The instrument was connected and the specimen was placed according to Fig. 2; A channel calibration was performed through VA-Lab before testing, and the channel sensor was placed in the calibrator for calibration; After setting the parameters of a medium frequency-large tube (100 mm), high-frequency-small tube (30 mm) and sample thickness t (m), the transfer function test method was adopted, and the sound insulation cycle test was performed alternately with and without back cover. Finally, the material sound insulation results and graphs were obtained.

2.3.2 Material Dynamic Characteristic Test

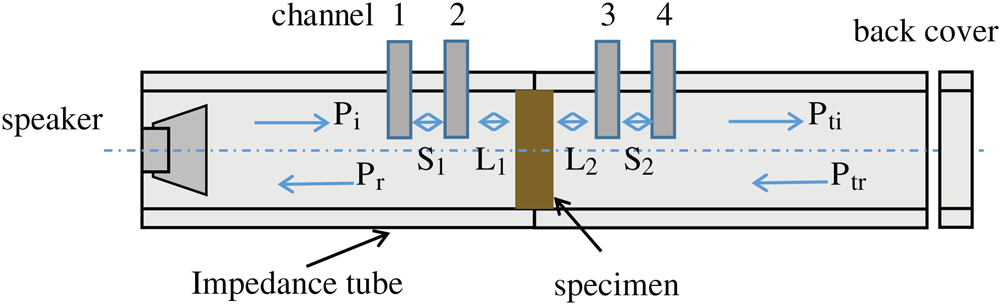

The test was carried out in the laboratory. The transient excitation method was used to test the damping ratio and elastic modulus of cork boards, BGL boards, EPP boards, and OSB boards. The main test principle: the free beam specimen was hit with a hammer to obtain its time-domain spectrum and frequency spectrum. Then the calculation of the logarithmic reduction coefficient  and the damping ratio

and the damping ratio  was made through the time domain spectrum [16,17]. Finally, the elastic modulus E was calculated through its first-order bending frequency value f1:

was made through the time domain spectrum [16,17]. Finally, the elastic modulus E was calculated through its first-order bending frequency value f1:

where, ρ – the air-dry density of the test material, in kg·m-3; l–the length of the test material, in mm; h–the thickness of the test material, in mm.

Figure 3: Schematic diagram of free plate vibration method for testing the elastic modulus

The main test steps: According to Fig. 3, the freeboard support mode was set, the instrument was connected, and the accelerometer was placed on the centerline of the first end of the board; Then a hammer was used to hit the corresponding corner position of the other end to identify the first-order bending frequency value and the elastic modulus E of the material was calculated.

2.3.3 Sound Insulation Test of the Floor under Jumping Excitation Method of Daily Behavior

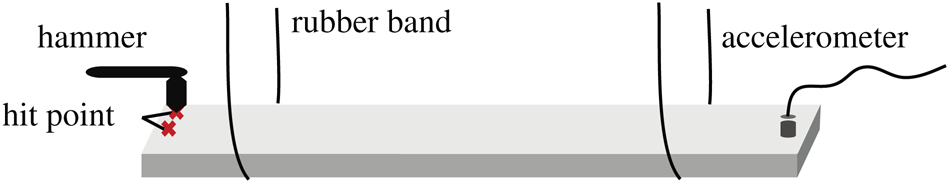

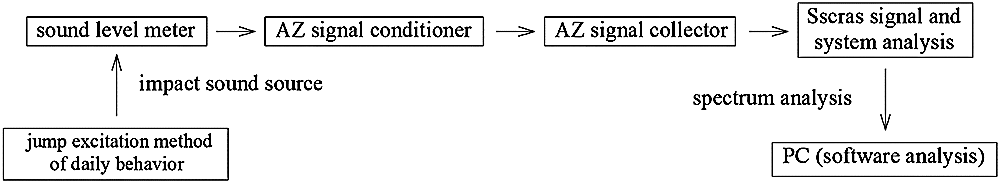

The test was carried out in the field situations. Jumping is one of the most common activities in life. And the adult jumping is classified as a heavyweight shock source. For this reason, the transient excitation method was used to measure the impact sound insulation of four types of floor slabs in the jumping mode under the condition of closed doors and windows and to study their impact sound insulation characteristics. The flowchart of the test is shown in Fig. 4.

Figure 4: The flowchart of standard impact sound test

Figure 5: Schematic diagram of a single jump

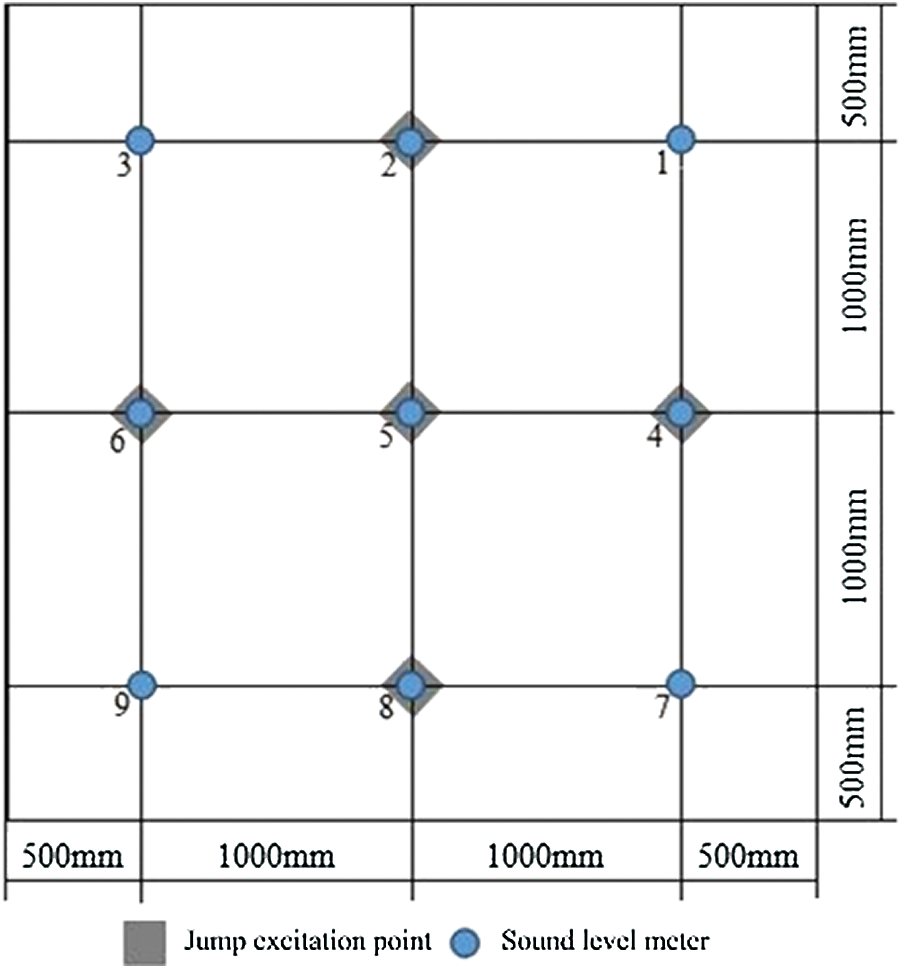

Figure 6: Plan view of the impact point and sound level meter location for a single jump

In the actual measurement, the expression of weighted average impact sound pressure level L in the room under test is:

The expression of impact sound improvement ΔL is:

The main test steps: First, 9 fixed measuring points of the sound level meter were installed; An adult (man, 175 cm and 70 kg) performed jumps on the floor according to the fixed-point jump excitation method, the jump height was 150 ± 10 mm (Fig. 5, and the transient excitation method was used to test the impact sound insulation of the four types of floors disturbed by adults. The arrangement of the impact point of a single jump excitation is shown in Fig. 6. In addition, socks and slippers were chosen as the most commonly used footwear at home.

3.1 Sound Insulation of the Material

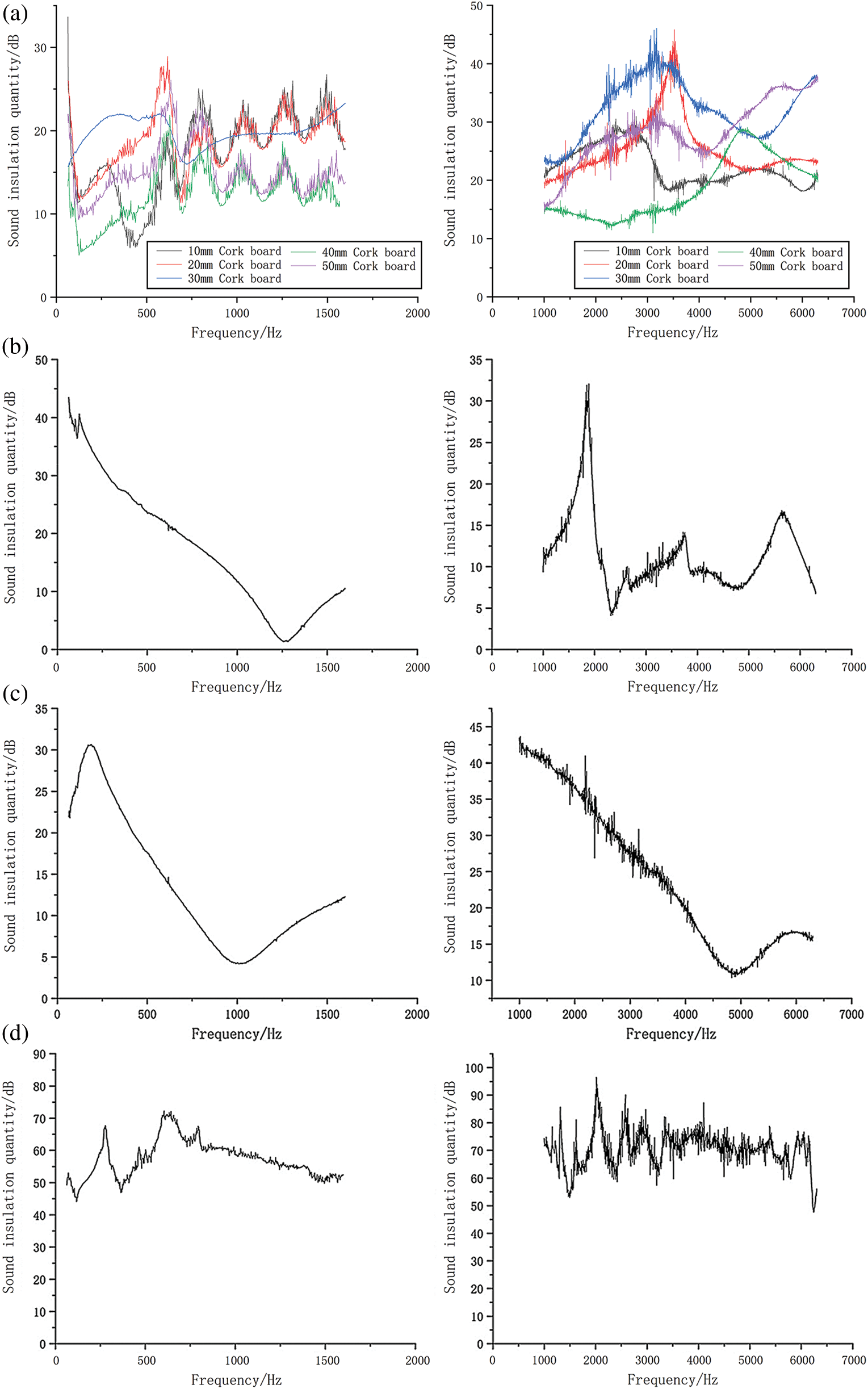

The sound insulation curves of the four material plate specimens are shown in Fig. 7.

Figure 7: Sound insulation curve of the specimens (a) Sound insulation curve of cork board (left: mid-low frequency, right: medium-high frequency) (b) Sound insulation curve of BGL board (left: mid-low frequency, right: medium-high frequency) (c) Sound insulation curve of EPP board (left: mid-low frequency, right: medium-high frequency) (d) Sound insulation curve of OSB board (left: mid-low frequency, right: medium-high frequency)

The sound insulation effect of a cork board with thickness of 20 mm is better within the frequency of 500–1000 Hz. However, when the frequency exceeds 1000 Hz, the sound insulation effect is achieved with a cork board of 30 mm thick. This is because sound waves are transmitted inside the material and resonate, causing the sound insulation curve of the material to appear low in sound insulation. BGL board and EPP board are both extruded foamed materials. At 1000 Hz and 1200 Hz, foam boards have obvious sound insulation troughs respectively. Due to a large number of bubble structures in the foam material, the sound wave resonates in its internal transmission, causing the material to locally reduce the sound insulation. When the frequency is less than 1000 Hz, the sound insulation performance of two sound insulation panels gradually decreases as the frequency increases. BGL board has high sound insulation characteristics within 2000–3000 Hz, while the sound insulation performance of the EPP board decreases with the increase of frequency within 1000–4000 Hz. In the high-frequency range, the sound insulation performance of two materials is relatively low. OSB board has few internal pores and high density, and its airborne sound insulation performance is relatively stable in the middle and high-frequency range.

3.2 Damping Ratio and Elastic Modulus of Materials

3.2.1 Damping Ratio Test Results and Analysis of Materials

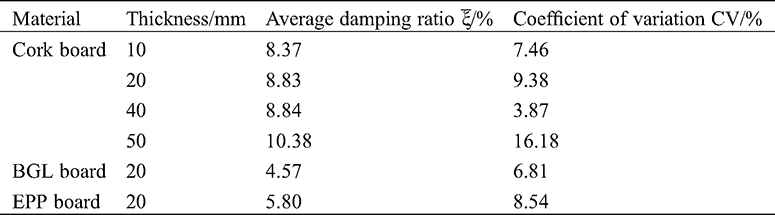

The dynamic test of the damping ratio ξ of the flexible cushion material of the light frame wood floating floor considering cork board, BGL board, and EPP board is carried out by the transient excitation method. The average damping ratio ξ of the elastic cushion material is shown in Tab. 3, and the time-domain spectrum of the cork board is shown in Fig. 8.

Tab. 3 shows that the order of the damping ratio of the materials under the same thickness is: Cork board> EPP board> BGL board. Among them, the cork board has the best comprehensive damping performance. This is because, inside the cork board material, the fibers are bonded to each other by resin. The cell cavity is filled with air and the cell structure is closed [18]. A single cell forms an air spring, and when the vibration energy passes through the cork, a better vibration reduction effect can be achieved. Both the EPP board and the BGL board are extruded foamed high molecular polymer materials with a large number of closed bubble system inside the structure. When it is vibrated, its internal bubble system forms an air spring, and internal friction occurs between the molecules, which further consumes vibration energy and achieves the effect of damping and vibration reduction.

Figure 8: Cork board (20 mm thick) time-domain spectrum

Table 3: Average damping ratio (¯ξ) of elastic cushion material (%)

3.2.2 Modulus of Elasticity of Materials

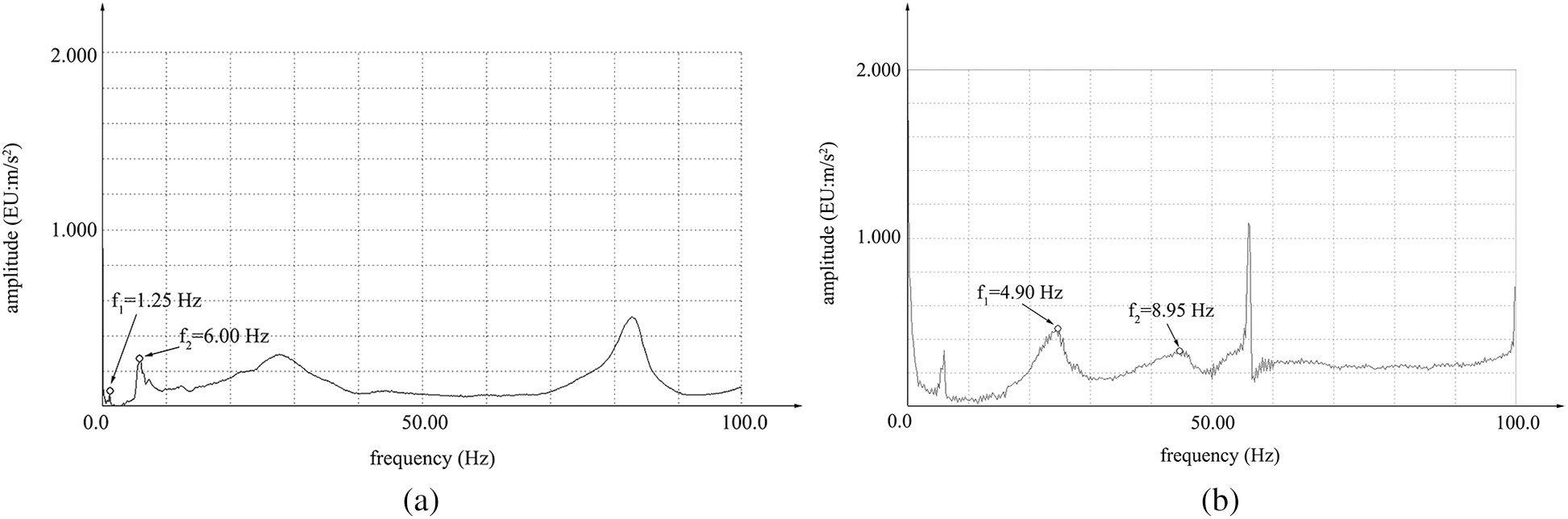

Fig. 9 shows the dynamic test spectrum of the BGL board and EPP board materials. Measured from the frequency spectrum and Eq. (2) the elastic modulus of the floor structure material is 12366.61 MPa for pine board, 10276.7 MPa for solid wood floor, 6078.8 MPa for OSB board, 0.375 MPa for cork board, 0.055 MPa for EPP board and 0.011 MPa for BGL board. Under the condition of the same thickness, the BGL board material has the lowest elastic modulus and the best elasticity, that is, a strong vibration damping ability.

Figure 9: Dynamic test spectrum of floor structure materials (a) BGL board (b) EPP board

The energy consumption mechanism of BGL board and EPP board is as follows: When subjected to vibration, the foam board itself produces large deformation to consume impact energy. The vibration wave forms reflection and refraction on the bubble wall and cavity structure inside the material, continuously consuming energy, and its transmission energy attenuation effect is good. Because the wave structure at the bottom of the BGL board can effectively improve its overall vibration reduction, the BGL board has the greatest flexibility. When the cork board is subjected to an external seismic source, its deformation is relatively small, and its energy consumption is mainly through its internal cavity structure and internal friction. As the surface structure of the floor, the solid wood floor is in direct contact with the impact noise source. Because of its high elastic modulus, the vibration reduction effect is relatively small. However, considering the actual stress of the floor structure, the solid wood floor can effectively ensure the overall stiffness of the floor structure.

3.3 Sound Insulation under Jump Excitation Method of Daily Behavior

3.3.1 Test Results and Analysis of Sound Insulation of Jumping Excitation

Under the condition of closed doors and windows, the improvement ΔL of the impact sound of BGL, EPP, cork board, and ordinary OSB floor covers measured by the transient excitation method are 22.2, 20.3, 15.9, and 12.6 dB, respectively. Obviously, this is because the cork board, BGL board, and EPP board all have a higher damping ratio and smaller elastic modulus value to achieve the vibration and sound insulation effect.

3.3.2 Sound Insulation Spectrum Analysis of Jumping Excitation

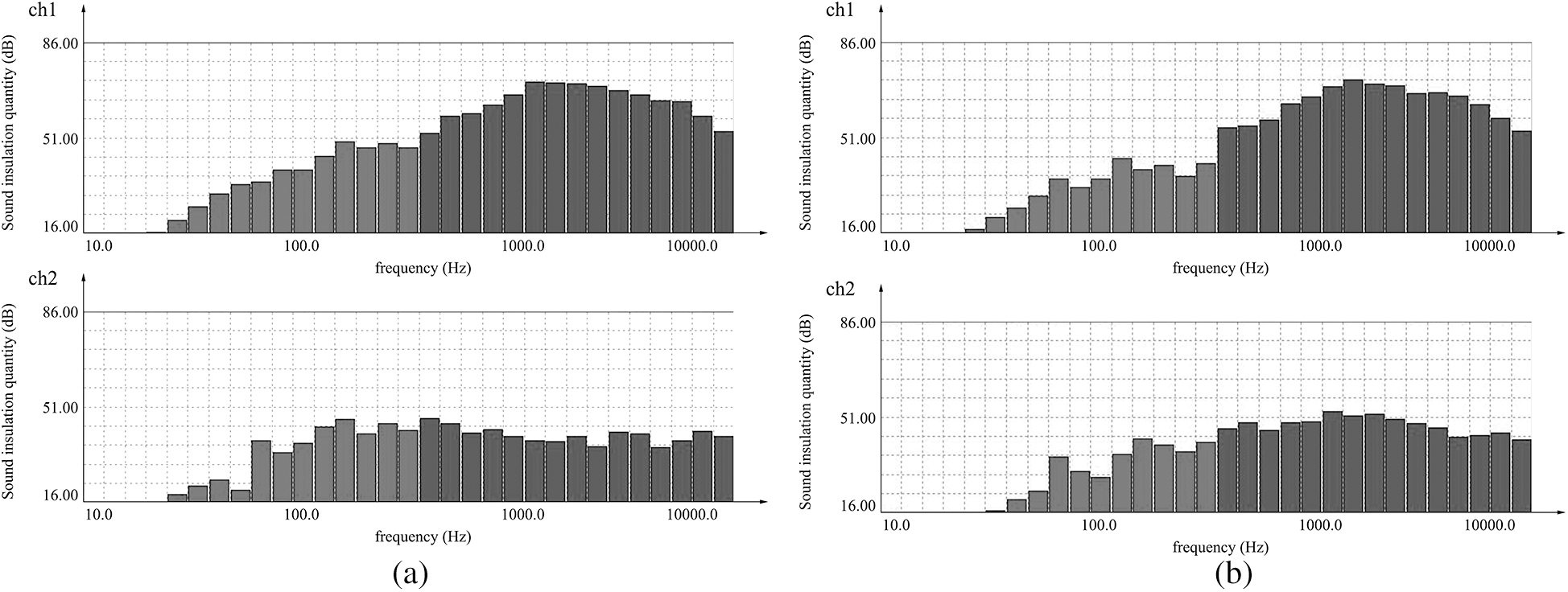

As a kind of instantaneous motivation, jumping is one of the most common activities in life. Under the condition of closed doors and windows the measured frequency spectrum of the BGL and EPP floor structures selected in the article is shown in Fig. 10. The channels Ch1 and Ch2 respectively represent the frequency distribution of the weighted impact sound pressure level measured in the sound source room and the receiving room of the building.

In Fig. 10, the instantaneous impact energy of the jumping excitation on the floor structure is concentrated, especially the sound pressure within 800–6000 Hz is significantly increased. In the high-frequency range, the sound pressure of impact excitation is large, and the sound effect is also more obvious. The BGL and EPP floating floor can effectively improve the impact sound insulation performance of the structure in the middle and low-frequency range. As the person jumps on the floor, the potential energy is transformed into a large impact kinetic energy, which produces a large impact on the floor. Therefore, vibration and noise can be reduced through the better elasticity and damping properties of BGL, EPP, and cork board elastic cushion materials.

Figure 10: BGL, EPP floor’s jump excitation impact sound insulation spectrogram (jump excitation with closed doors and windows) (a) BGL board floating floor (b) EPP board floating floor

In this experiment, only one adult male participated in the experiment, and certain training was given to him in the early stage of the experiment to ensure that the jumping height was maintained at 150 ± 10 cm, and the soles of the feet should land as much as possible. The experimental data was screened, but the results have certain errors and limitations. In the future, more people of different heights and weights will need to be involved in order to explore the impact of different heights and weights on the experimental results, and make the experiment more perfect. The data is more comprehensive and the conclusion is more precise.

Among the materials tested in this research, the damping ratio of the cork board is the highest, followed by the EPP board, and the BGL board, and the damping ratio of the OSB is the lowest. In the terms of the elastic modulus of the tested materials, OSB has the highest values, followed by cork boards, EPP, and BGL board has the lowest. Three elastic cushion materials of BGL, EPP, and cork board have strong vibration and sound insulation performance. Therefore, under the jump excitation mode, the measured impact sound insulation of three types of floating floors, considering BGL, EPP, and cork board, is 3–10 dB higher than the sound insulation of ordinary OSB floors, and the impact sound pressure is 1.97–8.61 times higher than the ordinary OSB floor respectively. This can effectively improve the sound pressure ratio of the indoor space of the building. The overall sound insulation performance of BGL floors is the highest, followed by EPP and cork floors, and ordinary OSB floors are the lowest. On the other hand, under the jump excitation mode, due to the concentration of the instantaneous impact energy of people on the floor structure, the sound pressure of the impact excitation is large in the high-frequency range, and the sound effect is more obvious. Three types of floating floor coverings, considering BGL, EPP, and cork board, can effectively improve the impact sound insulation performance of the structure in the middle and low-frequency bands and can improve the user’s living comfort conditions.

Funding Statement: This study was funded by Co-Innovation Center of Efficient Processing and Utilization of Forest Resources (Nanjing Forestry University, Nanjing, 210037, China).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Davern, W. A. (1988). Impact noise on two timber floors with vinyl floor coverings on resilient underlays. Applied Acoustics, 24(2), 157–163. DOI 10.1016/0003-682X(88)90037-0. [Google Scholar] [CrossRef]

2. Caniato, M., Bettarello, F., Ferluga, A., Marsich, L., Schmid, C. et al. (2017). Acoustic of lightweight timber buildings: A review. Renewable and Sustainable Energy Reviews, 80, 585–596. DOI 10.1016/j.rser.2017.05.110.

3. Caniato, M., Bettarello, F., Gasparella, A. (2019). Energy and acoustic performances of timber in buildings. Reference Module in Materials Science and Materials Engineering, Elsevier, 2, 78–91.

4. Schiavi, A. (2018). Improvement of impact sound insulation: A constitutive model for floating floors. Applied Acoustics, 129, 64–71. DOI 10.1016/j.apacoust.2017.07.013. [Google Scholar] [CrossRef]

5. Roswall, N., Raaschou-Nielsen, O., Jensen, S. S., Tjnneland, A., Srensen, M. (2018). Long-term exposureto residential railway and road traffic noise and risk for diabetes in a Danishcohort. Environmental Research, 160, 292–297. DOI 10.1016/j.envres.2017.10.008. [Google Scholar] [CrossRef]

6. Sang, H. P., Lee, P. J. (2017). Effects of floor impact noise on psychophysiological responses. Building and Environment, 116, 173–181. DOI 10.1016/j.buildenv.2017.02.005. [Google Scholar] [CrossRef]

7. Yang, R. Y., Li, H. T., Lorenzo, R., Ashraf, M., Sun, Y. F. et al. (2020). Mechanical behaviors of steel-timber composite shear connections. Construction and Building Materials, 258, 119605. DOI 10.1016/j.conbuildmat.2020.119605. [Google Scholar] [CrossRef]

8. Frescura, A., Lee, P. J., Schöpfer, F., Schanda, U. (2021). Correlations between standardised and real impact sound sources in lightweight wooden structures. Applied Acoustics, 173, 107690. DOI 10.1016/j.apacoust.2020.107690. [Google Scholar] [CrossRef]

9. Kylliäinen, M., Hongisto, V., Oliva, D., Rekola, L. (2017). Subjective and objective rating of impact sound insulation of a concrete floor with various coverings. Acta Acustica united with Acustica, 103(2), 236–251. DOI 10.3813/AAA.919053. [Google Scholar] [CrossRef]

10. Wang, Z., Li, H. T., Lorenzo, R., Corbi, I., Corbi, O. et al. (2020). Review on bond properties between wood and fiber reinforced polymer. Journal of Renewable Materials, 8(8), 993–1018. DOI 10.32604/jrm.2020.012488. [Google Scholar] [CrossRef]

11. Li, H. T., Zhang, H. Z., Qiu, Z. Y., Su, J. W., Wei, D. D. et al. (2020). Mechanical properties and stress strain relationship models for bamboo scrimber. Journal of Renewable Materials, 8(1), 13–27. DOI 10.32604/jrm.2020.09341. [Google Scholar] [CrossRef]

12. Yang, D., Li, H. T., Xiong, Z. H., Mimendi, L., Lorenzo, R. et al. (2020). Mechanical properties of laminated bamboo under off-axis compression. Composites Part A: Applied Science and Manufacturing, 138, 106042. DOI 10.1016/j.compositesa.2020.106042. [Google Scholar] [CrossRef]

13. Gil, L. (2015). New cork-based materials and applications. Materials, 8(2), 625–637. DOI 10.3390/ma8020625. [Google Scholar] [CrossRef]

14. Silva, S. P., Sabino, M. A., Fernandes, E. M., Correlo, V. M., Boesel, L. F. et al. (2013). Cork: Properties, capabilities and applications. International Materials Reviews, 50(6), 345–365. DOI 10.1179/174328005X41168. [Google Scholar] [CrossRef]

15. Yang, X. J., Zhao, Q., Hao, D., Wang, J. Y., Fu, S. et al. (2020). Flexural behavior of OSB reinforced wood truss. Wood Research, 65(2), 245–256. DOI 10.37763/wr.1336-4561/65.2.245256. [Google Scholar] [CrossRef]

16. Carvalho, A., Vafiadis, C., Borrego, H. (1999). The use of agglomerated cork as an underlay for improvement of impact sound insulation in buildings. Journal of the Acoustical Society of America, 105(2), 1259. DOI 10.1121/1.426028. [Google Scholar] [CrossRef]

17. Yoo, S. Y., Jin, Y. J. (2014). Investigation of the effects of different types of interlayers on floor impact sound insulation in box-frame reinforced concrete structures. Building and Environment, 76(6), 105–112. DOI 10.1016/j.buildenv.2014.03.008. [Google Scholar] [CrossRef]

18. Knapic, S., Oliveira, V., Machado, S. J., Pereira, H. (2016). Cork as a building material: A review. European Journal of Wood and Wood Products, 74(6), 775–791. DOI 10.1007/s00107-016-1076-4. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |