Journal of Renewable Materials

Journal of Renewable Materials

Journal of Renewable Materials Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2021.014114

ARTICLE

Dynamic Elastic Modulus and Damping Ratio of Lignin-Modifi ed Loess

1Key Laboratory of Loess Earthquake Engineering, China Earthquake Administration & Gansu Province, Lanzhou, 730000, China

2College of Civil Engineering and Mechanics, Lanzhou University, Lanzhou, 730000, China

*Corresponding Authors: Qian Wang. Email: wangq0930@126.com; Zhaozhao Liu. Email: liuzhzh17@lzu.edu.cn

#These authors contributed to this work equally and should be regarded as co-first authors

Received: 01 September 2020 Accepted: 19 September 2020

Abstract: To effectively improve the poor engineering properties of loess and enhance its seismic performance, the industrial by-product lignin is used as a modified material. Based on lots of dynamic triaxial tests, the dynamic elastic modulus and damping ratio of lignin-modified loess were tested. The effects of lignin content on the dynamic elastic modulus and damping ratio of lignin-modified loess were analyzed. Combined with scanning electron microscopy (SEM) and X-ray diffraction (XRD), the microscopic mechanism of lignin to improve the dynamic properties of loess was studied. The results show that lignin can effectively modify the dynamic deformation of loess under dynamic load. Under the same dynamic stress condition, the dynamic strain of lignin-modified loess is smaller than compacted loess. The dynamic elastic modulus of modified loess with different lignin content are quite different, but both decrease with the increase of dynamic strain. And the dynamic elastic modulus of modified loess is greater than compacted loess. The maximum dynamic elastic modulus of modified loess with a lignin content of 1% are significantly greater than others. Under the same dynamic strain condition, the damping ratio of lignin-modified loess is smaller than compacted loess. Lignin can effectively fill loess pores and cement loess particles. Compared with compacted loess, no new mineral components are generated in the lignin-modified loess. The optimum lignin content of dynamics characteristic of modified loess is present, and the optimum lignin content is 1%.

Keywords: Lignin; modified treatment; dynamic triaxial test; SEM; XRD

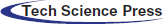

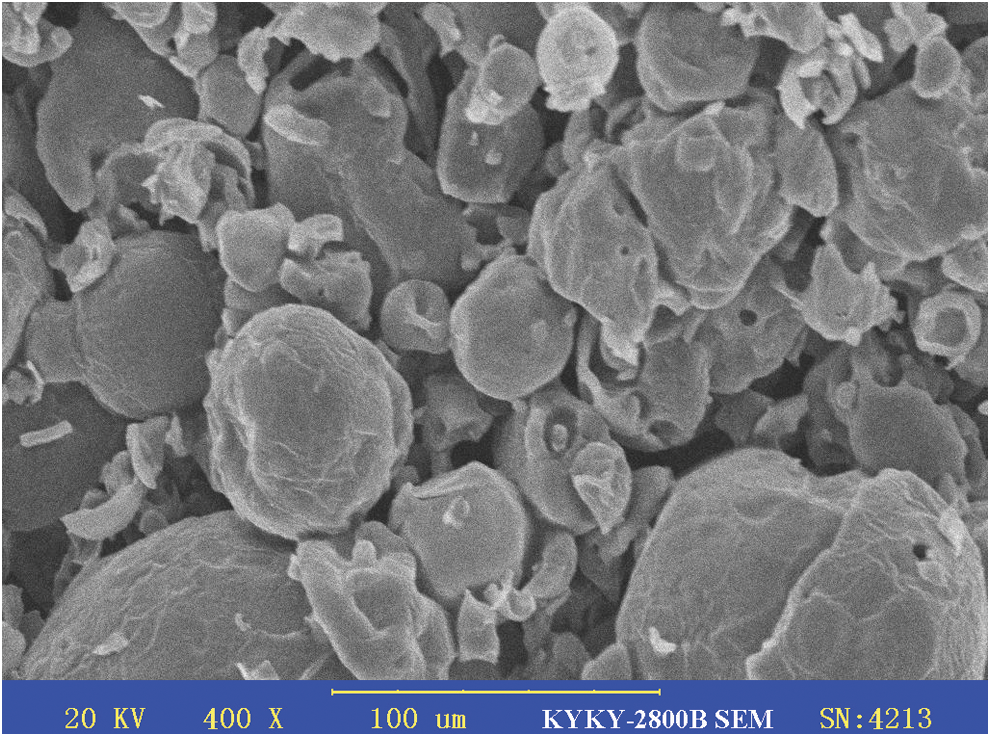

Loess is a special quaternary unconsolidated sediment with large pore, rich soluble salt and weak cementation (Fig. 1). The special structure of loess determines it has a huge catastrophic risk under dynamic load [1–3]. Loess is found all over the world including in Asia, Europe, and North and South America. The Loess Plateau is the most concentrated and continuous area of loess in the world, covers more than 440,000 km2. It is characterized by ravines and gullies, complex topographical conditions, complex geological structures, strong neotectonics activities and many strong earthquakes in history [2,3]. The poor engineering properties of loess and the high-risk seismic background of the Loess Plateau determine that the seismic geological disasters related to loess are very well developed. The loess seismic subsidence has caused a huge threat to the safety of people’s life and property, urban and rural construction.

Figure 1: Microstructure of tested loess

Previous researches and reports have proved that adding modified materials to soil can effectively improve its seismic performance and resist seismic subsidence. Many scholars have also made great achievements in the dynamic characteristics of modified soil. Gao et al. [4] studied the dynamic shear modulus and damping ratio of expanded polystyrene composite soil under traffic loading based on the hollow cylindrical torsional shear test. According to the resonant column test results, Li et al. [5] studied the damping ratio and dynamic shear modulus of steel slag sand mixtures and cement sand mixtures under different confining pressures, mix proportions and curing ages. Zhang et al. [6] studied the dynamic elastic modulus and critical dynamic stress of coal gangue modified soil under different dynamic load frequencies and confining pressures, and established the dynamic elastic modulus attenuation model. Wang et al. [7] used fly ash as a modified material to study the dynamic characteristics of saturated loess based on dynamic triaxial liquefaction tests. Fei et al. [8] carried out lots of stress controlled cyclic triaxial tests on Clay-Aggregate mixtures with different coarse particle contents, and analyzed the influences of coarse particle content and composite stress on the damping ratio and dynamic modulus. Volkan et al. [9] studied kaolinite and montmorillonite modified with boron slag by using resonant column and dynamic torsional shear tests, and proposed that the shear modulus and damping ratio of the two clays increase with the increase of the boron slag content. Jia et al. [10] explored the effects of the amount of binder materials, curing time and porosity on the static characteristics of lime-fly ash-SAC stabilized loess. In addition, the dynamic characteristics of many modified materials such as cement, lime, ionic stabilizers and geosynthetics have also developed greatly [11–14]. These modified treatment technologies can modify the dynamic characteristics of soil and enhance the seismic performance, but there are also a series of problems such as practical application difficulty, high cost and serious environmental pollution. Therefore, it is urgent to search for a new modified material with good engineering applicability, non-polluting and excellent seismic performance for loess engineering construction.

As the main component in the pulping waste liquid of paper mills, lignin is a polymer material with a huge network structure. Lignin has the characteristics of filling, corrosion resistance and strong adhesion, which can significantly modify cementing performance of soil [15,16]. Moreover, it is an economical and environmentally friendly modified material. Study on the application of lignin in soil reinforcement has been carried out for a long time. Buddhima et al. [17–22] studied the corrosion resistance, compressive strength, stiffness and microstructure of lignin modified soils, and proposed that lignin could effectively improve the compactness and strength of soil. Zhang et al. [23–26] systematically studied the modified technology and engineering application of lignin-modified silt, analyzed the influences of lignin content and curing age on the physical and mechanical properties, durability and thermal conductivity of modified silt, and clarified the mechanism of lignin-modified silt. Chen et al. [27,28] studied the dynamic characteristics of lignosulfonate-treated sandy silt. Hou et al. [29] and He et al. [30] verified the feasibility of lignosulfonate to modify loess, and studied the water stability and compressive strength of lignin-modified loess. Liu et al. [31] found the shear strength and strain hardening of lignin modified loess increase with the increase of the amount of modified materials. At present, the researches on lignin-modified soil are mostly concentrated in sand, silt and clay. The limited researches on lignin-modified loess are revolved around static behaviors, while there are few researches on dynamic behaviors of lignin-modified loess.

Therefore, considering the poor engineering properties of loess, the frequent earthquakes on the Loess Plateau, the limitations of existing modified materials, and the application prospects of lignin, lignin was selected to modify the dynamic characteristics of loess. In this paper, the dynamic elastic modulus and the damping ratio of lignin-modified loess were discussed based on some dynamic triaxial tests. The effects of lignin content on the dynamic elastic modulus and damping ratio of lignin-modified loess were analyzed. In addition, combined with scanning electron microscopy (SEM) and X-ray diffraction (XRD), the microstructural differences and mineral composition of modified loess were studied. The optimum lignin content was determined based on the research results, and the reinforcement mechanism of the resist seismic of modified loess was studied.

Compared with previous studies, its innovation is to effectively improve the dynamic vulnerability of loess, a new environmentally friendly reinforcement material lignin was selected as the improved material. Based on a series of research of dynamic elastic modulus and damping ratio, it was found that lignin-modified loess has good dynamic stability. The research results of lignin-modified loess can provide theoretical reference and basic data for the seismic stability analysis of the loess foundation, and help to further modify the seismic performance of engineering construction in the loess area.

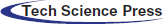

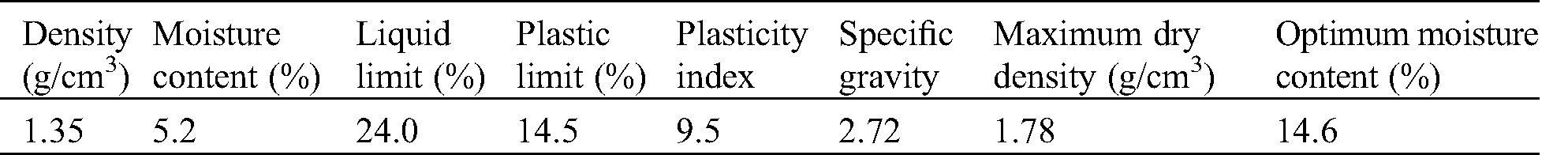

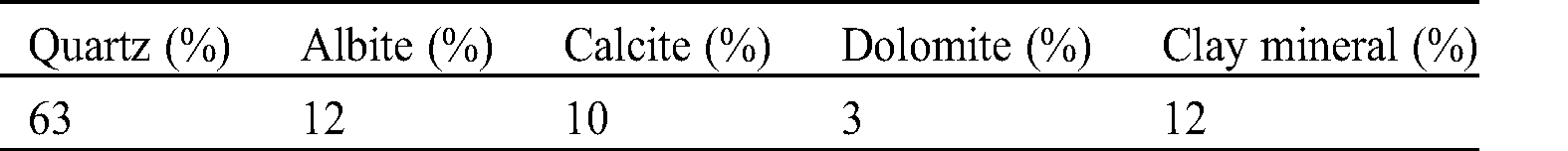

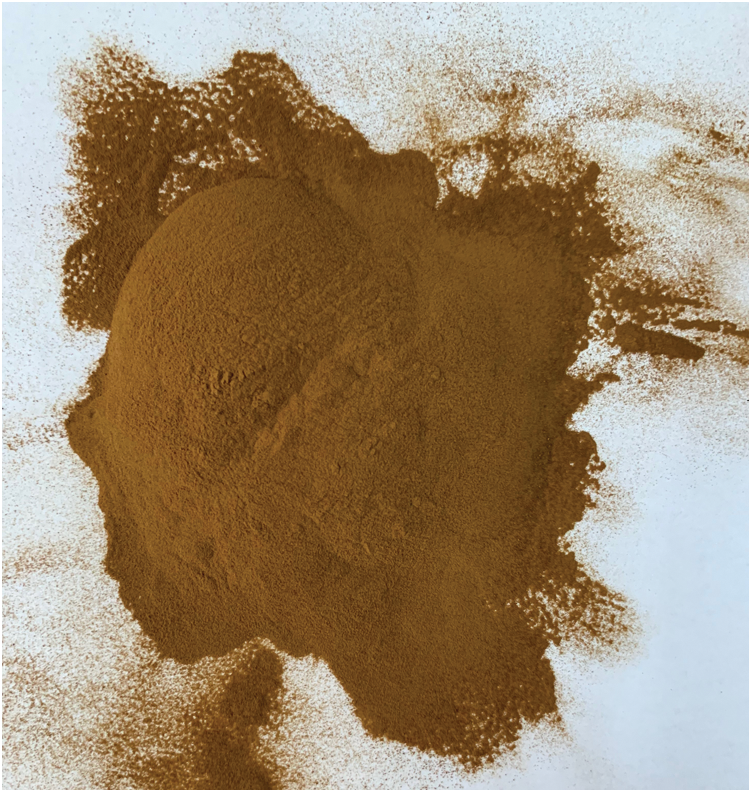

The loess used in the tests was taken from a site in XiJi County, Ningxia Hui Autonomous Region, China (Fig. 2). The subgrade fillers in the loess region generally choose local materials. Thus, shallow loess without the plant layer is generally used as subgrade fillers. Therefore, the sampling depth of loess in this study is 3 m. According to Specification of soil test: GB/T50123-2019 [32], the basic physical parameters of the loess used in the tests were laboratory-tested, and are shown in Tab. 1. The particle cumulative size distribution curve of loess is shown in Fig. 3. The loess comprised 13.7% sand, 80.2% silt and 6.1% clay. The mineral composition of loess were tested by X-ray diffraction system, which is included quartz, albite, calcite, dolomite and kaolin. The XRD results are shown in Tab. 2.

Figure 2: Sample collection on the Loess Plateau

Table 1: Basic physical parameters of tested loess

Table 2: Mineral composition of tested loess

Figure 3: Particle cumulative size distribution of tested loess and lignin

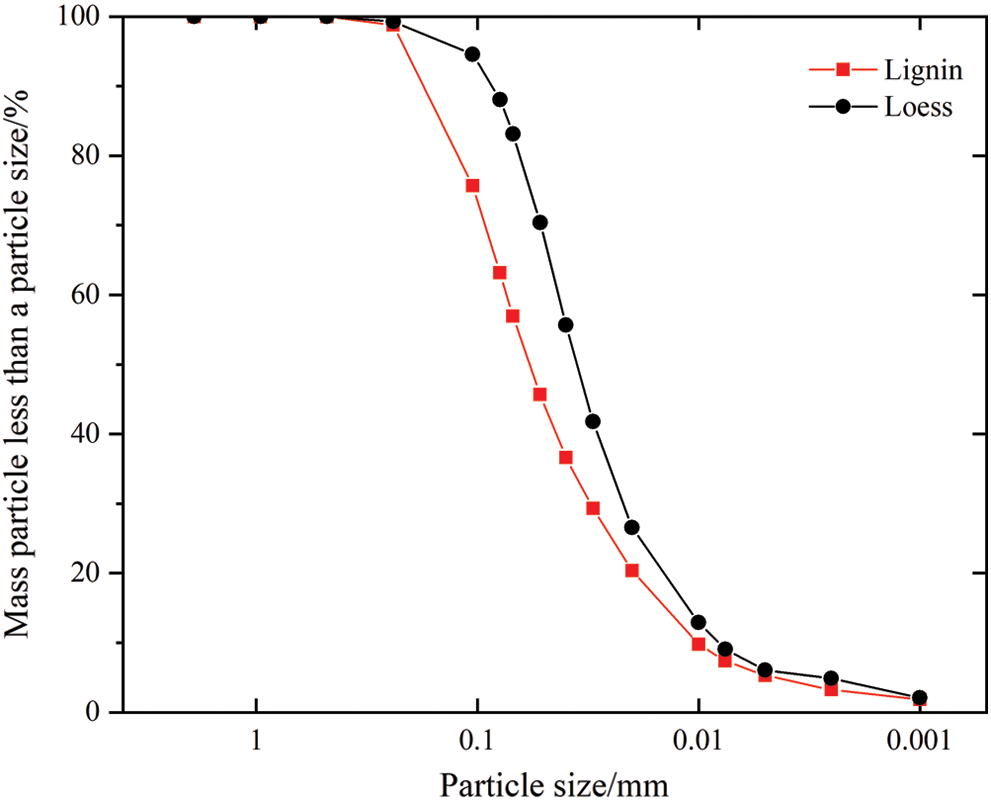

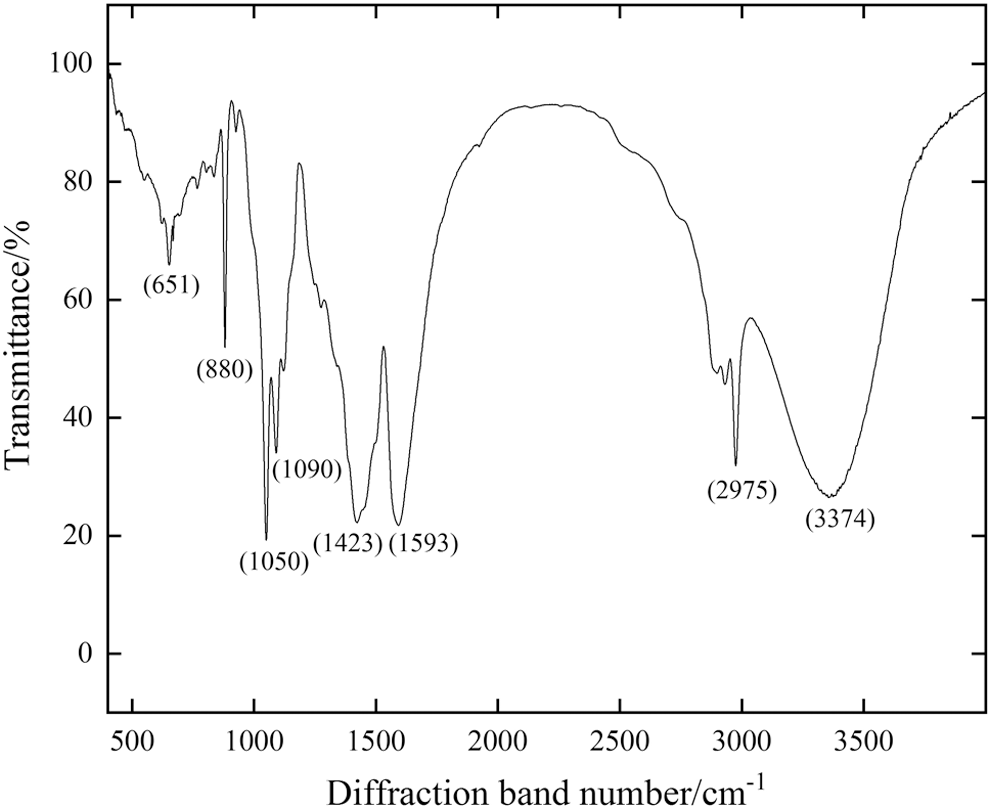

The lignin used in this study is a pure H-lignin. And it was extracted from the waste liquid of a paper mill in Fujian Province, China. This lignin is a yellow-brown powdery solid with a special aroma like wood, which has good viscosity and can be dissolved in water. In addition, its pH value is 9.0, which is alkaline and non-toxic [25,26]. Fig. 4 is a photograph of the lignin used in the tests. In order to clarify the microstructure and particle composition of the tested lignin, scanning electron microscope tests and particle analysis tests were performed. This lignin is a dispersed particle on the microscopic level, and the particle composition is mainly powder. The test results are shown in Figs. 3 and 5. In order to clarify the chemical composition and molecular structure of the tested lignin, Fourier transform infrared spectroscopy (FTIR) was performed on lignin. The test results are shown in Fig. 6. The lignin mainly contains active functional groups such as alcohol hydroxyl group (-OH, 3374 cm–1), benzene ring C=C bond (651 cm–1, 880 cm–1, 1593 cm–1), alkane (C-H (CH2), 1423 cm–1, 2975cm–1), primary alcohol (R1-CH2-OH, 1050 cm–1) and secondary alcohol (R1-CH(R2) -OH, 1090 cm–1).

Figure 4: The lignin used in this study

Figure 5: Microstructure of tested lignin

Figure 6: FTIR results of the lignin used in this study

The lignin content was defined as the mass ratio of lignin to loess. The specimens were prepared at lignin content (m) = 0%, 0.5%, 1%, 1.5%, 2%, 3% and 4% respectively [30,31]. First, the loess used in the tests was dried, crushed and screened (2 mm). when we prepared the modified loess specimens, the dry loess powder and lignin powder was mixed firstly. We put the loess in a certain preparation into a bowl. Then, stirred the loess slowly and added the lignin powder gradually. When the lignin powder was completely added, continue stirring clockwise and counterclockwise for more than 5 min to make sure the lignin and loess are considered to be uniform mixed. The corresponding purified water was added to the dry mixed loess based on the optimal moisture content (14.6%) of loess obtained by compaction tests. Meanwhile, continue stirring the mixture clockwise and rubbing it repeatedly to make sure the mixture uniform and without granule. Finally seal and let it stand for 24 h until water is transferred and ready for use.

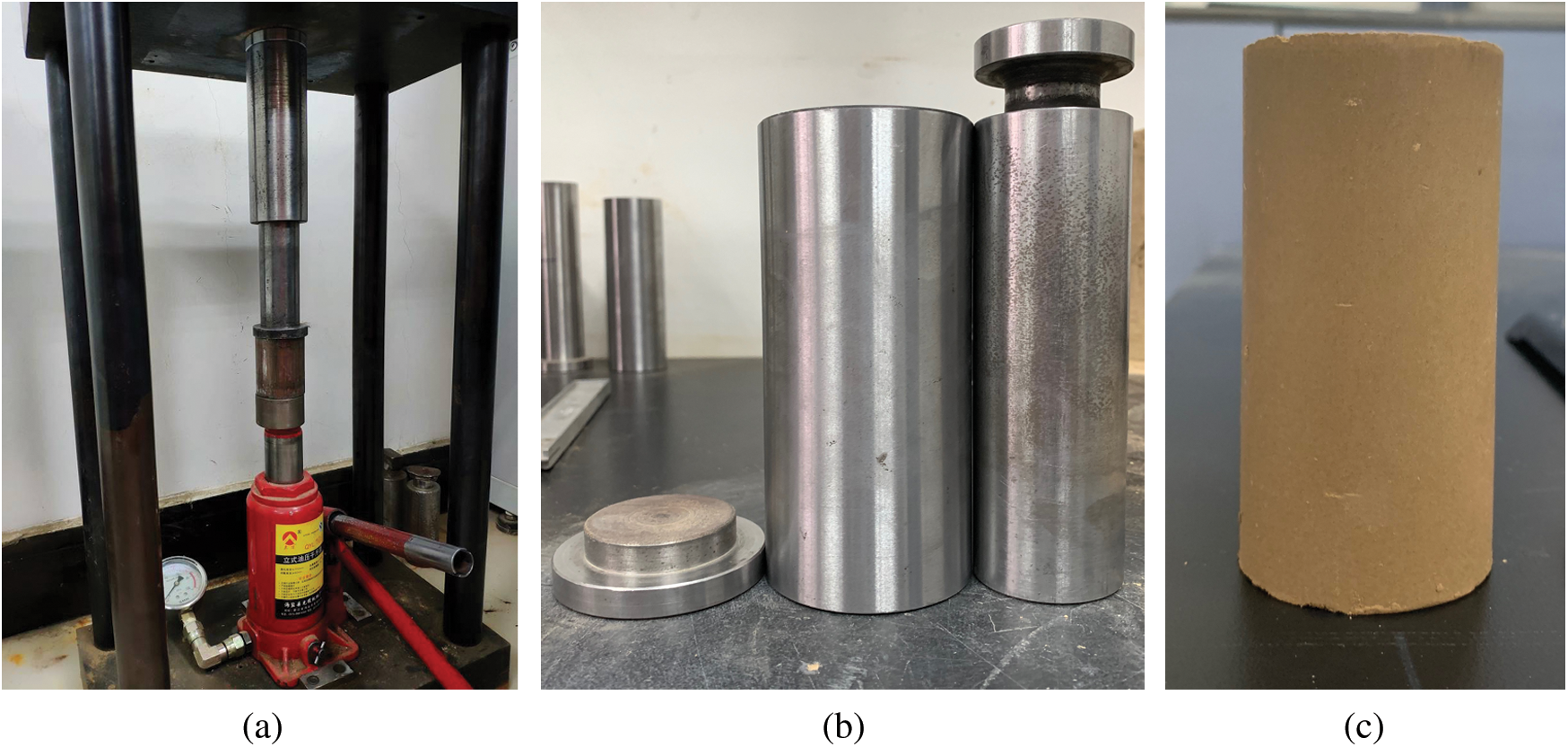

The cylindrical specimens of height 100 mm and diameter 50 mm were prepared in this study. First, the mixed loess was placed in a cylindrical mold with diameter 50 mm in four sequential layers. After tamping during specimen preparation, scratch the surface of each layer to eliminate delamination effects. The cylindrical specimens were compacted based on the double-end static pressure method. Then, the cylindrical mode was warily removed to ensure that the modified loess specimens were not damaged. In order to ensure the comparability of the specimens in each group, all cylindrical specimens were compacted in the same operation method and the dry density of the samples is uniformly set as the maximum 1.78 g/cm3. The compaction coefficient of lignin-modified loess specimens was determined as 0.95 [32]. The specimens were cured to 28 days under standard curing conditions (20 ± 2°C, a relative humidity of 95%) [25,26]. Fig. 7 shows the molds and specimen used in the experiment.

Figure 7: Cylindrical mold and specimen used in this study

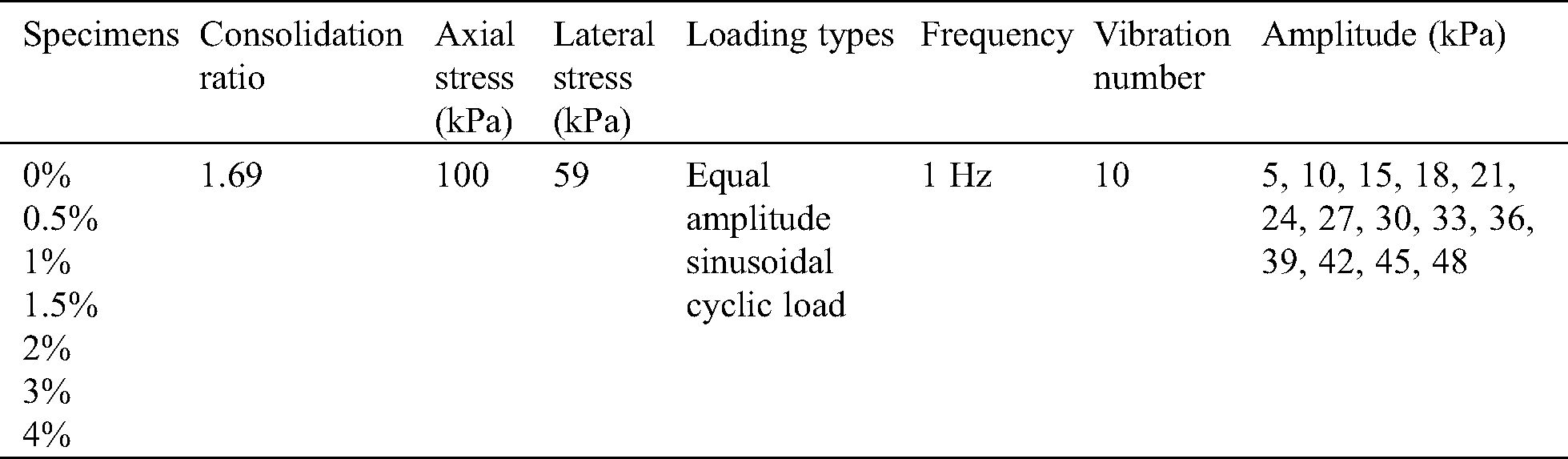

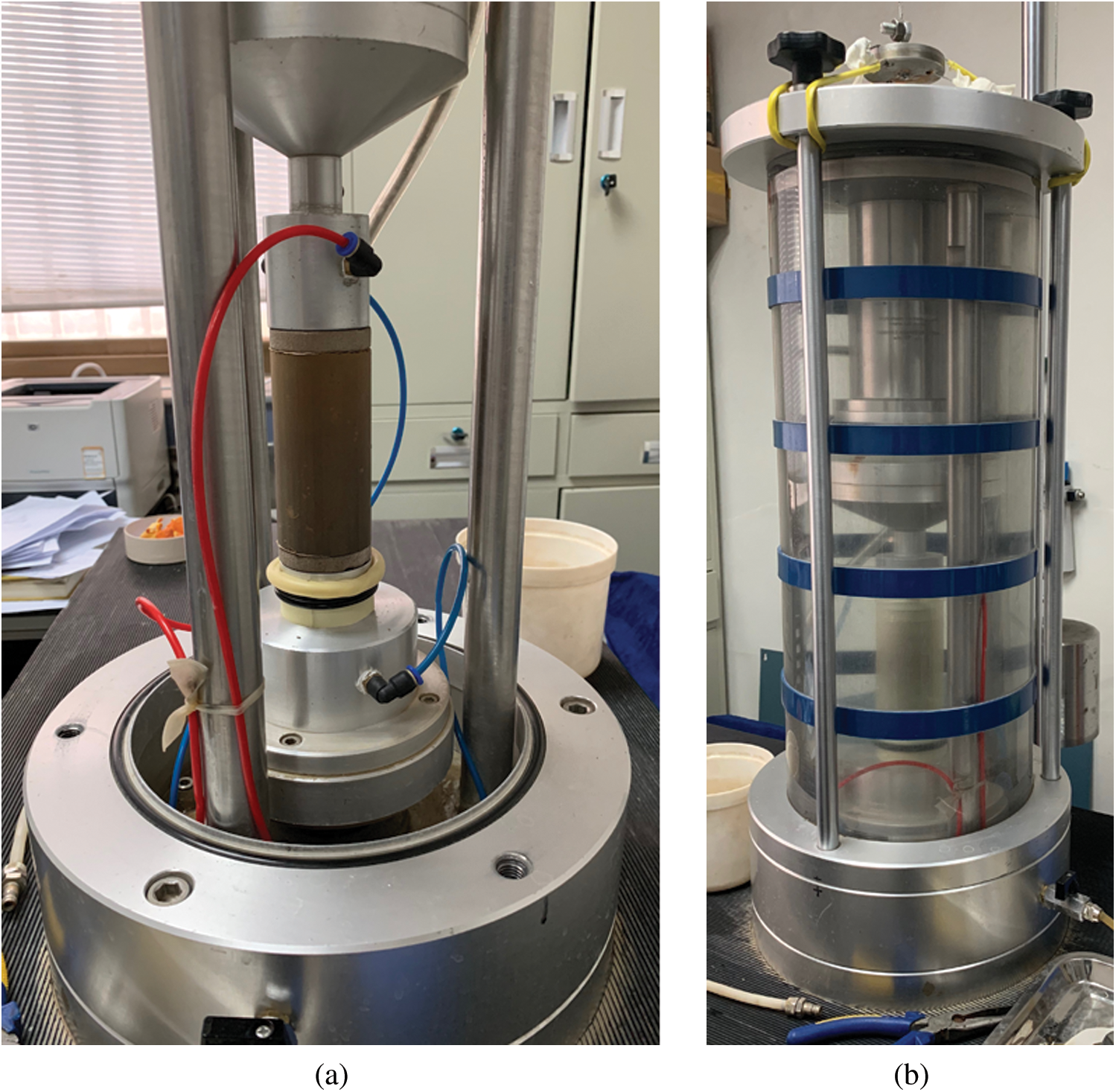

The dynamic triaxial tests equipment is the WF-12440 test system produced by Wykeham Farrance Company, UK (Fig. 8). The strain test accuracy can reach 1 × 10–5. The test procedure complies with the “Specification of soil test” (GB/T50123-2019) [32]. The dynamic response of loess under dynamic load is simulated by applying dynamic load on the axial direction of the cylindrical sample. This helps to evaluate the seismic performance of lignin-modified loess. The test consists of two steps: Consolidation and cyclic shear. In the consolidation step, anisotropic consolidation was adopted considering the pressure conditions of the original overburden layer of the loess. The axial consolidation pressure of specimens in different groups was set at 100 kPa, the consolidation ratio is 1.69, the confining pressure is 59 kPa, the consolidation loading rate is 2 kPa/min. The modified loess specimens were considered stable when the axial deformation rate of the specimens is lower than 0.00005 mm/min. In the cyclic shear step, we set 14 levels of the amplitude of the dynamic loading as 5 kPa, 10 kPa, 15 kPa, 18 kPa, 21 kPa, 24 kPa, 27 kPa, 30 kPa, 33 kPa, 36 kPa, 39 kPa, 42 kPa, 45 kPa and 48 kPa in each group respectively. Each specimen used the same 14-level dynamic loading to ensure the comparability of test results. Since the specimen is unsaturated and relatively hard, the 1st level of the amplitude of the dynamic load was chosen as 5 kPa. Meanwhile, considering the dynamic-static ratio of the test instrument, the maximum amplitude of the dynamic load is 48 kPa, which a little lower than the cell pressure [33]. In order to obtain more data, 14 levels of dynamic loading were carried out relatively evenly. According to the GB/T50123-2019 Code [32], the vibration times in the dynamic elastic modulus and damping ratio tests should not be greater than 10 times. Therefore, to reduce the systematical error as much as possible and ensure the authenticity of the data, we took the vibration 10 times to load. Considering the excellent frequency of ground motion is more than 1~5 Hz and the soil deformation caused by low frequency load is relatively large. Therefore, a constant amplitude sinusoidal cyclic load with a frequency of 1 Hz was used in tests [34]. All specimens were tested in the same procedure. In addition, During the dynamic modulus and damping ratio tests, two parallel samples with the same lignin content in each group were prepared. The test results were the average of parallel tests. And the test results of the parallel samples show that the systematical error is quite small. The dynamic triaxial test conditions are shown in Tab. 3.

Table 3: Summary the triaxial test condition

Figure 8: WF-12440 dynamic triaxial-torsion shear test system

The SEM tests equipment is the KYKY-2800B scanning electron microscope. First, the vacuum freeze–drying equipment was used to dry specimens, then obtain fresh sections at the top, middle and bottom of specimens. The fresh sections were manually grinded as slices. The slices were sprayed with gold and placed in the scanning electron microscope. During the SEM tests, the magnification of the microstructure images was set to ×500, and 8 images were obtained for each slice. SEM can clearly reflect the distribution characteristics of particles and pores of loess. This helps to analyze the reinforcement mechanism of modified loess from the internal microstructure.

The XRD tests equipment is the XRD system X’Pert Pro. XRD can effectively obtain the composition and content of each mineral in the loess. First, the vacuum freeze–drying equipment was used to dry specimens. Then the specimens were thoroughly grounded until there are no particles in the specimens, and place it in the XRD system for test. By clarifying the changes in mineral composition before and after loess modification, the interaction between the modified material and loess can be accurately and effectively analyzed. This helps to analyze the reinforcement mechanism of modified loess from the internal mineral.

Dynamic elastic modulus is the elastic modulus of soil under cyclic dynamic load. It reflects the elastic properties of soil. It is obtained from the following expression:

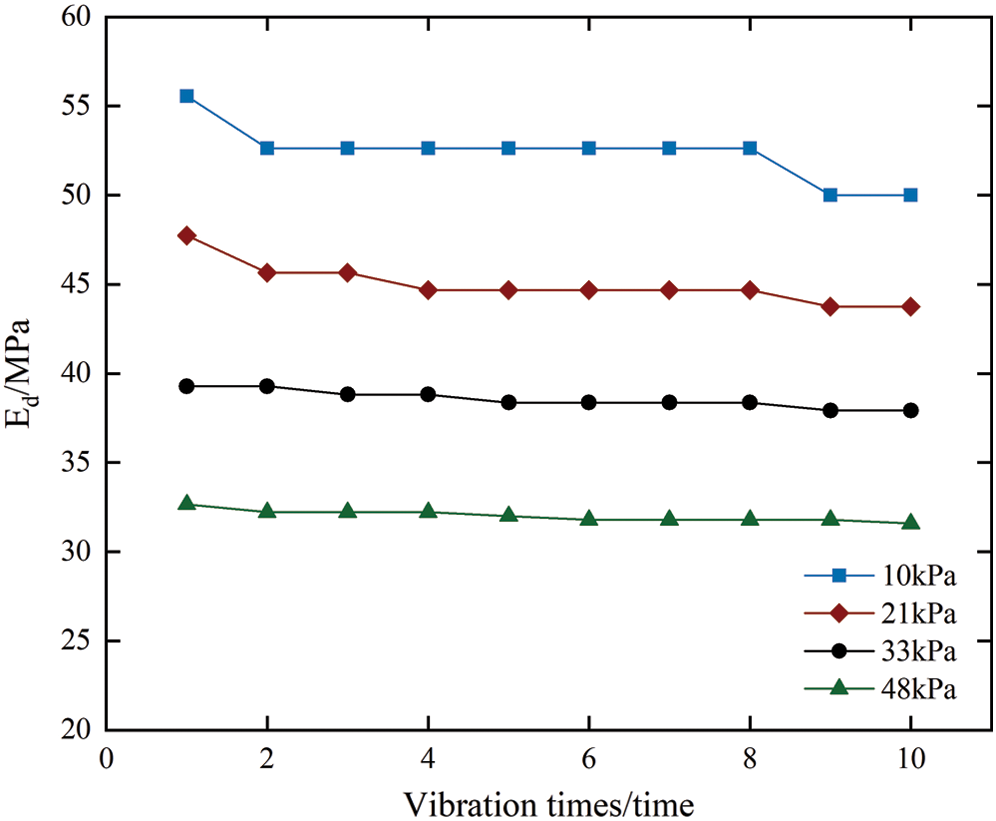

The Ed is dynamic elastic modulus, σd is dynamic stress and εd is dynamic strain. Firstly, the influence of dynamic loading vibration times on the Ed of lignin-modified loess should be determined so as to carry out further research. Fig. 9 shows the interrelation between the dynamic elastic modulus and the vibration times of modified loess with lignin content of 1% under different dynamic stress amplitudes. In this study, the test results were the average of parallel tests. All the parallel test results of lignin-modified loess are available showed similar trends.

Figure 9: Relationship between the dynamic elastic modulus and the vibration times of lignin-modified loess with lignin content of 1%

Under different dynamic stress amplitudes, the Ed of lignin-modified loess gradually slightly decreases with the increase of the vibration times, and the anti-deformation performance decreases gradually. However, the decrease magnitude of vibration times is different. The larger the σd, the smaller the decrease of the Ed. And under the same vibration times, the larger the σd, the smaller the Ed. Therefore, in order to eliminate the influence of the vibration times on the subsequent analysis, the dynamic strain data of the 5th to 6th times are selected under each dynamic stress of all the dynamic triaxial test data, which is convenient for comparative study.

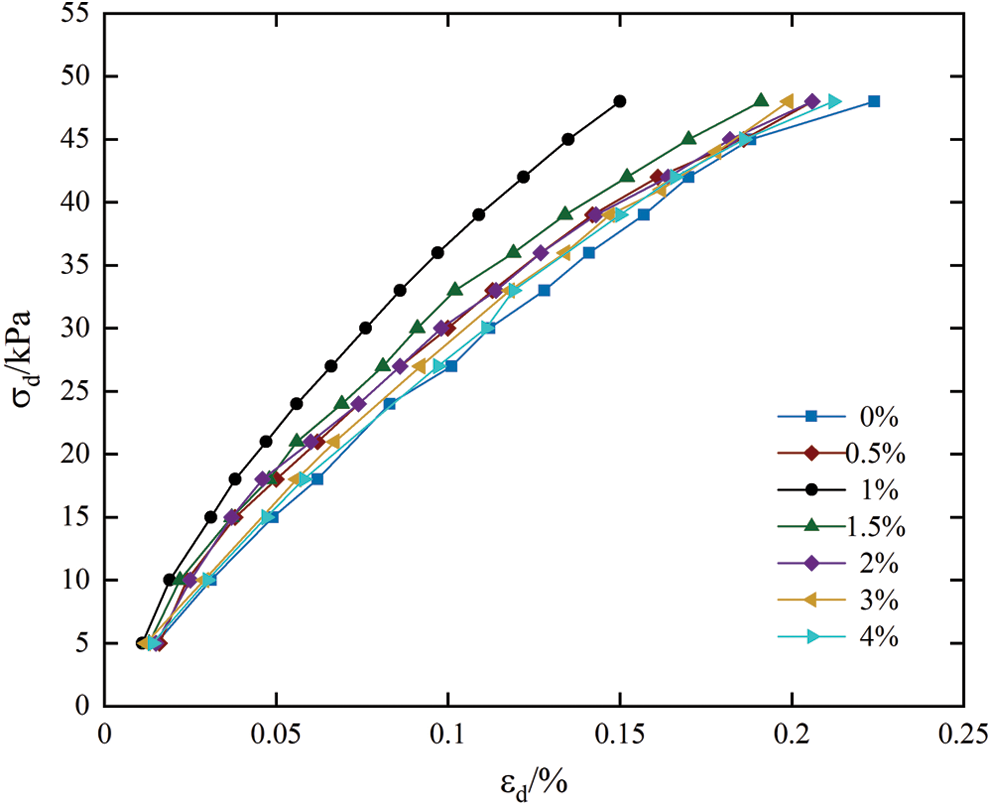

According to the σd and εd recorded data of tests, the σd–εd curves of lignin-modified loess were obtained, as shown in Fig. 10.

Figure 10: σd–εd curves of lignin-modified loess

The εd of modified loess shows an obvious trend of gradually increase with the increase of dynamic stress. However, due to the difference of lignin content, there are some differences in the εd of modified loess. When the σd is consistent, the εd of compacted loess is the highest. The εd of modified loess decreases first and then increases with the increase of lignin content. The εd of modified loess reaches the lowest when the lignin content is 1%. It is indicated that the lignin content has a great influence on the σd–εd curves of lignin-modified loess.

The σd and εd of loess conforms to the Hardin–Drnevich hyperbolic model [3]. Therefore, the relationship between the εd and the reciprocal of the dynamic elastic modulus 1/Ed of lignin-modified loess can be expressed by the following formula:

a and b are fitting parameters. a can reflect the maximum dynamic elastic modulus (Edmax). b can reflect the maximum dynamic stress amplitude (σdmax). Fitting parameters a and b were obtained from the following expression:

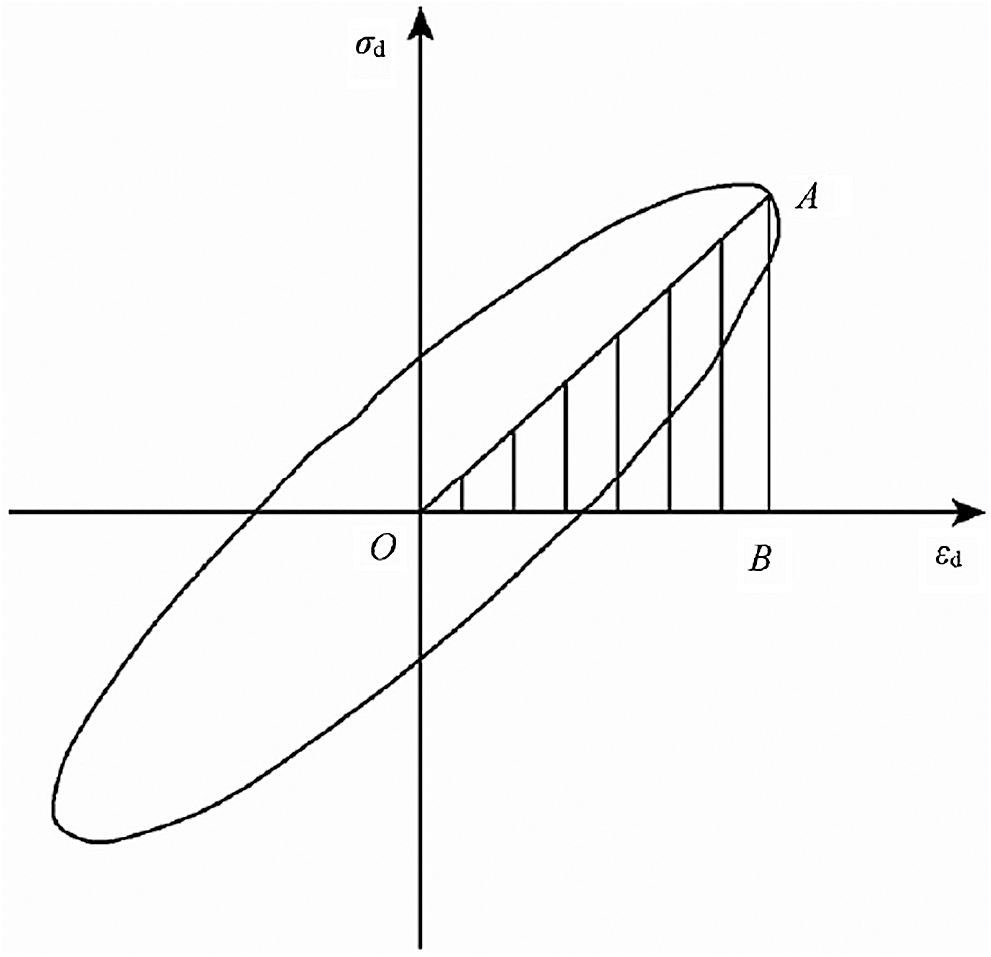

The damping ratio can reflect the internal energy dissipation of soil under dynamic load. As shown in Fig. 11, the damping ratio is calculated by Eq. (5) by calculating the area ΔW of the hysteresis curve and the area W of the ΔAOB.

Figure 11: Calculation method of damping ratio D

3.1 Dynamic Elastic Modulus Characteristics of Lignin-Modified Loess

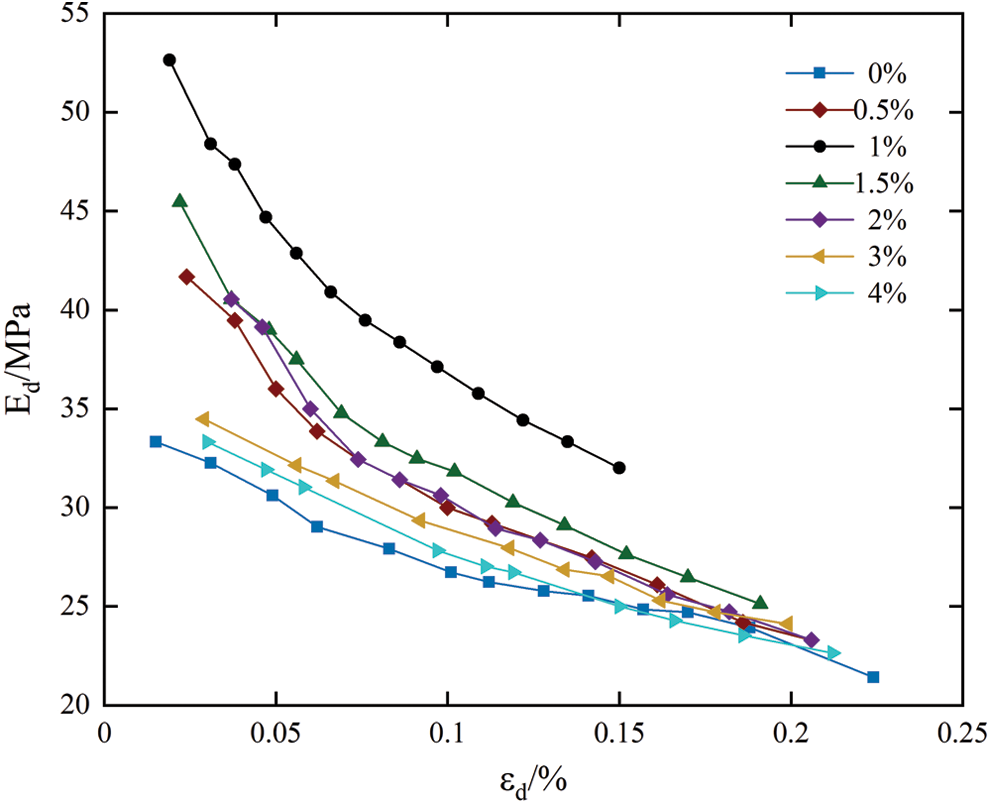

According to the test results of dynamic triaxial tests, the dynamic elastic modulus Ed corresponding to different dynamic strains εd was calculated according to Eq. (1). The relationship curves between the Ed and εd were drawn and shown in Fig. 12.

Figure 12: Dynamic elastic modulus of lignin-modified loess

According to Fig. 12, the Ed of modified loess with different lignin content are quite different. When the lignin content is constant, the Ed of lignin-modified loess gradually decreases with the increase of dynamic strain. Under the same dynamic strain condition, the Ed of lignin-modified loess is larger than compacted loess. In addition, under the same the εd, the Ed of compacted loess is the lowest, and the Ed of the modified loess with 1% lignin content is the highest. It is proved that the addition of lignin can effectively improve the anti-deformation ability of loess under dynamic load and enhance seismic performance. When lignin is added to loess, its fine particles fill the large and medium pores. As a result, the porosity of lignin-modified loess decreases significantly, and the large and medium pores are transformed into the small and micro pores. The soil tends to be dense and the strength is increased. Moreover, lignin has good bonding and chelating properties, which can effectively improve the cementing performance of granular structure. The fine particles in the loess are bound to form agglomerates and the lignin is attached to the joints of the loess particles, so that the cementation between the soil particles is further enhanced, thereby effectively improving the skeleton strength of the loess. This is confirmed in the scanning electron microscope analysis results later.

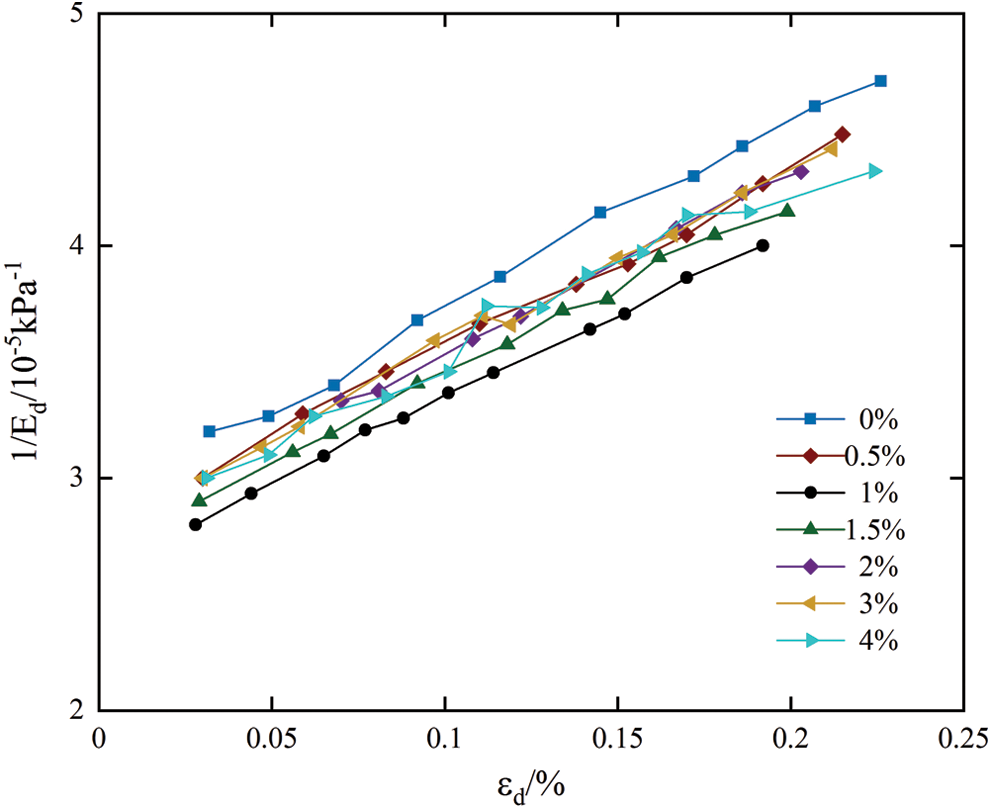

According to results of dynamic elastic modulus and Eq. (2), the 1/Ed~εd relationship curves were drawn and shown in Fig. 13.

Figure 13: 1/Ed~εd relationship of lignin-modified loess

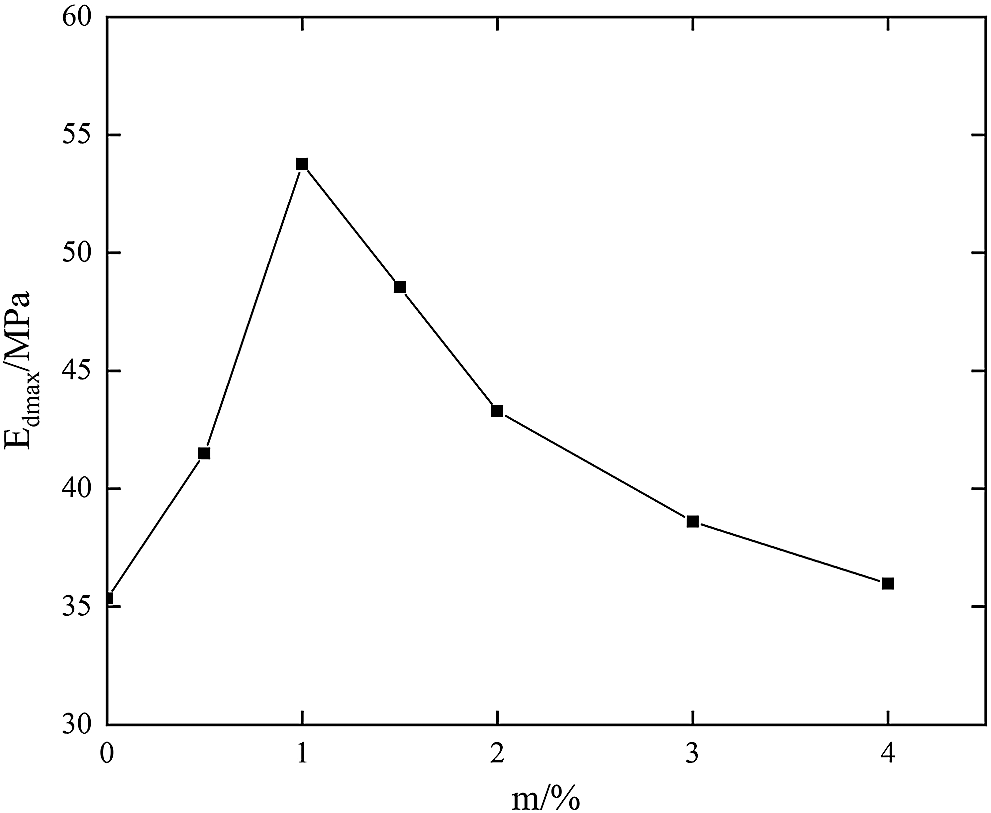

Fig. 13 shows that lignin content has a greater impact on the 1/Ed~εd curves. The 1/Ed~εd curve of compacted loess has the characteristics of the largest slope and the largest intercept. When the lignin is added, the slope and intercept of the 1/Ed~εd curve are smaller than compacted loess. Then, the Edmax and σdmax are calculated according to the Eqs. (3) and (4). Because the Edmax and σdmax have exactly the same change trend, so only the Edmax images are listed, as shown in Fig. 14.

Figure 14: Maximum dynamic elastic modulus of lignin-modified loess

According to Fig. 14, the Edmax of lignin-modified loess is significantly larger than compacted loess. At the same time, the lignin content also has a significant effect on the Edmax of modified loess. The Edmax of lignin-modified loess increases rapidly with the increase of lignin content, and then decreases gradually. When lignin content is 1%, the Edmax reaches the maximum, which is 54.3% higher than that of compacted loess. Related studies on loess dynamics show that the Ed of soil under the same consolidation pressure reflects the bearing capacity and seismic performance of soil [3]. The larger dynamic modulus indicates that the bearing capacity and seismic performance of the soil are better, which further demonstrates the effectiveness of lignin in improving the seismic performance.

3.2 Damping Ratio of Lignin-Modified Loess

The damping ratio of soil represents the influence of soil viscosity on its dynamic constitutive relation, that is, the energy consumed by the internal action of the material when the soil is subjected to dynamic load.

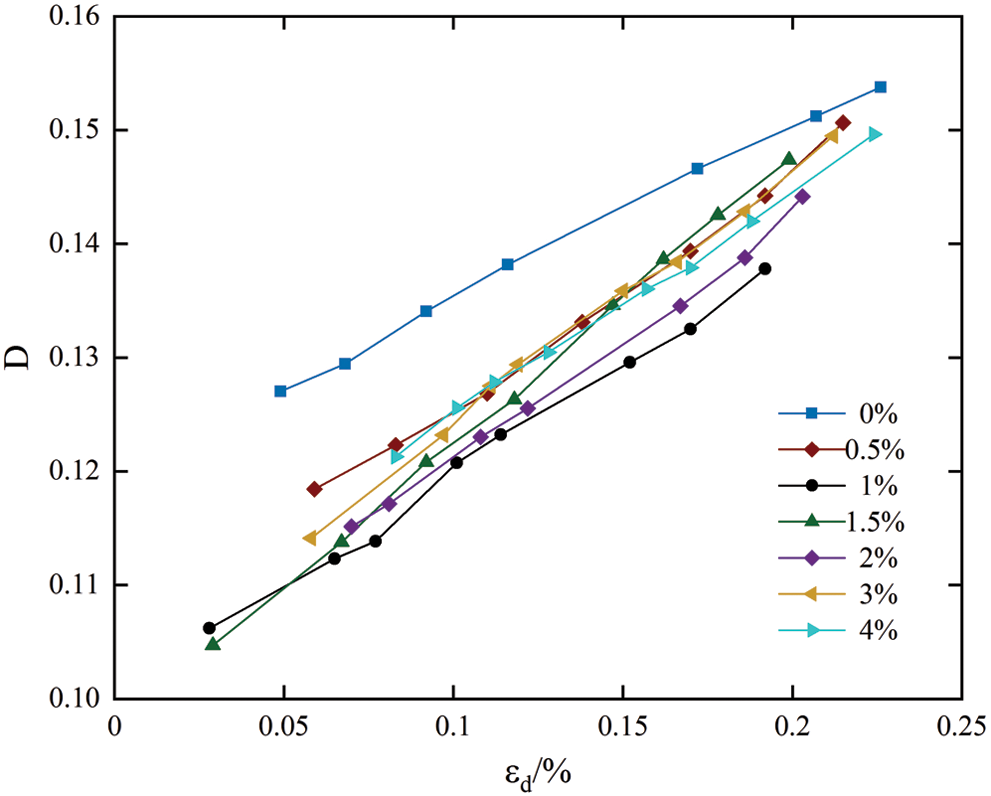

According to the σd and εd recorded results of the dynamic triaxial tests and the Eq. (5), the damping ratio D of lignin-modified loess is shown in Fig. 15.

Figure 15: Damping ratio of lignin-modified loess

The damping ratio D of modified loess with different lignin content increases with the increase of the εd, but the growth trend is not the same. The compacted loess has a relatively large damping ratio at low dynamic strain, but the growth rate is slow. After adding lignin, it is completely opposite to the compacted loess. At low dynamic strain, the damping ratio is relatively small, but the growth rate is relatively fast. And under the same εd, the damping ratio of compacted loess is the largest, and the damping ratio of modified loess with 1% lignin content is the smallest. In addition, the damping ratio of lignin-modified loess is smaller than that of compacted loess, and it has better seismic performance. This is because the dynamic strain of compacted loess increases with the increase of dynamic stress under dynamic load. The cementation and skeletal structure between the loess particles are gradually destroyed, and the soil particles are prone to relative slippage. The energy consumed by the internal friction of the soil increases, and the damping characteristics also increase, so the damping ratio also increases. However, when lignin is added, the large and medium pores of the soil are fully filled, and the cementation strength of the particles increases. This is confirmed in the scanning electron microscope analysis results later. Under dynamic load, the hysteresis loop is difficult to deploy, and the energy consumed is also reduced, so the damping ratio is also reduced.

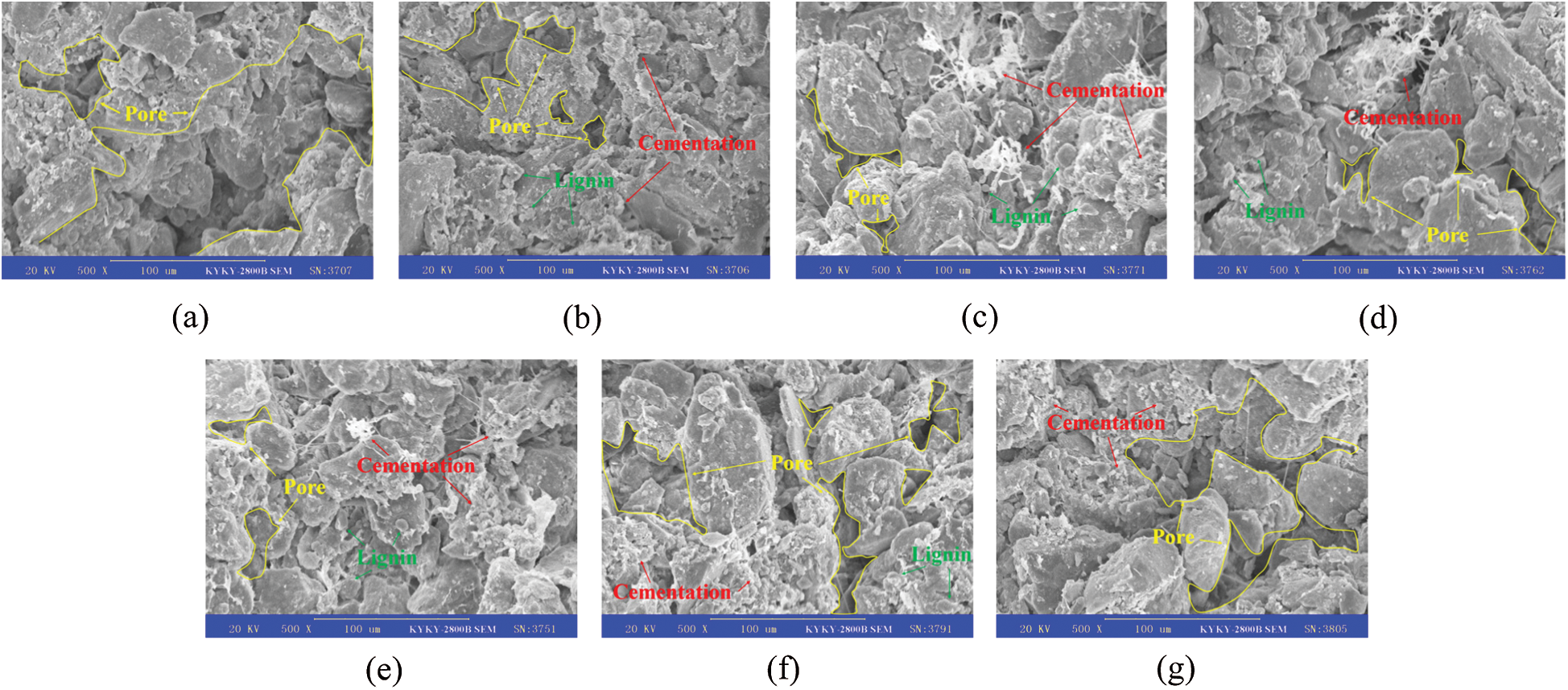

The improvement of the mechanical properties of modified loess is closely related to its microstructure. To analyze the mechanical effect of lignin, SEM was used to compare the microstructures of the modified (0.5%–4% lignin) and compacted (0% lignin) loess samples. Fig. 16 shows the results of this analysis.

Figure 16: The microstructure of modified loess: (a) m = 0; (b) m = 0.5%; (c) m = 1%; (d) m = 1.5%; (e) m = 2%; (f) m = 3%; (g) m = 4%

There are still many pores inside the soil, and the overhead pores are very obvious in compacted loess. Its particles are mainly overlapped, and the contact type is still mainly “point contact”. It has less flocculent cementing material and is prone to deformation and failure under dynamic load. When lignin is added to loess, there is a significant increase of fine granular, spherical or flocculent lignin between the particles. When the lignin content is 0.5%–2%, the lignin makes the flocculent cement material in the soil increase significantly. It shows that lignin has a good cementing effect on loess particles and strengthens the particle skeleton. In addition, the fine lignin particles fill the pores in the loess, reducing the pore area of modified loess, thereby enhancing the strength of loess soil. Lignin makes the structure type gradually change from mosaic structure to clot cement structure. The contact type between loess particles has also changed from “point contact” to “surface contact”. When the lignin content is 3%–4%, the filling amount of lignin particles in the pores is significantly reduced. The pore filling effect of lignin is significantly weakened, and the pore area is significantly increased. In addition, some lignin binds and cements with itself to form agglomerates without cementing with loess particles. This leads to a weakening of the cement strength between the particles, and the structure type is again transformed into mosaic structure.

The results of microstructure analysis show that the lignin content is too high or too low to fully and effectively reinforce the loess. This is because when the lignin content is too low (m ≤ 0.5%), the rare lignin cannot fully fill pores inside the loess, and its own cohesiveness and chelation property cannot fully cement the particles and strengthen the loess skeleton. On the contrary, because lignin is a lightweight material with low density, when the lignin content is high (m ≥ 3%), the volume of lignin mixed into loess is already large enough, and the lignin will preferentially combine with itself, resulting in ineffective modify soil [15,35]. Lignin itself is relatively loose, and too much lignin will form a porous structure after combining with itself, resulting in increased porosity [35]. In addition, the increase of lignin particles between soil particles will increase the distance between soil particles, resulting in the increase of double electric layer thickness and the decrease of the attraction between particles [23,35]. As a result, lignin changed from “cementing action” to “lubricating action”, thus reducing the strength of modified loess.

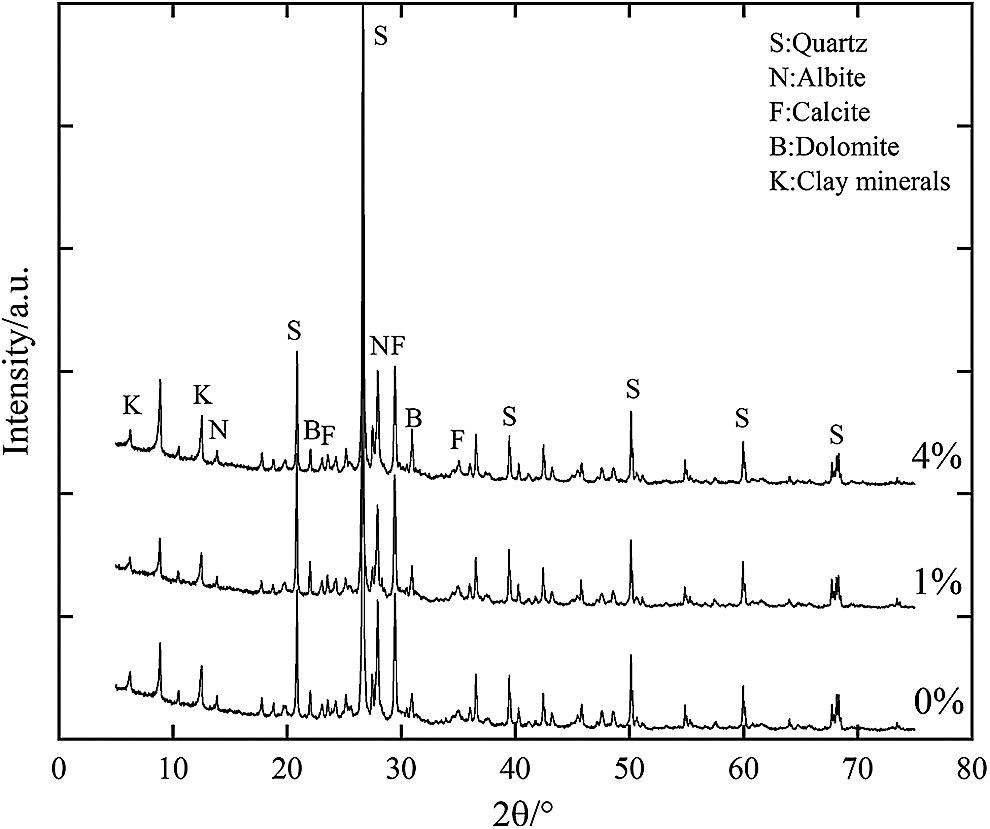

Studying the difference in mineral composition of modified loess with different lignin content is helpful to determine the interaction between lignin and loess, and analyze the reinforcement mechanism. Through the comparative analysis of X-ray diffraction patterns, it is found that the diffraction peaks of compacted loess and modified loess appear basically at the same positions, and no new diffraction peaks appear. This shows that compared with compacted loess, no new mineral components are generated in lignin-modified loess. Three XRD results of typical lignin content (0%, 1%, 4%) are selected for illustration (Fig. 17).

Figure 17: The XRD results of lignin-modified loess

Based on the test results and analysis of the dynamic characteristics and microstructure of lignin-modified loess, it is found that the dynamic characteristics with different lignin content are obviously different. So, there is the possibility of optimal lignin content. According to Fig. 12, under the same εd condition, the Ed of compacted loess is the lowest, and Ed of the modified loess with 1% lignin content is the highest. According to Fig. 14, it is found that the Edmax of lignin-modified loess gradually increases with the increase of the lignin content, and reach the maximum when the lignin content is 1%, and then gradually decrease. The Edmax of the modified loess with 1% lignin content increased by 54.3% compared with compacted soil. Fig. 15 shows that lignin content has a great influence on the D of lignin-modified loess. Under the same the εd condition, the D of compacted loess is the largest, and the D of modified loess with 1% lignin content is the smallest. According to Fig. 16, the modified loess with 1% lignin content has the best microstructure stability. These show that the addition of lignin enhances the anti-deformation ability of loess under dynamic load and enhances the seismic performance of loess foundation, and lignin-modified loess has the best dynamic characteristics when the lignin content is 1%.

In this paper, the dynamic elastic modulus and damping ratio of lignin-modified loess have been discussed and the following conclusions can be drawn:

(1) Lignin can effectively modify the dynamic deformation of loess under dynamic load. When the σd is consistent, the εd of lignin-modified loess is smaller than compacted loess.

(2) The Ed of the lignin-modified loess with different lignin content is quite different, but both decrease with the increase of dynamic strain. The Edmax of modified loess with lignin content of 1% is significantly greater than other lignin contents.

(3) The damping ratio of lignin-modified loess with different lignin content increases with the increase of dynamic strain. Under the same the εd condition, the damping ratio of lignin-modified loess is smaller than compacted loess, and reach the minimum at lignin content of 1%.

(4) Lignin can effectively fill loess pores and cement loess particles. Compared with compacted loess, no new mineral components are generated in lignin-modified loess. The optimum lignin content of dynamics characteristic of modified loess is present, and the optimum lignin content is 1% based on the analysis of the dynamic elastic modulus, damping ratio and microstructure of lignin-modified loess.

Funding Statement: This study was supported in part by the Funding of Science for Earthquake Resilience (Grant Nos. XH20057, XH21034, XH21036Y), the National Natural Science Foundation of China (Nos. 51778590, 51408567), the grant of the Fundamental Research Funding for the Institute of Earthquake Forecasting, China Earthquake Administration (Grant Nos. 2018IESLZ06, 2016IESLZ01), the Science and Technology Projects Funding for Lanzhou City (Grant No. 2018-1-123).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Boulanger, R. W., Meyers, M. W., Mejia, L. H., Idriss, I. M. (1998). Behavior of a fine-grained soil during Loma Prieta earthquake. Canadian Geotechnical Journal, 35(1), 146–158. DOI 10.1139/t97-078. [Google Scholar] [CrossRef]

2. Jefferson, I. F., Evstatiev, D., Karastanev, D. (2003). Engineering geology of loess and loess-like deposits: A commentary on the Russian literature. Engineering Geology, 68(3–4), 333–351. DOI 10.1016/S0013-7952(02)00236-3. [Google Scholar] [CrossRef]

3. Wang, L. M., Shi, Y. C., Liu, X. (2003). Loess dynamics. China: Seismological Press. [Google Scholar]

4. Gao, H., Bu, C. Y., Wang, Z. H., Shen, Y. Q., Chen, G. X. (2017). Dynamic characteristics of expanded polystyrene composite soil under traffic loadings considering initial consolidation state. Soil Dynamics and Earthquake Engineering, 102, 86–98. DOI 10.1016/j.soildyn.2017.08.012. [Google Scholar] [CrossRef]

5. Li, W., Lang, L., Wang, D. (2018). Investigation on the dynamic shear modulus and damping ratio of steel slag sand mixtures. Construction and Building Materials, 162, 170–180. DOI 10.1016/j.conbuildmat.2017.12.026. [Google Scholar] [CrossRef]

6. Zhang, X. D., Ren, K. (2018). Experimental study on dynamic elastic modulus and critical dynamic stress of cinder-improved soil subgrade. Journal of Highway and Transportation Research and Development (English Edition), 12(4), 25–32. DOI 10.1061/JHTRCQ.0000650. [Google Scholar] [CrossRef]

7. Wang, Q., Wang, L. M., Zhong, X. M., Guo, P., Wang, J. et al. (2019). Dynamic behavior and constitutive relationship of saturated fly ash-modified loess. European Journal of Environmental and Civil Engineering, 98(1), 1–16. DOI 10.1080/19648189.2019.1577181. [Google Scholar] [CrossRef]

8. Fei, K., Xu, J. X. (2017). Dynamic behavior of clay-aggregate mixtures. Advances in Materials Science and Engineering, 2017(5), 1–10. DOI 10.1155/2017/2479507. [Google Scholar] [CrossRef]

9. Volkan, O., Kubra, A. (2018). Dynamic behavior of soft subgrade soils treated with boron waste. Advances in Materials Science and Engineering, 2(2), 1–10. DOI 10.1155/2018/2390481. [Google Scholar] [CrossRef]

10. Jia, L., Li, C. X., Guo, J. (2020). Mechanical properties of lime-fly ash-sulphate aluminum cement stabilized loess. Journal of Renewable Materials, 8(10), 1357–1373. DOI 10.32604/jrm.2020.012136. [Google Scholar] [CrossRef]

11. Wang, J. D., Peng, S. J., Xie, W. L. (2014). Study on the cement-improved loess under the vibratory load by dynamic tests. Advanced Materials Research, 838–841, 1302–1308. DOI 10.4028/www.scientific.net/AMR.838-841.1302. [Google Scholar] [CrossRef]

12. Wang, M., Kong, L. W., Wang, X. Y. (2012). Study on dynamical modulus and damping ratio of lime-treated soil. Advanced Materials Research, 487, 534–538. DOI 10.4028/www.scientific.net/AMR.487.534. [Google Scholar] [CrossRef]

13. Lu, X. S., Xiang, W. (2011). Experimental study on dynamic characteristics of ionic soil stabilizer reinforcing red clay. Advanced Materials Research, 374–377, 1391–1395. DOI 10.4028/www.scientific.net/AMR.374-377.1391. [Google Scholar] [CrossRef]

14. Shi, W., Hu, R., Zhang, L. L., Pan, Y. (2016). Experimental study on geosynthetic reinforced soil dynamic characteristics under cyclic loading. DEStech Transactions on Engineering and Technology Research, 2016, 832–838, DOI 10.12783/dtetr/ictim2016/5573. [Google Scholar] [CrossRef]

15. Jiang, T. D. (2008). Lignin. China: Chemical Industry Press. [Google Scholar]

16. Sevastyanova, O., Qin, W., Kadla, J. F. (2010). Effect of nanofillers as reinforcement agents for lignin composite fibers. Journal of Applied Polymer Science, 117(5), 2877–2881. DOI 10.1002/app.32198. [Google Scholar] [CrossRef]

17. Buddhima, I., Thevaragavan, M., Hadi, K. (2009). Modelling the erosion rate of chemically stabilized soil incorporating tensile force-deformation characteristics. Canadian Geotechnical Journal, 46(1), 57–68. DOI 10.1139/T08-103. [Google Scholar] [CrossRef]

18. Puppala, A. J., Hanchanloet, S. (1999). Evaluation of a new chemical (SA-44/LS-40) treatment method on strength and resilient properties of a cohesive soil. Transportation Research Board, Washington, DC, USA, 1–11. [Google Scholar]

19. Gaetan, B., Oliver, C., Farimah, M. (2014). Soil treatment with organic non-traditional additives for the improvement of earthworks. Acta Geotechnica, 9(6), 1111–1122. DOI 10.1007/s11440-013-0251-6. [Google Scholar] [CrossRef]

20. Halil, C., Kasthurirangan, G., Sunghwan, K. (2010). Soil stabilization with bioenergy coproduct. Transportation Research Record: Journal of the Transportation Research Board, 2186(1), 130–137. DOI 10.3141/2186-14. [Google Scholar] [CrossRef]

21. Xiao, L. G., Liu, G., Feng, S., Zhang, S. T. (2013). Preparation and properties of a new polymer-modified cement mortar containing iron tailings sand. Advanced Materials Research, 687, 107–111. DOI 10.4028/www.scientific.net/AMR.687.107. [Google Scholar] [CrossRef]

22. Sadeghi, N., Shayesteh, K., Lotfiman, S. (2016). Effect of modified lignin sulfonate on controlled-release urea in soil. Journal of Polymers and the Environment, 25(3), 792–799. DOI 10.1007/s10924-016-0848-6. [Google Scholar] [CrossRef]

23. Zhang, T., Liu, S. Y., Cai, G. J., Puppala, A. J. (2014). Study on strength characteristics and microcosmic mechanism of silt improved by lignin-based bio-energy coproducts. Geoshanghai2014. ASCE, Shanghai, China, 220–230. DOI 10.1061/9780784413401.022. [Google Scholar] [CrossRef]

24. Zhang, T., Liu, S. Y., Cai, G. J., Puppala, A. J. (2014). Stabilization of silt using a lignin-based bioenergy coproduct. 93th Transportation Research Board Annual Meeting, Washington, DC, USA. [Google Scholar]

25. Zhang, T., Liu, S. Y., Cai, G. J., Puppala, A. J. (2015). Experimental investigation of thermal and mechanical properties of lignin treated silt. Engineering Geology, 196, 1–11. DOI 10.1016/j.enggeo.2015.07.003. [Google Scholar] [CrossRef]

26. Zhang, T., Liu, S. Y., Cai, G. J., Puppala, A. J. (2016). Engineering properties and microstructural characteristics of foundation silt stabilized by lignin-based industrial by-product. KSCE Journal of Civil Engineering, 20(7), 2725–2736. DOI 10.1007/s12205-016-1325-4. [Google Scholar] [CrossRef]

27. Chen, Q. S., Indraratna, B. (2014). Shear behaviour of sandy silt treated with lignosulfonate. Canadian Geotechnical Journal, 52(8), 1180–1185. DOI 10.1139/cgj-2014. [Google Scholar] [CrossRef]

28. Chen, Q. S., Indraratna, B. (2014). Deformation behavior of lignosulfonate-treated sandy silt under cyclic loading. Journal of Geotechnical and Geoenvironmental Engineering, 141(1), 06014015. DOI 10.1061/(ASCE)GT.1943-5606.0001210. [Google Scholar] [CrossRef]

29. Hou, X., Ma, W., Li, G. Y., Mu, Y. H., Zhou, Z. W. et al. (2017). Influence of lignosulfonate on mechanical properties of lanzhou loess. Rock and Soil Mechanics, 38(S2), 18–26. DOI 10.16285/j.rsm.2017.S2.003. [Google Scholar] [CrossRef]

30. He, Z. Q., Fan, H. H., Wang, J. Q., Liu, G. (2017). Experimental study of engineering properties of loess reinforced by lignosulfonate. Rock and Soil Mechanics, 38(3), 731–739. DOI 10.16285/j.rsm.2017.03.015. [Google Scholar] [CrossRef]

31. Liu, W., Wang, J., Lin, G. C., Li, W. (2019). Microscopic mechanism affecting shear strength in lignin-treated loess samples. Advances in Materials Science and Engineering, 2019(3), 1–12. DOI 10.1155/2019/7126040. [Google Scholar] [CrossRef]

32. Ministry of Housing and Urban-Rural Development of the People’ Republic of China. (2019). Specification of Soil Test: GB/T50123-2019. China: China Architecture & Building Press. [Google Scholar]

33. Wang, Q., Ma, J. L., Ma, H. P., Wang, J., Wang, L. M. et al. (2019). Dynamic shear modulus and damping ratio of saturated loess. Chinese Journal of Rock Mechanics and Engineering, 38(09), 1919–1927. DOI 10.13722/j.cnki.jrme.2019.0249. [Google Scholar] [CrossRef]

34. Xie, D. Y. (1988). Soil dynamics. China: Xian Jiaotong University Press. [Google Scholar]

35. Wang, Q., Zhong, X. M., Ma, H. P., Wang, S. Y. Liu, Z. Z. et al. (2020). Microstructure and reinforcement mechanism of lignin-modified loess. Journal of Materials in Civil Engineering, 32(11), 04020319. DOI 10.1061/(ASCE)MT.1943–5533.0003422. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License,, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |