DOI:10.32604/jrm.2021.013134

| Journal of Renewable Materials DOI:10.32604/jrm.2021.013134 |  |

| Article |

Ancient Materials and Substitution Materials Used in Thai Historical Masonry Structure Preservation

Department of Civil Engineering, Faculty of Engineering, King Mongkut’s University of Technology Thonburi, Bangkok, 10140, Thailand

This paper is an extended and revised version of an article presented at the International Conference on Sustainable Energy and Green Technology 2019 (SEGT 2019) on 11-14 December 2019 in Bangkok, Thailand

*Corresponding Author: Chainarong Athisakul. Email: chainarong.ath@kmutt.ac.th

Received: 27 July 2020; Accepted: 08 September 2020

Abstract: The historical structures of Thailand are some of the most fascinating ancient sites in Asia. Their architectures reveal past cultures, traditions, knowledge, and expertise. Masonry materials are the major materials used to construct the historical structures in Thailand. One of the essential problem of Thai historical structure preservation is a shortage of engineering properties data for the structural stability assessment. Moreover, the in-depth engineering properties and the suitable substitution materials for Thai historical preservation are rarely found. Therefore, the engineering properties of the ancient masonry materials have to be explored together with the development of suitable substitute materials. This paper presents the physical and engineering properties of ancient materials and substitution materials for the preservation of Thailand’s historical structures. The ancient materials, including brick and mortar, are collected from historical places in the Bangkok and Ayutthaya Provinces. The physical and engineering properties of the masonry materials, such as the chemical composition, mineralogical composition, density, porosity, absorption, water vapor transmission, compressive strength, and modulus of elasticity, were evaluated in the laboratory. Fly ash was used as a pozzolanic material to partially replace the slaked lime to restore the historical mortar. The binder to sand ratio was controlled at 1:3 by weight. The slaked lime was substituted by fly ash at the rates of 10–30% by weight of binder. The engineering properties of the substitution mortars were also evaluated and compared with the ancient masonry materials. A masonry prism was also constructed to evaluate the compressive strength and the modulus of elasticity of the masonry structures. The physical and engineering properties of the ancient masonry materials obtained in this study can be included in a database for the preservation of Thailand’s historical masonry structures. The use of fly ash to partially replace the slaked lime could decrease the setting time and increase the compressive strength of historical repair mortar. The empirical equation obtained from this study could be used to predict the compressive strength of the masonry prisms of Thailand’s historical structures.

Keywords: Ancient masonry materials; engineering properties; fly ash; historical structures of Thailand; substitution materials

The historical sites are valuable pieces of cultural heritage that reflect the history of the nation. Updated scientific knowledge, including engineering, architecture, history, archeology, painting, and fine arts, is essential to preserve these ancient sites. The increasing incidence and changing patterns of natural disasters affect the structural stability and the mechanical properties of old masonry materials, which may lead to an eventual structure collapse. In Thailand, many historical masonry structures are at risk of being damaged by natural disasters and deteriorating materials, as shown in Fig. 1. A shortage of data on the engineering properties of these structures may cause long time damage to the masonry caused by unsuitable preservation methods and materials.

Figure 1: Examples of masonry structures damaged by deteriorating materials

Masonry is a general construction material used in historical structures worldwide. In the literature, there are many related reports on the experimental data of masonry materials [1,2]. Curtin et al. [3] proposed that the compressive strength of masonry prisms depends on the brick and mortar strength, the area of the masonry prisms, and the height-to-thickness (h/t) ratio. Basha et al. [4] presented the stress-strain characteristic of fly ash masonry. The results showed that the compressive strength and modulus of elasticity of masonry prisms made with fly ash brick and cement to sand (1:4) mortar were 3.9 MPa and 2,667 MPa, respectively. The predictive equation of the modulus of elasticity was  , where

, where  is the compressive strength of the masonry. Murugan et al. [5] also proposed fly ash bricks prisms and clay brick prisms made with cement-sand (1:4) mortar. It was found that the compressive strength of a fly ash brick prism was 2.73 MPa, while that of the clay brick prism was 1.17 MPa. The Young’s modulus values of the fly ash and clay brick prisms were 13,693 and 8,463 MPa, respectively. The brick type affects the compressive strength and modulus of elasticity of the masonry prism. According to the previous research, the compressive strength of masonry prisms was constructed with new bricks and cement sand mortar, which are not appropriate for historical structures. However, the mechanical properties of masonry prisms made with the slaked lime mortar have not been reported. For ancient materials, Bhattarai et al. [6] studied the physical and mechanical properties of ancient clay bricks from 7 samples of Kathmandu valley in Nepal. It was found that the compressive strength values of all the ancient brick samples ranged between 5 and 23 MPa. San et al. [7] proposed the physical, mechanical, and chemical characterization of ancient brick in 8 monuments in Myanmar. The range of the compressive strength varies from 2.33 to 16.65 MPa. In Thailand, Phansuwan [8] reported the compressive strength and modulus of elasticity of ancient bricks in 9 monuments in Ayutthaya Province. The results showed that the compressive strength of ancient bricks ranged between 3.69 and 5.61 MPa while the modulus of elasticity of cube brick ranged from 2,612.7 to 4,159.4 MPa. Moreover, other materials, such as bamboo [9,10], were investigated to determine the mechanical properties for structural behavior analysis in green buildings.

is the compressive strength of the masonry. Murugan et al. [5] also proposed fly ash bricks prisms and clay brick prisms made with cement-sand (1:4) mortar. It was found that the compressive strength of a fly ash brick prism was 2.73 MPa, while that of the clay brick prism was 1.17 MPa. The Young’s modulus values of the fly ash and clay brick prisms were 13,693 and 8,463 MPa, respectively. The brick type affects the compressive strength and modulus of elasticity of the masonry prism. According to the previous research, the compressive strength of masonry prisms was constructed with new bricks and cement sand mortar, which are not appropriate for historical structures. However, the mechanical properties of masonry prisms made with the slaked lime mortar have not been reported. For ancient materials, Bhattarai et al. [6] studied the physical and mechanical properties of ancient clay bricks from 7 samples of Kathmandu valley in Nepal. It was found that the compressive strength values of all the ancient brick samples ranged between 5 and 23 MPa. San et al. [7] proposed the physical, mechanical, and chemical characterization of ancient brick in 8 monuments in Myanmar. The range of the compressive strength varies from 2.33 to 16.65 MPa. In Thailand, Phansuwan [8] reported the compressive strength and modulus of elasticity of ancient bricks in 9 monuments in Ayutthaya Province. The results showed that the compressive strength of ancient bricks ranged between 3.69 and 5.61 MPa while the modulus of elasticity of cube brick ranged from 2,612.7 to 4,159.4 MPa. Moreover, other materials, such as bamboo [9,10], were investigated to determine the mechanical properties for structural behavior analysis in green buildings.

However, the assessment of the masonry prisms strength for engineering analysis was difficult to achieve, as there are limited samples of the ancient materials from historical places. Therefore, many researchers have developed an empirical equation for predicting the compressive strength of masonry prisms. Sajanthan et al. [11] evaluated the compressive strength of stabilized earth block masonry with a block strength range of 4.61–12.19 MPa and a cement-soil mortar strength range of 1.64–6.90 MPa. Kaushik et al. [12] conducted a compression test of clay brick, mortar, and masonry to formulate the prediction equation. The results showed that the strength values of clay brick and cement-lime-mortar ranged between 16.1–28.9 MPa and 3.1–20.6 MPa, respectively. Gumaste et al. [13] presented models to predict the compressive strength of two types of masonry as bonded stacks and English boned prisms with cement-soil mortar. Christy et al. [14] derived a prediction model for the strength of masonry after testing unreinforced and reinforced masonry prisms made with clay brick and fly ash bricks with different cement mortar strength values. Lumantarna et al. [15] performed testing on a masonry prism made with vintage clay bricks extracted from a historical site in New Zealand. The strength values of the bricks ranged from 8.5 to 43.4 MPa, while the cement-lime-sand mortar strength values ranged from 0.69 to 23.2 MPa. Kumavat [16] proposed a model for predicting the compressive strength of masonry prisms made from cement-sand mortar and clay brick. The strength of clay bricks is in the range of 4.60–5.53 MPa and that of cement-sand mortar is in the range of 24.98–28.67 MPa.

The important problem of Thai historical structure preservation is the use of white cement mixed with the slaked lime as the mortar for restoring these structures. However, a specialist from ICOMOS suggested that the use of cement in mortars should be replaced with lime [17]. Many studies presented suitable mortars for the restoration of historical structures. For example, Moropoulou et al. [18] proposed mortars mixed with hydraulic lime, lime, and a lime-pozzolanic additive for the restoration of the historical masonry of Hagia Sophia. Viega et al. [19] proposed the mortar properties by using lime and pozzolanic materials added for the restoration of a historical building in Portugal. It was observed that the mortars mixed with lime to sand (1:3) had a compressive strength range of 0.6–1.6 MPa. Then, there is the development of the lime mortar mixed with rice husk ash for ancient masonry prisms by Almeida et al. [20]. The results showed that the use of rice husk ash could increase the compressive strength, flexural strength, and modulus of elasticity of mortar. Faria et al. [21] proposed a comparison between lime putty and the slaked lime mortar at the ages of 10 months. It was found that the compressive strength of slaked lime mortars is higher than that of lime putty. In Thailand, Watsantachard [22] presented that the ancient mortar of the historical structures in Ayutthaya is mainly composed of lime and sand. On the other hand, the lime to sand ratio and the physical and mechanical properties of ancient mortar depend on the historical place. As mentioned above, the highlight and novelty of this work are to produce the suitable substitution material made from the slaked lime mixed with fly ash for Thai historical preservation. In-depth engineering properties of Thai historical masonry structures are investigated in order to use as engineering data-base for engineer and people who is interesting in historical preservation. Moreover, the empirical equations for predicting the compressive strength of masonry prisms made with slaked lime mortars in Thailand are presented in this study.

Consequently, the objective of this study is to investigate the physical and engineering properties of ancient masonry and substitution materials for the preservation of Thailand’s historical structures. The physical and engineering properties of masonry materials, such as the chemical composition, mineralogical composition density, porosity, absorption, water vapor transmission, compressive strength, and modulus of elasticity, are determined. The strength and setting time of substitute mortars using fly ash as a pozzolanic material are investigated. Masonry prisms were constructed to evaluate the compressive strength and the modulus of elasticity of the masonry. The relationship between the density, the strength of the brick, and the strength of the masonry prism are presented. Finally, the equation for predicting the compressive strength of bricks and masonry prisms can be developed.

Knowledge of the physical and engineering properties of materials is essential for the assessment of the structural stability. In this study, the density, porosity, absorption, water vapor transmission, and compressive strength of masonry materials were evaluated in the laboratory. The testing for the density, water vapor transmission, and setting time of the materials was performed according to ASTM C134, E96/E96M, and C807 [23–25], respectively. The porosity and absorption testing of the materials follows guideline of the international center for the study of the preservation and restoration of cultural property (ICCROM) [26]. The compressive strength values of the bricks and mortars were obtained by laboratory testing based on ASTM C67/C67M [27] and ASTM C109/C109M [28], respectively. The XRF analysis was applied to identify the primary chemical compositions of specimens from various Thai historical structures. The XRD analysis was used to investigate the mineral phases of the ancient materials. The compression and elastic modulus of the masonry prism are also investigated. The following sections present the details of the material preparation and the test set up for the masonry prism.

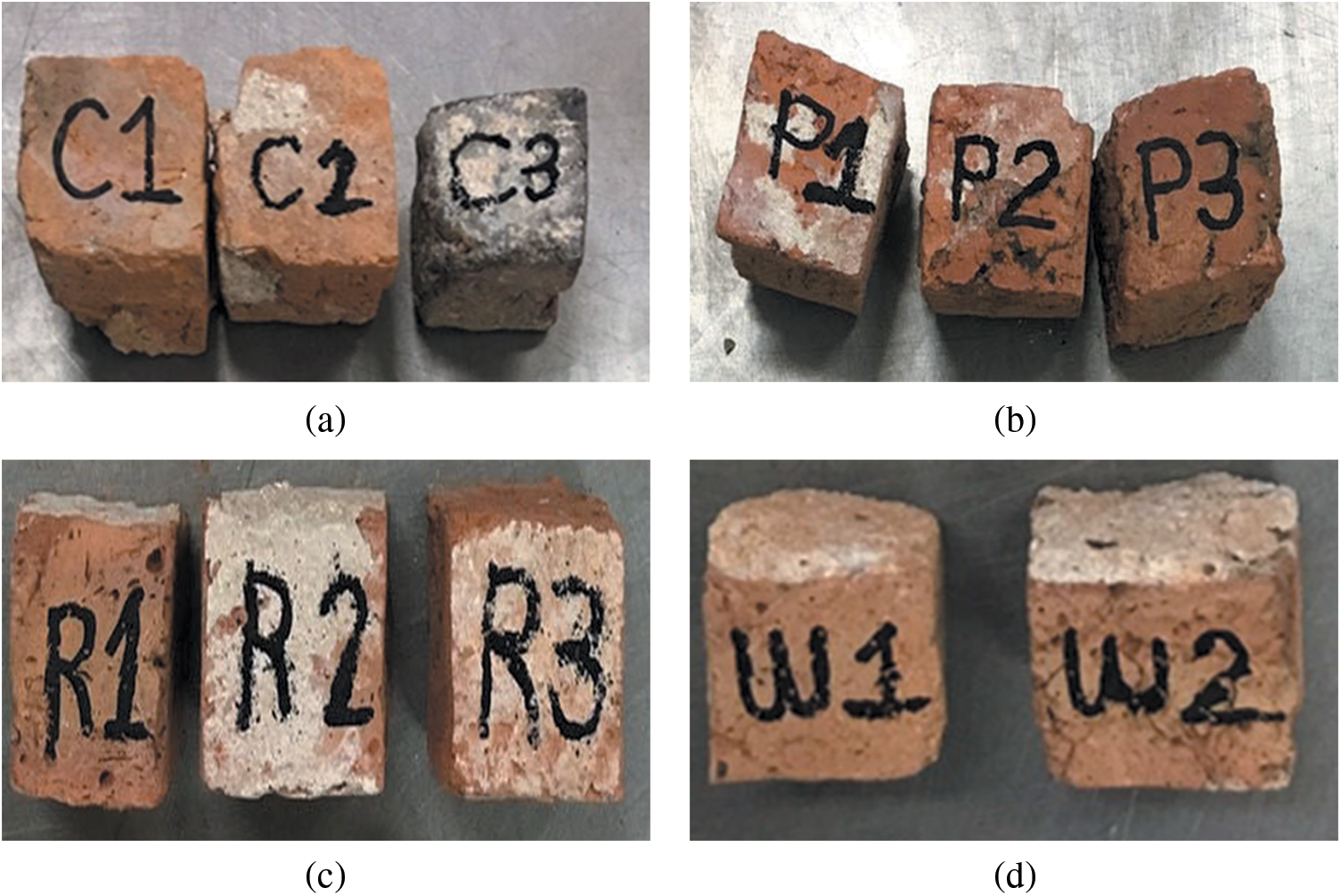

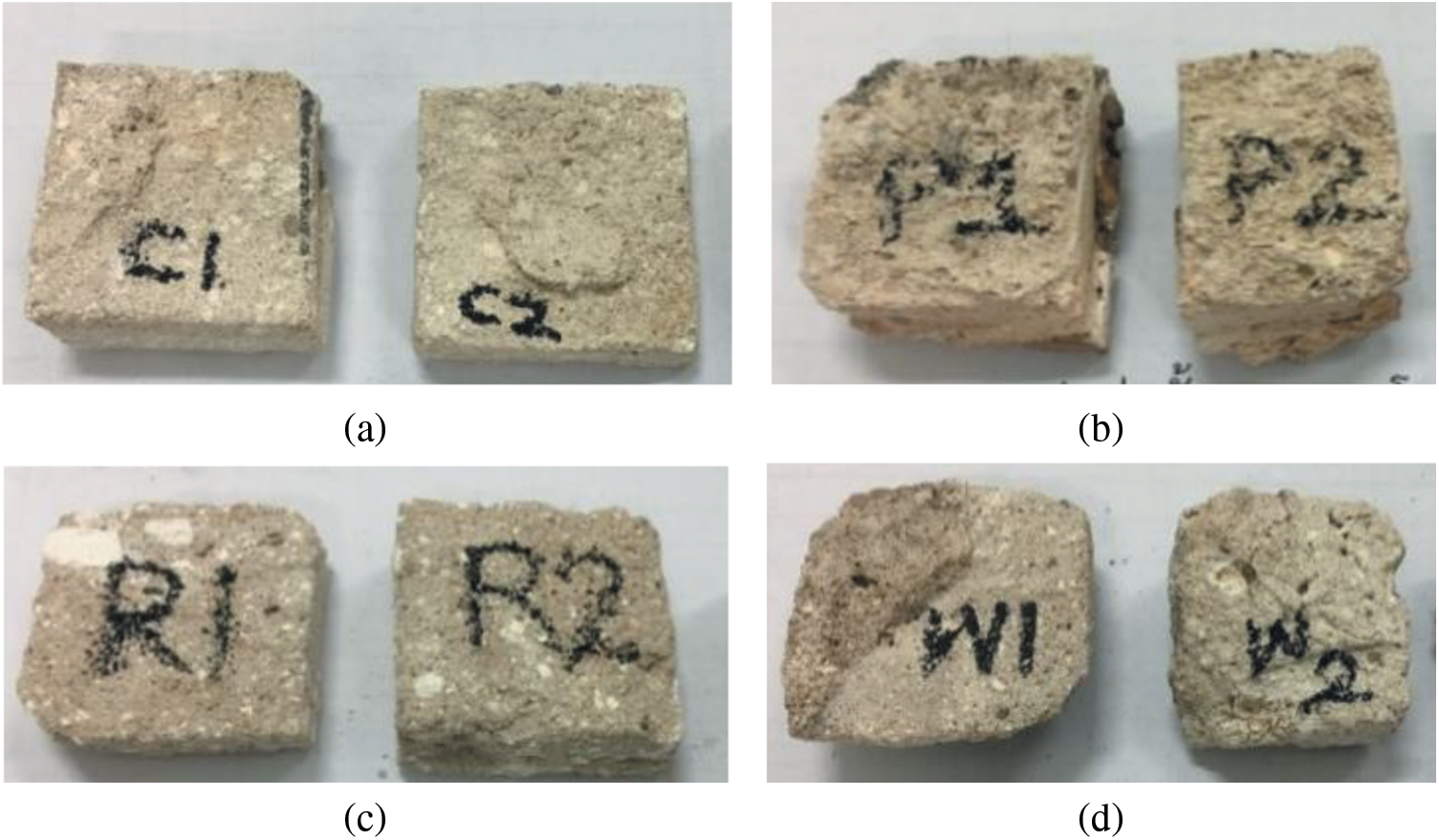

The samples of ancient bricks and ancient mortars were collected from various historical sites in the Bangkok and Ayutthaya Provinces, which are Wat Chaiwatthanaram, Wat Phrasrisanphet, Werng Nakhon Kasem and Ancient Palace. The abbreviations for the ancient brick samples obtained from these sites are BC, BP, BW, and BA, respectively. Correspondingly, the ancient mortars from these sites are also abbreviated as MC, MP, MW, and MA, respectively. Figs. 2a–2d and 3a–3d show examples of ancient bricks and ancient mortar from four historical sites. According to the inconsistency in the shapes of the specimens, the specimens of ancient bricks and mortar were made into cube shapes. The size of each specimen is approximately 50 mm 50 mm

50 mm  50 mm.

50 mm.

Figure 2: Examples of ancient bricks from four Thai historical sites. (a) brick of Wat Chaiwatthanaram, (b) brick of Wat Phrasrisunphet, (c) brick of Ancient Palace, (d) brick of Werng Nakorn Kasem

Figure 3: Examples of ancient mortars from four historical sites. (a) mortar of Wat Chaiwatthanaram, (b) mortar of Wat Phrasrisunphet, (c) mortar of Ancient Palace, (d) mortar of Werng Nakorn Kasem

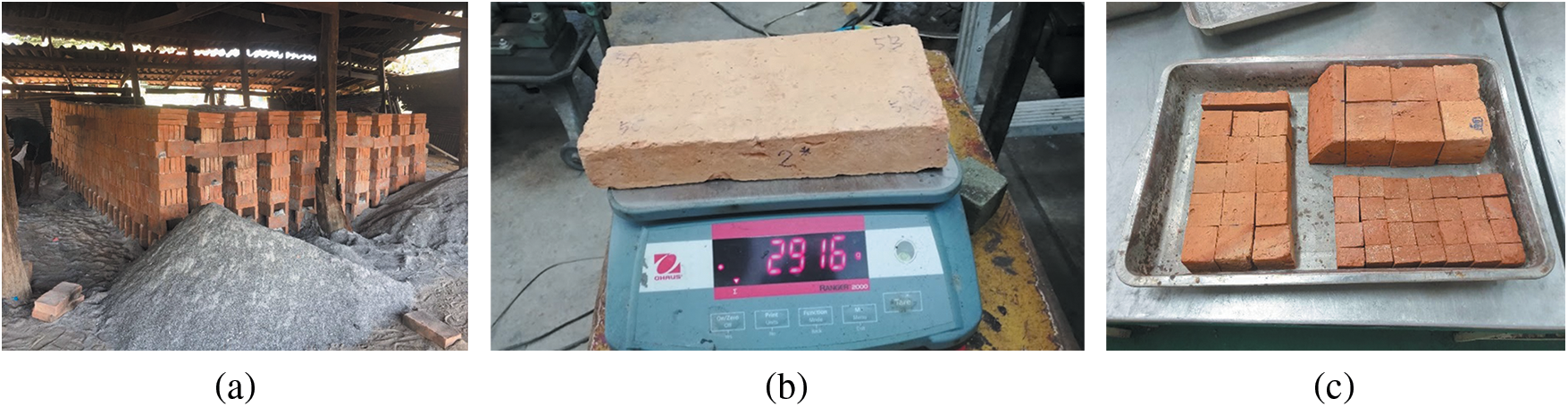

The substitution bricks (BS) and the slaked lime in a wet condition are obtained from the restoration site in Ayutthaya Province. Fig. 4a shows a brick factory in Ayutthaya Province. The conventional sized bricks in Thailand are mostly manufactured by a hand molding process and are fired in rudimentary kilns. Consequently, the obtained bricks are warped and usually unevenly burned. Since the compressive strength values of the bricks depend on the sizes of the specimens, the substitution brick specimens are prepared into two shapes. The first is the original flatwise bricks of size 300 mm  150 mm

150 mm  50 mm, as shown in Fig. 4b. The second is the decorated brick in a cube shape of size 50 mm

50 mm, as shown in Fig. 4b. The second is the decorated brick in a cube shape of size 50 mm  50 mm

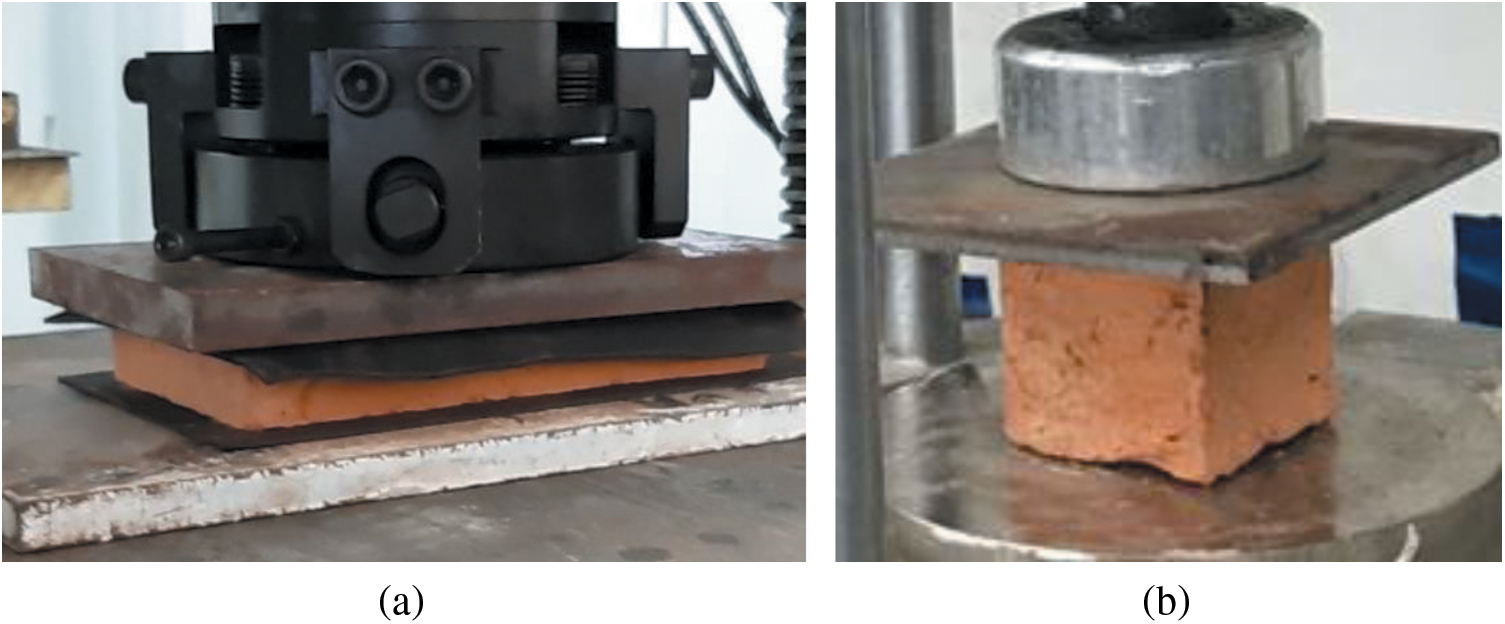

50 mm  50 mm, as shown in Fig. 4c. At least three specimens of each shape were prepared for the compression test. Fig. 5 shows the compression tests of both shapes of substitution bricks.

50 mm, as shown in Fig. 4c. At least three specimens of each shape were prepared for the compression test. Fig. 5 shows the compression tests of both shapes of substitution bricks.

Figure 4: Examples of substitution bricks. (a) bricks factory, (b) flatwise bricks, (c) cube bricks

Figure 5: Substitution brick compression test. (a) flatwise brick testing, (b) cube brick testing

2.2 Mix Proportions of Substitution Mortars

In this study, Fly ash (FA) was used as a pozzolanic material to partially replace the slaked lime for developing the substitution mortars. The slaked lime in a wet condition was also obtained from the restoration site in Ayutthaya Province. Fly ash was collected from the Mae-Moh power plant in Thailand (Lampang Province).

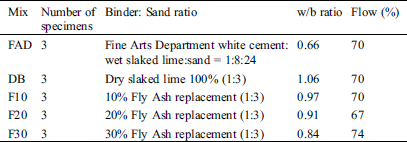

According to the Fine Art Department (FAD) specification, the mix proportion of mortar recommended for historical structure restoration is the ratio of 1:8:24 by weight of white cement, wet slaked lime, and sand, respectively. To investigate the properties of the substitution mortars, the mix proportions of mortars used in this research are listed in Tab. 1. Three specimens were tested and an average value was used for each testing. The flow rate of the mortar was controlled in the range of 65–75%. According to Tab. 1, it is found that the highest mixing water requirement was exhibited in the mortar made with 100% dry slaked lime (DB). The increase in the percent of fly ash replacement could reduce the water requirement for mixing. Cubed mortar samples of size 50 mm  50 mm

50 mm  50 mm are prepared for each type of mortar and are listed in Tab. 1. All the substitution mortars were tested to determine the compressive strength values at 7, 28, and 90 days. The water absorption, porosity, and water vapor transmission were investigated at 60 days.

50 mm are prepared for each type of mortar and are listed in Tab. 1. All the substitution mortars were tested to determine the compressive strength values at 7, 28, and 90 days. The water absorption, porosity, and water vapor transmission were investigated at 60 days.

Table 1: Mix proportion of mortars

2.3 Test Set-Up of Masonry Prisms

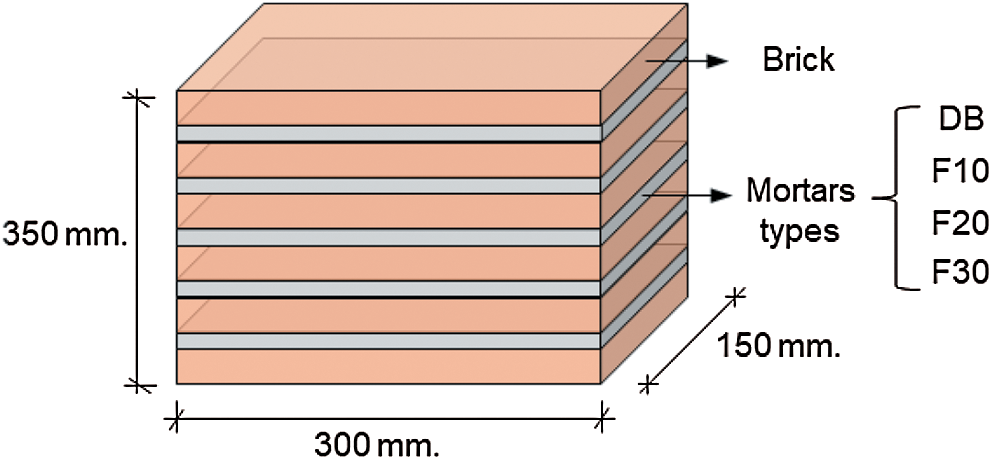

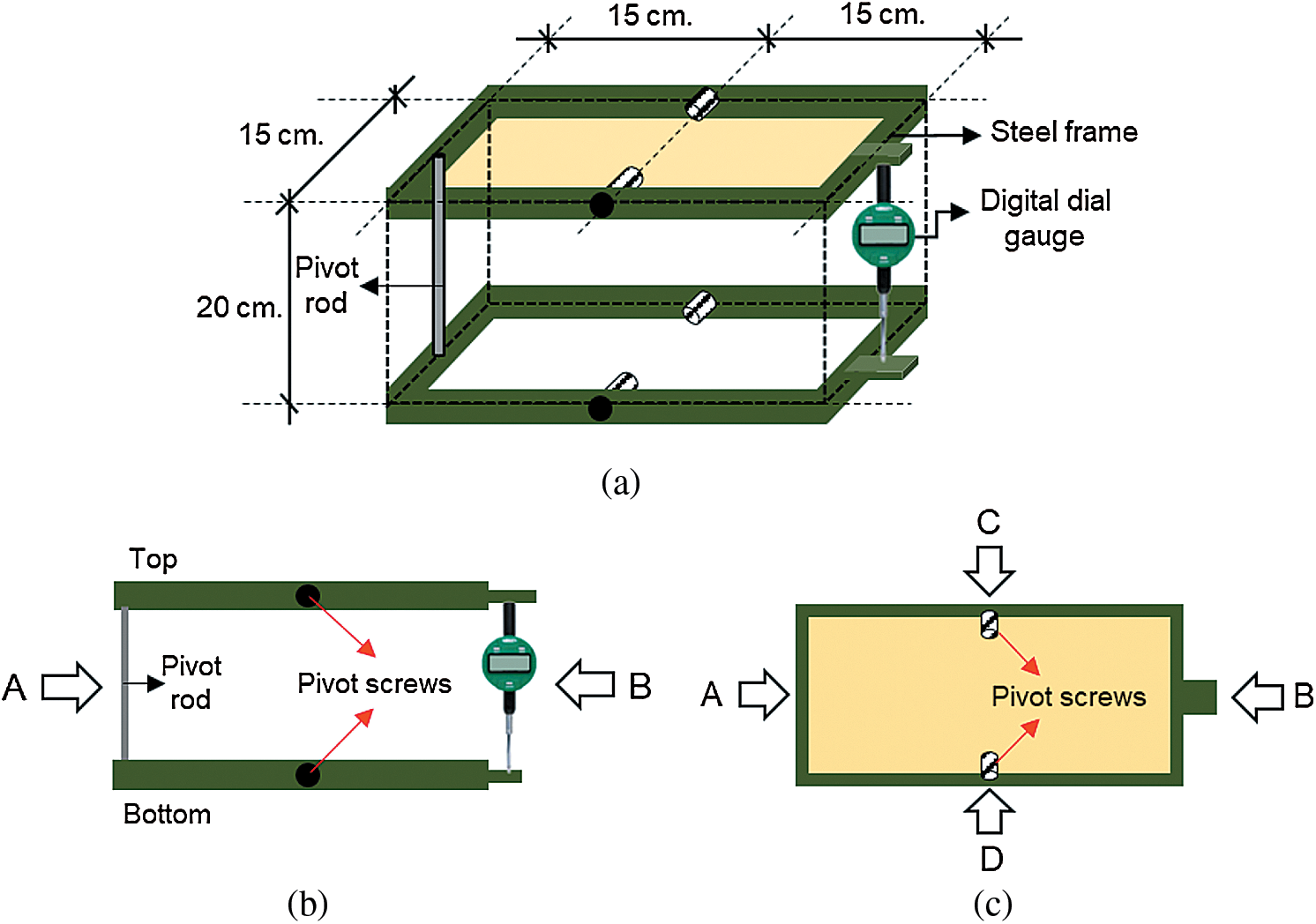

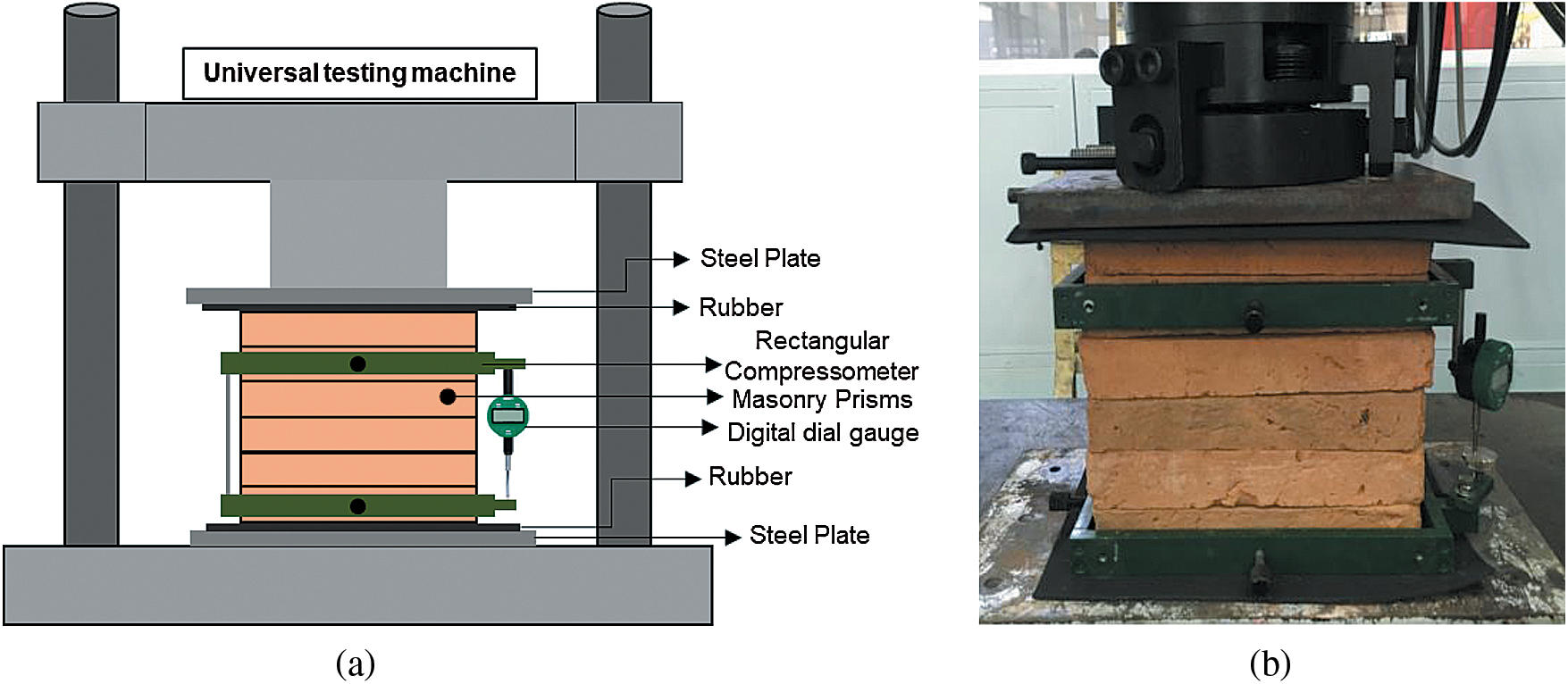

In this study, the solid stack bond of masonry prism filled mortar joints are constructed. The masonry prisms consist of six flatwise bricks and five layers of mortar, as shown in Fig. 6. The dimensions of the flatwise bricks are 300 mm × 150 mm × 50 mm. The thickness of the mortar for each layer is approximately 1 cm. Four groups of specimens representing the four types of substitution mortars (DB, F10, F20, and F30) are defined as MDB, MF10, MF20, and MF30, respectively. Three specimens were tested for each group and the average value for each property was taken. The compressive strength and modulus of elasticity of the masonry prisms were determined at 60 days. The modulus of elasticity of the masonry prism was tested by using a rectangular compressometer, as shown in Fig. 7, which is composed of a steel frame and a digital dial gauge. Fig. 8 shows the test setup of the masonry prisms.

Figure 6: The dimensions of solid stack bond of masonry prisms are 300 mm × 150 mm × 350 mm

Figure 7: Rectangular compressometer. (a) Schematic diagram (3D View), (b) Side view, (c) Top view

Figure 8: Test set up for determining the compressive strength and modulus of elasticity of the masonry prisms. (a) Schematic diagram, (b) Photo

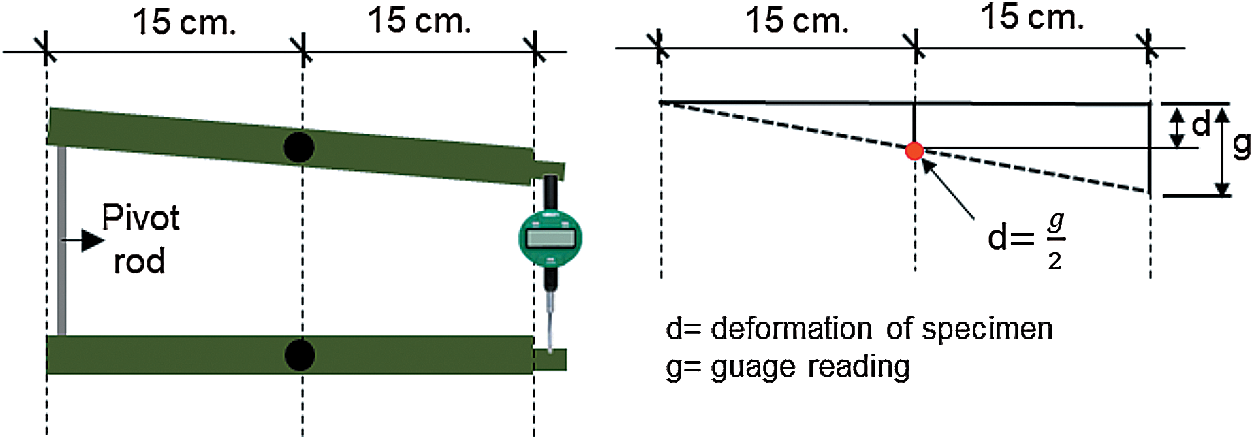

The compression test of the masonry prisms was based on ASTM C1314 [29]. The universal testing machine (UTM) used in this study has a maximum capacity of 1,000 kN. The masonry prisms were placed at the center of the loading platform. The load is applied slowly (2 mm/min) until the specimen is crushed. The load at the point of specimen crushing is represented as the ultimate compressive strength. In this study, the modified ASTM C469/C469M [30] method was used to determine the modulus of elasticity of the masonry prism. The testing procedure is summarized as follows. The masonry prism with the compressometer attached was placed on the loading plate of a universal testing machine. The steel frame was fitted with adjustable screws with a pivot rod at the center of both the top and bottom in the positions of C and D, as shown in Fig. 7c, to tighten the frame of the masonry prism specimen. The position of A in Fig. 7b was fixed by a pivot rod to prevent deformation while loading. Then, the digital dial gauge (least count = 0.001 mm) was set up at the position of B, as shown in Fig. 7b, for recording the deformation of the masonry prism. While testing the specimen, the load was applied axially at a uniform rate (2 mm/min). The compressometer was centrally pivoted, then the vertical movement of the masonry prism was observed while increasing the axial load, and the consistency readings were recorded at load intervals until the prism reaches failure. The deformation of the masonry prism is equal to one-half the gauge reading, as shown in Fig. 9. According to the testing results, the modulus of elasticity values of the masonry prisms can be calculated from the stress-strain relationship curve at 40% of the ultimate stress according to ASTM C469/C469M [30]. This is due to the stress-strain relation curve at 40% of the ultimate stress of masonry prisms is the linear-elastic behavior which is conformed to Basha et al. [4].

Figure 9: Schematic diagram of displacement

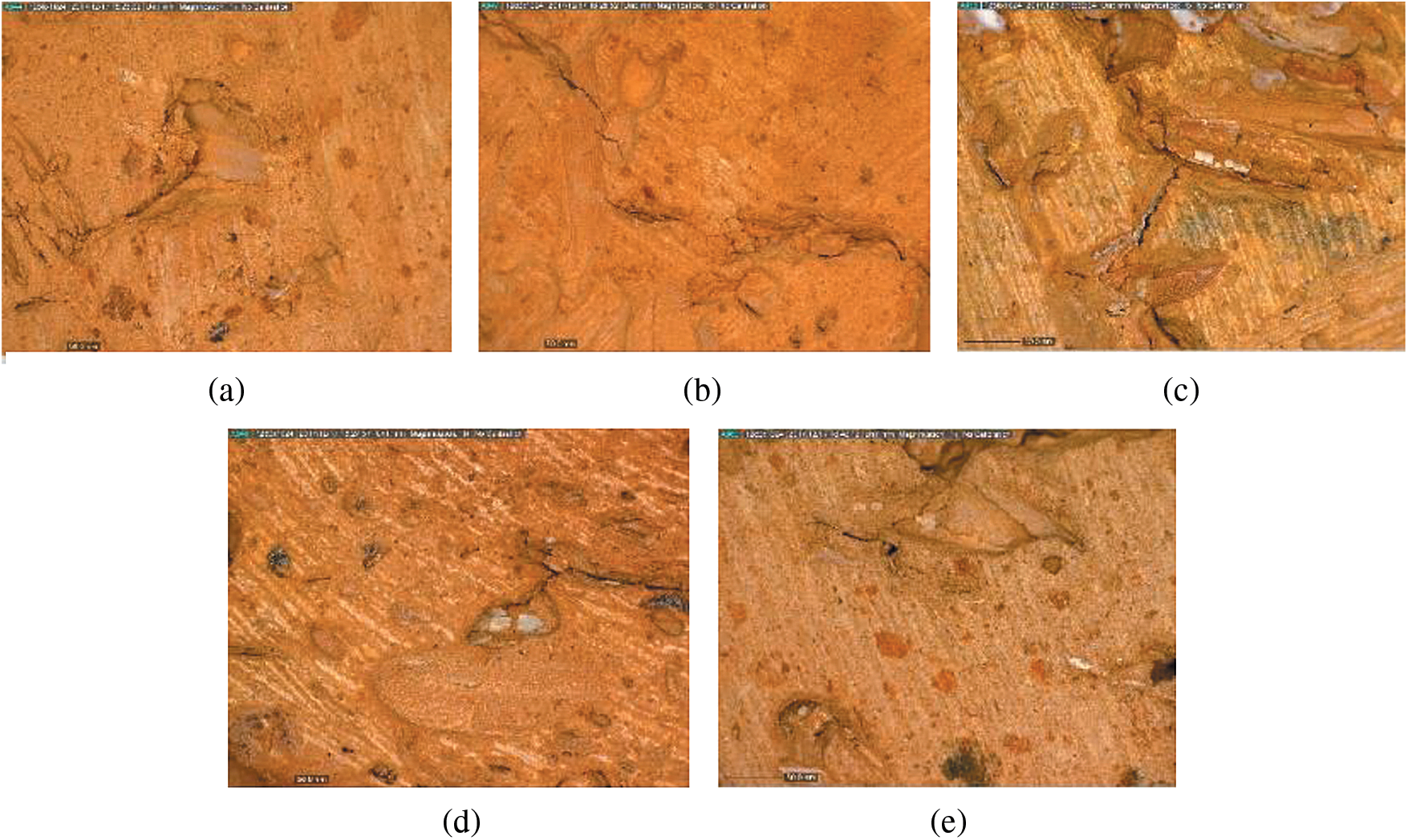

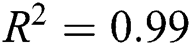

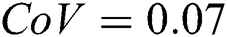

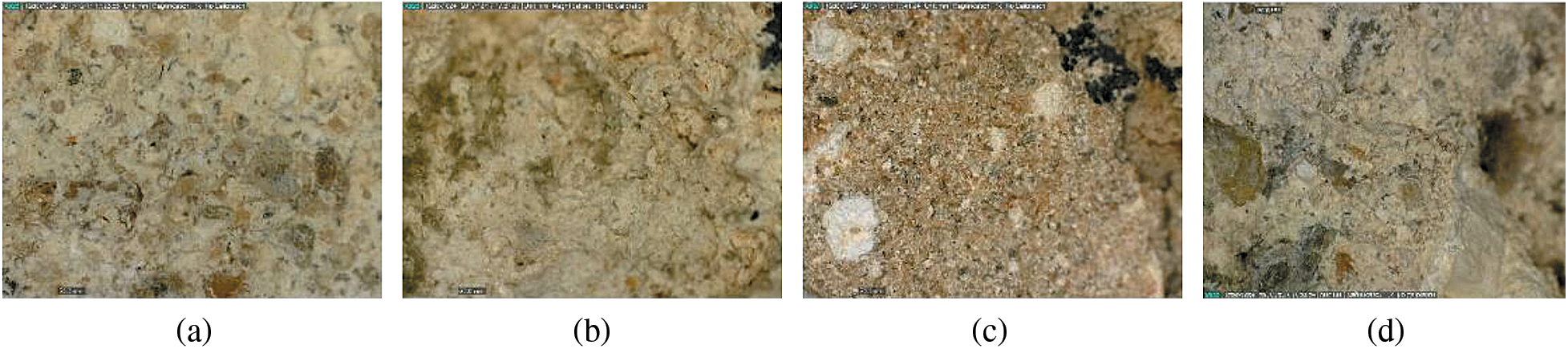

3.1 Characteristics of Ancient Bricks and Substitution Bricks

Figs. 10a–10e show the characteristics of the substitution bricks and ancient bricks; it was observed that the colors and textures of the substitution bricks and ancient bricks collected from each site were not much different, which agreed with the previous research [8]. It was also found that the substitution bricks had a lighter colors than the ancient bricks, which may be due to their different ages. However, the visual inspection indicated that the ancient bricks had more pores and voids distributed on the surface of the specimen. According to a report by Bhattarai [6], the characteristics of bricks depend on the manufacturing process at the time.

Figure 10: Characteristics of bricks. (a) Substitution bricks, (b) Wat Chaiwatthanaram, (c) Wat Phrasrisanphet, (d) Werng Nakhon Kasem, (e) Ancient Palace

3.2 Chemical Compositions and Mineralogical Compositions of the Ancient Bricks and Substitution Bricks

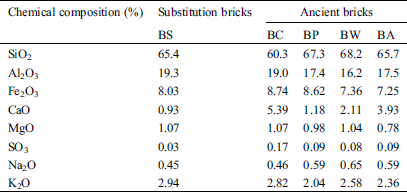

The chemical compositions analyzed by X-ray Fluorescence of the substitution bricks (BS) and ancient bricks (BC, BP, BW, and BA) are presented in Tab. 2. The major chemical composition of the substitution brick was SiO2, Al2O3, Fe2O3, and CaO, with the proportions of 65.4, 19.3, 8.03, and 0.93%, respectively. While the main chemical composition of the ancient bricks from the four historical places was SiO2, Al2O3, Fe2O3, and CaO, with the average proportions of 65.38, 17.53, 7.99, and 3.15%, respectively. It was found that the ancient brick had a slightly higher calcium oxide (CaO) proportion than the substitution bricks because of the different age. However, this result conforms to the result of Gulzar et al. [1], who reported that the chemical compositions of the ancient bricks for the conservation of the monuments in the city of Lahore, Pakistan were composed of high amounts of SiO2, Al2O3, Fe2O3 and considerably low amounts of CaO, MgO, Na2O, and K2O. Therefore, the substitution bricks of this study are appropriate for the existing Thai historical structure preservation in regard to the chemical characteristics.

Table 2: Chemical compositions of the substitution bricks and ancient bricks

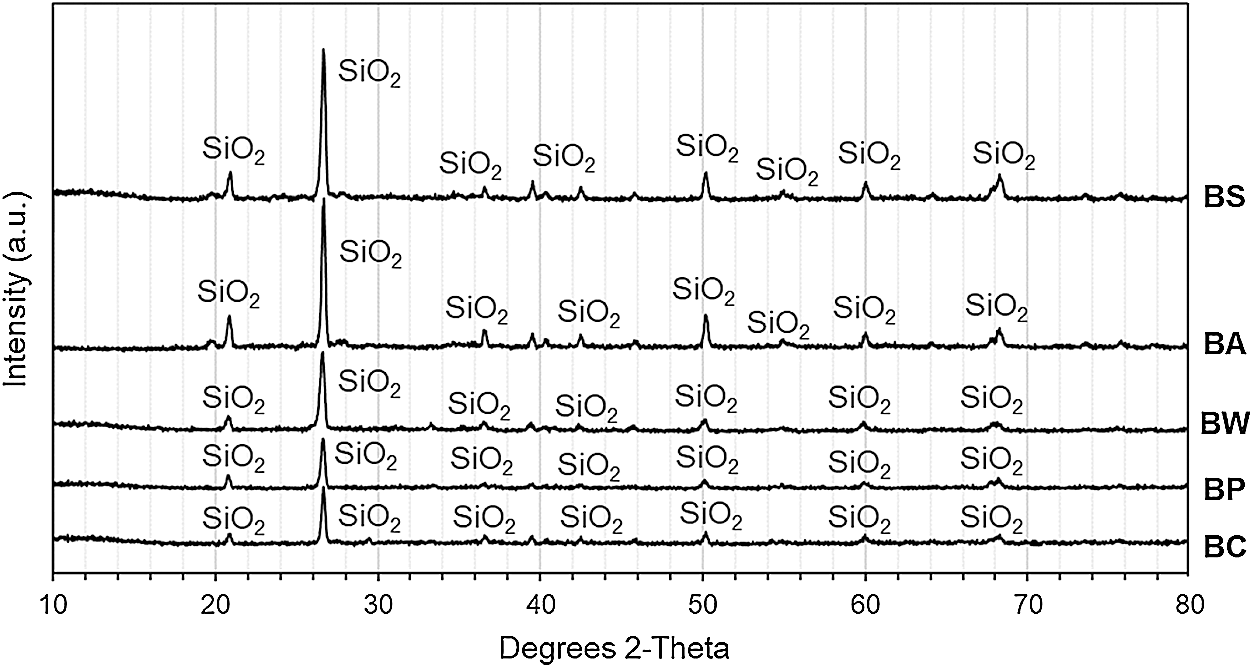

Fig. 11 exhibits the XRD patterns of the testing samples of the substitution bricks and ancient bricks. The results of the XRD patterns of all the specimens indicated that the main product is SiO2 (Silicon dioxide). It was found that the SiO2 peaks of the samples from the four historical places are found at the same point. Moreover, the results of the XRD analysis conform to the XRF result. From the previous research, San et al. [7] reported that the results of the testing of most ancient bricks in Myanmar showed very high amounts of silicon dioxide, which has a silicon dioxide range of 65–70%. It was observed that the main chemical composition of ancient brick in Myanmar is similar to the ancient brick in Thailand.

Figure 11: X-ray diffraction (XRD) patterns of substitution bricks and ancient bricks

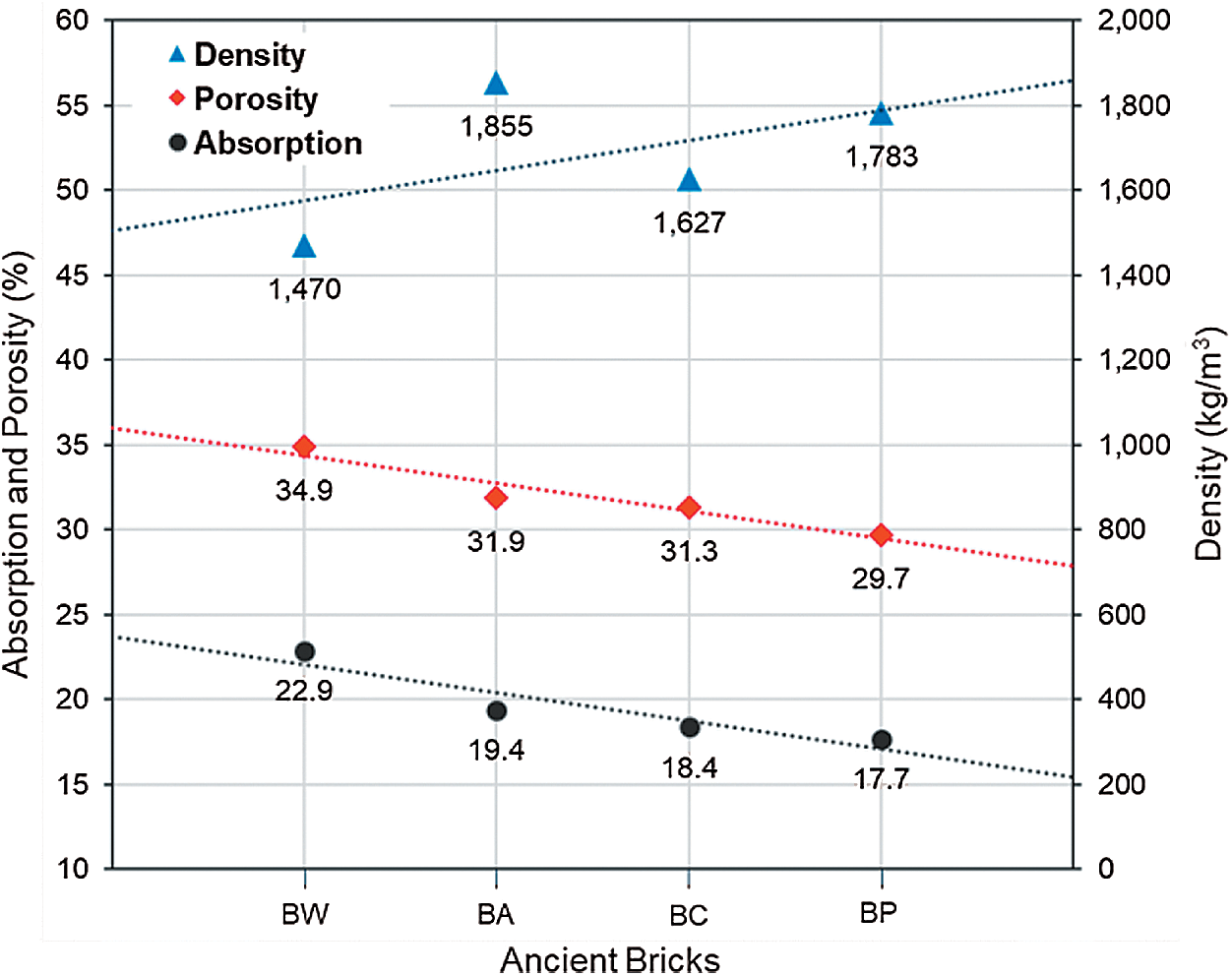

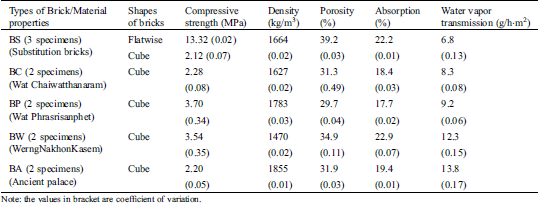

3.3 Physical and Engineering Properties of Ancient Bricks and Substitution Bricks

The physical properties of the substitution brick and ancient bricks used in this investigation are shown in Tab. 3. The number of test samples are 3 samples for substitution brick and 2 samples for the ancient brick, respectively. The density is an important parameter that affects the weight of the historical structure. The result showed that the density values of the substitution bricks and ancient bricks from the historical sites ranged from 1,470 to 1,855 kg/m3. The ancient bricks from the historical palaces had slightly higher density values than the substitution bricks. Phansuwan [8] reported that the density of ancient bricks in nine monuments in Ayuttaya Province ranged between 1,322 and 1,475 kg/m3, which was not significantly different from the results of this study. The porosity values of the substitution bricks and ancient bricks were 29.7–39.2%. This result showed that the porosity value of the substitution brick was higher than those of the ancient bricks. The absorption values of the substitution bricks and ancient bricks were in the range of 17.7–22.9%. Moreover, there is good correlation between the absorption, porosity, and density results of all the ancient bricks. Both the absorption and porosity of the ancient bricks were found to be decreased with increasing the density, as shown in Fig. 12. It was observed that the water absorption was increased when the increased porosity. Considering, water vapor transmission of substitution brick and ancient brick was in the range of 6.8–13.8 g/h m2. It was clearly seen that water vapor transmission of the substitution brick was less than those of the ancient bricks. However, the physical properties of an ancient brick from historical sites may depend on the manufacturing process.

m2. It was clearly seen that water vapor transmission of the substitution brick was less than those of the ancient bricks. However, the physical properties of an ancient brick from historical sites may depend on the manufacturing process.

Figure 12: Relationship between the water absorption, as well as porosity with the density of the ancient bricks

Table 3: Physical and engineering properties of the substitution bricks and ancient bricks

Note: the values in bracket are coefficient of variation.

Tab. 3 summarizes the compressive strength results of the substitution brick and ancient bricks used in this investigation. San et al. [7] reported that the compressive strength of brick was influenced by the characteristics of the raw materials and the production process. From the test result, it was found that the average compressive strength values of the substitution flatwise bricks (300  150

150  50 mm.) and cube bricks (50

50 mm.) and cube bricks (50  50

50  50 mm.) were 13.32 MPa and 2.12 MPa, respectively. The compressive strength of the flatwise bricks was higher than that of the cube bricks, which was in agreement with the previous research [31]. It should be noted that the sizes of the bricks affected the compressive strength values of the bricks. In this study, the equation for predicting the compressive strength differences between the flatwise bricks and cube bricks was formulated. Three samples for each type of brick were tested to obtain the average data. The result shows a very good coefficient of determination and coefficient of variation (

50 mm.) were 13.32 MPa and 2.12 MPa, respectively. The compressive strength of the flatwise bricks was higher than that of the cube bricks, which was in agreement with the previous research [31]. It should be noted that the sizes of the bricks affected the compressive strength values of the bricks. In this study, the equation for predicting the compressive strength differences between the flatwise bricks and cube bricks was formulated. Three samples for each type of brick were tested to obtain the average data. The result shows a very good coefficient of determination and coefficient of variation ( and

and  ) and shown in Eqs. (1) and (2).

) and shown in Eqs. (1) and (2).

where  is the compressive strength of flatwise bricks and

is the compressive strength of flatwise bricks and  is the compressive strength of cube bricks. The compressive strength values of the ancient bricks from the four historical places ranged between 2.20 and 3.70 MPa. It should be noted that the compressive strength values of the substitution bricks were slightly less than those of the ancient bricks. Phansuwan [8] reported that the compressive strength values of ancient bricks from nine monuments in Ayutthaya Province ranged between 3.69 and 4.43 MPa. The compressive strength of the ancient brick in that study was slightly higher than the compressive strength of this study. However, the compressive strength of ancient brick may depend on the historical place.

is the compressive strength of cube bricks. The compressive strength values of the ancient bricks from the four historical places ranged between 2.20 and 3.70 MPa. It should be noted that the compressive strength values of the substitution bricks were slightly less than those of the ancient bricks. Phansuwan [8] reported that the compressive strength values of ancient bricks from nine monuments in Ayutthaya Province ranged between 3.69 and 4.43 MPa. The compressive strength of the ancient brick in that study was slightly higher than the compressive strength of this study. However, the compressive strength of ancient brick may depend on the historical place.

3.4 Characteristics of Ancient Mortars

The colors and textures of the collected ancient mortars are shown in Figs. 13a-13d. It was found that the slaked lime was clustered around the specimen with a distribution of sand surrounding all the specimens.

Figure 13: Characteristics of ancient mortar. (a) Wat Chaiwatthanaram, (b) Wat Phrasrisanphet, (c) Werng Nakhon Kasem, (d) Ancient Palace

3.5 Chemical Compositions and Mineralogical Compositions of Ancient Mortars

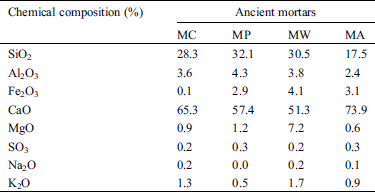

The chemical compositions of the ancient mortars are presented in Tab. 4. The primary chemical composition of the ancient mortar was CaO, SiO2, Al2O3, and Fe2O3, with the average proportions of 61.98, 27.10, 3.53, and 2.55%, respectively. The ancient mortars were mainly composed of 51.3–73.9% CaO, 17.5–32.1% SiO2, 2.4–4.3% Al2O3, and 0.1–4.1% Fe2O3. The results showed that the chemical compositions of the ancient mortars have the highest CaO, although each a historical place was slightly different.

Table 4: Chemical compositions of the binders and ancient mortars

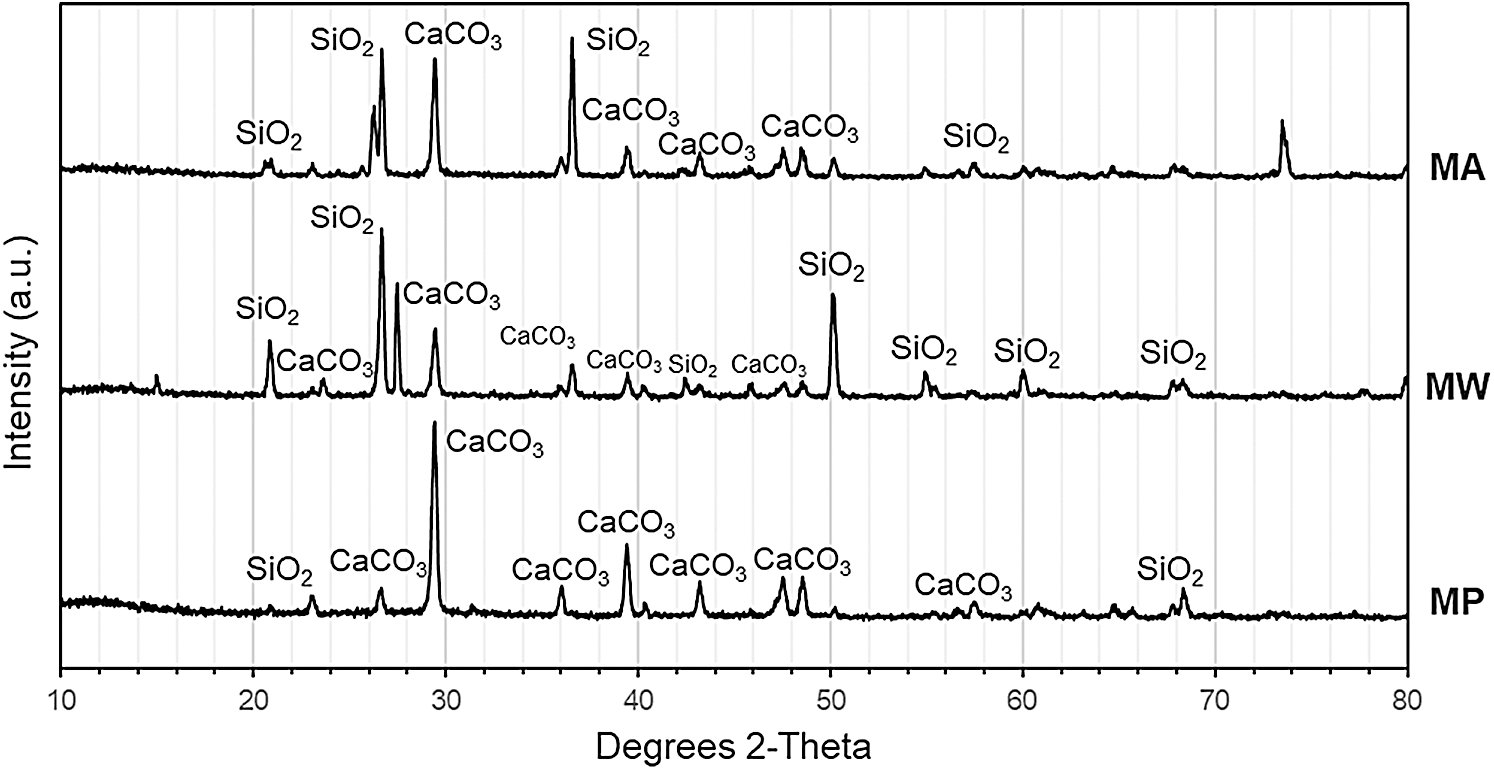

The XRD mineralogical compositions of the ancient mortars from the samples of the historical places were mainly calcium carbonate (CaCO3) and silicon dioxide (SiO2), as shown in Fig. 14. It was observed that the main reaction of the ancient mortars made with the slaked lime mortar was the carbonation reaction. The carbonation reaction was the reaction between calcium hydroxide in the slaked lime mortar and the carbon dioxide in the air. This reaction typically needs a very long time to achieve the target strength. Therefore, the ancient mortars are not suitable for use under conditions of high humidity or underground with high groundwater levels [22]. Moreover, the peaks of the XRD patterns of the ancient mortars were related to the chemical composition that was exhibited by the XRF analysis.

Figure 14: X-ray diffraction (XRD) patterns of ancient mortars

3.6 Binder to Sand Ratio of the Ancient Mortars

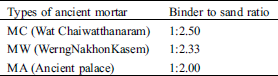

The binder to sand ratio by weight of the ancient mortar can be investigated by using a sulfuric acid solution to extract sand from the mortar. The weight of sand in the ancient mortar affecting the porosity and compressive strength of the mortar was determined. The procedure to find the binder to sand ratio of the mortar was performed according to ASTM C25 [32] began with the weighing of the specimen before and after immersing it in an acid solution. Next, the ancient mortar specimen was soaked with 96% of sulfuric acid and then, the ancient mortar residue was weighted again. The result showed that the binder to sand ratio of the ancient mortars ranged from 1:2.00 to 1:2.50, as shown in Tab. 5. The results of this study conform to the previous research by Watsantachard [22], who reported that the binder to sand ratio ranged from 1:1.9 to 1:2.3. Moreover, the binder to sand ratio of the ancient mortars was similarly compared with the suggestion from the Fine Arts Department (1:3).

Table 5: Binder to sand ratio of ancient mortars

3.7 Physical and Engineering Properties of Ancient Mortars

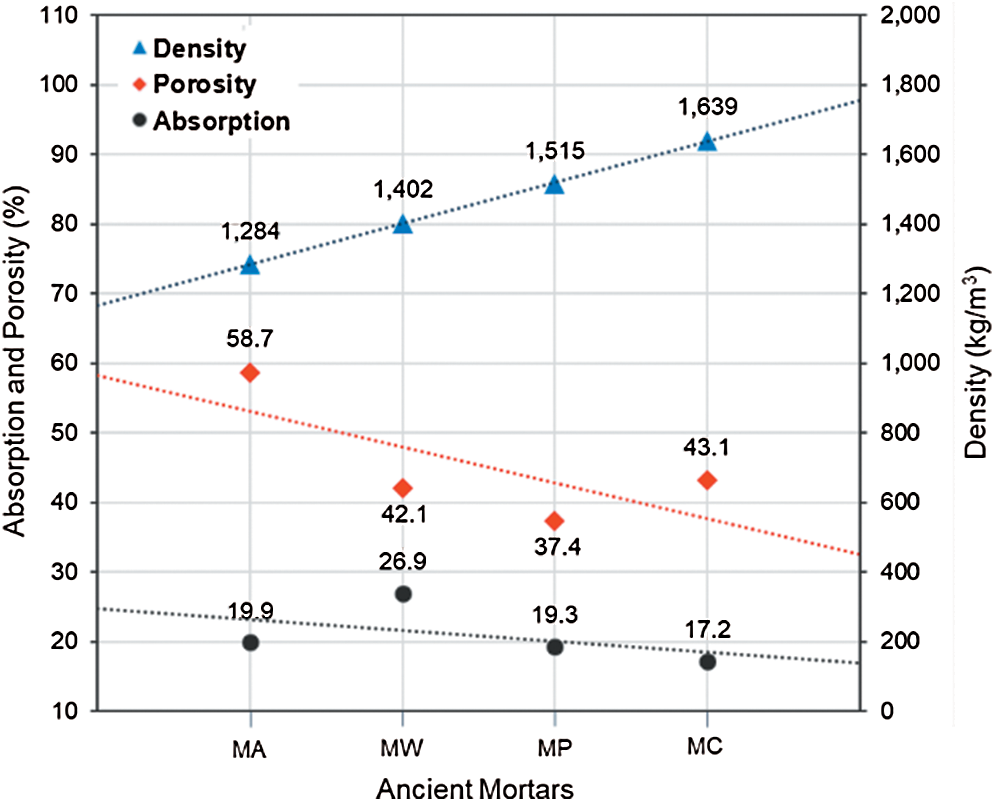

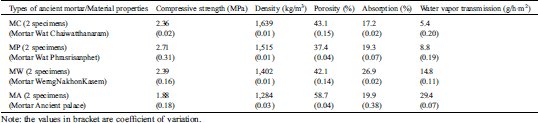

Tab. 6 reports the physical and engineering properties of ancient mortars from a sample of historical places. The number of test samples of ancient mortar is 2 samples. The density values of the ancient mortars ranged between 1,284 and 1,639 kg/m3. It was observed that the ancient bricks have slightly higher density values than the ancient mortar. A comparison between the density of the ancient mortar and Portland cement found that the density of the cement mortar was 2,400 kg/m3, which is much higher than that of the ancient mortar. The ancient mortars had porosity values ranging from 37.4 to 58.7%, which were higher than those of the ancient bricks. Watsantachard [22] reports that the porosity values of the ancient mortar from the Ayutthaya Province by the Mercury Intrusion Porosimetry (MIP) technique ranged between 26 and 54%, which was a similar result to this study. The water absorption range of the ancient mortars was the same as that of the ancient bricks, which ranged between 17.2 and 26.9%. This result conforms to the result of Watsantachard [22], who reported that the water absorption of ancient mortars from Ayutthaya Province ranged between 9 and 29% depending on the historical site. While the water vapor transmission of the ancient mortar ranged between 5.4 and 29.4 g/h m2, which was observed to have high variation. Moreover, the relations between the density, porosity, and water absorption are shown in Fig. 15. Both the water absorption and porosity values of the ancient mortars were found to be decreased by increasing the density. As mentioned above, the physical properties of the ancient mortars conformed to those of the ancient bricks.

Figure 15: Relation between the water absorption, as well as the porosity with the density of the ancient mortars

Table 6: Physical and engineering properties of ancient mortars

Note: the values in bracket are coefficient of variation.

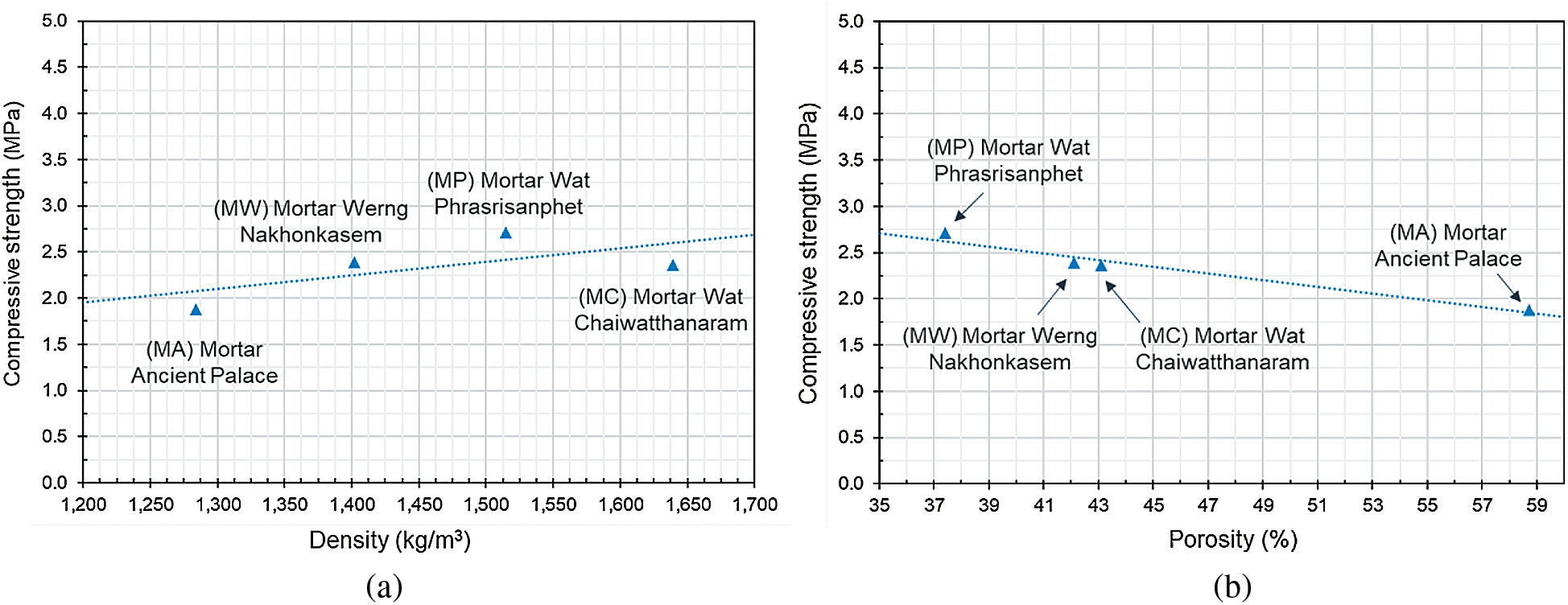

The compressive strengths of ancient mortars from historical places are presented in Tab. 6. The ancient mortars had the compressive strength in the range of 1.88–2.71 MPa. It was observed that the ancient mortars have compressive strength values similar to those of the ancient bricks. According to Watsantachard [22], the average compressive strength value of ancient mortars from historical sites in Ayutthaya were 2.9 MPa, which was slightly higher than the result from this study. Moreover, the relation between the compressive strength and density of the ancient mortars is presented in Fig. 16a. It was observed that the trend of the compressive strength of the ancient mortars increased with increasing density, while the trend of compressive strength of the ancient mortars decreased when the porosity was increased, as shown in Fig. 16b.

Figure 16: Relation of the ancient mortars. (a) Compressive strength and density, (b) Compressive strength and porosity

3.8 Physical and Engineering Properties of the Substitution Mortars

As discussed above, the physical properties of the ancient mortar have compatible properties with ancient bricks. However, the main problem of the ancient mortar with the slaked lime by the traditional method was the need for a very long setting time. This is a major problem for the restoration work for Thai historical structures in the present preservation. Additionally, the amount of water contained in the slaked lime, is difficult to control and the consistency of the mortar is a strict requirement. Therefore, this research has developed substitution mortars used for the restoration of historical sites in Thailand. According to the previous research by Almeida et al. [20] and Veiga et al. [19] were used the pozzolanic materials such as fly ash and rice husk ash as an admixture for the improvement of the ancient mortars for the restoration of the historical building. However, fly ash in Thailand is regarded as a byproduct of burning lignite coal in power plants which is waste materials. This research has chosen to use residual fly ash with the slaked lime in order to develop properties and possibilities for using as binder materials for the restoration of historical sites in Thailand. The results of testing and comparing properties between ancient mortars and substitution mortars can be explained as follows.

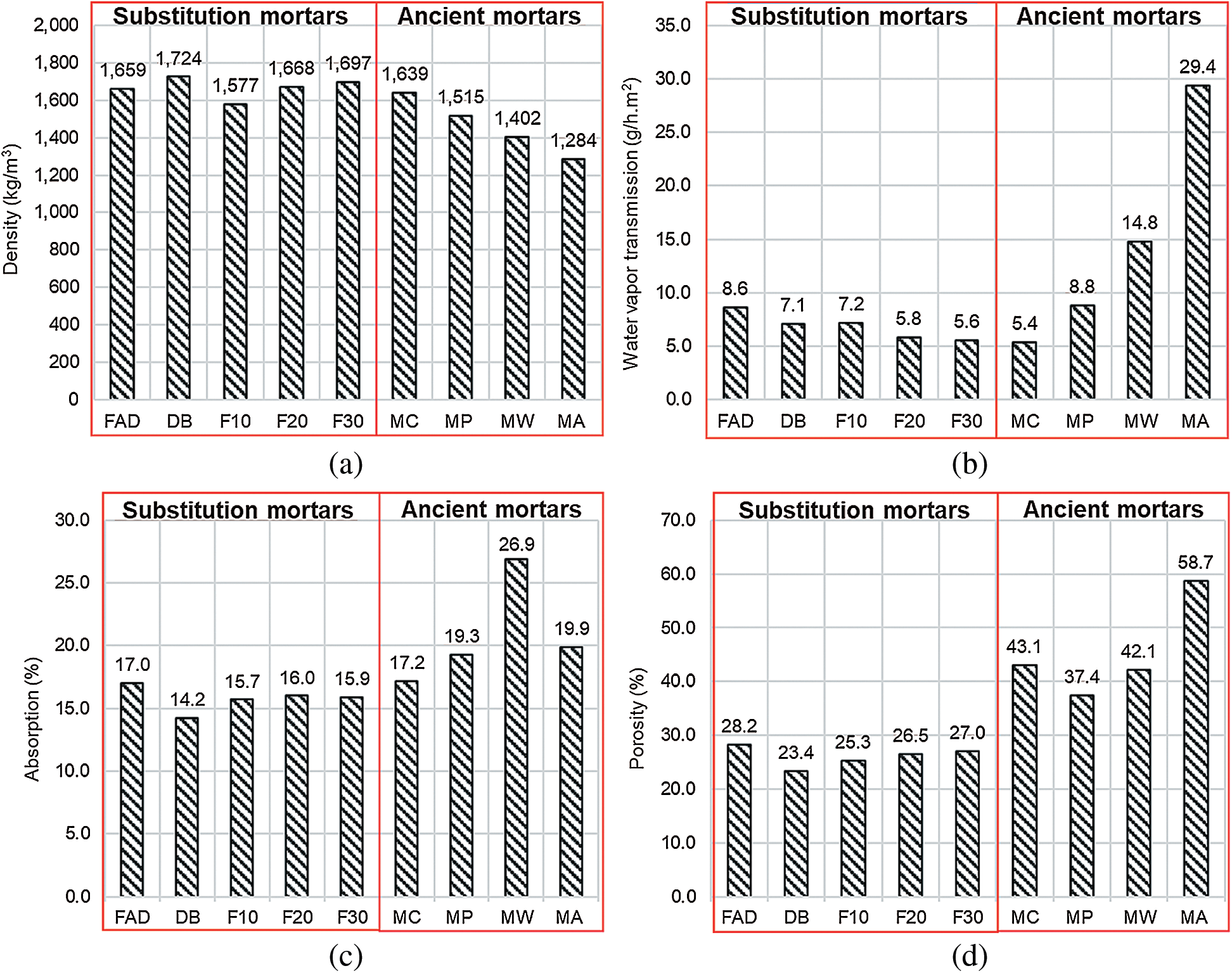

Figs. 17a–17d present the physical properties composed of the density, porosity, absorption, and water vapor transmission of the substitution mortars compared to the ancient mortars. The results showed that the DB mortar had a density of 1,724 kg/m3, while the density of FAD mortar was 1,659 kg/m3. The density values of the DB and FAD mortars were slightly higher than those of the ancient mortars, as shown in Fig. 17a. It was also found that both the DB and FAD mortars were similar to the mortar of Wat Chaiwatthanaram and the ancient bricks. The water vapor transmission values of the DB and FAD mortars were 7.1 and 8.6 g/h m2, respectively. As observed in Fig. 17b, the MW and MA mortars had higher water vapor transmission values than the DB and FAD mortars. However, the water vapor transmission values of all the ancient mortars had high variance. According to Watsantachard [22], who reported that water vapor transmission was an essential property because water and moisture was the main problem that causes the deterioration of materials. The water absorptions of the FAD and DB mortars were 17% and 14.2%, respectively, as illustrated in Fig. 17c. It was found that the water absorption values of the FAD and DB mortars were slightly less than that of the ancient mortar. The porosity values of the FAD and DB mortars were 28.2 and 23.4%, respectively, while the porosity range of the ancient mortars from the four historical places was 37.4–58.7%, as shown in Fig. 17d. The results indicated that the FAD and DB mortars had porosity and absorption values less than those of the ancient mortars. Therefore, due to the physical properties of these mortars, there is less of a risk of the material deterioration than with the ancient mortars.

Figure 17: Relationship between the physical properties of the substitution mortars and ancient mortars. (a) Density, (b) Water vapor transmission, (c) Absorption, (d) Porosity

The results of the use of fly ash as a partial replacement for the slaked lime mortar compares to the ancient mortar are shown in Figs. 17a–17d. It was observed that the density values of the F10, F20, F30 mortars did not show significant differences when compared to the ancient mortars, as shown in Fig. 17a. It was clearly indicated that the water vapor transmission of the substitution mortar made with fly ash was less than that of the ancient mortars According to Watsantachard [22], who reported that the mortars used to restore historical structures should allow for the easy evaporation of water or moisture. Considering the substitution mortars (F10-F30), the increase in the amount of fly ash at 10–30% showed no significant difference in terms of both the water absorption and the porosity, as shown in Figs. 17c and 17d, respectively. As discussed above, the physical properties of the substitution mortars of FAD, DB, F10, F20, and F30 have the possibility to be used for the restoration of historical structures.

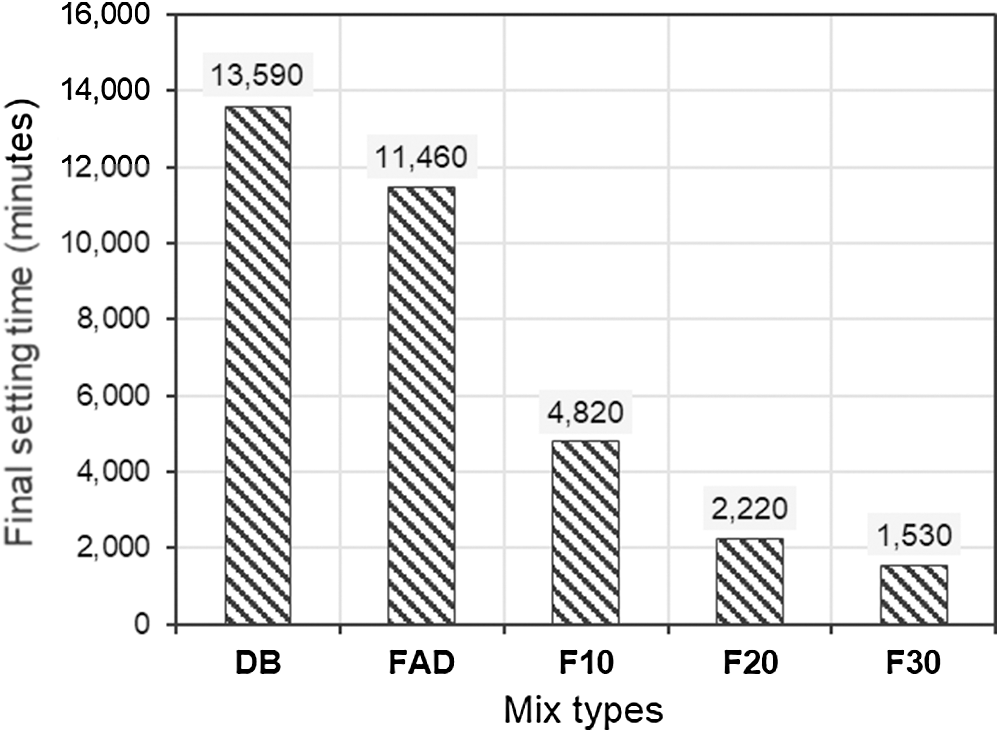

The setting times of all mortars (DB, FA, F10, F20, and F30) are presented in Fig. 18. All the mortars were tested to determine the setting time, according to ASTM C807 [25]. The results showed that the setting times of the DB and FAD mortars ranged between 13,590 and 11,460 minutes. The DB mortar had the longest setting time, while the mix proportion of the FAD mortar recommended for historical structure restoration was 1:8:24 by weight of white cement, wet slaked lime, and sand, respectively. It was found that the setting time decrease of 15.7% compared with that of the DB mortars. The slaked lime was substituted by fly ash at 10–30% (F10, F20, and F30) by weight of binder, where the setting times of those mortars were 4,820, 2,220, and 1,530 minutes, respectively. It should be noted the use of fly ash at 10%, 20%, and 30% could decrease the setting times of the mortars by 64.5%, 83.66%, and 88.74%, respectively compared with the slaked lime mortars (DB). Similarly, the setting times of the F10, F20, and F30 mortars were decreased by 57.9, 80.6, and 86.6% compared with the setting times of the FAD mortars. These results indicated that the slaked lime mortar (DB) containing fly ash of up to 30% by weight of binder had a rapid setting time of approximately one day. Moreover, the decrease in the setting times of the mortars was useful for the construction process, which could be decrease the working hours of the workers and a lower project cost.

Figure 18: Final setting time of substitution mortars

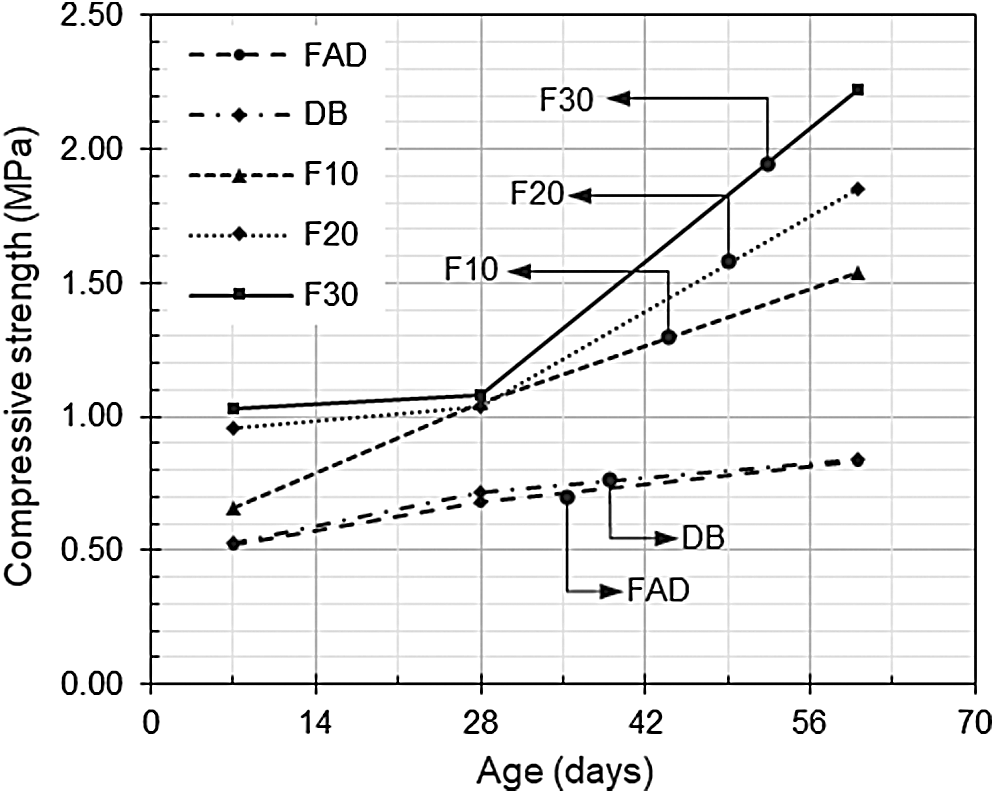

The compressive strength of the substitution mortars was tested according to ASTM C109/C109M [28]. The compressive strength values of the F10, F20, and F30 mortars compared with those of the DB and FAD mortars are shown in Fig. 19. The compressive strength values of the DB mortar at 7, 28, and 60 days were 0.53, 0.72, and 0.84 MPa, respectively. The FAD mortar had compressive strength values of 0.52, 0.68, and 0.83 MPa at 7, 28, and 60 days, respectively. It was observed that the compressive strength values of the DB and FAD mortars were the same. Moreover, the strength development of the FAD and DB mortars was very slow at both early and later ages.

Figure 19: Compressive strength values of the (FAD, DB, F10, F20, and F30) mortars at 7, 28, and 60 days

As observed in Fig. 19, the use of fly ash at 10–30% could develop the compressive strength of the mortar. It was observed that at the ages of 7–28 days, the F10 mortar had a compressive strength increase of 59%, while F20 and F30 had compressive strength increases of 8.3 and 4.9%, respectively. At the later ages of 28–60 days, it was observed that the compressive strength values of the F20 and F30 mortars had rapidly increased by 46.7% and 105.5%, respectively. Furthermore, the replacement of fly ash at 10% by weight of binder could improve the compressive strength of mortar at 60 days up to 83.3% compared with the DB mortars. The compressive strengths of the F20 mortar were 0.96 and 1.04 MPa at 7 and 28 days, respectively, and increased to 1.85 MPa at 60 days. The use of fly ash at 30% increased the compressive strength at 60 days, which was 2.22 MPa, while the average compressive strength of ancient mortars by laboratory testing in this study was 2.34 MPa. It was observed that the compressive strength of the F30 mortar was similar to the compressive strength of the ancient mortars. These results indicated the appropriateness of the use of fly ash in concrete [33].

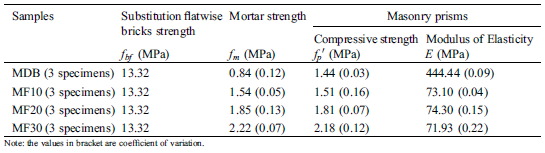

In this section, the masonry prisms were constructed using the substitution bricks and four types of substitution mortars (DB, F10, F20, and F30). The solid stack bond of the masonry prisms was constructed with a height-to-thickness (h/t) ratio between 1.3 and 5, according to the ASTM C1314 [29]. The ratio of height to thickness of prism is 2.3 which is corresponding to a correction factor for masonry prism compressive strength of 1.03. The compressive strength and modulus of elasticity of the masonry prisms of this study are summarized in Tab. 7. The average of three specimens was used to represent the compressive strength and modulus of elasticity of the masonry prism.

Table 7: Compressive strength and modulus of elasticity of the masonry prisms

Note: the values in bracket are coefficient of variation.

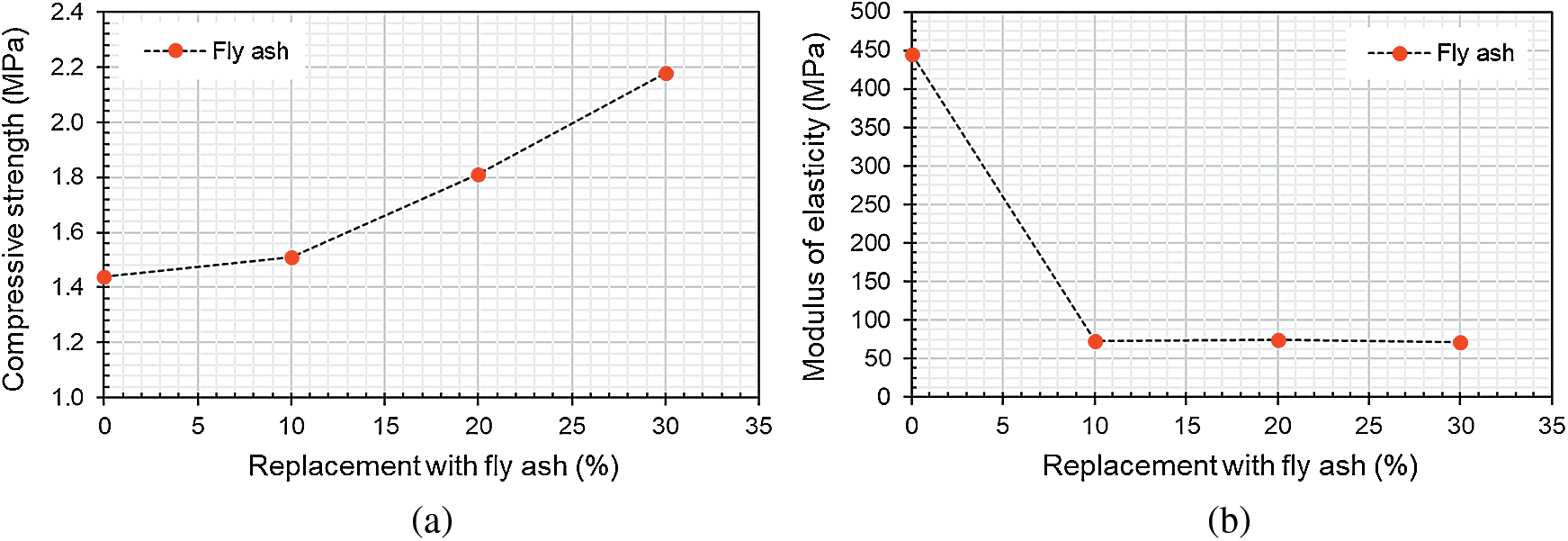

The results revealed that the compressive strength of the masonry prisms made with slaked lime mortars (MDB) was 1.44 MPa, which was higher than the slaked lime mortar strength (DB mortar). It was shown that the compressive strength of the masonry prisms was mainly affected by the bricks. Additionally, the result showed that with the use of fly ash at 10–30% by weight of the binder, the compressive strength values of the masonry prisms increased up to 5–50% compared with the compressive strength of masonry prisms made with the slaked lime, as shown in Fig. 20a. Additionally, the previous research from Wang et al. [34] found that the change in mortar strength had slightly effected on the compressive strength of masonry similar result was found from this study.

Figure 20: The comparison effect of the masonry prism with slaked lime and fly ash. (a) Compressive strength, (b) Modulus of elasticity

Fig. 20b illustrates the elastic modulus results of the masonry prisms by calculation, according to ASTM 469/C469M [30]. The masonry prisms with the slaked lime mortars (MDB) under compression had a modulus of elasticity of 444.44 MPa. The addition of fly ash at 10–30% was found to decrease the modulus of elasticity by 83.2–83.8% compared with the masonry prisms made with slaked lime mortar, while the modulus of elasticity with the addition of fly ash at 10–30% was not significantly different. It should be noted that the increase in the percent replacement with fly ash had an effect on decreasing the modulus elasticity.

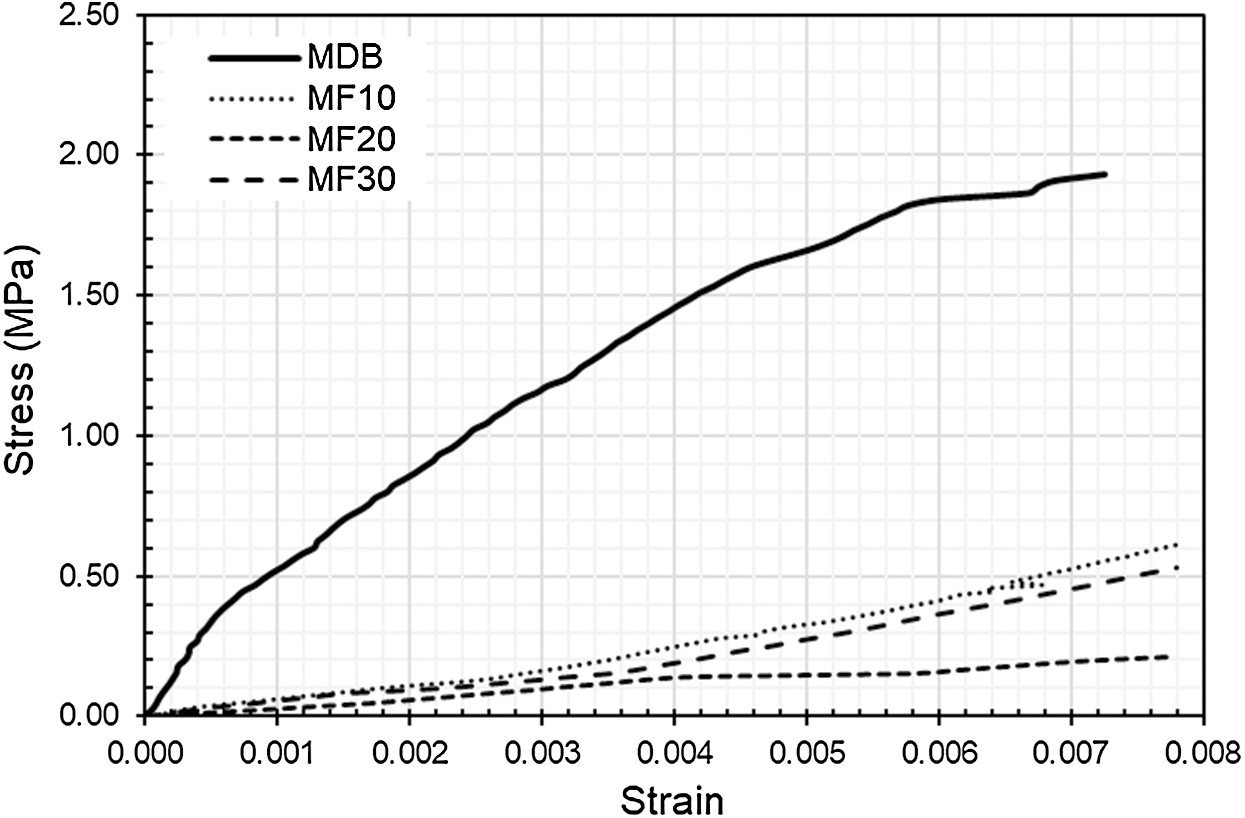

The stress-strain relation is the essential property of masonry prisms that can predict the behavior of masonry prisms by testing, according to ASTM1314 [29] and ASTM 469/C469M [30]. The masonry prism specimens were compressed, and the strain was measured by the compressometer.

Fig. 21 shows the stress-strain curves of the four groups of masonry prisms (MDB, MF10, MF20, and MF30) obtained from an average of 3 samples. The results showed that the compressive strength results of the masonry prisms made with slaked lime mortars exhibited higher compressive strength values than the masonry prisms made with fly ash. It was clearly indicated that the replacement of the slaked lime with fly ash in the mortar could enhance the load-carrying capacity of the masonry prisms. The previous research by Christy et al. [14] reported that the pozzolanic reaction of fly ash was shown to have significant long-term strength development, while the stress-strain relationships of the masonry prisms with fly ash at 10–30% were similar.

Figure 21: Compressive stress-strain curves of MDB, MF10, MF20, and MF30

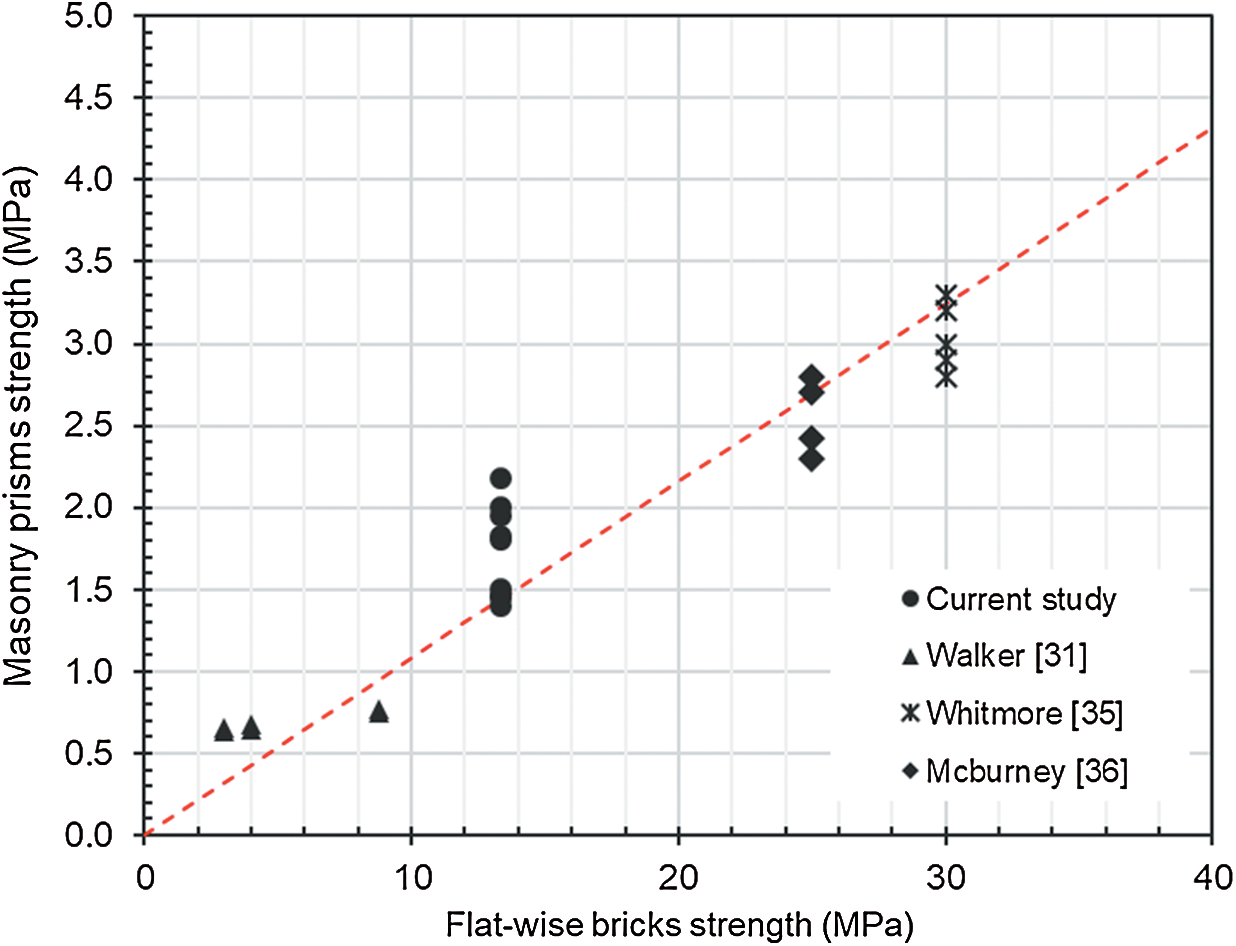

3.10 Estimation of Compressive Strength of Masonry Prism

In this study, the samples of ancient materials received directly from historical places were limited. The compressive strength assessment by the equation to estimate the masonry prisms of the historical structures was developed by Walker [31], Whitmore [35], and Mcburney [36]. It was observed that the compressive strength of masonry prisms depended on the strength of the bricks. The strength prediction of masonry prisms was determined from experimental data. After that, the equation for predicting the compressive strength of masonry prisms was developed. The results indicated that the compressive strength of masonry prisms depended on the strength of flatwise bricks and cube bricks, as shown in Eqs. (3) and (4). However, the equations were presented based on the assumption that the effects of mortar strength on the compressive strength of masonry prisms were very low. The relationship between the flatwise brick and masonry prism strengths is shown in Fig. 22. It was observed that the compressive strength of masonry prisms shown in this study conformed to the previous research [31,35,36].

Figure 22: The relationship between the flatwise brick strength and masonry prism strength

where  is the compressive strength of masonry prisms,

is the compressive strength of masonry prisms,  is the compressive strength of flatwise bricks, and

is the compressive strength of flatwise bricks, and  is the compressive strength of cube bricks.

is the compressive strength of cube bricks.

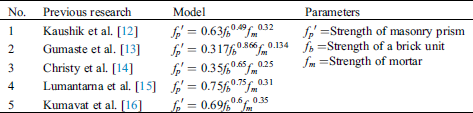

As discussed above, the prediction of the compressive strength of masonry prisms is based on the brick strength. The strength of the mortar is neglected. However, some researchers showed that the prediction model of the compressive strength of masonry prisms depended on the brick strength and mortar strength, such as Kaushik et al. [12], Gumaste et al. [13], Christy et al. [14], Lumantarna et al. [15], and Kumavat et al. [16], which are summarized in Tab. 8. Moreover, the compressive strength of masonry prisms was calculated by using Eurocode 6 [37], as shown in Eq. (5).

Table 8: Model to predict the masonry compressive strength from the previous research [12–16]

where  and

and  are constants,

are constants,  is the compressive strength of the bricks,

is the compressive strength of the bricks,  is the compressive strength of the mortar, and

is the compressive strength of the mortar, and  is the compressive strength of the masonry prism. In Eurocode 6, the values of

is the compressive strength of the masonry prism. In Eurocode 6, the values of  and

and  were specified as 0.7 and 0.3, respectively, for masonry prisms made with lightweight mortar. The value of

were specified as 0.7 and 0.3, respectively, for masonry prisms made with lightweight mortar. The value of  varied from 0.35 to 0.55 depending on the brick types and brick-mortar joint.

varied from 0.35 to 0.55 depending on the brick types and brick-mortar joint.

This study presented a model similar to Eurocode 6 for developing the prediction equation for the compressive strength of masonry prisms by using the strength of the brick, mortar, and masonry prism. The prediction model for the compressive strength of masonry prisms is carried out into two models, including masonry prisms with the slaked limed mortars (MDB) and masonry prisms made with fly ash (MF10-MF30). The compressive strength of flatwise brick was defined constant at 13.32 MPa. The regression analysis was carried out using the least-squares fit method to identify the values of the constants  and

and , as follows.

, as follows.

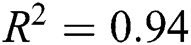

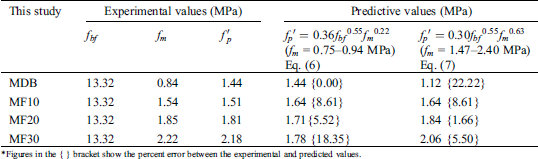

The regression analysis of the first model is the masonry prism with the slaked lime mortar. The use of 3 data sets were obtained from the experimental results in which the compressive strength of the slaked lime mortar ranged from 0.75 to 0.84 MPa, while the compressive strength of the masonry prisms with the slaked lime mortar ranged between 1.40 and 1.47 MPa. The results showed that  and

and  were 0.36, 0.55, and 0.22, respectively, with the coefficient of determination

were 0.36, 0.55, and 0.22, respectively, with the coefficient of determination , as shown in Eq. (6).

, as shown in Eq. (6).

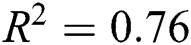

The second model is for the masonry prisms made with mortars containing fly ash at 10–30% (MF10–MF30). This model used the 9 data sets for the regression analysis. The compressive strengths of fly ash mortar ranged between 1.54 and 2.22 MPa. While the compressive strength values of masonry prisms with fly ash mortar ranged 1.51–2.18 MPa. The result showed that  and

and  were 0.30, 0.55, and 0.63, respectively, with the coefficient of determination

were 0.30, 0.55, and 0.63, respectively, with the coefficient of determination  , as shown in Eq. (7). For this model, it was found that the coefficient of determination is not good. Therefore, it should be further tested to develop the coefficient of determination.

, as shown in Eq. (7). For this model, it was found that the coefficient of determination is not good. Therefore, it should be further tested to develop the coefficient of determination.

Tab. 9 shows the experimental results of the masonry prisms compared with the analytical prediction. The comparison of the two equations was presented in the different mortar strength ranges. According to Eq. (6), the range of the compressive strength of the mortar strength was 0.75–0.94 MPa, where the masonry prisms (MDB) had mortar strength values withing this range. It was found that the proposed equation is in good agreement with the masonry prism strength, while the compressive strength values of the masonry prisms outside the mortar strength range had percent error values in the range of 5.52-29.59%. Considering Eq. (7), the compressive strength of the mortar ranged between 1.47 and 2.40 MPa and the masonry prisms (MF10–MF30) had mortar strength values within these ranges. The percent error compared with the experimental result was between 1.66 and 8.61%. The proposed equation has a relatively low coefficient of determination. For this model, the test should use similar strength mortar to develop a more accurate prediction equation. The proposed equation used outside the range of the mortar strength was found to have an error range of 22.22–48.98%. The MDB and MF10-MF30 were outside the range of the mortar strength. It was found that the error in estimating the masonry prisms’ compressive strength ranged from 52.78 to 124.50%. As discussed above, it could be observed that the range of the mortar strength affects the compressive strength of the masonry prisms greatly, while the brick strength is constant. Therefore, the equation is used to predict the compressive strength of the masonry prisms. The range of the mortar strength should be taken into account.

Table 9: Experimental results of the masonry prisms with analytical predictions

*Figures in the { } bracket show the percent error between the experimental and predicted values.

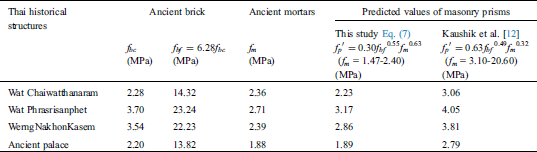

The predictions of the compressive strength of the masonry prisms of Thai historical structures are summarized in Tab. 10. The compressive strength experimental results of ancient brick and ancient mortar from were used for predicting the strength of the masonry prisms of historical places. The compressive strength of ancient brick for the cube sample must be changed to Eq. (1) to use the compressive strength of ancient brick as the flatwise type. Eqs. (6)–(7) were presented for predicting the compressive strength of masonry prisms for different mortar strength values. According to the results, the compressive strength of ancient mortar ranged between 1.88 and 2.71 MPa, which was similar to the mortar strength of 1.47–2.40 MPa obtained from Eq. (7). The compressive strength values of the masonry prisms of Wat Chaiwatthanaram, Wat Phrasrisanphet, WerngNakhonKasem, and Ancient palace were 2.23, 3.17, 2.86, and 1.89 MPa, respectively. However, the predicted equation of Kaushik et al. [12] was calculated for predicting of Thai historical structures to compare with the equation of this study. It was observed that the strength results of the masonry prisms of the four historical sites by Kaushik et al. [12] are higher than the strength results of the masonry prisms of this study. The prediction model of the strength of masonry prisms obtained from this study was given an upper safety. The use of an equation to estimate the compressive strength of masonry prisms should consider the brick strength and mortar strength ranges.

Table 10: Prediction of the compressive strength of masonry prisms of Thai historical structures

This paper presents the physical and engineering properties of ancient materials and substitution materials, the formula results of suitable substitution mortars, and the empirical equation for estimating the compressive strength of the historical structures in Thailand. Based on the results from the experiment, the following conclusion can be drawn.

1. The physical and engineering properties of ancient materials and substitution materials obtained from this study can be used to form the database for Thai Historical Masonry Structures preservation.

2. The average compressive strength of the cube and flatwise of substitution bricks are 2.12 MPa and 13.32 MPa, respectively. The compressive strengths of the ancient bricks are ranged from 2.20 to 3.70 MPa. The density of substitution bricks and ancient bricks are ranged from 1,470 to 1855 kg/m3. The porosity and absorption of substitution bricks and ancient brick are varied between 29.7–39.2% and 17.7–22.9%, respectively. Water vapor transmission of substitution bricks and ancient brick is in the range of 6.8–13.8 g/hr m2.

3. The sizes of bricks affected the compressive strength results of the bricks, and the compressive strength of the flatwise brick was higher than that of the cube bricks. The strength of cube bricks is approximately 16% of the strength of flatwise bricks.

4. The use of fly ash to partially replace the slaked lime at 10–30% could significantly decrease the setting time by 64.5–88.7% compared to the slaked lime mortars and increase the compressive strength of historical repair mortars. This is a suitable substitution material for the restoration of Thai historical structures.

5. Masonry prisms made with fly ash can increase the compressive strength similar to the ancient bricks and ancient mortars of the historical structures.

6. The empirical equation was presented for the assessment of the compressive strength of masonry prisms of Thai historical structures, and the assessment by an empirical equation of the compressive strength results of four Thai historical places are in the range of 1.89–3.17 MPa.

7. The physical and engineering properties data, the formula of suitable substitution materials, and the predicted model in this paper can be used for structural health monitoring and long-term maintenance for the preservation of Thai historical structures. These data are useful for engineering architects and other interested people.

Funding Statement: The authors would like to acknowledge the Thailand Research Fund (TRF) and King Mongkut’s University of Technology Thonburi (KMUTT) for their joint support through the Royal Golden Jubilee Ph.D. (RGJ-PHD) Program (Grant No. PHD/0042/2559).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Phaiju, S., Pradhan, P. M. (2018). Experimental work for mechanical properties of brick and masonry panel. Journal of Science and Engineering, 5, 51–57. DOI 10.3126/jsce.v5i0.22372. [Google Scholar] [CrossRef]

2. Sathiparan, N., Rumeshkumar, U. (2018). Effect of moisture condition on mechanical behavior of low strength brick masonry. Journal of Building Engineering, 17, 23–31. DOI 10.1016/j.jobe.2018.01.015. [Google Scholar] [CrossRef]

3. Curtin, W. G., Shaw, G., Beck, J. K., Bray, W. A. (1995). Structural Masonry Designer’s Manual. Cambridge, Great Britain: University Press. [Google Scholar]

4. Basha, S. H., Kaushik, H. B. (2015). Evaluation of nonlinear material properties of fly ash brick masonry under compression and shear. Journal of Materials in Civil Engineering, 27(8), 04014227. DOI 10.1061/(ASCE)MT.1943-5533.0001188. [Google Scholar] [CrossRef]

5. Murugan, P., Jayaram, P. (2012). Experimental study on Masonry infill material properties. International Journal of Scientific & Engineering Research, 3(7), 360–364. DOI 10.15373/22778179/MARCH2014/123. [Google Scholar] [CrossRef]

6. Bhattarai, J., Ghale, D., Chapagain, Y., Bohara, N., Duwal, N. (2018). Study on the physical and mechanical properties of ancient clay brick samples of Kathmandu valley, Nepal. Tribhuvan University Journal, 32(2), 1–18. DOI 10.3126/tuj.v32i2.24699. [Google Scholar] [CrossRef]

7. San, T. M., Kyaw, K., Kyaw, N. M. (2018). Physical, mechanical and chemical characterization on ancient brick masonry of monuments, Bagan, Myanmar. International Journal of Trend in Scientific Research and Development, 3(1), 875–881. DOI 10.31142/ijtsrd19100. [Google Scholar] [CrossRef]

8. Phansuwan, S. (2000). Engineering analysis of masonry historic monument (Master of Engineering Thesis) Kasetsart University. Bangkok, Thailand, (in Thai). [Google Scholar]

9. Li, H., Qiu, Z., Wu, G., Wei, D., Lorenzo, R. et al. (2019). Compression behaviors of parallel bamboo strand lumber under static loading. Journal of Renewable Materials, 7(7), 583–600. DOI 10.32604/jrm.2019.07592. [Google Scholar] [CrossRef]

10. Li, H., Zhang, H., Qiu, Z., Su, J., Wei, D. et al. (2020). Mechanical properties and stress strain relationship models for bamboo scrimber. Journal of Renewable Materials, 8(1), 14–27. [Google Scholar]

11. Sajanthan, K., Balagasan, B., Sathiparan, N. (2019). Prediction of compressive strength of stabilized earth block masonry. Advances in Civil Engineering, 2019, Article ID 2072430, 1–13. [Google Scholar]

12. Kaushik, H. B., Rai, D. C., Jain, S. K. (2007). Stress-strain characteristics of clay brick masonry under uniaxial compression. Journal of Materials in Civil Engineering, 19(9), 728–739. DOI 10.1061/(ASCE)0899-1561(2007)19:9(728). [Google Scholar] [CrossRef]

13. Gumaste, K. S., Nanjunda Rao, K. S., Venkatarama Reddy, B. V., Jagadish, K. S. (2007). Strength and elasticity of brick masonry prisms and wallettes under compression. Materials and Structures, 40(2), 241–253. DOI 10.1617/s11527-006-9141-9. [Google Scholar] [CrossRef]

14. Christy, C. F., Tensing, D., Shanthi, R. M. (2013). Experimental study on axial compressive strength and elastic modulus of the clay and fly ash brick masonry. Journal of Civil Engineering and Construction Technology, 4(4), 134–141. [Google Scholar]

15. Lumantarna, R., Biggs, D. T., Ingham, J. M. (2014). Uniaxial compressive strength and stiffness of field-extracted and laboratory-constructed masonry prisms. Journal of Materials in Civil Engineering, 26(4), 567–575. DOI 10.1061/(ASCE)MT.1943-5533.0000731. [Google Scholar] [CrossRef]

16. Kumavat, H. R. (2016). An experimental investigation of mechanical properties in clay brick masonry by partial replacement of fine aggregate with clay brick waste. Journal of the Institution of Engineers (IndiaSeries A, 97(3), 199–204. DOI 10.1007/s40030-016-0178-7. [Google Scholar] [CrossRef]

17. ICOMOS. (2014). Report on the ICOMOS advisory mission to historic city of Ayutthaya (C 576). https://whc.unesco.org/document/136457. [Google Scholar]

18. Moropoulou, A., Bakolas, A., Moundoulas, P., Aggelakopoulou, E., Anagnostopoulou, S. (2013). Optimization of compatible restoration mortars for the earthquake protection of Hagia Sophia. Journal of Cultural Heritage, 14(3), e147–e152. DOI 10.1016/j.culher.2013.01.008. [Google Scholar] [CrossRef]

19. Veiga, R., Fragata, A., Velosa, A., Magalhães, A., Margalha, G. (2008). Substitution mortars for application in historical buildings exposed to the sea environment. Analysis of the viability of several types of compositions. Historical Mortars Conference: Characterization, Diagnosis, Conservation, Repair and Compatibility, LNEC, Lisbon, Portugal. [Google Scholar]

20. Almeida, N. G., Faria, P., Pinto, A. P. (2008). Lime mortars with rice husk ash for ancient masonry. Historical Mortars Conference: Characterization, Diagnosis, Conservation, Repair and Compatibility. LNEC, Lisbon, Portugal. [Google Scholar]

21. Faria, P., Henriques, F., Rato, V. (2008). Comparative evaluation of lime mortars for architectural conservation. Journal of Cultural Heritage, 9(3), 338–346. DOI 10.1016/j.culher.2008.03.003. [Google Scholar] [CrossRef]

22. Watsantachad, N. (2018). The properties of historic mortar and plaster in the historic city of Ayutthaya world heritage site. NAJUA Architecture Design and Built Environment, 33(B), 43–92 (in Thai). [Google Scholar]

23. ASTM C134-95 (2016). Standard test methods for size, dimensional measurements, and bulk density of refractory brick and insulating firebrick. West Conshohocken, ASTM International. [Google Scholar]

24. ASTM E96/E96M (2016). Standard test methods for water vapor transmission of materials. West Conshohocken, ASTM International. [Google Scholar]

25. ASTM C807-18 (2018). Standard test method for time of setting of hydraulic cement mortar by modified vicat needle. West Conshohocken, ASTM International. [Google Scholar]

26. Borrelli, E. (1999). (, Conservation of architectural heritage, historic structures and materials, Rome, Italy: International Centre for the Study of the Preservation and Restoration of Cultural Property. [Google Scholar]

27. ASTM C67/C67M-18 (2018). Standard test methods for sampling and testing brick and structural clay tile. West Conshohocken, ASTM International. [Google Scholar]

28. ASTM C109/109M-16a (2016). Standard test method for compressive strength of hydraulic cement mortars (Using 2-in. or [50-mm] cube specimens). West Conshohocken, ASTM International. [Google Scholar]

29. ASTM C1314 (2016). Standard test method for compressive strength of masonry prisms. West Conshohocken, ASTM International. [Google Scholar]

30. ASTM C469/C469M (2014). Standard test method for static modulus of elasticity and poisson’s ratio of concrete in compression. West Conshohocken, ASTM International. [Google Scholar]

31. Walker, P. J. (2004). Strength and erosion characteristics of earth blocks and earth block masonry. Journal of Materials in Civil Engineering, 16(5), 497–506. DOI 10.1061/(ASCE)0899-1561(2004)16:5(497). [Google Scholar] [CrossRef]

32. ASTM C25-19 (2019). Standard test method for chemical analysis of limestone, quicklime, and hydrated lime. West Conshohocken, ASTM International. [Google Scholar]

33. Tangchirapat, W., Buranasing, R., Jaturapitakkul, C. (2010). Use of high fineness of fly ash to improve properties of recycled aggregate concrete. Journal of Materials in Civil Engineering, 22(6), 565–571. DOI 10.1061/(ASCE)MT.1943-5533.0000054. [Google Scholar] [CrossRef]

34. Wang, X., Lam, C. C., Iu, V. P. (2020). Characterization of mechanical behaviour of grey clay brick masonry in China. Construction and Building Materials, 262, 119964. DOI 10.1016/j.conbuildmat.2020.119964. [Google Scholar] [CrossRef]

35. Whittemore, H. L., Hathcock, B. D. (1926). Some compressive test of hollow tile walls. Technologic Papers of the Bureau of Standards, 17, 513–527. [Google Scholar]

36. McBurnby, J. W. (1929). The compressive and transverse strength of brick. Journal of the American Ceramic Society, 12(4), 217–229. DOI 10.1111/j.1151-2916.1929.tb18041.x. [Google Scholar] [CrossRef]

37. BS EN 1996-1-1. (2005). Eurocode 6 design of masonry structures Part 1-1: General rules for reinforced and unreinforced masonry structures. Brussels. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |