Open Access

Open Access

ARTICLE

Different Effects of Wet and Dry Grinding on the Activation of Iron Ore Tailings

1

College of Engineering, Anhui Agricultural University, Hefei, 230036, China

2

College of Civil Engineering, Hunan University, Changsha, 410082, China

* Corresponding Author: Yingchun Yang. Email:

Journal of Renewable Materials 2021, 9(12), 2261-2276. https://doi.org/10.32604/jrm.2021.015793

Received 14 January 2021; Accepted 09 March 2021; Issue published 22 June 2021

Abstract

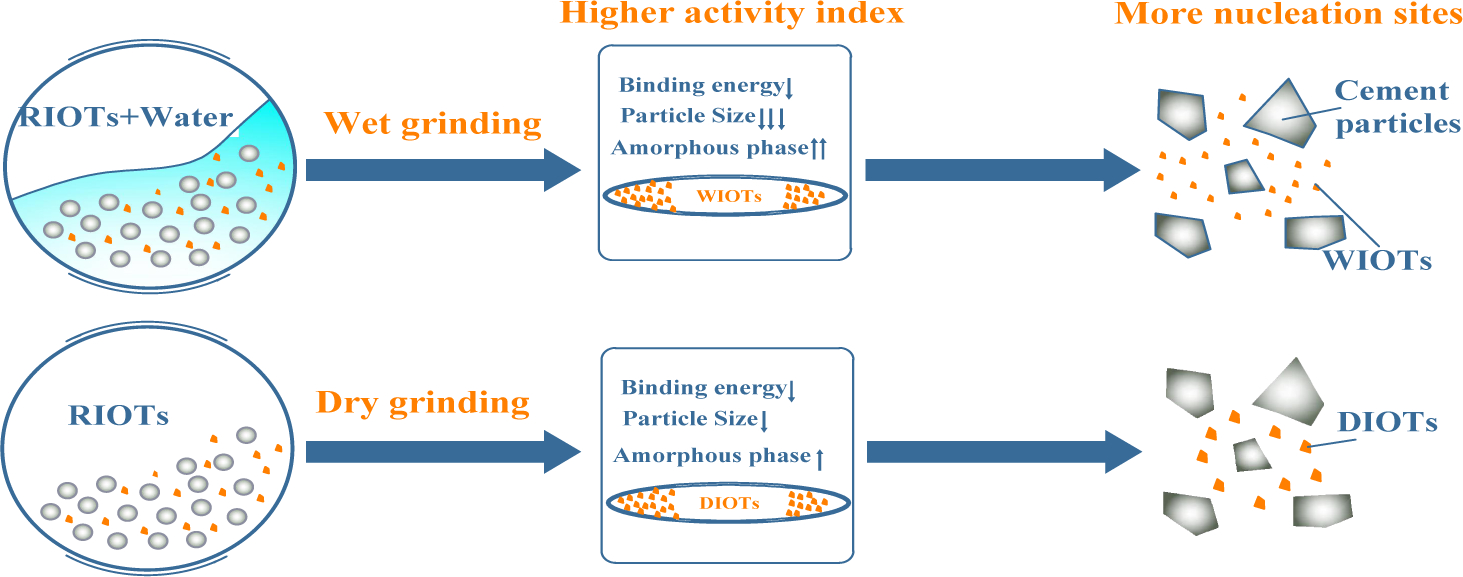

Improving the activity of Iron Ore Tailings (IOTs) to utilize them as a mineral admixture in cement-based minerals is still challenging. In this paper, the wet grinding technology was employed to stimulate the activity of IOTs, and the traditional dry grinding method was used as a reference. The effect of wet grinding on the activation of IOTs was evaluated through ion leaching from an alkaline solution and the reactivity index. Additionally, a detailed comparison between Dry-grinding Iron Ore Tailings (DIOTs) and Wet-grinding Iron Ore Tailings (WIOTs) was made. This comparison was based on particle characteristics, crystal structures, chemical structure, and surface properties. The results showed that the particle size of IOTs reduced rapidly during wet grinding. In addition, WIOTs had a higher activity index compared to DIOTs. The storage of lattice distortions in the quartz crystal structure was also more significant during the wet grinding process than during the dry grinding process. Moreover, both prolonged dry and wet grinding could destabilize the Si-O bond and decrease the surface binding energy.Graphic Abstract

Keywords

Cite This Article

Citations

Copyright © 2021 The Author(s). Published by Tech Science Press.

Copyright © 2021 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF

Downloads

Downloads

Citation Tools

Citation Tools