Open Access

Open Access

ARTICLE

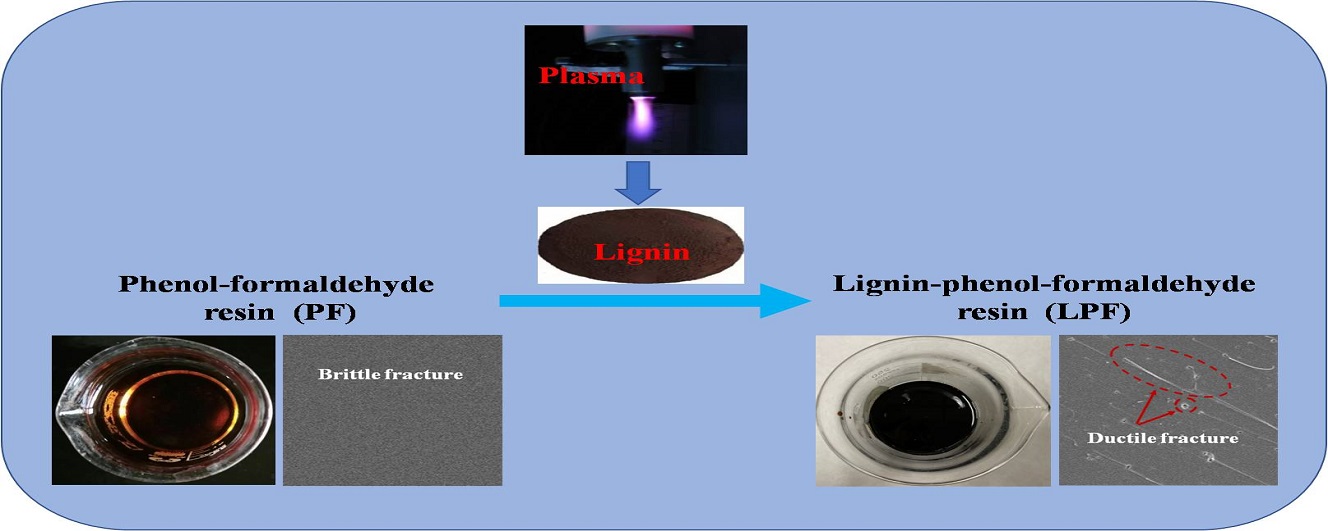

Plasma Treatment Induced Chemical Changes of Alkali Lignin to Enhance the Performances of Lignin-Phenol-Formaldehyde Resin Adhesive

1 College of Forestry, Guizhou University, Guiyang, 550025, China

2 Kaili University, Qiandongnan, 556011, China

3 ENSTIB-LERMAB, University of Lorraine, Epinal, 88051, France

4 Yunnan Provincial Key Laboratory of Wood Adhesives and Glued Products, Southwest Forestry University, Kunming, 650224, China

* Corresponding Authors: Bengang Zhang. Email: ; Hong Lei. Email:

# Zhigang Wu and Sicheng Chen have contributed equally to this work

(This article belongs to the Special Issue: Renewable and Biosourced Adhesives-2021)

Journal of Renewable Materials 2021, 9(11), 1959-1972. https://doi.org/10.32604/jrm.2021.016786

Received 26 March 2021; Accepted 19 April 2021; Issue published 04 June 2021

Abstract

Alkali lignin was processed by plasma and then used in modification of phenol formaldehyde resin in this study. Chemical structural changes of lignin which was processed by plasma as well as bonding strength, tensile property, curing performance and thermal property of the prepared phenol formaldehyde resin which was modified by the plasma processed lignin were analyzed. Results demonstrated that: (1) Alkali lignin was degraded after the plasma processing. The original groups were destroyed, and the aromatic rings collected abundant free radicals and oxygen-containing functional groups like hydroxyls, carbonyls, carboxyls and acyls were introduced into increase the reaction activity of lignin significantly. (2) The introduction of alkali lignin decreased the free formaldehyde content and increased bonding strength and toughness of the prepared phenol formaldehyde resin, especially after the introduction of lignin treated with plasma. (3) The introduction of alkali lignin led to high curing temperature for the prepared phenol formaldehyde resin, but that was reduced by the plasma processed alkali lignin. (4) The introduction of alkali lignin could also increase thermal stability of phenol formaldehyde resin, but that was modified by plasma processed alkali lignin was better than the unprocessed lignin. Based on the results, the plasma processed lignin was used to modify phenol formaldehyde resin, which could increase the strength and toughness of phenol formaldehyde resin significantly.Graphic Abstract

Keywords

Cite This Article

Citations

Copyright © 2021 The Author(s). Published by Tech Science Press.

Copyright © 2021 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF

Downloads

Downloads

Citation Tools

Citation Tools