| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2021.016221

ARTICLE

Conceptual Design of Glass/Renewable Natural Fibre-Reinforced Polymer Hybrid Composite Motorcycle Side Cover

1Department of Mechanical and Manufacturing Engineering, Universiti Putra Malaysia, Serdang, 43400, Malaysia

2Laboratory of Biocomposite Technology, Institute of Tropical Forestry and Forest Products (INTROP), Universiti Putra Malaysia, Serdang, 43400, Malaysia

3Department of Mechanical and Manufacturing Engineering, Faculty of Engineering, Universiti Malaysia Sarawak, Kota Samarahan, 94300, Malaysia

**Corresponding Author: S. M. Sapuan. Email: sapuan@upm.edu.my

Received: 20 February 2021; Accepted: 15 April 2021

Abstract: This paper presents the development process relating to the conceptual design of glass/renewable natural fibre-reinforced polymer hybrid composite motorcycle side cover. Motorcycle side cover is a component frequently made from plastic or steel that functions on covering the motorcycle parts, components and systems such as frame, battery, electrical systems and mechanical systems. Function Analysis Systems Techniques (FAST) is used to identify the functions of motorcycle side cover. The right-side cover of motorcycle model SYM E-Bonus 110 has been physically studied to identify the competitive benchmarking criteria. The functions and competitive benchmarking criteria are then compiled and integrated with the environmental requirements to identify the Product Design Specifications (PDS). The coir fibre has been selected from six identified dominant renewable natural fibre used for automotive component through integration of Ranking Method and Quality Based Selection (QBS). Then the polypropylene matrix is selected after shortlisting the existing thermoplastic that is used with coir fibre and has high suitability for injection moulding manufacturing. The polypropylene matrix is then evaluated using Weighted Evaluation Matrix (WEM) by comparing to benchmark material which is Acrylonitrile Butadiene Styrene (ABS). After that, the conceptual design development of glass/renewable coir fibre-reinforced polypropylene motorcycle side cover is carried out using an integrated Theory of Inventive Problem Solving (TRIZ) and Morphological Chart, followed by final conceptual design selection using integration of Pugh Scoring Method and QBS. The conceptual design development intended on improving the biodegradability to reduce pollution to the environment. However, the usage of glass/coir fibre-reinforced polypropylene hybrid composite may increase the weight due to higher density. Four innovative design concepts have been developed and the selected final concept design has the most minimum number of ribs and minimum thickness with the same ratio of glass fibre and natural fibre composition.

Keywords: Renewable natural fibre; coir fibre; hybrid composite; conceptual design; PDS; TRIZ; morphological chart; QBS; FAST diagram; WEM; natural fibre selection; pugh scoring method

The world has become more environmentally conscious, impacting the product development and manufacturing [1]. Demands towards green or environmentally friendly product keep increasing which indirectly pushed for the creation of green materials Manufacturing industries are forced to protecting the world climate and start producing greener product. Utilisation of renewable natural fibre as the reinforcement or biodegradable resin as the matrices in composite material is one of the solutions towards producing environmentally friendly product [1–3]. The usage of renewable natural fibre in automotive product has high potential in contributing to better environment [1,4]. Renewable natural fibre has several weaknesses and one of it is high water absorption characteristic that may limits the application in wet environments [5,6]. In order to enhance the characteristic of the composite, at least two different type of fibre can be used as a reinforcement in a single matrix of material which may form hybrid composite [7]. In hybrid composite, a combination of renewable natural fibre and synthetic fibre as a reinforcement may potentially resulting in a green material with exceptional strength, stiff and light-weight [1,6,8,9].

Renewable natural fibre such as jute, sisal, kenaf, hemp, oil palm, date palm, rami and flax have become one of the alternatives materials for eco-friendly product. Natural fibre came from renewable sources with biodegradable characteristic. The utilisation of renewable natural fibre may reduce agriculture waste. Other than that, the biodegradable characteristic of renewable natural fibre became a solution to reduce waste disposal issues and reduce impact to environment [5]. As a part of green composite, renewable natural fibre application has significant potential in consumer products, biomedical applications, packaging, transportation industry, construction, energy industry and sports and leisure industry [10]. Renewable natural fibre with adequate reinforcement of synthetic polymer is a good alternatives for glass fibre application in automotive components [10]. Mastura et al. selecting sugar palm fibre for their Automotive Anti-roll Bar conceptual design after comparing with a six dominant natural fibre in automotive components (hemp, sisal, flax, kenaf, coir and jute) and locally available renewable natural fibre (sugar palm, oil palm and pineapple) [11].

It was recorded that there are 60.1 million units of motorcycles sold globally in year 2019, where 22.4% is from Association of Southeast Asian Nations (ASEAN) region [12]. In year 2019, Malaysia become the fastest growing with 15.9% from total of 13.75 million units of motorcycle sold in ASEAN region [13]. The application of renewable natural fibre in motorcycle component such as side cover, may potentially improve our environment. Motorcycle side cover is one of the motorcycle’s body cover set which also include fairing, headlamp cover, front cover, and rear cover. Currently, most motorcycle’s side cover is made from plastic.

Innovation on developing hybrid-composite motorcycle’s side cover can be facilitated through conceptual design development which may provide initial strategy to combine and evaluate various design ideas into design solutions. Conceptual design may provide better insight on the expected product, which may reduce waste in terms of rework and minimize the problems when the product is manufactured [14,15]. Other than that, during conceptual stage, cost of change is the lowest but the potential cost saving is the highest, shown in Fig. 1 [16]. In concept design development, several steps such as ideas generation, ideas refinement, concept design development and concept design evaluation and selection are conducted based on product design specifications [17].

Figure 1: Stage of project and savings potential [16]

There are several methodologies that have been introduced for conceptual design of the composite’s automotive product. Among the famous methodologies include Theory of Inventive Problem Solving (TRIZ), Analytical Hierarchy Process (AHP), Technique of Order Preference Similarity to the Ideal Solution (TOPSIS), Blue-Ocean Strategy (BOS) and optimization techniques [4,18–21]. These methodologies are parts of the conceptual design process which concentrates on specific output or outcome. In order to ensure a good value of the conceptual design, a comprehensive conceptual design strategy such as Quality Based Selection (QBS) analysis is used to choose and propose the final conceptual design of hybrid composites motorcycle’s side cover.

The better understanding on motorcycle side cover functions are achieved through Function Analysis System Technique (FAST). The functions statements are simplified into verb and noun and categorised according to their type. The constructed FAST diagram for motorcycle side cover is as shown in Fig. 2.

Figure 2: FAST diagram of motorcycle side cover

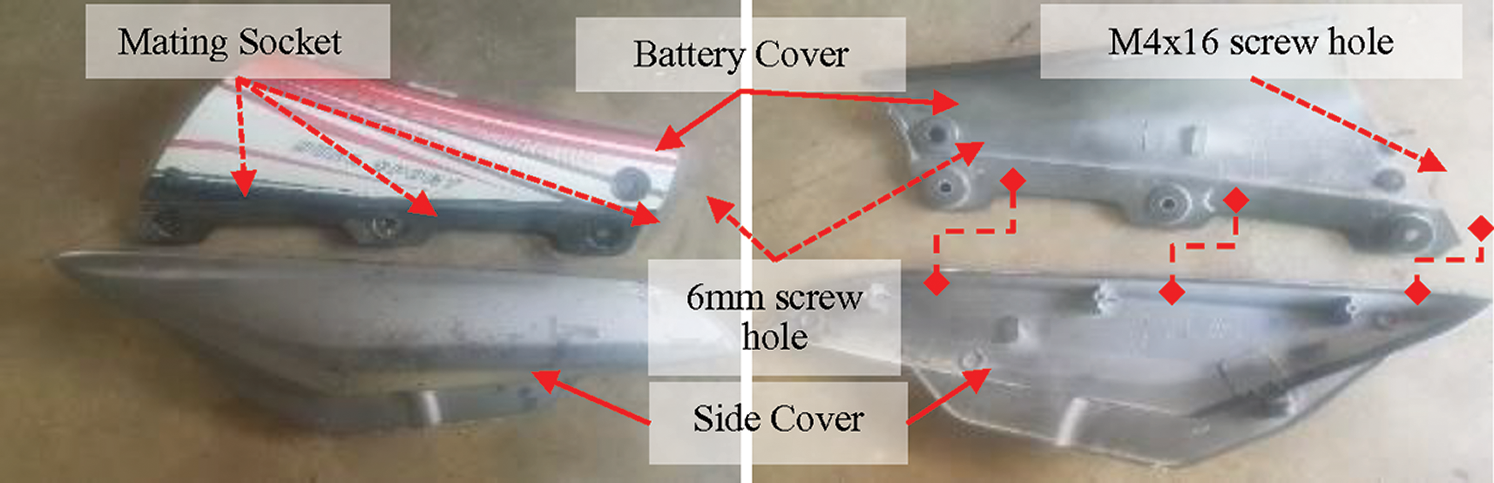

In case of SYM E-Bonus 110, the right-side cover installed together with battery cover to cover area that have wiring system, fuse, battery and some other parts and component which shown in Fig. 3. The side cover manages to prevent any unwanted contact and in the same time, enhances the appearance of the motorcycle by hiding those parts, components and systems.

Figure 3: (a) Important items covered by right-side cover and (b) Areas of side cover and battery cover

3 Competitive Benchmarking Information

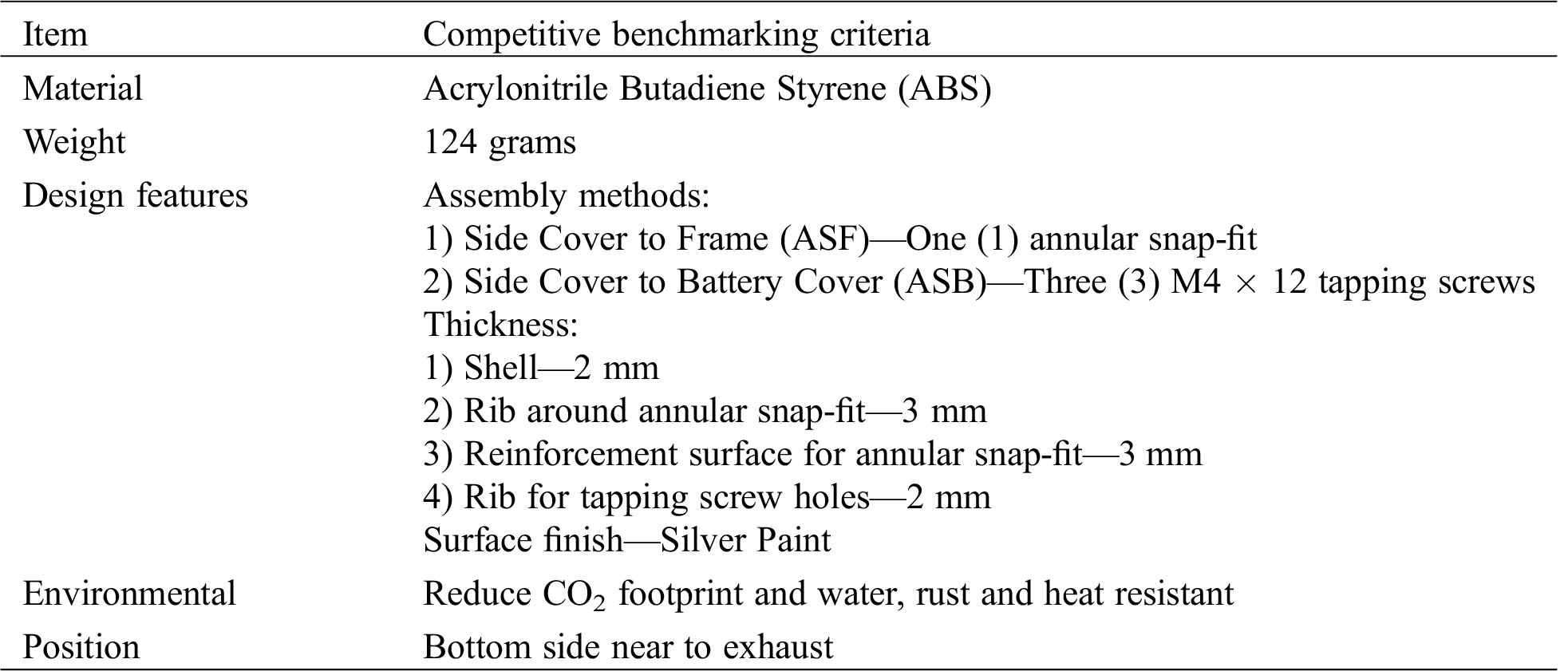

Based on motorcycle side cover functions, the side cover is not expected to transmitting any load and just need to have adequate strength and stiffness to maintain its shape and stands some external forces. The competitive benchmarking criteria are identified from physical inspection on SYM E-Bonus 110 right side cover as per shown in Figs. 4–8 and summarize in Tab. 1.

Figure 4: Top view of SYM E-Bonus 110 right-side cover

Figure 5: Bottom view of SYM E-Bonus 110 right-side cover

Figure 6: Assembly between right-side cover and battery cover

Figure 7: Assembly position of side cover and battery cover on motorcycle

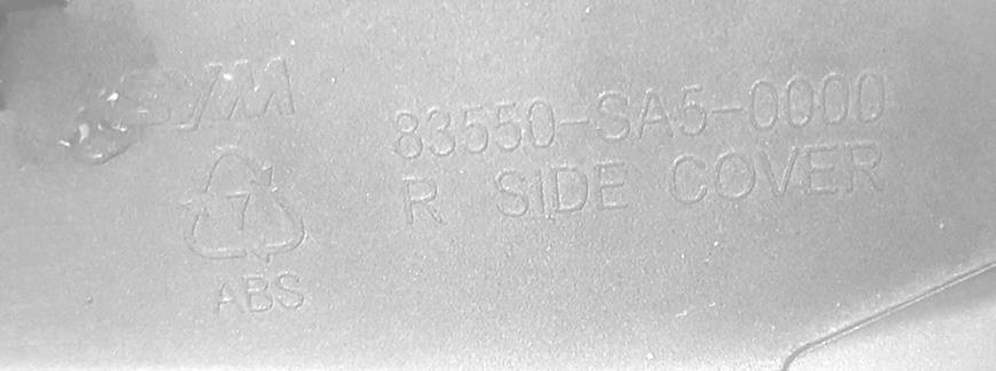

Figure 8: Information markings on SYM E-Bonus 110 right-side cover

Table 1: Summary of competitive benchmarking criteria

Based on the assembly method of SYM E-Bonus 110 right-side cover, it is crucial to ensure the extruded structure placing the mating holes for M4 × 12 tapping screw and annular snap-fit have enough strength especially in term of shear. Referring to Fig. 8, based on the information markings, the right-side cover is made from Acrylonitrile Butadiene Styrene (ABS), a thermoplastic, which is expected to have tensile strength of approximately 40.71 MPa and impact strength (Izod) of 320.28 J/m [22]. The markings also indicate that the right-side cover is class-7 recycle-able product. Even though, the current right-side cover which made from ABS can be recycled, it is not biodegradable [23–25].

Other than that, the right-side cover position is near to the motorcycle exhaust. Due to that matter, the side cover must have enough heat resistant to prevent heat distortion. Smith & Hashemi mention that ABS used for general purpose has maximum-use temperature (no load) of between 71–93˚C [22]. Which means that the motorcycle side cover made from ABS has adequate heat resistant to prevent heat distortion. The side cover is also painted to the desired colour for aesthetical purpose. Other than that, paint also provide additional protection to the component, for an example UV protection, water repellent, weather resistant and protection from plastic corrosion.

Moreover, the right-side cover is electrical resistive to prevent risk of electrical-shock towards the rider and pillion. Even though the electrical system has been built in a way of preventing short-circuit and using water-resistant component, the side cover is also water repellent to provide additional protection from water-hazards towards the protected parts, component and system especially the electrical systems. In addition to that, the use of ABS makes side cover safe from rust.

Product that are design with environmental considerations should identify potential environmental impacts. Ulrich and Eppinger listed material goals on design for environment, which are reducing usage of raw materials, using renewable raw materials that is plenty, eliminate toxic materials, increase the energy efficiency of material extraction process, reduce discards and waste, increased the use of recovered and recycled materials [26]. To put more emphasis, according to Mansor et al. [27], environmental life cycle assessment of the materials, to further assess each of the material performance in term of environmental sustainability including energy consumption and carbon footprint. DeSimone et al. [28] as cited by Chang and Chen had listed 7 eco-efficiency elements which are material reduction, energy reduction, toxicity reduction, material retrieval, resource sustainable, product durability and product service [29]. The environmental requirement for this research is only considering on the final product in term of partial-biodegradability, reduce dependent on petroleum-based materials as well as reduce CO2 footprint. Partial biodegradability and low CO2 footprint is considered because of the exploration of glass/renewable natural fibre-reinforced polymer in this research due to its good water, heat and rust resistant properties.

5 Product Design Specifications (PDS)

Based on the inputs from side cover functions, benchmarking characteristic and environmental requirement, the decided PDS and its criteria are as shown in Fig. 9.

Figure 9: Product design specifications for motorcycle side cover

These material selections are focusing on choosing suitable renewable natural fibre from the six dominant renewable natural fibre in automotive component which are hemp, sisal, flax, kenaf, coir and jute. The glass fibre has been fixed to E-glass due to its popular usage in glass/renewable natural fibre hybrid composite research and its good mechanical properties and electric resistance. From the selected natural fibre, the existing glass/renewable natural fibre reinforced polymer matrix hybrid composite is identified from previous studies and manufacturer catalogue.

The disposal criteria are not evaluated during natural fibre selection process due to the fact that all natural fibre is recyclable, reusable, renewable and biodegradable. This makes the glass/renewable natural fibre-reinforced polymer hybrid composite to be recyclable, reusable and partially biodegradable. Moreover, the usage of polymer matrix in hybrid composite is providing electric insulation, water resistance and rust resistance characteristic towards the material. Other than that, heat resistance is also evaluated during polymer matrix selection since matrix is a part of composite that have contact with the surroundings and should resist corrosion, heat, and abrasion [5].

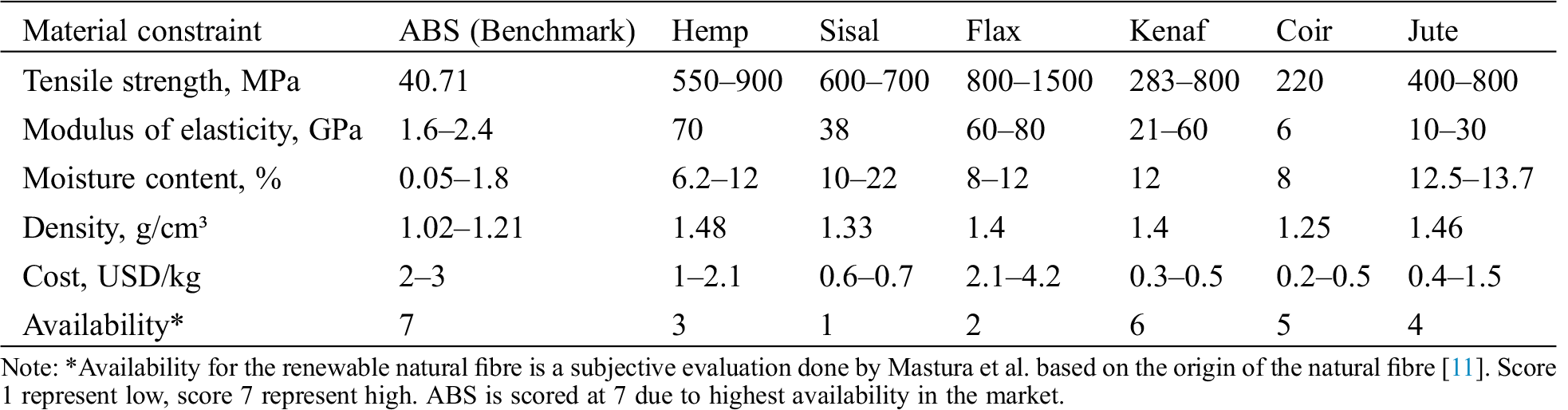

Tab. 2 shows the comparison between benchmark material and shortlisted renewable natural fibres. All of the listed natural fibre has better tensile strength and modulus of elasticity compared to ABS. However, all of the natural fibre have higher density and moisture content. Most of the renewable natural fibres cost cheaper than ABS but less available [30]. Based on the data, except cost, the mean values for each renewable natural fibre properties are calculated and ranked from 1–poor to 6-good. All of the renewable natural fibres are rank from 1 (lowest) to 6 (highest) according to their material constraint characteristic and then applied into Quality Based Selection to measure the value index of each natural fibre. The renewable natural fibre with the highest value index is selected as per shown in Fig. 10.

Figure 10: Renewable natural fibre selection using quality-based selection method

Table 2: Comparison between ABS and selected renewable natural fibres [1,30,32,34]

Non-monetary criteria selected from material constraint are weighted based on the importance of each criterion compared to other. For an example, AB means that the tensile strength is as importance as modulus of elasticity, D2 at column B means that density is a major preference compared to modulus of elasticity and E1 at column C means that availability is a minor preference compared to moisture of content. Finally, coir fibre is selected because of the highest value index compared to other natural fibre.

From Tab. 2 and Fig. 10, we could see the “Availability” term. Availability is a subjective evaluation done by Mastura et al. by mean of easiness level to achieve the natural fibre in Malaysia due to various conditions [11]. The authors scored ABS with 7 as we can easily get the materials in most stores across the country. Next, the facile production process and low cost associated with the highest availability in the market. Whereas, kenaf, coir and jute fibres were scored with 6, 5 and 4, respectively, which were associated by the massive raw materials production as these type of fibres are originated from Malaysia [31,32], however, more complex manufacturing process are needed compared to ABS. On the other hand, hemp, sisal and flax natural fibres have lower scores which attributed by the limited sources and hardly to find in Malaysia. According to Peças et al, these fibres are mainly imported from India, South Africa and United States [33].

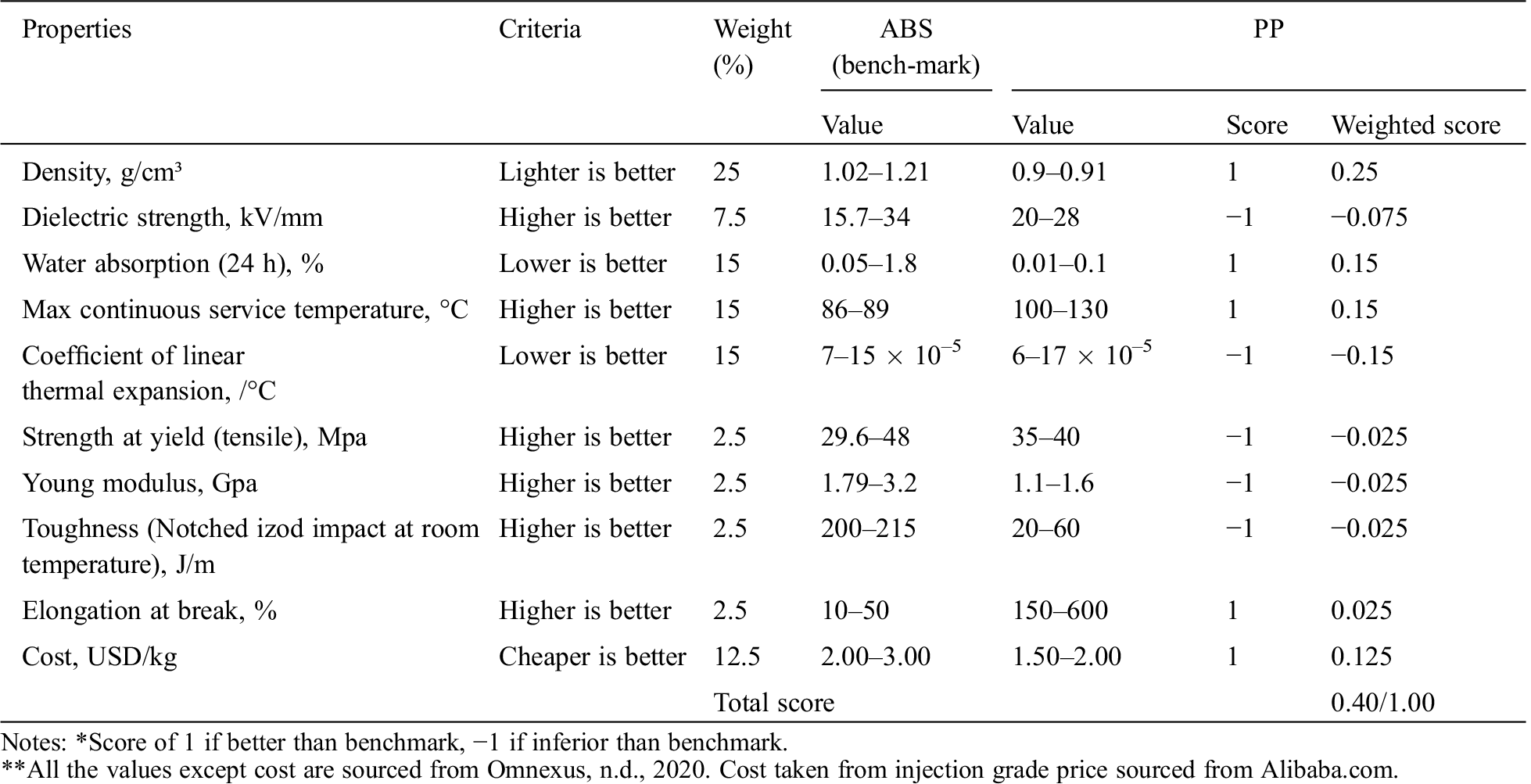

Polypropylene (PP) has been chosen as the matrix based on the previous research by Ayrilmis et al. which suggesting the usage of coir fibre-reinforced polypropylene for non-structural applications of automotive vehicles [35]. Other than that, PP is widely used in non-structural automotive applications such as battery cases and trays, bumpers, fender liners, interior trim, instrumental panels and door trims [36]. The evaluation of PP performance comparing to ABS is conducted using Weighted Evaluation Matrix as per shown in Tab. 3. Based on Tab. 3, PP scored 0.40 out of 1.00. It means that PP is better than ABS and suitable to be selected as the matrix. PP has lighter density which may compensate the heavier density of coir fibre and glass fibre [36]. Overall, from the material selections process, the selected hybrid composite for motorcycle side cover is glass/coir fibre-reinforce polypropylene.

Table 3: Evaluation of PP as matrix using Weighted Evaluation Matrix

7 Conceptual Design Development

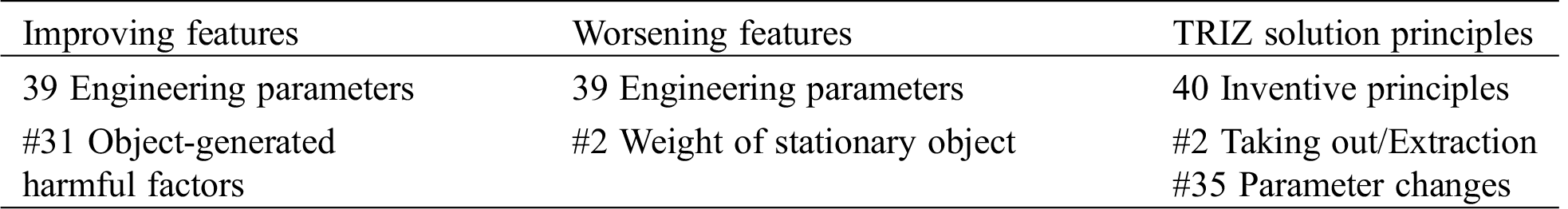

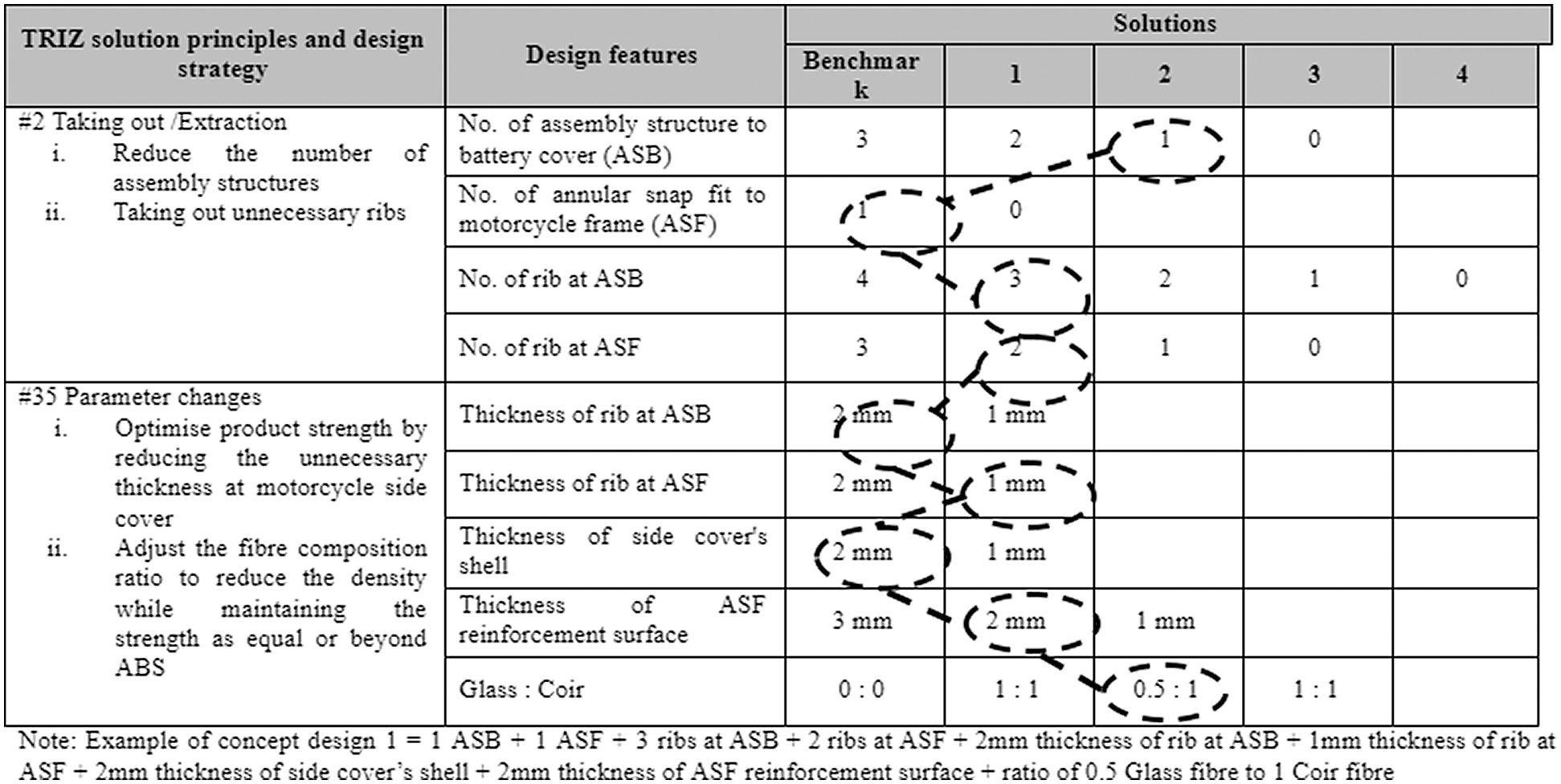

The development of conceptual design of motorcycle hybrid composite is conducted using Theory of Inventive Problem Solving (TRIZ). The TRIZ method had been extensively explained by Asyraf et al. [37] and Yusof et al. [38] which used to generate ideas in order to solve the identified issues. The design intent is to replace the ABS motorcycle side cover with glass/coir fibre-reinforced polypropylene to enhance the biodegradability in order of reducing pollution. However, the selected material is expected to increase the motorcycle side cover weight due to higher density of coir and glass fibres compared to ABS. Thus, the improving parameters is #31 Object-generated harmful factors and the worsening parameter is #2 weight of stationary object.

Contradiction matrix is then developed to identify the appropriate solution principles towards every worsening parameter that match with the problems occur in achieving the design intent. According to Shaharuzaman et al. [21] and Asyraf et al. [39], in the context of a TRIZ contradiction matrix methodology, the 39 engineering parameters help researchers and designers to discover the contradiction between the improvements and the aggravations during the preliminary development phase. Finally, the TRIZ 40 innovative principles methodology have been applied to provide an adequate solution theory for identifying the complication. Referring to Tab. 4, the identified solutions from 40 inventive principles to overcome the increase of #20 weight of stationary object are #2 taking out/extraction and #35 parameter changes. From the known solution principles, a design strategy has been identified. Tab. 5 describes the solution principle and its design strategy, respectively. The design strategy basically targeted on reducing the weight by minimizing usage and reducing density of the material.

Table 4: Contradiction matrix for glass/coir fibre-reinforced polypropylene motorcycle side cover

Table 5: Design strategy based on identified TRIZ solution principles

After the design strategy is identified, selected solution principles are refined into relevant alternative system elements [19]. The morphological chart is integrated into TRIZ solutions principles as to further enhance the effectiveness of TRIZ tools and ease the development of glass/coir fibre-reinforced polypropylene hybrid composite conceptual design as shown in Fig. 11. From the design strategy and the refinement of solution principles, there are four (4) new motorcycle side cover concept design have been developed as listed in Tab. 6.

Figure 11: Morphological chart of TRIZ solution principle and their related design features

Table 6: Developed conceptual design of motorcycle side cover

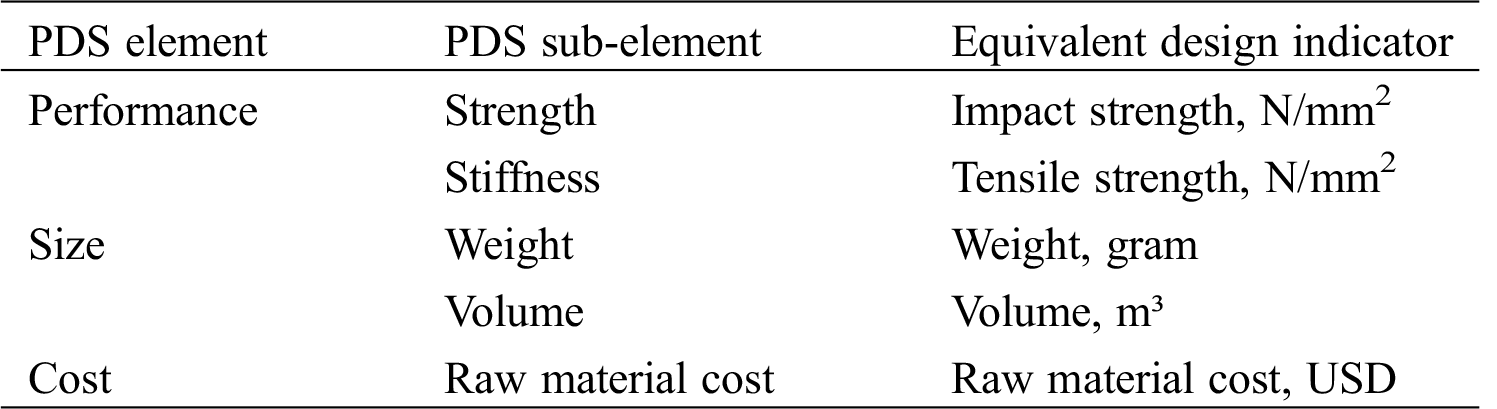

The final process of conceptual design development is doing conceptual design selection. The selection of conceptual design is done based on PDS elements. Out of all PDS element, only three elements and its sub-element are selected for the conceptual design selection purpose which are performance, size and cost [40,41]. However, the sub-element heat resistant is not considered since it is already considered during material selections together with PDS element of safety, disposal and environment. From the PDS sub-element, the equivalent design indicator is decided to evaluate all of concept designs. The summary of PDS elements and their equivalent design indicators is as shown in Tab. 7.

Table 7: Summary of PDS elements and their equivalent design indicator

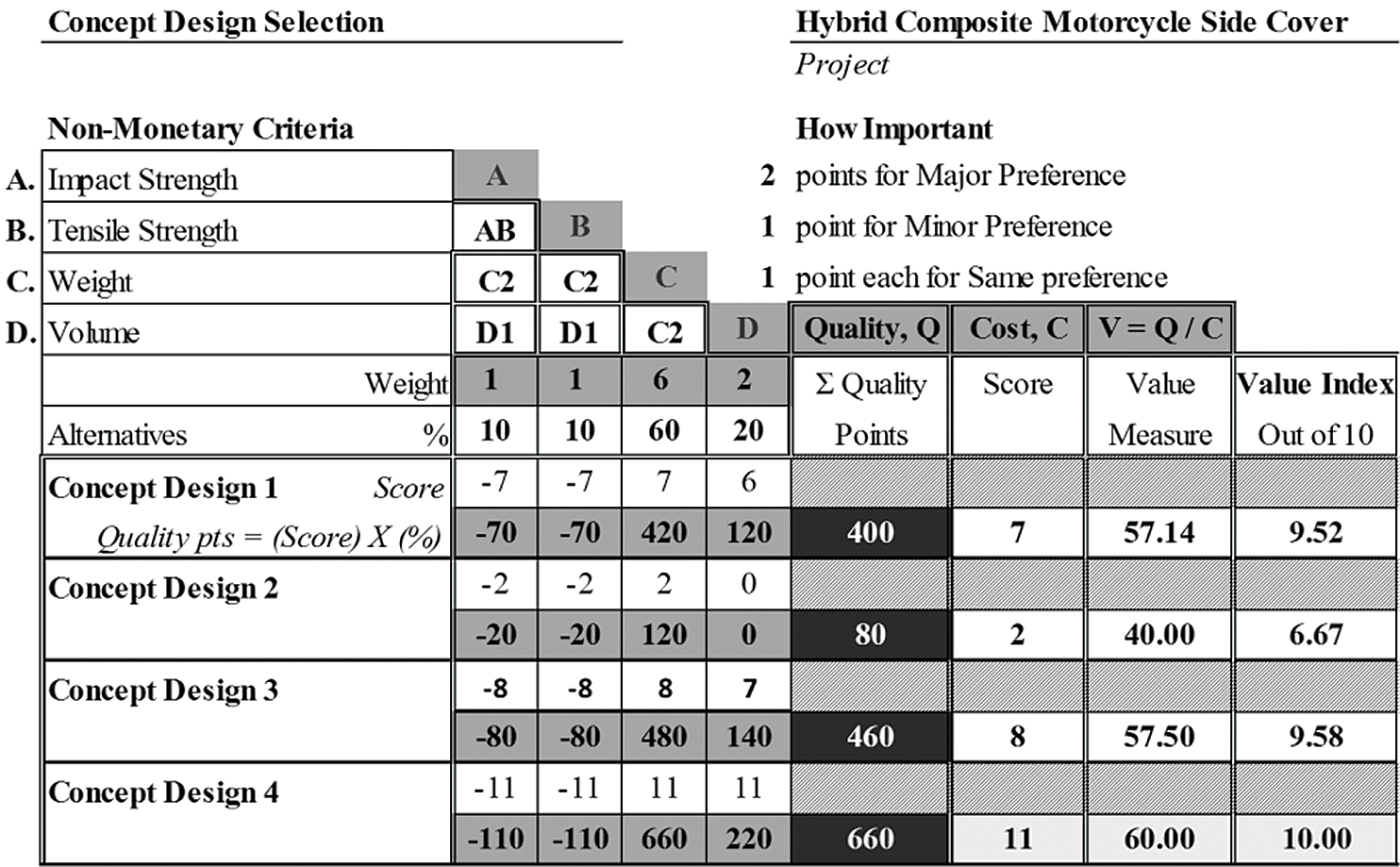

The final selection of conceptual design is done by combining Pugh selection method and QBS. Pugh selection method is used to determine weightage of each concept design with respect to their design features configuration [21,42]. Based on Sapuan [15], after a comprehensive idea creation process, the main purpose of the Pugh selection method is an assessment of the best design ideas. This procedure uses a current design concept as a datum reference. The design features on the benchmark motorcycle side cover become reference for this evaluation. Each design features are scored between −3 to 3 (Changes caused highest inferiority to Changes resulted greater improvement).

The score of each concept design respective to equivalent design indicators of PDS sub-element is as shown in Fig. 12. The scoring is done by judging the impact of design features changes towards the design indicators of PDS sub-element. The reduction on the number of assembly structure to battery cover (ASB) may result in inferiority towards the impact and tensile strength of the side cover but in the same time resulting on improvement in term of lighter side cover weight and lesser material volume. Lesser material volume may also reduce the raw material cost which is also considered as an improvement.

Figure 12: Scoring of each concept design respective to equivalent design indicators of PDS sub-element

The score of each design concept with respective to equivalent design indicators of PDS sub-element is then applied in QBS. Using the QBS, the value index of each design concept is measured and the design concept with the highest value index is selected as the final design concept. Fig. 13 show the concept design selection using QBS. The Concept Design 4 has been selected for conceptual design of glass/coir fibre-reinforced polypropylene motorcycle side cover due to the highest value index 10 out of 10 with quality point of 660 and value of 60 point.

Figure 13: Concept design selection using QBS

The design features of the benchmark motorcycle side cover are as shown in Fig. 14. The design of the benchmark motorcycle side cover consists of three extruded structure use to fix the screw when assemble to the motorcycle battery cover which will be called as ASB. Each of the extruded structure is supported by four ribs that have thickness of 2 mm each. Other than that, there are one annular snap fit function to assemble to the motorcycle frame (ASF) located on a square surface which is supporting by three ribs. The square surface and ribs thickness are 3 mm. The side cover shell surface around the annular snap fit is reinforced with a thicker surface measured at 3 mm. The thickness of the motorcycle side cover shell is 2 mm.

Figure 14: Design features of the benchmark motorcycle side cover

After the design strategy is identified, selected solution principles are refined into relevant alternative system elements. The morphological chart is integrated into TRIZ solutions principles as to further enhance the effectiveness of TRIZ tools and ease the development of glass/coir fibre-reinforced polypropylene hybrid composite conceptual design as shown in Fig. 15.

Figure 15: Morphological chart of TRIZ solution principle for the development of glass/coir fibre-reinforced polypropylene hybrid composite

In conclusion, glass/coir fibre-reinforced polypropylene hybrid composites material has been selected as a replacement to ABS material for the motorcycle side cover in order to enhance the environmental characteristic by utilising the agriculture waste. The usage of coir fibre makes the hybrid composites material to be partially biodegradable. Even though glass fibre and coir fibre are denser than ABS, they can be compensated through the usage of polypropylene and the reduction of raw material. Integration of Ranking method with QBS can ease the renewable natural fibre selection process and WEM is adequate to compare the performance of PP with ABS. Moreover, integration of TRIZ and Morphological Chart allows for systematic concept development while integration of Pugh scoring method and QBS allows for systematic final concept selection.

Acknowledgement: The authors would like to thank Faculty of Engineering, Universiti Putra Malaysia (UPM) for the facilities provided throughout this research.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Mastura, M. T., Sapuan, S. M., Mansor, M. R., Nuraini, A. A. (2017). Environmentally conscious hybrid bio-composite material selection for automotive anti-roll bar. International Journal of Advanced Manufacturing Technology, 89(5–8), 2203–2219. DOI 10.1007/s00170-016-9217-9. [Google Scholar] [CrossRef]

2. Azammi, A. M. N., Sapuan, S. M., Ishak, M. R., Sultan, M. T. H. (2018). Conceptual design of automobile engine rubber mounting composite using TRIZ-morphological chart-analytic network process technique. Defence Technology, 14(4), 268–277. DOI 10.1016/j.dt.2018.05.009. [Google Scholar] [CrossRef]

3. Harussani, M. M., Sapuan, S. M., Khalina, A., Ilyas, R. A., Hazrol, M. D. (2020). Review on green technology pyrolysis for plastic wastes. Proceedings of the 7th Postgraduate Seminar on Natural Fibre Reinforced Polymer Composites 2020, Institute of Tropical Forestry and Forest Product (INTROPpp. 50–53. Universiti Putra Malaysia. [Google Scholar]

4. Mansor, M. R., Sapuan, S. M., Zainudin, E. S., Nuraini, A. A., Hambali, A. (2014). Conceptual design of kenaf fiber polymer composite automotive parking brake lever using integrated TRIZ-morphological chart-analytic hierarchy process method. Materials and Design, 54, 473–482. DOI 10.1016/j.matdes.2013.08.064. [Google Scholar] [CrossRef]

5. Al-Oqla, F. M., Sapuan, M. S. (2017). Materials selection for natural fiber composites. Cambridge, England: Woodhead Publishing. DOI 10.1016/c2015-0-04877-8. [Google Scholar] [CrossRef]

6. Ilyas, R. A., Sapuan, S. M., Atikah, M. S. N., Ibrahim, R., Hazrol, M. D. et al. (2020). Natural fibre: A promising source for the production of nanocellulose. Proceedings of the 7th Postgraduate Seminar on Natural Fibre Reinforced Polymer Composites 2020. Institute of Tropical Forestry and Forest Product (INTROPUniversiti Putra Malaysia. [Google Scholar]

7. Callister, W. D. J., Rethwisch, D. G. (2015). Materials sciene and engineering SI version, 9th editionJohn Wiley & Sons (Asia) Pte. Ltd. [Google Scholar]

8. Sapuan, S. M., Lok, H. Y., Ishak, M. R., Misri, S. (2013). Mechanical properties of hybrid glass/sugar palm fibre reinforced unsaturated polyester composites. Chinese Journal of Polymer Science, English edition31(10), 1394–1403. DOI 10.1007/s10118-013-1342-4. [Google Scholar] [CrossRef]

9. Norizan, M. N., Harussani, M. M., Demon, S. Z. N., Halim, N. A., Samsuri, A. et al. (2020). Carbon nanotubes: Functionalisation and their application in chemical sensors. RSC Advances, 10(71), 43704–43732. DOI 10.1039/D0RA09438B. [Google Scholar] [CrossRef]

10. Georgios, K., Silva, A., Furtado, S. (2016). Applications of Green Composite Materials. In: Kalia S. (Ed.Biodegradable green composites, 1st edition, pp. 312–337. New Jersey, US: John Wiley & Sons, Inc. [Google Scholar]

11. Mastura, M. T. (2017). A new hybrid approach for conceptual design of sugar palm fibre-reinforced polyurethane composites for automotive anti-roll bar (Ph.D. Thesis). Universiti Putra Malaysia, Malaysia. [Google Scholar]

12. Data, M. (2020). World motorcycles market-data & fact 2020. motorCyclesData. https://www.motorcyclesdata.com/2021/04/08/world-motorcycles-market/. [Google Scholar]

13. Data, M. (2020). ASEAN motorcycles sales in the 2020. motorCycles data. https://www.motorcyclesdata.com/2021/03/17/asean-motorcycles-industry/. [Google Scholar]

14. Liker, J. K. (2004). The toyota way: 14 management principles from the world’s greatest manufacturer, CWL Publishing Enterprise Edition. New York: McGraw-Hill. [Google Scholar]

15. Sapuan, S. M. (2017). Composite materials: concurrent engineering approach. Oxford, UK: Butterworth-Heinemann. [Google Scholar]

16. Mat, M. M. C. (2002). Value management: Principles and applications: Towards achieving better value for your money. Selangor: Prentice Hall/Kreatif Kembara. [Google Scholar]

17. Pugh, S. (1991). Total design—Integrated methods for successful product engineering. Wokingham, England: Addison-Wesley Publishing Company. [Google Scholar]

18. Davoodi, M. M., Sapuan, S. M., Yunus, R. (2008). Conceptual design of a polymer composite automotive bumper energy absorber. Materials and Design, 29(7), 1447–1452. DOI 10.1016/j.matdes.2007.07.011. [Google Scholar] [CrossRef]

19. Ghici, G. Ă., Banciu, F. (2004). Development of a conceptual design methodology for products. timisoara. DOI 10.13140/2.1.4537.7920. [Google Scholar] [CrossRef]

20. Hambali, A. (2009). Selection of conceptual design using analytical hierarchy process for automotive bumper beam under concurrent engineering environment (Ph.D. Thesis). Universiti Putra Malaysia, Malaysia. [Google Scholar]

21. Shaharuzaman, M. A., Sapuan, S. M., Mansor, M. R., Zuhri, M. Y. M. (2020). Conceptual design of natural fiber composites as a side-door impact beam using hybrid approach. Journal of Renewable Materials, 8(5), 549–563. DOI 10.32604/jrm.2020.08769. [Google Scholar] [CrossRef]

22. Smith, W. F., Hashemi, J. (2006). Foundations of materials sciene and engineering, 4th edition. New York: McGraw-Hill Book Company. [Google Scholar]

23. Giang, K. (2020). PLA vs. ABS: What’s the difference? 3D hubs. 3dhubs.com. [Google Scholar]

24. Scott, M. (2017). 5 reasons Why ABS needs to Go away. All3DP. all3dp.com. [Google Scholar]

25. Pakkanen, J., Manfredi, D., Minetola, P., Iuliano, L. (2017). About the use of recycled or biodegradable filaments for sustainability of 3D printing. Sustainable Design and Manufacturing 2017, Smart Innovation, Systems and Technologies, 68, 776–785. DOI 10.1007/978-3-319-57078-5_73. [Google Scholar] [CrossRef]

26. Ulrich, K. T., Eppinger, S. D. (2011). Product design and development. 5th edition USA: McGraw-Hill Education. [Google Scholar]

27. Mansor, M. R., Sapuan, S. M. (2017). Concurrent conceptual design and materials selection of natural fiber composite products. New York: Springer. [Google Scholar]

28. DeSimone, L. D., Popoff, F. (1997). World business council for sustainable development. ECO-efficiency: The business link to sustainable development. Cambridge, USA: Massachusetts Institute of Technology. [Google Scholar]

29. Chang, H. T., Chen, J. L. (2003). Eco-innovative examples for 40 TRIZ inventive principles. The TRIZ Journal, 1–16. [Google Scholar]

30. Omnexus (2020). Properties of ABS. omnexus.specialchem.com. [Google Scholar]

31. Aisyah, H. A., Paridah, M. T., Sapuan, S. M., Khalina, A., Berkalp, O. B. et al. (2019). Thermal properties of woven kenaf/Carbon fibre-reinforced epoxy hybrid composite panels. International Journal of Polymer Science, 2019, 1–8. DOI 10.1155/2019/5258621. [Google Scholar] [CrossRef]

32. Wambua, P., Ivens, J., Verpoest, I. (2003). Natural fibres: Can they replace glass in fibre reinforced plastics? Composites Science and Technology, 63(9), 1259–1264. DOI 10.1016/S0266-3538(03)00096-4. [Google Scholar] [CrossRef]

33. Peças, P., Carvalho, H., Salman, H., Leite, M. (2018). Natural fibre composites and their applications: A review. Journal of Composites Science, 2(4), 66. DOI 10.3390/jcs2040066. [Google Scholar] [CrossRef]

34. Mohanty, A. K., Misra, M., Hinrichsen, G. (2000). Biofibres, biodegradable polymers and biocomposites: An overview. Macromolecular Materials and Engineering, 276(1), 1–24. DOI 10.1002/(SICI)1439-2054(20000301)276:1<1::AID-MAME1>3.0.CO;2-W. [Google Scholar] [CrossRef]

35. Ayrilmis, N., Jarusombuti, S., Fueangvivat, V., Bauchongkol, P., White, R. H. (2011). Coir fiber reinforced polypropylene composite panel for automotive interior applications. Fibers and Polymers, 12(7), 919–926. DOI 10.1007/s12221-011-0919-1. [Google Scholar] [CrossRef]

36. Omnexus (2021). Polypropylene (PP) plastic: Types, properties, uses & structure info. https://omnexus.specialchem.com/selection-guide/polypropylene-pp-plastic. [Google Scholar]

37. Asyraf, M. R. M., Ishak, M. R., Sapuan, S. M., Yidris, N. (2019). Conceptual design of creep testing rig for full-scale cross arm using TRIZ-morphological chart-analytic network process technique. Journal of Materials Research and Technology, 8(6), 5647–5658. DOI 10.1016/j.jmrt.2019.09.033. [Google Scholar] [CrossRef]

38. Yusof, N. S. B., Sapuan, S. M., Sultan, M. T. H., Jawaid, M. (2020). Conceptual design of oil palm fibre reinforced polymer hybrid composite automotive crash box using integrated approach. Journal of Central South University, 27(1), 64–75. DOI 10.1007/s11771-020-4278-1. [Google Scholar] [CrossRef]

39. Asyraf, M. R. M., Ishak, M. R., Sapuan, S. M., Yidris, N. (2020). Conceptual design of multi-operation outdoor flexural creep test rig using hybrid concurrent engineering approach. Journal of Materials Research and Technology, 9(2), 2357–2368. DOI 10.1016/j.jmrt.2019.12.067. [Google Scholar] [CrossRef]

40. Sapuan, S. M. (2021). “Green” conceptual design toward design for environmental sustainability. Design for Sustainability, pp. 3–23. Amsterdam, Netherlands: Elsevier. DOI 10.1016/B978-0-12-819482-9.00008-3. [Google Scholar] [CrossRef]

41. Sapuan, S. M., Shafiqa, F. N., Mastura, M. T., Ilyas, R. A. (2020). 6 conceptual design. Composites in biomedical applications, pp. 117. DOI 10.1201/9780429327766. [Google Scholar] [CrossRef]

42. Brunetti, G., Golob, B. (2000). A feature-based approach towards an integrated product model including conceptual design information. Computer-Aided Design, 32(14), 877–887. DOI 10.1016/S0010-4485(00)00076-2. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |