Open Access

Open Access

ARTICLE

Effect of Alkaline Electrolyzed Water on Performance Improvement of Green Concrete with High Volume of Mineral Admixtures

1

Center for Technological Development, Qingdao Qingjian New Material Group Co., Ltd., Qingdao, 266108, China

2

College of Civil Engineering & Architecture, Qingdao Agricultural University, Qingdao, 266109, China

* Corresponding Author: Liang Wang. Email:

(This article belongs to the Special Issue: Renewable building materials and properties)

Journal of Renewable Materials 2021, 9(11), 2051-2065. https://doi.org/10.32604/jrm.2021.015398

Received 16 December 2020; Accepted 20 February 2021; Issue published 04 June 2021

Abstract

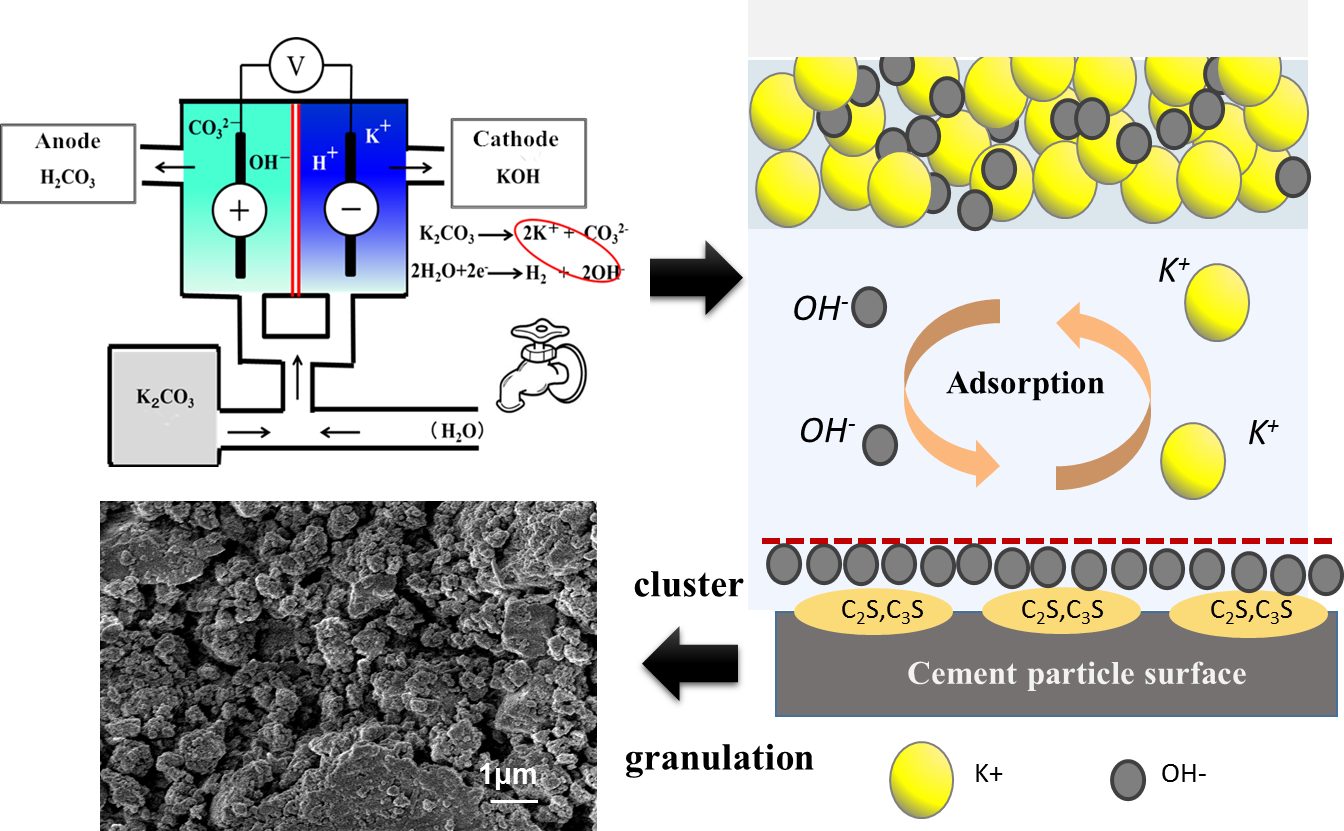

The strength and durability of concrete will be significantly reduced at high volume of mineral admixture, and the poor early strength of concrete also still needs to be solved. In this investigation, a highly active alkaline electrolyzed waters was used as mixing water to improve the early strength and enhance the durability of green concrete with high volume mineral admixture, the influences of alkaline electrolyzed water (AEW) on hydration activity of mineral admixture and durability of concrete were determined. The results showed that compared with natural tap water, AEW can accelerate early hydration process of cement in concrete and produce comparatively more hydrated products, leading to a 13.6% higher compressive strength than that of ordinary concrete at early age, but the improvement effect of AEW concrete was relatively reduced at long-term age. Meanwhile, the activity of mineral admixtures could be stimulated by AEW to some extent, the strength and durability performance of AEW concrete after double doping 25% slag and 25% fly ash can still reach the level of ordinary cement concrete without mineral admixtures. The SEM micromorphology of 7 d hydrated natural tap water cement paste was observed to be flaky and tabular, but the AEW cement pastes present obvious cluster and granulation phenomenon. The SEM microstructure of AEW concrete with mineral admixtures is more developed and denser than ordinary tap water concrete with mineral admixtures. Therefore, the AEW probably could realize the effective utilization of about 50% mineral admixture amount of concrete without strength loss, the cement production cost and associated CO2 emission reduced, which has a good economic and environmental benefit.Graphic Abstract

Keywords

Cite This Article

Copyright © 2021 The Author(s). Published by Tech Science Press.

Copyright © 2021 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools