Materials

| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2021.015659

ARTICLE

Effect of Encapsulation Combined with Microwave Heating on Self-Healing Performance of Asphalt Mixture

1Foshan Transportation Science and Technology Co., Ltd., Foshan, 528000, China

2China Academy of Building Research, Beijing, 100000, China

3School of Civil Engineering and Architecture, Wuhan Institute of Technology, Wuhan, 430070, China

4Department of Civil and Environmental Engineering, Norwegian University of Science and Technology, Trondheim, 7491, Norway

5State Key Laboratory of Silicate Materials for Architectures, Wuhan University of Technology, Wuhan, 430070, China

*Corresponding Authors: Benan Shu. Email: shuba@whut.edu.cn; Shaopeng Wu. Email: wusp@whut.edu.cn

Received: 03 January 2021; Accepted: 04 February 2021

Abstract: As an innovative maintenance technology of asphalt pavement, encapsulated rejuvenator used to improve its self-healing performance has been widely investigated by researchers in recent years. In this work, the self-healing properties of asphalt mixture with and without encapsulations were comparatively studied considering these parameters: Healing time, healing cycles and microwave heating. Three-point bending strength recovery test and fatigue loading cycles recovery test were conducted for two kinds of encapsulations containing the healing agents present inside the asphalt mixture, namely compartmented Ca-alginate/SiO2 fiber and compartmented Ca-alginate/graphene oxide fiber. The results showed that the optimum healing time was three days. After the 30 s of microwave heating, the recovery of fatigue loading cycles of asphalt mixture with compartmented Ca-alginate/graphene oxide fiber was four times larger than that of control asphalt mixture. Compared with the single effect related to the encapsulated healing agent or temperature, the synergistic effect of temperature and encapsulation could further significantly improve the self-healing properties of asphalt mixture. The compartmented Ca-alginate/graphene oxide fiber not only could soften asphalt through the encapsulated healing agent to improve self-healing properties of asphalt, but also could repeatedly and quickly heal cracks thanks to microwave action. The synthesis of the fiber breaks the current boundary between the two technologies (capsules healing method and induction healing method) and opens up a new horizon for the asphalt self-healing technology.

Keywords: Asphalt mixture; self-healing; compartmented fiber; encapsulation; microwave heating

Abbreviations

| CaS: | Compartmented Ca-alginate/SiO2 fiber encapsulating healing agent |

| CaG: | Compartmented Ca-alginate/graphene oxide fiber encapsulating healing agent |

| CaSA: | Asphalt mixture with CaS |

| CaGA: | Asphalt mixture with CaG |

| CA: | Control asphalt mixture |

As a cementing material, asphalt is widely used in the construction of high-speed pavement. Compared to concrete pavements, asphalt pavements offer many advantages, such as the generation of less dust and less noise when driving [1,2]. Under the influence of traffic load and external environment (such as temperature stress and ultraviolet radiation), cracks will generate inside asphalt, which will greatly increase maintenance cost and seriously shorten the service life of asphalt pavement [3,4].

It was considered as an advanced maintenance concept to add the encapsulated healing agent to improve the self-healing performance of asphalt mixture, thus reducing maintenance costs and extending the service life of asphalt pavement [5–7]. The encapsulated healing agents were different kinds of rejuvenator [8,9], such sunflower oil [10,11], waste cooking oil [12–15]. Furthermore, a variety of encapsulation technologies were developed to improve the efficacy of asphalt self-healing, such as core-shell microcapsules [16,17], multi-core capsules [18–21], and compartmented fiber [22,23]. Sun et al. [24] synthesized a kind of MUF microcapsules with a core-shell structure. A kind of light component oil was encapsulated in the microcapsules to improve the self-healing properties of asphalt mixture. Four-point bending fatigue test showed that the microcapsule could extend the fatigue life of asphalt mixture by double [25]. García et al. [26] synthesized calcium alginate capsules with a multi-core structure. Sunflower oil as healing agent was encapsulated in the capsules. CT scanning test was conducted and revealed that the capsules could accelerate the healing of cracks inside asphalt. Tabakovic et al. [27] synthesized calcium alginate compartmented fiber encapsulating rejuvenator by wet spinning technology, the strength of asphalt mastic containing the fibers increased by over 30%.

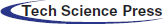

Shu et al. [28] synthesized calcium alginate fiber with a unique compartment structure. Sunflower oil as healing agent was encapsulated in the compartments in the form of droplet. The effectiveness of the compartmented fibers to improve the self-healing properties of asphalt has been confirmed. The self-healing process of cracks in asphalt containing the compartmented fibers was microscopically monitored by fluorescence microscope test, the effect mechanism of the compartmented fibers was thus revealed. As shown in the Fig. 1, the healing mechanism by the compartmented fibers is that a compartment was ruptured by a crack, then healing agent filled into the crack under capillary action. Asphalt was wetted by healing agent. After that, healing agent rapidly diffused inside asphalt. The viscosity of asphalt was thus decreased sharply, and asphalt flowed and filled up the crack more quickly. Finally, the crack disappeared and asphalt performance was restored. Sunflower oil could soften and regenerate asphalt by supplementing light components, thereby reducing asphalt viscosity, improving asphalt flow performance and improving asphalt self-healing performance [29].

Figure 1: Effect mechanism of the compartmented fiber improving self-healing performance of asphalt [29]

Besides the encapsulated rejuvenators, another innovative technology is being largely investigated to improve the maintenance of asphalt roads, namely microwave heating. The advantage of this approach is clearly related to the quick improvement of the self-healing properties: The beneficial effect related to the application of microwave for some minutes is equivalent to the healing supported by the capsules during several days. On the other hand, the microwave heating cannot improve the brittleness of aged asphalt. Based on these premises, we proposed a kind of novel Ca-alginate/graphene oxide compartmented fiber encapsulating sunflower oil (CaG) [30], the fiber displaying excellent microwave heating ability offers the possibility to merge the two healing technologies presented so far. The scope of the fiber application is two-fold: (i) Provide the asphalt with the encapsulated light components and (ii) Quickly and repeatedly heal the asphalt cracks by microwave heating.

However, the advantages of the CaG over the compartmented Ca-alginate/SiO2 fiber encapsulating healing agent (CaS) documented previously (please add reference) have not completely investigated. Therefore, the goal of this study is to compare the performance of three types of asphalt mixtures, namely one type with compartmented Ca-alginate/SiO2 fiber (CaSA), one type with compartmented Ca-alginate/graphene oxide fiber (CaGA) and control asphalt mixture (CA), under the influence of different parameters: healing time, healing cycles and microwave heating action.

Sodium alginate, nano silica particles, graphene oxide and calcium chloride were bought from Sinopharm Group Co., Ltd. The specific surface and average size of nano silica particles were 395 m2/g and 15 nm, respectively. Sunflower oil was bought from Arowana Group Co., Ltd., China. The relative content of saturates and aromatics in sunflower oil were 23.5% and 66.1%, respectively. Deionized water was prepared by the laboratory.

70# asphalt was got from KOCH asphalt Co., Ltd, the penetration (20°C, 0.1 mm), softening point and ductility (15°C) were 68.5, 48.2°C and 148 cm, respectively. Fine aggregates and coarse aggregates were both limestone. Apparent relative density and Los Angeles abrasion value of coarse aggregate were 2.746 g/cm3 and 10.7%, respectively. Apparent relative density and sand equivalent of fine aggregates were 2.731 g/cm3 and 75.5, respectively.

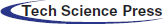

2.2 Preparation of the Compartmented Fibers

According to the previous work [31], CaS and CaG were synthesized by a microfluidic device (as shown in Fig. 2). The flow rates of alginate/SiO2 solution and sunflower oil were 4.1 ml/h and 9 ml/h, respectively. The flow rates of alginate/GO solution and sunflower oil were 4.5 ml/h and 9 ml/h, respectively. Based on the previous work, the optimum content of nano silica particles and GO were 1.0% and 1.5%, respectively. The healing agent and alginate solution were pushed into the calcium chloride solution simultaneously. The ion exchange reaction between alginate and calcium ion occurred, the reaction was completed instantaneously. The structure of alginate was quickly changed into a three-dimensional network structure, so the healing agent could be encapsulated in the calcium alginate fiber.

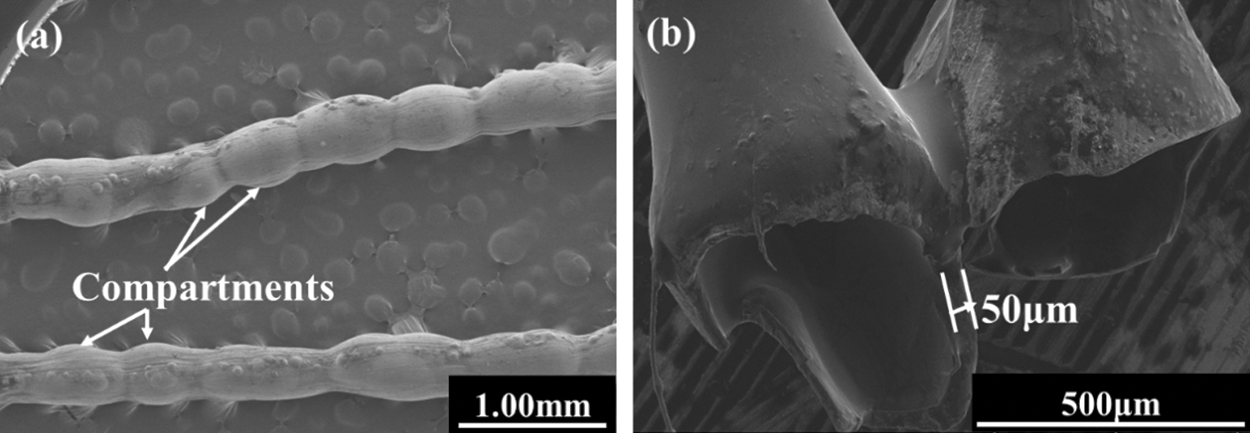

The diameters of two kinds of compartmented fiber were both about 400 μm. The diameter of encapsulated sunflower oil droplet was about 300 μm. The microscopic image of typical compartment structure fiber is shown in Fig. 3. The continuous bulges are compartments encapsulated with rejuvenator (as shown at the arrow in Fig. 3a). The hollow compartments can be found in Fig. 3b, and the wall thickness of the compartment was about 50 μm. It has been confirmed that the three kinds of fibers meet the thermal and mechanical requirement and keep intact during the mixing and compaction of asphalt mixture [32].

Figure 2: Microfluidic device sketch used for the synthesis of CaS and CaG

Figure 3: Scanning electron microscopic test result of compartmented fibers

2.3 Preparation of Asphalt Mixture

AC-13 dense asphalt mixture was designed by the Marshall gradation design method. The proportions of aggregates with diameter of 0–3 mm, 3–5 mm, 5–10 mm and 10–16 mm gradation were 39%, 14%, 22% and 21%, respectively. The relative content of mineral powder was 4%. The optimum asphalt content was obtained as 4.7%. In order to prepare the bituminous mixture, the asphalt was heated at 135°C for 1 h while the aggregates and mineral power were heated at 165°C for 4 h. These three components were then mixed at 165°C for 90 s. Afterwards, the compartmented fiber (0.235 wt.%) was slowly added and mixed for 90 s. Finally, asphalt concrete slabs (300 × 300 × 50 mm) were created and subsequently cut to generate beam samples with dimensions 95 × 40 × 50 mm.

2.4 Self-Healing Properties Characterization

Three-point bending strength recovery test and three-point bending fatigue recovery test were conducted to evaluate the self-healing properties of asphalt mixture containing different kinds of compartmented fibers. The strength recovery test was performed at −10°C. The loading rate was 0.5 mm/min. The test was stopped when the specimen was broken to two parts. Then the two parts were completely spliced and fixed with three rubber bands, so that the same force was applied to both ends of different specimens. The healing temperature was 30°C. The healing time was increased from one day to five days. The healing cycles was increased from one cycle to five cycles. The self-healing property was defined as follows:

where

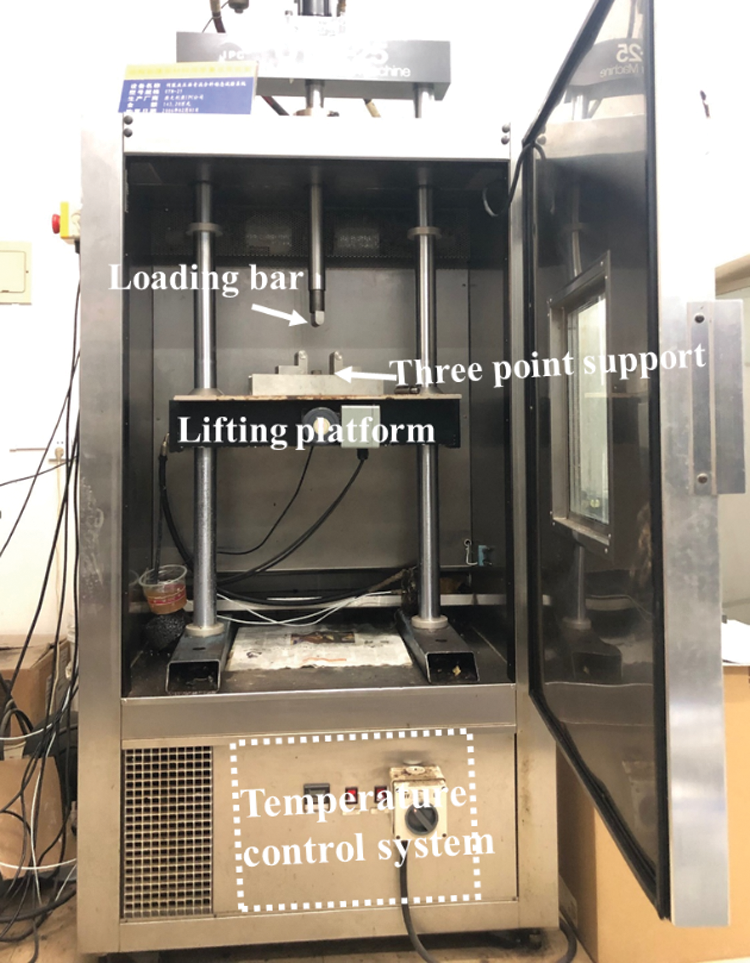

In order to conduct fatigue recovery test, the spliced beam was allowed to keep for one day at 30°C to evaporate water. Then the sample was heated by microwave in a microwave oven. The power and microwave frequency were 800 W and 2450 MHz, respectively. The microwave heating time was increased from 10 s to 50 s. The stress control mode was used for fatigue test. The loading stress was 500 N, Poisson’s ratio was 0.35, the test temperature was 15°C. The loading frequency was 1 Hz, namely the loading time was 0.1 s, and the intermittent period was 0.9 s in one fatigue loading cycle. Self-healing performance test of asphalt mixture was performed on a Universal Testing Machine (UTM) as shown in Fig. 4.

Figure 4: Universal Testing Machine (UTM) used in this work

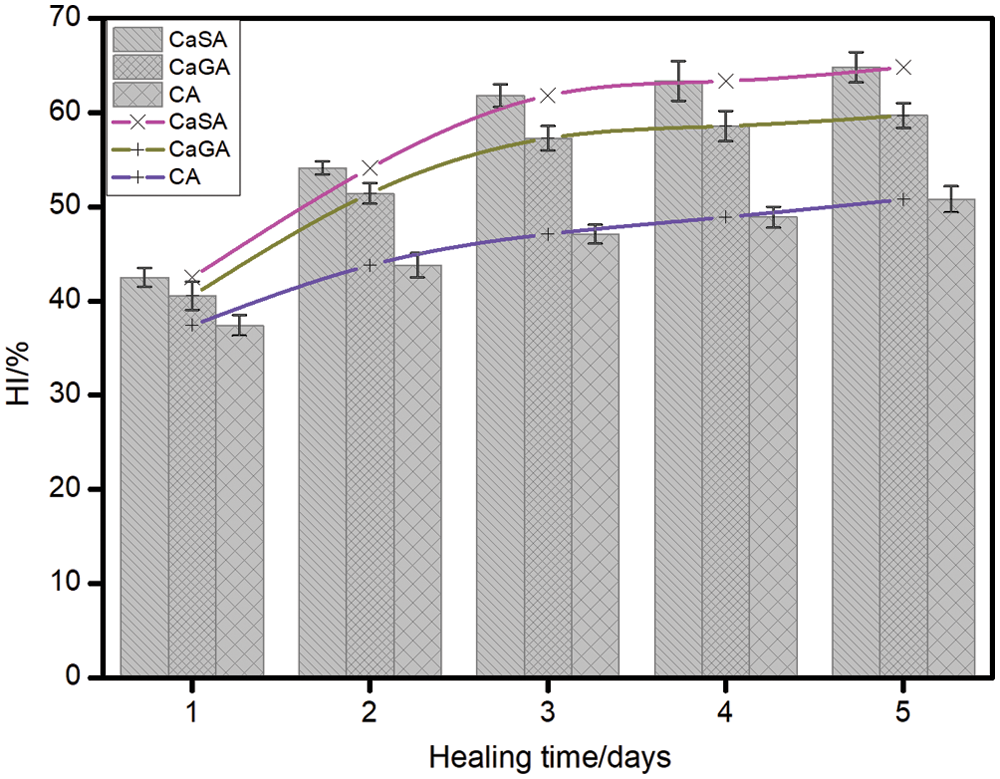

3.1 Self-Healing Capability of Asphalt Mixture at Different Healing Times

The effect of healing time on self-healing properties of asphalt mixture containing compartmented fibers is shown in Fig. 5. It can be seen that the HI values of asphalt mixture containing compartmented fibers are larger than that of without compartmented fiber in whole healing periods, which means that the compartmented fibers works and improves the self-healing property of asphalt mixture. Specifically, after a five days of healing period, compared with CA, HI values of CaSA and CaGA relatively improves by 28% and 20%, respectively. It also can be found that the HI values of CaSA were larger than that of CaGA. The reason is that more rejuvenator was encapsulated in CaS compared with CaG [32]. It is worth noting that the HI values of asphalt mixture containing compartmented fiber have a significantly improvement in the first three days healing period. As the healing time continues to increase, the value increases slowly. The result means that the optimum self-healing time of asphalt mixture containing the compartmented fibers is 3 days.

Figure 5: Influence of healing time on the self-healing performance (strength recovery) of the three kinds of asphalt mixture

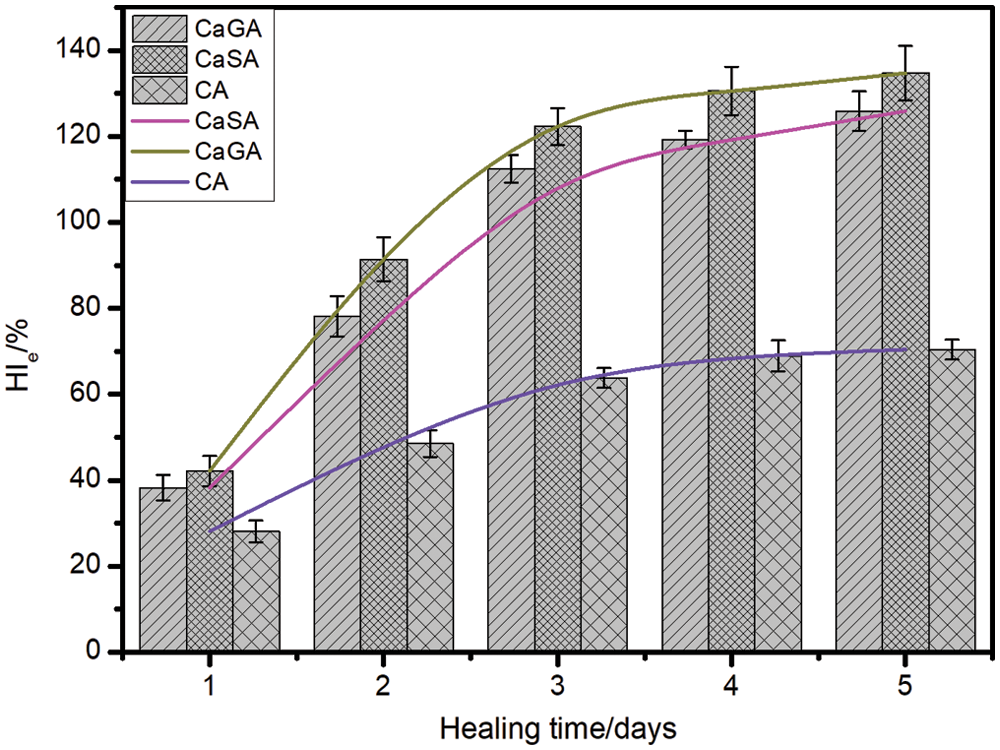

Fracture energy recovery of asphalt mixture with and without compartmented fiber was calculated and the results is shown in Fig. 6. It can be found that the fracture energy recovery of kinds of asphalt mixture showed a similar tendency to the strength recovery result. Recovery rate of fracture energy of asphalt mixture with compartmented fiber is larger than that of without fiber at each healing time, indicating that the healing agent released from the compartments could change the feature of asphalt, and thus increase the fracture energy of asphalt mixture. HIe values of CaSA are larger than that of CaGA at each healing time. Particularly, after a five days healing period, compared with CA, HIe values of CaSA and CaGA relatively increases by 93% and 80%, respectively. Similar to strength recovery, in the first three days of healing, the recovery of fracture energy of asphalt mixture containing compartmented fiber is obviously improved. Continue to extend the healing time, the increase of fracture energy recovery tends to be stable.

Figure 6: Influence of healing time on the self-healing performance (fracture energy recovery) of the three kinds of asphalt mixture

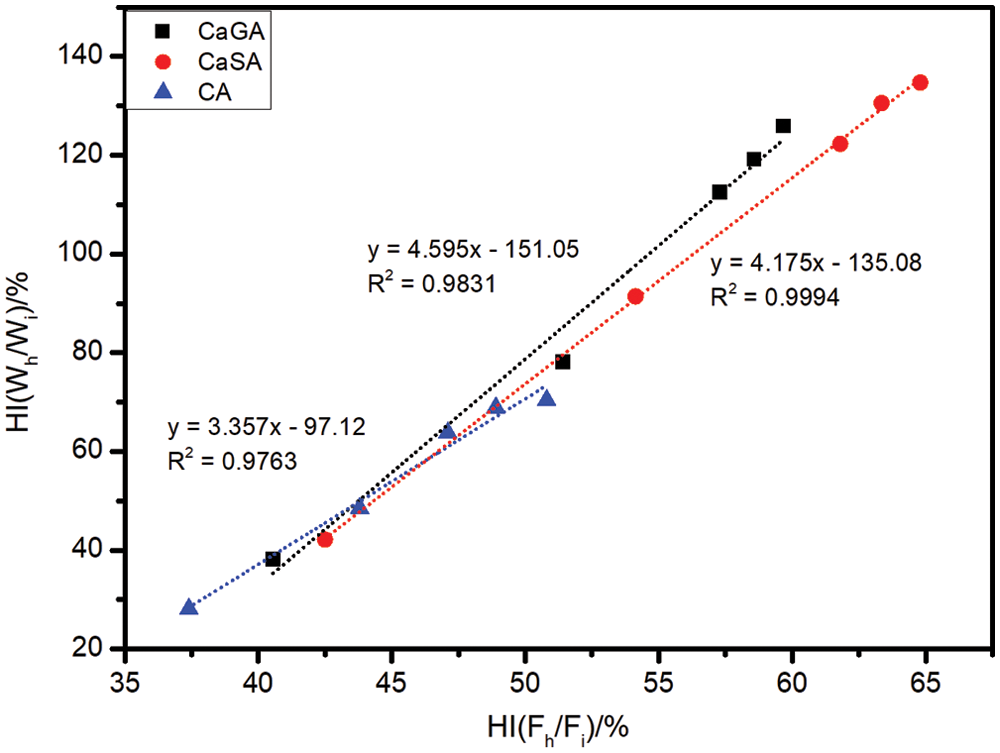

The correlation between fracture strength recovery and fracture energy recovery of the three kinds of asphalt mixture is shown in Fig. 7. For the CA, CaSA and CaGA, the correlation equations are presented as y = 3.357x−97.12, R2 = 0.9763. y = 4.175x−135.08, R2 = 0.9994. y = 4.595x−151.05, R2 = 0.983, respectively. It can be found that fracture strength recovery and fracture energy recovery showed a high linear relationship. It is interesting to note that the slope of CA is the smallest, followed by CaSA, the slope of CaGA is the largest, more relevant work will be done in the future.

Figure 7: Correlation rate between fracture energy recovery and fracture strength recovery

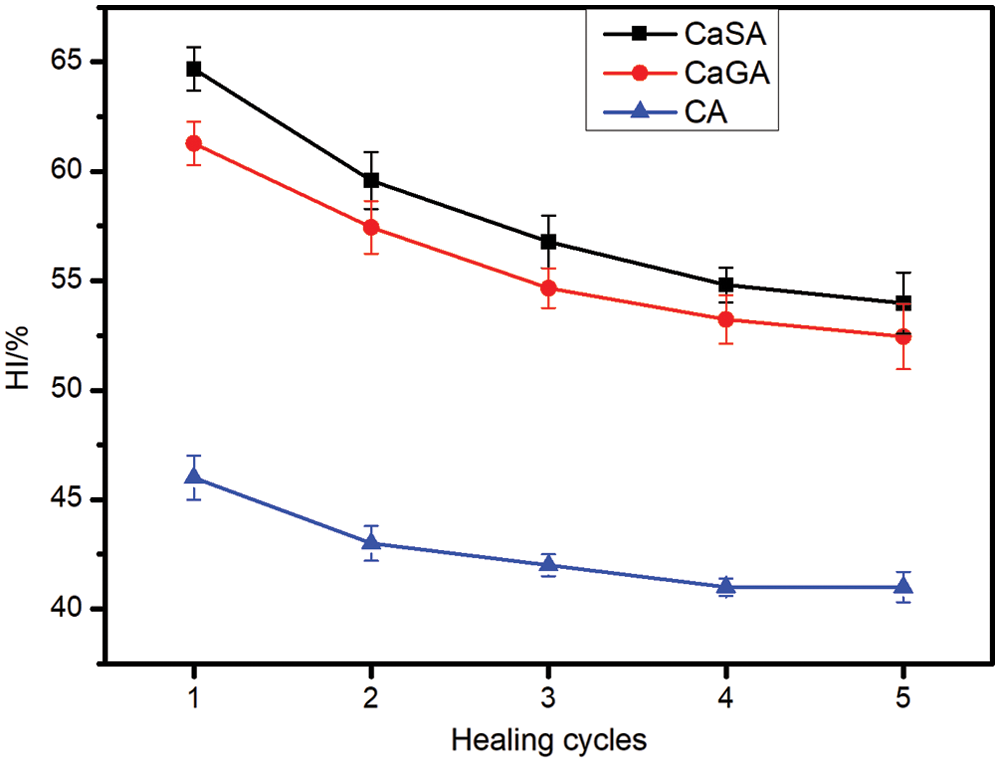

3.2 Self-Healing Capability of Asphalt Mixture at Different Healing Cycles

The effect of fracture-healing-fracture loading cycles on the asphalt mixture containing compartmented fiber is shown in Fig. 8. It can be found that in each healing cycle, the HI value of CaSA and CaGA was higher than that of CA. The reason is that healing agent released and effectively improved the self-healing performance of asphalt. The HI value of CaSA was always higher than that of CaGA, which attributed that the more healing agent was encapsulated in CaS fiber than CaG. In addition, with the increase of healing cycles, the HI value of the three kinds of asphalt mixture significantly decreased. When healing cycles increased to five times, the HI values of CaSA and CaGA relatively decreased by 17% and 14%, respectively. It is noting that the slope decreases gradually and finally tends to zero. The reason is that each fracture of the beam occurred at the same position, and the healing agent played a healing role after the first fracture. There was no extra healing agent release in the subsequent fracture. Therefore, with the increase of healing cycles, the viscosity of asphalt gradually increased, thus the self-healing performance gradually decreased, finally tends to a constant value.

Figure 8: Influence of healing cycles on the self-healing performance of the three kinds of asphalt mixture

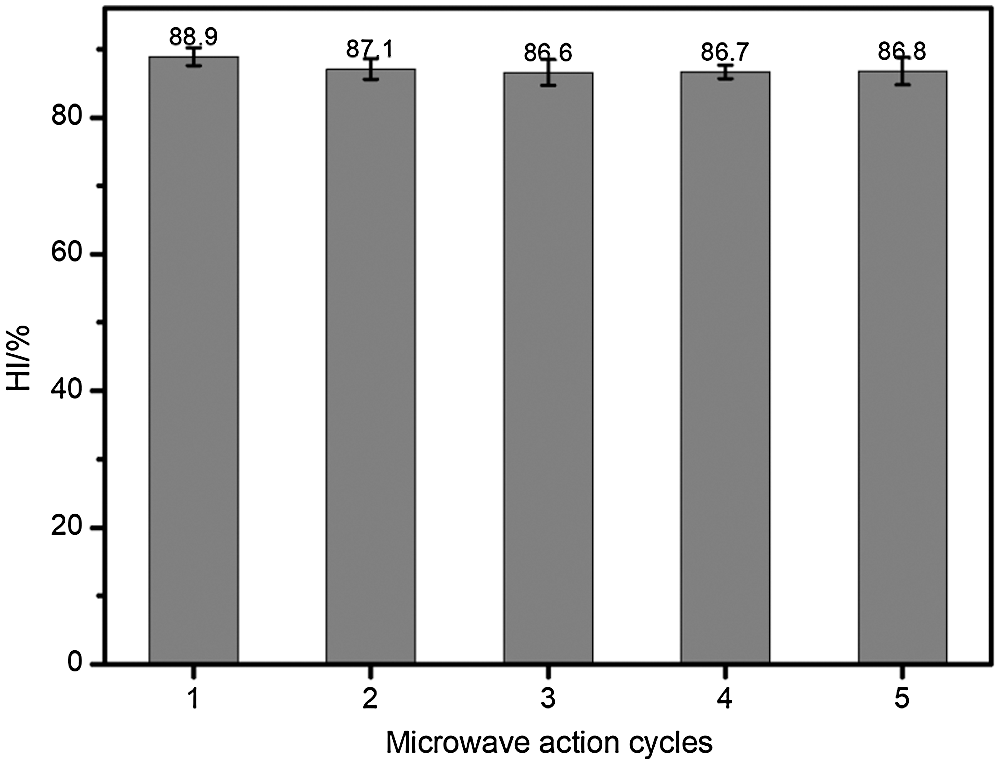

The influence of microwave heating cycles on self-healing properties of CaGA is shown in Fig. 9. After five times of fracture-microwave heating, the self-healing performance was slightly reduced from 88.9% to 86.8%, which indicated that the repeated application of microwave heating would not weaken the self-healing properties. Compared with encapsulated rejuvenator, the improved temperature of CaG plays a decisive role in the self-healing performance of asphalt mixture, therefore the cracks in asphalt mixture can be repaired many times by employing microwave heating acting on CaG.

Figure 9: Influence of microwave heating cycles on HI of CaGA

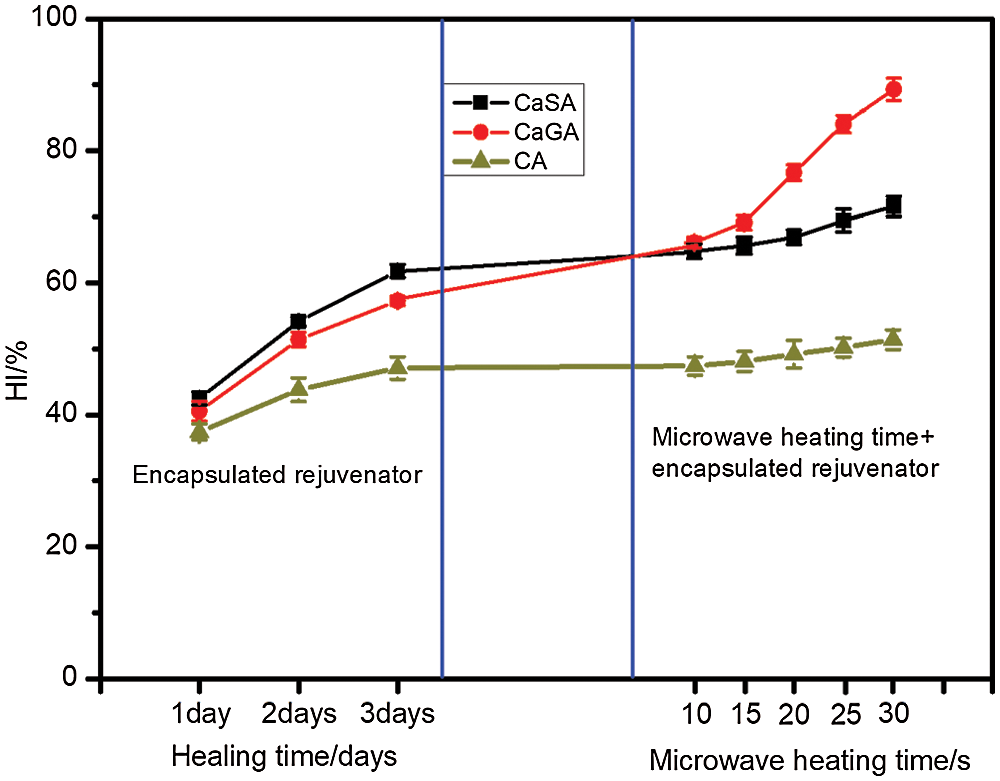

3.3 Self-Healing Capability of Asphalt Mixture under Microwave Heating

The effect of encapsulation combined microwave heating on self-healing performance of asphalt mixture is shown in Fig. 10. HI of CA is significantly lower than that of CaSA and CaGA with and without microwave action. The HI value of CaSA slowly augments as the microwave action occurs: the HI value of CaSA increases from 61.6% to 71.3% after 30 s. The temperature of CaSA samples did not undergo a large increase in temperature due to the weak microwave heating ability of the aggregates and healing agent encapsulated in the compartments. The HI of CaGA was larger than that of CaSA after the same microwave action time. The HI of CaGA increased about 5% during the first 15 s and then augmented significantly. Its HI value reached 88.9% after 30 s, this figure was approximately 76% higher than that of CA. The result showed that CaG had the excellent microwave heating performance.

The self-healing performance of CaGA could be further improved by the action of microwave heating on the basis of healing agent. Considering the findings reported so far, the HI of asphalt mixture asymptotically reaches a threshold value. If asphalt mixture was heated by microwave action, the self-healing performance of asphalt mixture can be further improved over the threshold value, which reveals that CaG has obvious advantages over CaS. After 30 s of microwave action, the surface temperature of CaGA could reach 80°C. The HI of CaGA relatively increased about 24.7% compared with CaSA. Norambuena Contreras [33] found that when the surface temperature of asphalt mixture with 2% waste shavings researched 80°C by effect of microwave action, the HI was about 72%. In this work, when the surface temperature of asphalt mixture was close to 80°C, the HI of CaGA relatively increased 23.6% when compared with the sample containing the microwave absorber (waste shavings). Therefore, the synergistic effect of encapsulated rejuvenator and improved temperature can improve the self-healing performance of asphalt mixture to a greater extent than the extent engendered by a single technology. The successful synthesis of the compartmented calcium alginate/graphene oxide fiber encapsulating healing agent successfully breaks the current boundary between the two technologies and opens up a new horizon for the asphalt self-healing technology.

Figure 10: Effect of encapsulation combined microwave heating on self-healing performance of asphalt mixture

3.4 Fatigue Restoration Capability of Asphalt Mixture with Compartmented Fiber

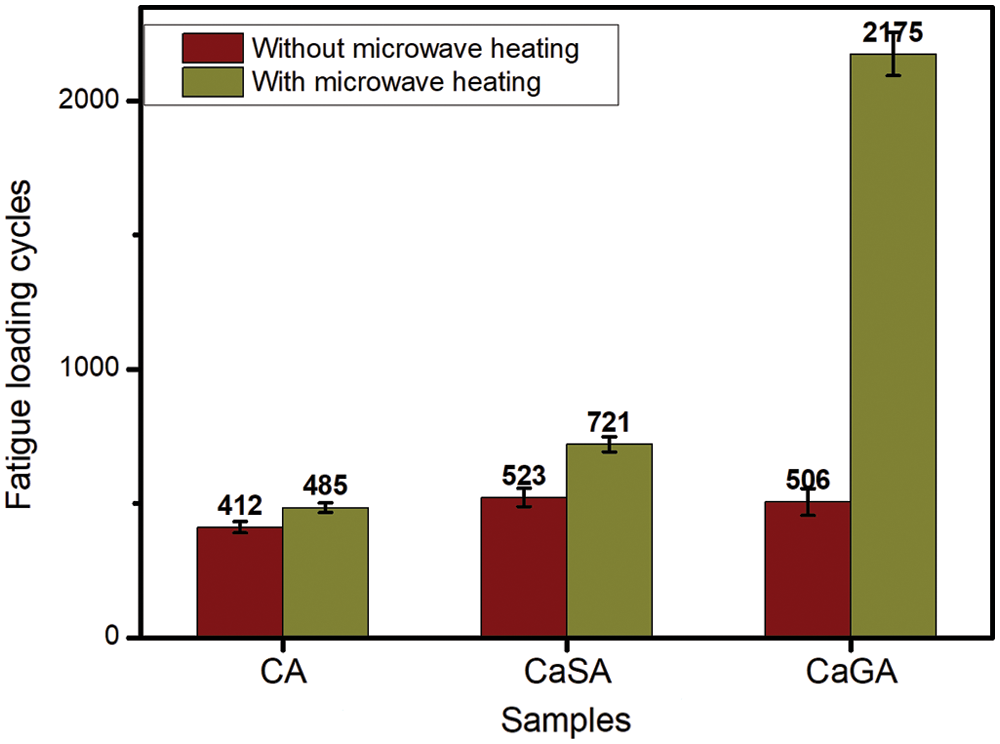

In order to study the effect of the synergistic effect of microwave action and encapsulation on the fatigue loading cycles recovery of asphalt mixture, a three-point fatigue recovery test was performed in this work. For that, test beams was brittlely fractured at −10°C by three-point bending strength test. The fracture surface was then spliced, and three rubber bands are used to fix the beams. The sample was conditioned at 30°C for one day, the fixed beam was then microwave-heated for 30 s, and the sample was healed for two days at 30°C. Finally a three-point fatigue test was performed. A Universal Testing Machine (UTM) was used to perform the three-point fatigue test on asphalt mix with and without compartmented fiber. The load was 500N, Poisson’s ratio is 0.35, test temperature is 15°C, loading frequency is 1 Hz (loading time 0.1 s, interval 0.9 s). The results are shown in Fig. 11.

Referring to the specimens that did not undergo microwave action, the fatigue loading cycles recovery properties of the asphalt mixture with compartmented fiber were significantly larger than that of CA. After three days of healing, the recovery of fatigue loading cycles of CaSA and CaGA were 26.9% and 22.8% higher than that of CA, respectively. After the 30 s of microwave heating, the recovery of fatigue loading cycles of all the beams were higher thant hose of the specimens that did not receive microwave heating. The recovery of fatigue loading cycles of CA and CaSA increased by 17.7% and 37.9% respectively. The former asphalt mixture type was characterized by a certain increment thanks to the aggregates showing weak microwave heating characteristics while the released rejuvenator in the latter bituminous asphalt mixture type showed better microwave heating characteristics. After 30 s of microwave action, the increased temperature of rejuvenator enhanced its molecular movement and diffusion. It is noting that the recovery of fatigue loading cycles of CaGA were several times larger than that of CA and CaSA. After 30 s of exposure to microwave, the fatigue loading cycles of CaGA was 2175 times, which was 329.8% higher than that of non-microwave heated CaGA, 315.9% higher than that of non-microwave heated CaSA, and 427.9% higher than that of non-microwave heated CA, respectively. This result can be explained taking into consideration that most of the defect points in the fracture surface of CA and CaSA were not been healed after three days of healing, therefore, the fractured surface was still in a fragile state. When the fatigue test was carried out again, the defect points present on the fracture surface would represent the preferential location for the generation of cracks.

For microwave heated CaGA, the raised temperature near the fracture surface not only improved the molecular movement and diffusion speed of the healing agent inside the asphalt, but also decreased the viscosity of asphalt. Under the double effect of healing agent and augmented temperature, the fluidity of asphalt improved, and most of the defects in the fracture surface would be self-healed in a short time. After three days of healing, only a few defects on the fracture surface were not been repaired; overall, the mechanical properties of the healed beams were greatly restored. Thus, the fatigue load of 500 N was not high enough to newly fracture the test beams. The recovery of fatigue loading cycles of the beam was significantly enhanced, and was several times higher than that of CA and CaSA.

Figure 11: Effect of microwave action and different kinds of fibers on fatigue loading cycles recovery of the three kinds of asphalt mixture

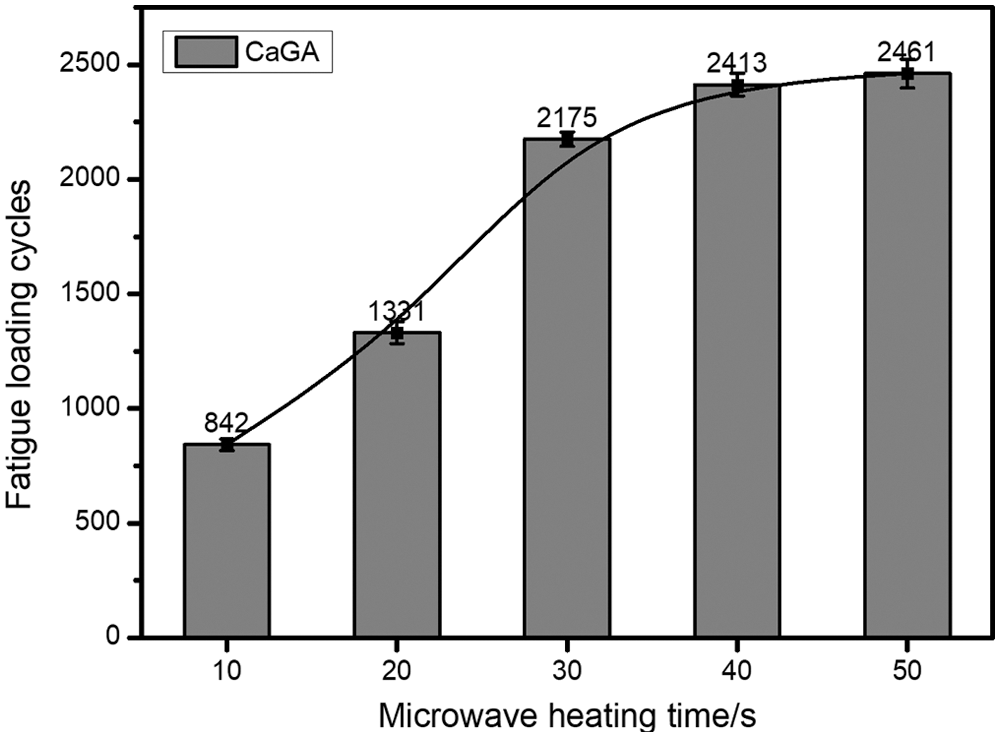

Fig. 12 shows the effect of microwave heating time on the recovery of fatigue loading cycles of CaGA. It can be found that the recovery of fatigue loading cycles of CaGA increased with the extension of microwave action time, and then tends to be stable until reaching the threshold value. The slope gradually decreased with the microwave action time and finally tended to zero. The reason is that with the extension of microwave heating time, the temperature of asphalt gradually increased, and the viscosity of asphalt gradually decreased. Therefore, the self-healing ability of asphalt mixture gradually increased under the synergistic effect of healing agent and temperature.

Figure 12: Effect of microwave action time on the recovery of fatigue loading cycles of CaGA

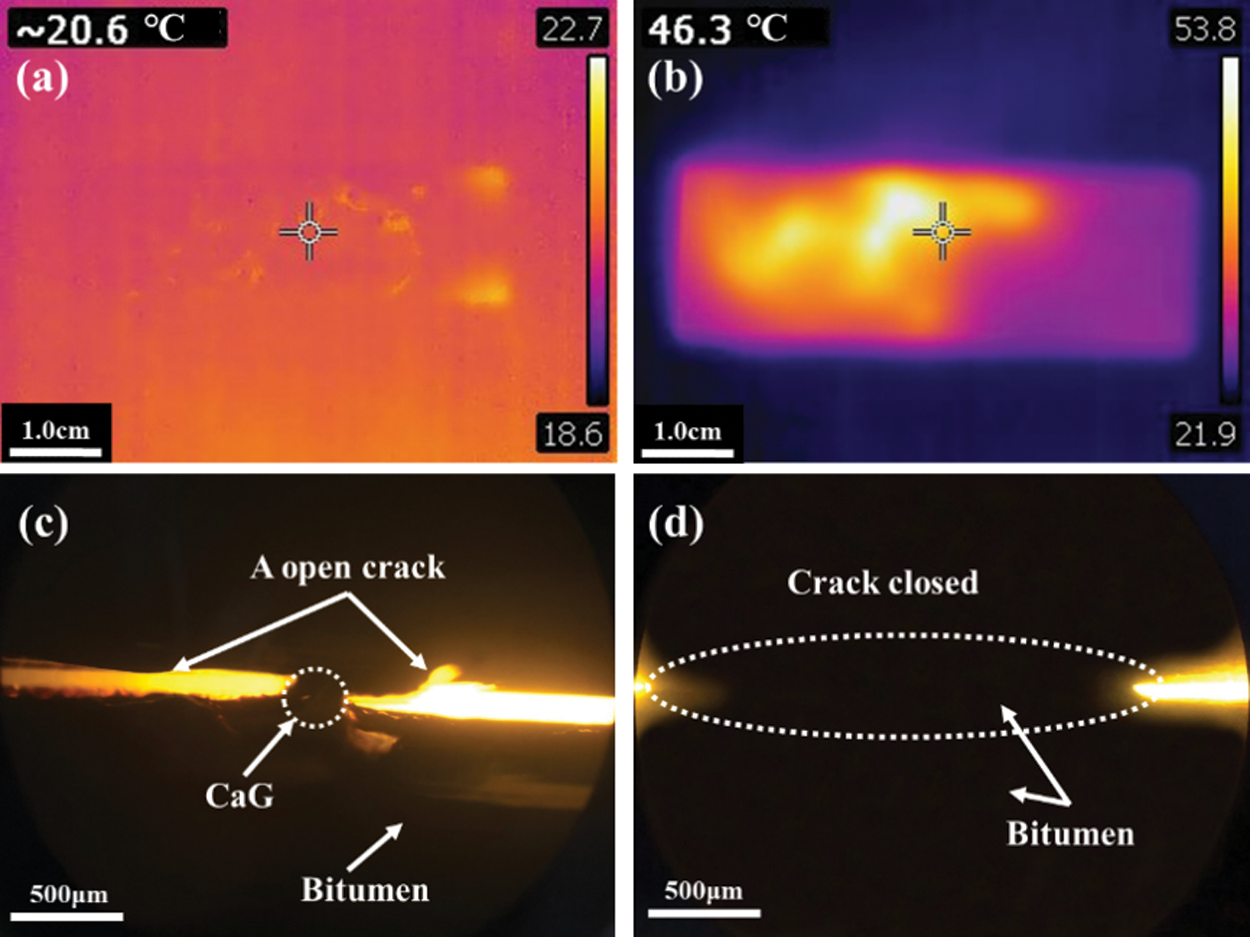

3.5 Self-Healing Capability of Asphalt at Micro Scale

A layer of asphalt containing 5% CaG was paved on a glass support. Before microwave action, the asphalt temperature was about 20°C (Fig. 13a) and An open crack with a width of about 100 μm was created (Fig. 13c). After a 10 s of microwave action, the temperature of asphalt increased to about 53°C (Fig. 13b), this is because of the excellent microwave heating characteristics of graphene oxide in CaG. Because the asphalt is a temperature sensitive material, its viscosity was sharply reduced, and the self-healing performance was significantly enhanced [34–36], the crack inside the asphalt was quickly repaired, and the crack disappeared (Fig. 13d). The time to complete the repair of cracks was shortened from minutes to seconds under the microwave action, and the mechanical performance of asphalt, such as the strength, was also recovered faster if compared to the single use of the healing agent. As mentioned above, it normally takes days for the encapsulated healing agent to recover the strength performance of asphalt, while it only takes minutes when adopting increased temperature. It can be concluded that CaG offers the advantages of capsule technologies, namely to provide lightweight components improving asphalt self-healing properties. In addition, the possibility to successfully make use of microwave induction heating method reduces the viscosity of asphalt rapidly thanks to the increased temperature, the internal cracks can be repaired faster and the performance can be restored quickly.

Figure 13: The self-healing mechanism of asphalt with 5% CaG: (a) Infrared image of asphalt before (a) and after (b) microwave action, and optical image of a crack inside the asphalt before (c) and after (d) microwave action

In this work, three-point bending test and three-point fatigue test were conducted to evaluate the self-healing properties of asphalt mixture with and without the compartmented fiber. Based on the results and analysis discussed above, the conclusions can be drawn as follows:

1. CaS and CaG worked and improved the self-healing properties of asphalt mixture. Three days is the optimum healing time. The HI of CaSA was relatively increased by 28% compared to CA.

2. With the increase of healing cycles, the self-healing performance of asphalt mixture with compartmented fiber gradually reduced. It is worth noting that microwave heating cycles did not reduce the self-healing performance of the asphalt mixture.

3. After the 30 s of microwave heating, the HI values of CaGA relatively increased 76% when compared with the HI of CA, which means that the self-healing performance of asphalt mixture could be further improved under the synergistic effect of increased temperature and encapsulated healing agent.

4. CaG could not only regenerate the asphalt mixture by means of encapsulated healing agent, but also could quickly and repeatedly heal the internal cracks by employing microwave heating. The fiber gave the bituminous mixture long-term self-healing performance.

Acknowledgement: Authors also thank the test support received from the Shiyanjia Lab (www.shiyanjia.com).

Author Contributions: B. Shu: Conceptualization; Investigation; Writing—review & editing; Writing—original draft; L. Guo: Funding acquisition. B. Qiu: Visualization. T. Yang: Visualization. T. Sun: Visualization. M. Zhou: Visualization. W. Qiu: Validation. P. Song: Validation. Y. Li: Validation. D. M. Barbieri: Validation; Writing—review & editing. S. Wu: Visualization; Supervision.

Funding Statement: This research was funded by Foshan Self-Finance Science and Technology Project (No. 2020001005441), the National Key R&D Program of China (No. 2018YFB1600200) and the National Natural Science Foundation of China (No. 51978547).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Xiao, F., Su, N., Yao, S., Amirkhanian, S., Wang, J. (2019). Performance grades, environmental and economic investigations of reclaimed asphalt pavement materials. Journal of Cleaner Production, 211(1), 1299–1312. DOI 10.1016/j.jclepro.2018.11.126. [Google Scholar] [CrossRef]

2. Kogbara, R. B., Masad, E. A., Kassem, E., Scarpas, A. T., Anupam, K. (2016). A state-of-the-art review of parameters influencing measurement and modeling of skid resistance of asphalt pavements. Construction and Building Materials, 114(5), 602–617. DOI 10.1016/j.conbuildmat.2016.04.002. [Google Scholar] [CrossRef]

3. Ziari, H., Aliha, M. R., Moniri, A., Saghafi, Y. (2020). Crack resistance of hot mix asphalt containing different percentages of reclaimed asphalt pavement and glass fiber. Construction and Building Materials, 230(9), 117015. DOI 10.1016/j.conbuildmat.2019.117015. [Google Scholar] [CrossRef]

4. Gnatenko, R., Tsyrkunova, K., Zhdanyuk, V. (2016). Technological sides of crack sealing in asphalt pavements. Transportation Research Procedia, 14, 804–810. DOI 10.1016/j.trpro.2016.05.028. [Google Scholar] [CrossRef]

5. Norambuena-Contreras, J., Yalcin, E., Garcia, A., Al-Mansoori, T., Yilmaz, M. et al. (2018). Effect of mixing and ageing on the mechanical and self-healing properties of asphalt mixtures containing polymeric capsules. Construction and Building Materials, 175(3), 254–266. DOI 10.1016/j.conbuildmat.2018.04.153. [Google Scholar] [CrossRef]

6. Sun, D. Q., Sun, G., Zhu, X., Guarin, A., Li, B. et al. (2018). A comprehensive review on self-healing of asphalt materials: Mechanism, model, characterization and enhancement. Advances in Colloid and Interface Science, 256(1), 65–93. DOI 10.1016/j.cis.2018.05.003. [Google Scholar] [CrossRef]

7. Xu, S., Liu, X. Y., Tabaković, A., Schlangen, E. (2019). Investigation of the potential use of calcium alginate capsules for self-healing in porous asphalt concrete. Materials, 12(1), 168. DOI 10.3390/ma12010168. [Google Scholar] [CrossRef]

8. Li, R., Zhou, T., Pei, J. Z. (2015). Design, preparation and properties of microcapsules containing rejuvenator for asphalt. Construction and Building Materials, 99, 143–149. DOI 10.1016/j.conbuildmat.2015.09.017. [Google Scholar] [CrossRef]

9. Ma, Y., Hu, W., Polaczyk, P. A., Han, B., Xiao, R. et al. (2020). Rheological and aging characteristics of the recycled asphalt binders with different rejuvenator incorporation methods. Journal of Cleaner Production, 262(4), 121249. DOI 10.1016/j.jclepro.2020.121249. [Google Scholar] [CrossRef]

10. Xu, S. (2020). Self-healing porous asphalt: A combination of encapsulated rejuvenator and induction heating (Ph.D. Thesis). Delft University of Technology, Delft, Netherlands. [Google Scholar]

11. Xu, S., Liu, X., Tabakovi, A. (2020). A novel self-healing system: Towards a sustainable porous asphalt. Journal of Cleaner Production, 259, 120815. DOI 10.1016/j.jclepro.2020.120815. [Google Scholar] [CrossRef]

12. Ren, S., Liu, X., Fan, W. (2020). Investigating the effects of waste oil and styrene-butadiene rubber on restoring and improving the viscoelastic, compatibility, and aging properties of aged asphalt. Construction and Building Materials, 269(3), 121338. DOI 10.1016/j.conbuildmat.2020.121338. [Google Scholar] [CrossRef]

13. Ren, S., Liu, X., Wang, H. (2020). Evaluation of rheological behaviors and anti-aging properties of recycled asphalts using low-viscosity asphalt and polymers. Journal of Cleaner Production, 253(14), 120048. DOI 10.1016/j.jclepro.2020.120048. [Google Scholar] [CrossRef]

14. Ren, S., Liu, X., Fan, W. (2019). Rheological properties, compatibility, and storage stability of SBS latex-modified asphalt. Materials, 12(22), 3683. DOI 10.3390/ma12223683. [Google Scholar] [CrossRef]

15. Peng, L., Liu, X., Apostolidis, P. (2021). On the rejuvenator dosage optimization for aged SBS modified bitumen. Construction and Building Materials, 271(1), 121913. DOI 10.1016/j.conbuildmat.2020.121913. [Google Scholar] [CrossRef]

16. Chung, K., Lee, S., Cho, W., Seo, J., Hong, Y. (2018). Rheological analysis of self-healing property of microcapsule-containing asphalt. Journal of Industrial and Engineering Chemistry, 64, 284–291. DOI 10.1016/j.jiec.2018.03.026. [Google Scholar] [CrossRef]

17. Su, J., Han, S., Wang, Y., Schlangen, E., Han, N. et al. (2017). Experimental observation of the self-healing microcapsules containing rejuvenator states in asphalt binder. Construction and Building Materials, 147, 533–542. DOI 10.1016/j.conbuildmat.2017.04.190. [Google Scholar] [CrossRef]

18. Norambuena-Contreras, J., Yalcin, E., Hudson-Griffiths, R., García, A. (2019). Mechanical and self-healing properties of stone mastic asphalt containing encapsulated rejuvenators. Journal of Materials in Civil Engineering, 31(5), 4019052. DOI 10.1061/(ASCE)MT.1943-5533.0002687. [Google Scholar] [CrossRef]

19. Xu, S., Tabaković, A., Liu, X., Schlangen, E. (2018). Calcium alginate capsules encapsulating rejuvenator as healing system for asphalt mastic. Construction and Building Materials, 169(47), 379–387. DOI 10.1016/j.conbuildmat.2018.01.046. [Google Scholar] [CrossRef]

20. Garcia, A., Austin, C. J., Jelfs, J. (2016). Mechanical properties of asphalt mixture containing sunflower oil capsules. Journal of Cleaner Production, 118(4), 124–132. DOI 10.1016/j.jclepro.2016.01.072. [Google Scholar] [CrossRef]

21. Shu, B. A., Wu, S. P., Dong, L. J., Wang, Q., Liu, Q. T. et al. (2018). Microfluidic synthesis of Ca-alginate microcapsules for self-healing of bituminous binder. Materials, 11(4), 630. DOI 10.3390/ma11040630. [Google Scholar] [CrossRef]

22. Tabaković, A., Braak, D., Gerwen, M., Copuroglu, O., Post, W. et al. (2017). The compartmented alginate fibres optimisation for bitumen rejuvenator encapsulation. Journal of Traffic and Transportation Engineering (English Edition), 4(4), 347–359. DOI 10.1016/j.jtte.2017.01.004. [Google Scholar] [CrossRef]

23. Tabakovic, A., Schuyffel, L., Karač, A., Schlangen, E. (2017). An evaluation of the efficiency of compartmented alginate fibres encapsulating a rejuvenator as an asphalt pavement healing system. Applied Sciences, 7(7), 647. DOI 10.3390/app7070647. [Google Scholar] [CrossRef]

24. Sun, D. Q., Lu, T., Zhu, X. Y., Li, B., Tian, Y. et al. (2018). Optimization of synthesis technology to improve the design of asphalt self-healing microcapsules. Construction and Building Materials, 175(3), 88–103. DOI 10.1016/j.conbuildmat.2018.04.162. [Google Scholar] [CrossRef]

25. Sun, D. Q., Li, B., Ye, F. Y., Zhu, X. Y., Lu, T. et al. (2018). Fatigue behavior of microcapsule-induced self-healing asphalt concrete. Journal of Cleaner Production, 188(1), 466–476. DOI 10.1016/j.jclepro.2018.03.281. [Google Scholar] [CrossRef]

26. Garcia, A., Jelfs, J., Austin, C. J. (2015). Internal asphalt mixture rejuvenation using capsules. Construction and Building Materials, 101(4), 309–316. DOI 10.1016/j.conbuildmat.2015.10.062. [Google Scholar] [CrossRef]

27. Tabakovi, A., Post, W., Cantero, D., Copuroglu, O., Garcia, S. J. et al. (2016). The reinforcement and healing of asphalt mastic mixtures by rejuvenator encapsulation in alginate compartmented fibres. Smart Materials and Structures, 25(8), 84003. DOI 10.1088/0964-1726/25/8/084003. [Google Scholar] [CrossRef]

28. Shu, B. A., Zhang, L., Wu, S. P., Dong, L. J., Liu, Q. T. et al. (2018). Synthesis and characterization of compartmented Ca-alginate/silica self-healing fibers containing bituminous rejuvenator. Construction and Building Materials, 190(1), 623–631. DOI 10.1016/j.conbuildmat.2018.09.121. [Google Scholar] [CrossRef]

29. Shu, B. A., Wu, S. P., Dong, L. J., Norambuena-Contreras, J., Yang, X. et al. (2019). Microfluidic synthesis of polymeric fibers containing rejuvenating agent for asphalt self-healing. Construction and Building Materials, 219(1), 176–183. DOI 10.1016/j.conbuildmat.2019.05.178. [Google Scholar] [CrossRef]

30. Shu, B. A., Wu, S. P., Dong, L. J., Li, C., Kong, D. Z. et al. (2019). Synthesis and properties of microwave and crack responsive fibers encapsulating rejuvenator for bitumen self-healing. Materials Research Express, 6(8), 85306. DOI 10.1088/2053-1591/ab1e26. [Google Scholar] [CrossRef]

31. Shu, B. A., Wu, S. P., Dong, L. J., Norambuena-Contreras, J., Li, Y. Y. et al. (2020). Self-healing capability of asphalt mixture containing polymeric composite fibers under acid and saline-alkali water solutions. Journal of Cleaner Production, 268(5), 122387. DOI 10.1016/j.jclepro.2020.122387. [Google Scholar] [CrossRef]

32. Shu, B. A., Bao, S. W., Wu, S. P., Dong, L. J., Li, C. et al. (2019). Synthesis and effect of encapsulating rejuvenator fiber on the performance of asphalt mixture. Materials, 12(8), 1266. DOI 10.3390/ma12081266. [Google Scholar] [CrossRef]

33. Norambuena-Contreras, J., Gonzalez, A., Concha, J. L., Gonzalez-Torre, I., Schlangen, E. (2018). Effect of metallic waste addition on the electrical, thermophysical and microwave crack-healing properties of asphalt mixtures. Construction and Building Materials, 187(415), 1039–1050. DOI 10.1016/j.conbuildmat.2018.08.053. [Google Scholar] [CrossRef]

34. Grossegger, D., Garcia, A. (2019). Influence of the thermal expansion of bitumen on asphalt self-healing. Applied Thermal Engineering, 156(1), 23–33. DOI 10.1016/j.applthermaleng.2019.04.034. [Google Scholar] [CrossRef]

35. Gómez-Meijide, B., Ajam, H., Garcia, A., Vansteenkiste, S. (2018). Effect of bitumen properties in the induction healing capacity of asphalt mixes. Construction and Building Materials, 190(9), 131–139. DOI 10.1016/j.conbuildmat.2018.09.102. [Google Scholar] [CrossRef]

36. Liu, Q. T., Yu, W., Wu, S. P., Schlangen, E., Pan, P. (2017). A comparative study of the induction healing behaviors of hot and warm mix asphalt. Construction and Building Materials, 144(8), 663–670. DOI 10.1016/j.conbuildmat.2017.03.195. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |