DOI:10.32604/jrm.2021.013833

| Journal of Renewable Materials DOI:10.32604/jrm.2021.013833 |  |

| Article |

Improving the Properties of Fast-Growing Chinese Fir by Vacuum Hot Pressing Treatment

1College of Materials Science and Engineering, Nanjing Forestry University, Nanjing, 210037, China

2College of Civil Engineering, Yangzhou Polytechnic Institute, Yangzhou, 225127, China

*Corresponding Author: Xiaoning Lu. Email: luxiaoning-nfu@126.com

Received: 23 August 2020; Accepted: 24 September 2020

Abstract: Chinese fir was compressed by vacuum hot pressing and conventional hot pressing at different temperatures (180°C, 200°C and 220°C), respectively. The color parameters of the heat-compressed sample were measured, the relative mechanical properties of the material were tested and changes in the chemistry of fir were investigated using Fourier transform infrared spectroscopy (FTIR) and X-ray photoelectron spectroscopy (XPS). The results indicated that the color difference between compressed and untreated wood increased gradually with the increase of temperature. Compared with the conventional hot pressing treatment, the color difference (∆E*) of the Chinese fir treated by vacuum hot pressing decreased by 43.73%, 69.91%, and 77.17%, respectively. The mechanical properties (bending elastic modulus and bending strength) of Chinese fir treated by vacuum hot pressing were significantly improved. The 24-hour water absorption thickness expansion rate of fir treated by vacuum hot pressing is smaller than that of conventional hot pressing. It is implied that vacuum hot pressing treatment is an effective method to produce compressed wood, which can improve the mechanical properties and dimensional stability of wood, and reduce the influence of carbonization on wood color.

Keywords: Chinese fir; vacuum hot pressing; color; mechanical properties; dimensional stability

Chinese fir is a native and fast-growing tree species, widely used in the fields of architecture, furniture and wood-based panel. However, as a fast-growing wood, Chinese fir has some disadvantages, such as big differences between earlywood and latewood, low strength and dimensional instability, which limits its industrial applications [1]. Improving the wood properties of fast-growing Chinese fir is one of the main methods to expand its utilization scope. Densification is an effective modification method to improve the properties of fast-growing wood [2,3]. The traditional process of wood compaction mainly includes three steps: Softening before compression, lateral compression and compression deformation after fixation, which has a long production period and low efficiency. Heat treatment is a well-developed technology to improve the properties of wood without using any chemicals [4–7]. In recent years, as a new method of heat treatment, vacuum heat treatment refers to the use of heat radiation to modify wood, using vacuum environment as heat treatment medium [8–10]. The dimensional stability of the material with vacuum heat treatment is improved, but its bending strength decreases with the increase of treatment temperature and time [11]. In addition, during the process of wood compression or vacuum heat treatment with a long treatment time, a series of chemical changes, such as degradation of hemicellulose and lignin, condensation of lignin and the formation and reaction of volatile products, change the color of wood surface and affect the appearance and quality of products [12]. However, there is no relevant research on a method that can simultaneously carry out wood compression and vacuum heat treatment.

In this paper, the vacuum technology was applied to the wood compression process, and the effects of vacuum hot pressing treatment on wood color, mechanical properties and dimensional stability were investigated to find a innovative and effective method to improve the properties of fast-growing wood.

Chinese fir (Cunninghamia lanceolata) from Jurong city of China were used as testing materials. Sapwood from Chinese fir were processed into dimensions of 300 mm × 100 mm × 20 mm (length × width × height). The dry density of Chinese fir was 365 kg m−3. All specimens were oven-dried at 50°C to a moisture content (MC) of 13 ± 1%.

Chinese fir was compressed in the conventional and vacuum hot pressing process respectively by using a vacuum press equipment. The heat compressed treatment of materials can be carried out in vacuum environment, which was formed before manufacturing began. The samples were hot pressed at varying hot pressing temperature (180°C, 200°C, 220°C). The vacuum degree of the vacuum enclosure was controlled between –0.09 MPa and –0.095 MPa. The pressure was 2 MPa and the whole heat compression time was 30 min. The compression ratio is 25%, and the target thickness of board is 15 mm. Six experimental panels were obtained, and ten repetitions for each composition were measured.

2.3 Evaluation of Mechanical Properties

The bending modulus of elasticity and bending strength of compressed Chinese fir specimens were tested by the wood mechanical testing machine (WDW-50M, China) for ten times according to the GB/T 1936.2–2009. The samples were cut to dimensions of 300 mm (length) × 20 mm (width) × 15 mm (height), and the loading speed of machine was 2 mm min−1.

Mass loss (ML) was determined by weighing the specimen prior to the heat compressed treatment and immediately after and is expressed in percent, which is calculated by the following equation,

where M1 and M2 are the weight of the specimen before and after hot pressing treatment.

2.5 Thickness Expansion Rate of Water Absorption

The water absorption thickness expansion rate of wood compression direction (thickness) is selected as the index to analyze the dimensional stability of samples. After heat-compressed treatment, the specimens are soaked in water at 20°C, and the thickness of specimens after compression is measured 24 h later, and the swelling rate of water absorption thickness of the specimens is calculated by the following equation,

where T1 and T2 are the thickness of the specimen before and after soaking in water.

The degree of change in color of compressed wood can be characterized by color difference values with a colorimeter (model YJD-500, China). The change of surface color was measured and calculated by the CIE (1976) L*A*B color system recommended by the international lighting committee, where L* mean the lightness value, where a* indicates the index of red-green and the b* indicates the index of yellow-blue color. The total color change ∆E* can be obtained by the following equation,

where ∆L*, ∆a*, and ∆b* are color changes between heat-compressed and untreated wood specimens.

2.7 Fourier Transform Infrared Spectrometry (FTIR)

Samples were collected from the same surface of the specimens used for color change measurement, ground to a particle size of 100 mesh and measured by Fourier transform infrared spectroscopy. The instrument VERTEX 80V (Thermo Nicolet Company, USA) was used in the KBr pellet technique. The measuring range was 400–4000 cm−1, the resolution was 2 cm−1, and the scanning times were 32.

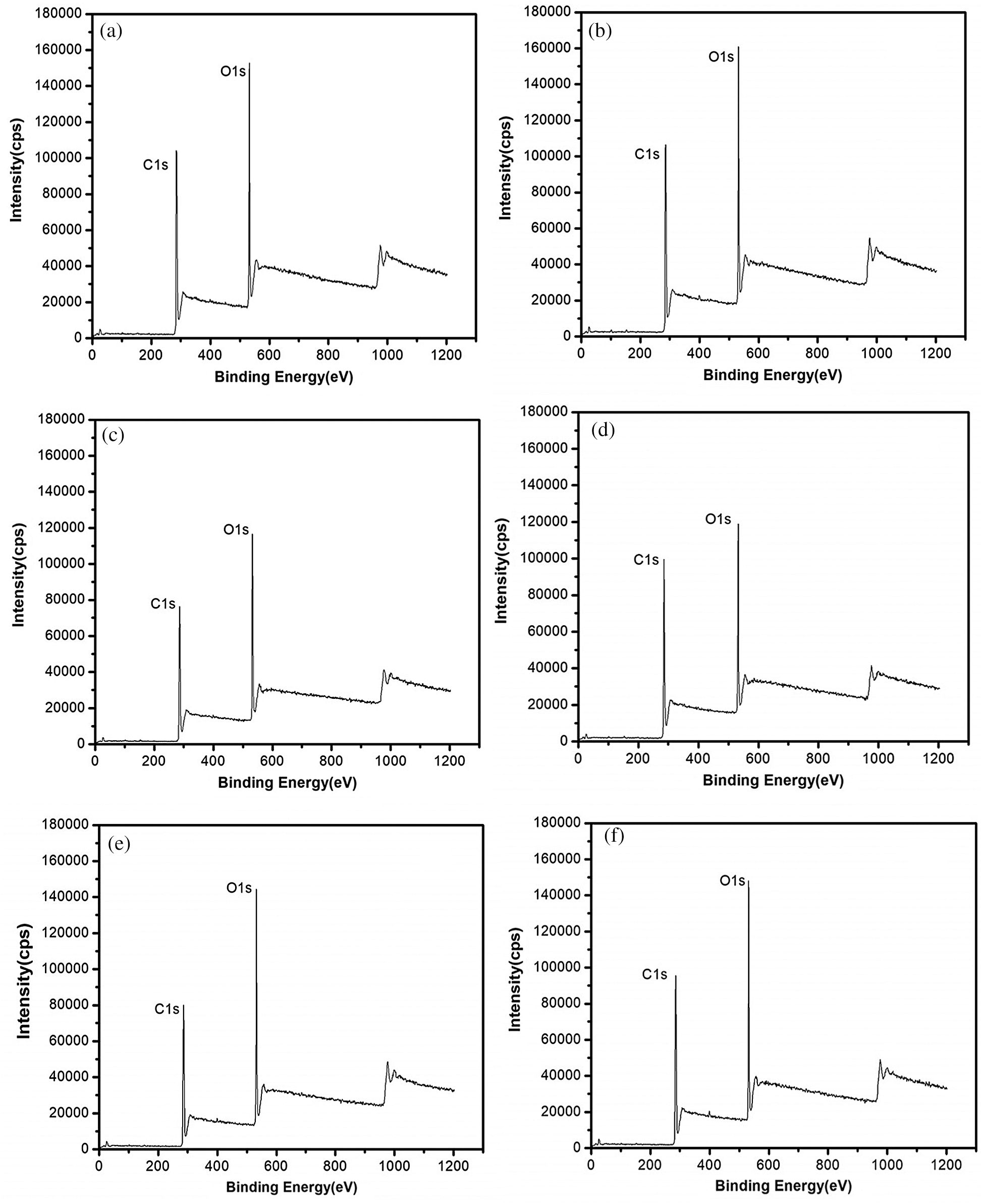

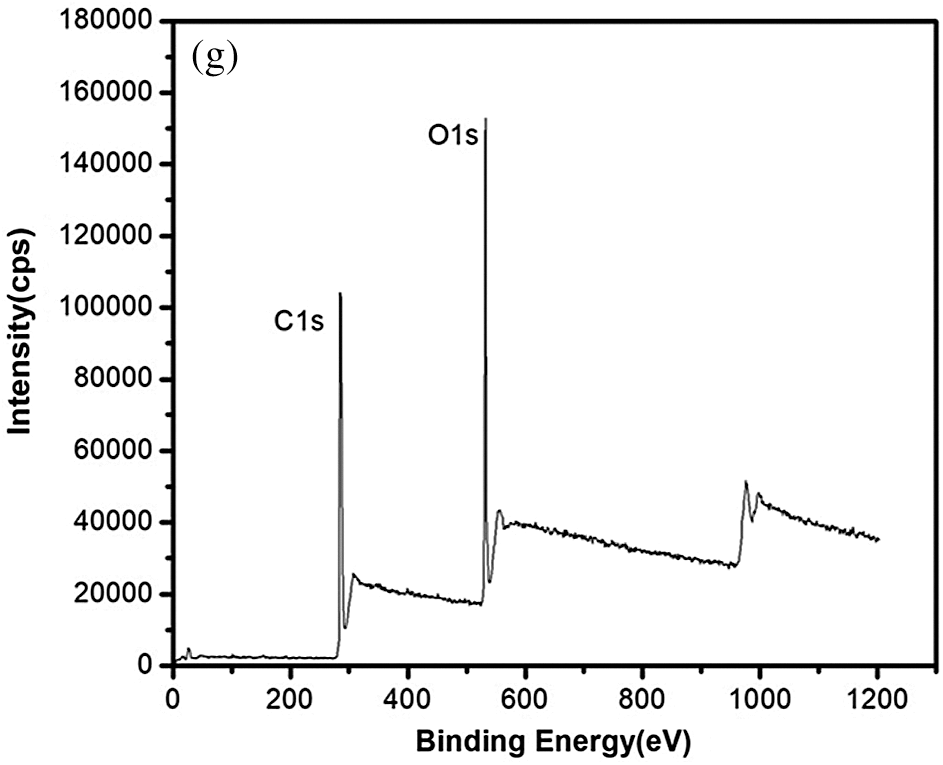

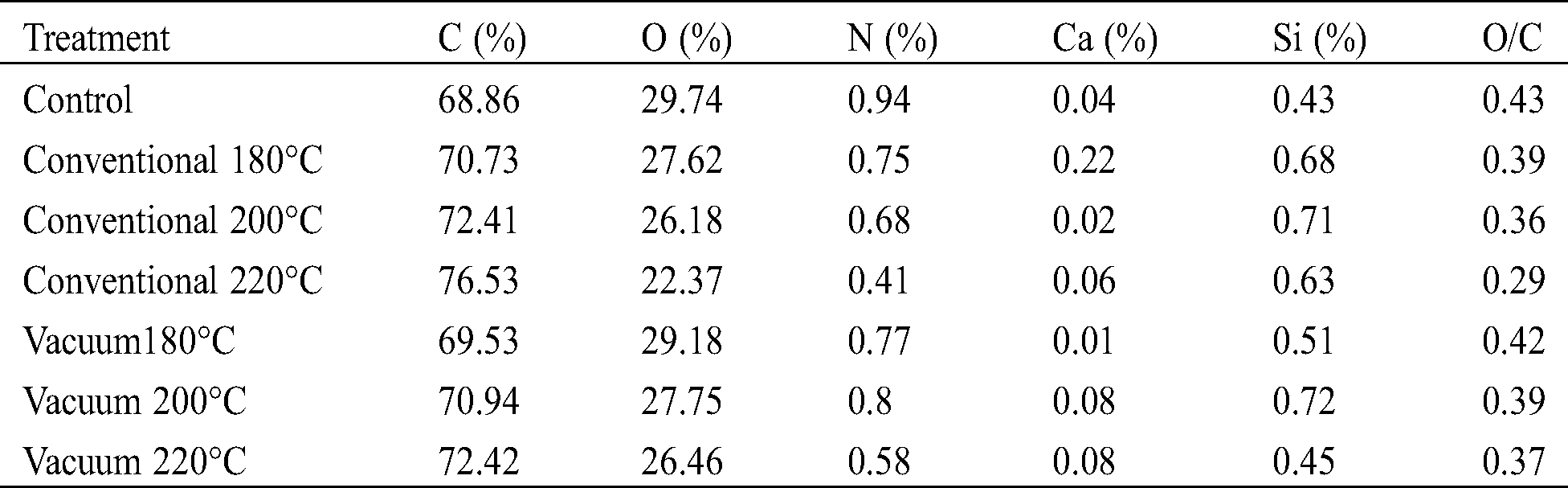

2.8 X-Ray Photoelectron Spectroscopy (XPS)

The elemental composition of heat compressed fir and untreated samples was investigated by X-ray photoelectron spectroscopy (AXIS UltraDLD, England) to analyze major elements of oxygen (O1s, 532 eV) and carbon (C1s, 284 eV). A monochromatic aluminium Kα line (1486.71 ev) was used as X-ray source with a power of 225W (15 mA, 15 kV), and oxygen to carbon (O/C) ratio were also determined.

3.1 Color Changes of Hot Compressed Chinese Fir

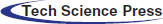

The color change data of Chinese fir by vacuum and conventional hot pressing treatment are presented in Tab. 1. The results showed that the color of treated wood was deepened with the increase of heating temperature. The brightness value (L*) of Chinese fir samples treated with conventional hot pressing decreased sharply, which was similar to the previous studies [13]. At the same time, the samples became redder and bluer by the increasing a* and decreasing b* value. The samples treated with vacuum hot pressing become brighter after treatment. The decrease of lightness indicates that more visible light absorption components are produced during heat treatment. The a* values of samples with the two treatments increased with the increase of treatment temperature. The increase of a* value indicates that there are condensation, degradation or oxidation products in the process of heat treatment, which absorb the complementary light of red light and makes the fir turn red gradually [14]. The ΔE* values of samples treated with conventional hot pressing increased from 1.35 to 25.44 with the increase of temperature from 180°C to 220°C. The color difference (ΔE*) of Chinese fir before and after vacuum hot pressing treatment was 43.73%, 69.91% and 77.17% lower than that before and after conventional hot pressing treatment, respectively, indicating that the vacuum hot pressing treatment can effectively reduce the discoloration of wood.

Table 1: Color change values of wood

3.2 The Mechanical Properties and Dimensional Stability of Chinese Fir

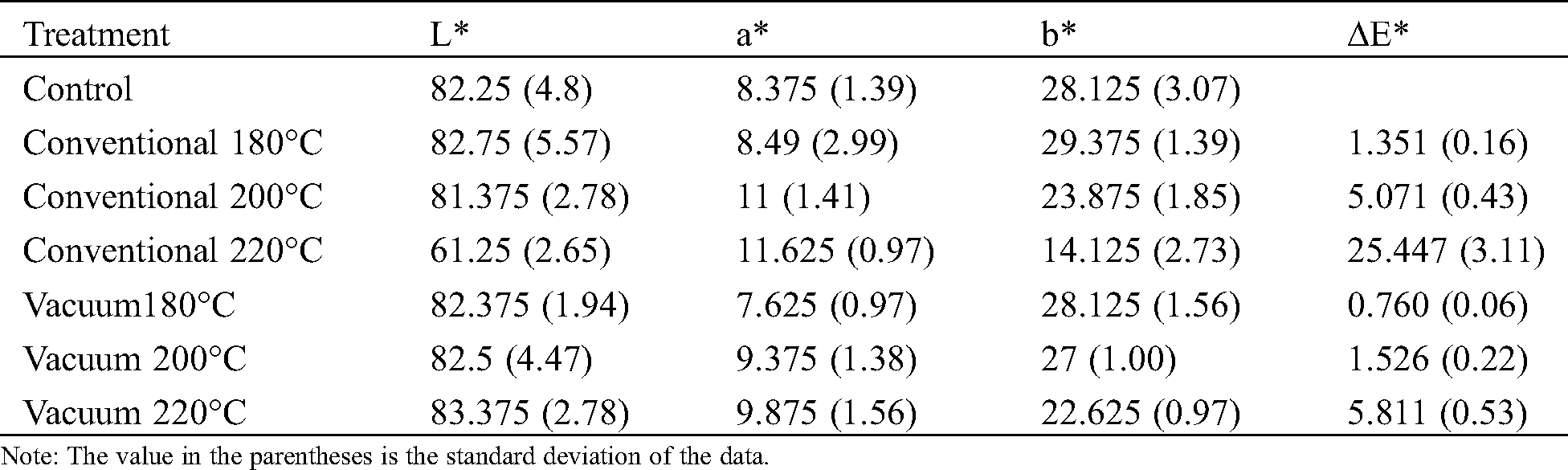

Fig. 1 shows the mass loss of fir by hot pressing treatment and compared with the control. The mass loss rate of wood increases with the increase of hot pressing temperature. The increase of mass loss rate is due to dehydration of wood and thermal degradation of some components of wood, especially hemicellulose, and some volatile products are generated [15]. The mass loss rate of fir compressed by vacuum heat treatment is higher than that of those by the conventional hot pressing. This is due to the fact that the pressure difference generated by the vacuum environment accelerates the speed of outward movement of water and volatile products in wood [16–18]. However, when the temperature is 220°C, the mass loss rate of the specimens with conventional hot pressing treatment is higher, which is because the presence of oxygen will accelerate the pyrolysis of wood components in the process of heat treatment, and the rate of wood under vacuum will be reduced [19,20].

Figure 1: Mass loss of Chinese fir by vacuum and conventional hot pressing treatment

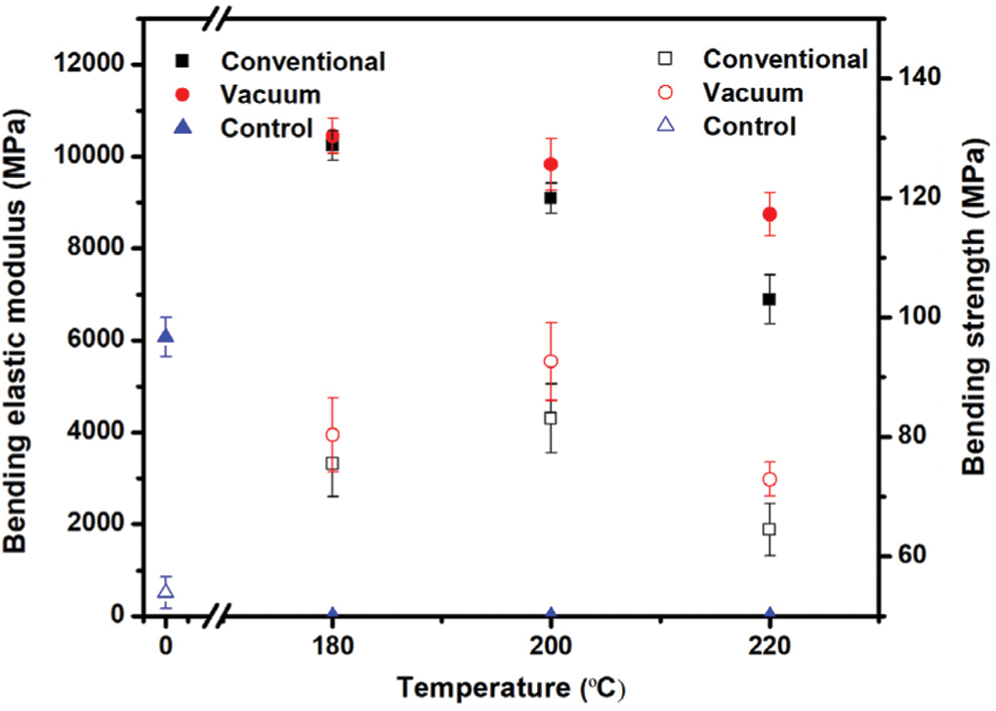

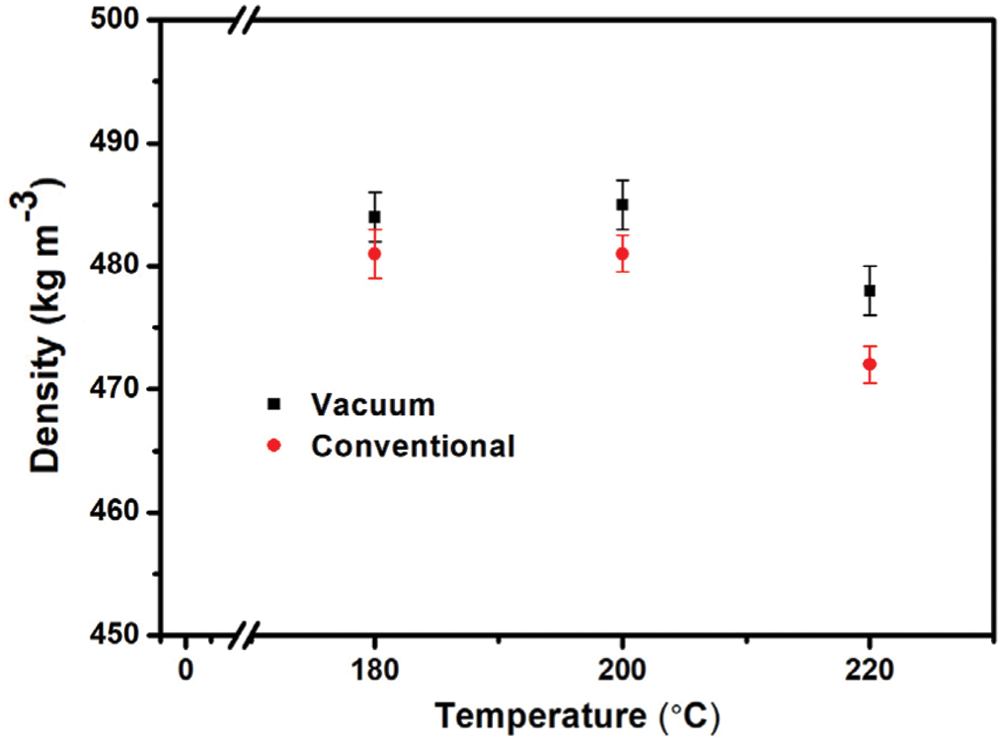

The mechanical properties of untreated fir and compressed fir specimens are shown in Fig. 2, and the dry density of the samples after treatment are shown in Fig. 3. The results show that bending modulus of elasticity and bending strength of the original Chinese fir were 6069.97 MPa and 53.94 MPa respectively. The bending strength of treated Chinese fir is significantly higher than that of untreated one. This is mainly due to the reduction of porosity in the compressed fir, and the increase in the mass of wood cell wall material contained in the unit volume, resulting in an increase in density. When the hot pressing temperature was 180°C, 200°C and 220°C, the average bending modulus of elasticity of compressed Chinese fir under vacuum hot pressing treatment increased by 80.35%, 61.84% and 43.95% respectively, the bending strength increased by 48.88%, 71.67% and 35.08% respectively compared with the control. With the increase of treatment temperature, the bending strength and density of fir first increases and then decreases, and the elastic modulus decreases gradually, which is mainly caused by the gradual thermal degradation of chemical components in wood [21]. The bending strength of Chinese fir with vacuum hot pressing treatment is higher than that with conventional hot pressing treatment, which is because vacuum limits the reduction of mechanical properties caused by heat treatment.

Figure 2: Bending strength and elastic modulus of compressed fir by vacuum and conventional hot pressing

Figure 3: Density of compressed fir by vacuum and conventional hot pressing

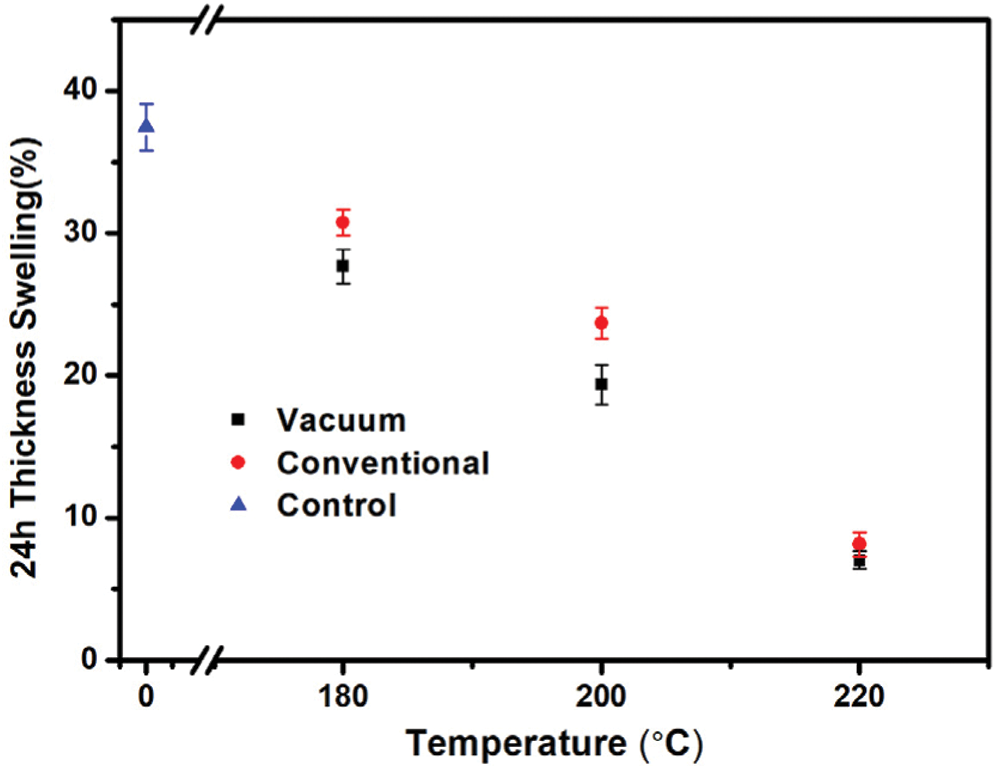

In this paper, the water absorption thickness expansion rate of wood compression direction (thickness) is selected as the index to analyze the dimensional stability of materials. Fig. 4 shows the 24 h thickness swelling of compressed fir specimens by vacuum hot pressing and compared with the control. Similar to the previous studies, the dimensional stability of heat-treated wood was also significantly improved compared with untreated wood, which was related to the thermochemical properties of the main components of the wood. The main reason for moisture absorption of wood is the hydrophilicity of hydroxyl groups on hemicellulose [22]. When the heat treatment temperature reaches 200°C or above, the hemicellulose with high hygroscopicity decomposes to furfural with low hygroscopicity, thus reducing the hygroscopicity of wood. The continuous increase of temperature is conducive to the continuous improvement of dimensional stability. However, it also leads to more pronounced degradation of hemicelluloses, the decline of wood strength and the change of wood surface color. Compared with conventional hot pressing treatment, the 24-hour water absorption thickness expansion rate of compressed wood treated by vacuum hot pressing is smaller, which can improve the dimensional stability of wood to a greater extent.

Figure 4: The 24h Thickness Swelling of Chinese fir by vacuum and conventional hot pressing treatment

3.3 Chemical Composition Analysis

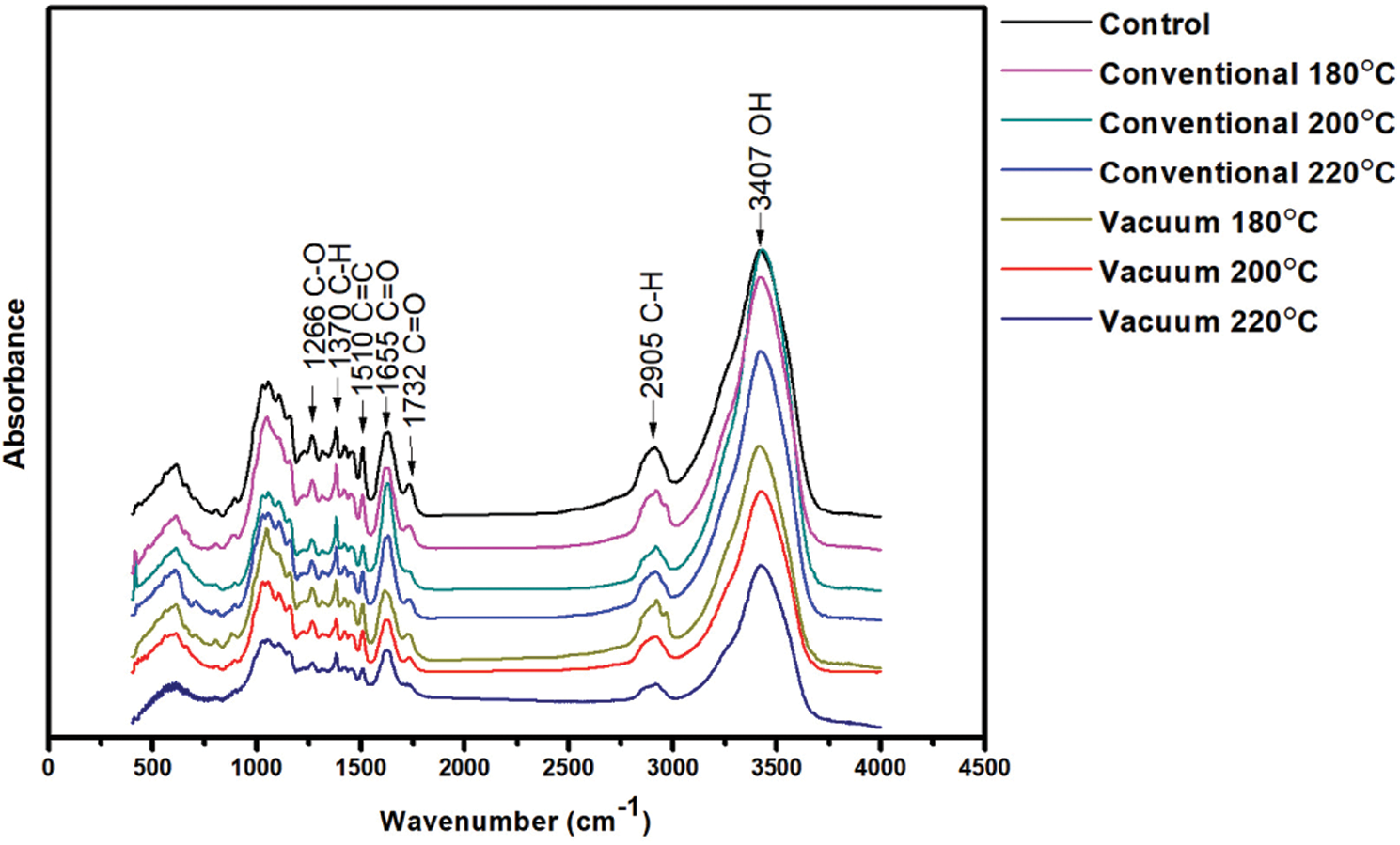

Fig. 5 shows the FTIR spectra of untreated fir and compressed fir specimens from 400 to 4000 cm−1. The absorption bands at 1732 cm−1, which is attributed to CO stretching vibrations of carbonyl, acetyl and carboxyl groups, was decreased with increasing hot pressing temperature, which was due to the cleavage of acetyl side chains from hemicelluloses [23–25]. The absorption peak near 1655 cm−1 is attributed to C=O stretching vibration (lignin conjugated carbonyl) and adsorbed water. The absorption peak intensity gradually decreases with the increase of temperature, which indicates that the carbonyl content of wood is significantly reduced by hot pressing, thus reducing the moisture absorption rate of wood. The absorption peak near 1510 cm−1 is the stretching of aromatic skeletal in lignin [26], the peak intensity after hot pressing treatment is slightly weaker than that of untreated one, which indicates that lignin has slight pyrolysis reaction at the temperature of 220°C, especially after vacuum hot pressing. Meanwhile, vacuum can remove volatile wood degradation by-products, limiting the acid hydrolysis and recondensation reaction of wood [21], which also explains the small color change of the samples treated by vacuum hot pressing.

Figure 5: FTIR spectra of compressed Chinese fir samples with different hot pressing treatment parameters compared with the control

The discoloration and degradation of wood are affected by the chemical composition and atomic concentrations of wood surface [27]. X-ray photoelectron spectroscopy (XPS) is an effective method to analyze the chemical composition of polymer surface [28]. Fig. 6 shows the XPS survey spectrum of untreated and heat compressed treated fir wood, and Tab. 2 lists the experimental atomic composition and the calculated oxygen-carbon (O/C) ratio for all specimens. Carbon and oxygen were the major elements on the surface of wood, and their electronic binding energies are about 284 eV and 532 eV, respectively. In addition, it also contains a small amount of inorganic elements (silicon, calcium and nitrogen). The results show that the oxygen-carbon ratio gradually decreases with the increase of hot pressing temperature. At the same temperature, this trend is more obvious under the conventional hot pressing, and O/C ratios were reduced from 0.43 to 0.29. The carbon content of wood treated by vacuum hot pressing is increased. The high carbon content may be due to dehydration of wood components, resulting in the production of new products with low oxygen content and migration to the surface of wood [29]. The celluloses and hemicelluloses contents were decreased with increasing heat compressed treatment temperature [30,31], the surface of wood, which resulted in the decrease of O/C ratio.

Figure 6: XPS survey spectra of untreated and compressed treated fir wood: (a) Control; (b) Conventional hot pressing at 180°C; (c) Conventional hot pressing at 200°C; (d) Conventional hot pressing at 220°C; (e) Vacuum hot pressing at 180°C; (f) Vacuum hot pressing at 200°C; (g) Vacuum hot pressing at 220°C

Table 2: Relative amount of atoms and O/C ratio determined by XPS for treated and untreated wood

With the increase of temperature, the color difference between compressed and untreated wood increased gradually. When the temperature is 220°C, the lightness values (L*) of the compressed fir sample by conventional hot pressing decreases rapidly. When the hot pressing temperature was 180°C, 200°C and 220°C, the color difference (ΔE*) of Chinese fir before and after vacuum hot pressing treatment was 43.73%, 69.91% and 77.17% lower than that before and after conventional hot pressing treatment, respectively. The average bending modulus of elasticity of compressed Chinese fir under vacuum hot pressing treatment increased by 80.35%, 61.84% and 43.95% respectively, the bending strength increased by 48.88%, 71.67% and 35.08% respectively compared with the control. The 24-hour water absorption thickness expansion rate of compressed wood treated by vacuum hot pressing is smaller, which can improve the dimensional stability of wood to a greater extent. Vacuum can remove volatile wood degradation by-products, limiting the acid hydrolysis and recondensation reaction of wood. Therefore, vacuum hot pressing treatment is an effective method to improve the mechanical properties and dimensional stability of wood and reduce the degree of wood discoloration.

Acknowledgement: All authors contributed equally to this work.

Funding Statement: The Authors acknowledge funding support by the National Key R&D Program of China (2017YFC0703501), the Doctorate Fellowship Foundation of the Nanjing Forestry University and the China Double First Class University Plan. All authors contributed equally to this work.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Cao, Y., Lu, J., Huang, R., Jiang, J. (2012). Increased dimensional stability of Chinese fir through steam-heat treatment. European Journal of Wood and Wood Products, 70(4), 441–444. DOI 10.1007/s00107-011-0570-y. [Google Scholar] [CrossRef]

2. Gao, Z., Huang, R., Lu, J., Chen, Z., Guo, F. et al. (2016). Sandwich compression of wood: control of creating density gradient on lumber thickness and properties of compressed wood. Wood Science and Technology, 50(4), 833–844. DOI 10.1007/s00226-016-0824-2. [Google Scholar] [CrossRef]

3. Kutnar, A., Kamke, F. A. (2013). Transverse compression behavior of Douglas-fir (Pseudotsuga menziesii) in saturated steam environment. European Journal of Wood and Wood Products, 71(4), 443–449. DOI 10.1007/s00107-013-0698-z. [Google Scholar] [CrossRef]

4. Ratnasingam, J., Ioras, F. (2012). Effect of heat treatment on the machining and other properties of rubberwood. European Journal of Wood and Wood Products, 70(5), 759–761. DOI 10.1007/s00107-011-0587-2. [Google Scholar] [CrossRef]

5. Mohareb, A., Sirmah, P. K., Pétrissans, M., Gérardin, P. (2012). Effect of heat treatment intensity on wood chemical composition and decay durability of Pinus patula. European Journal of Wood and Wood Products, 70(4), 519–524. DOI 10.1007/s00107-011-0582-7.

6. Dubey, M. K., Pang, S., Walker, J. (2012). Oil uptake by wood during heat-treatment and post-treatment cooling, and effects on wood dimensional stability. European Journal of Wood and Wood Products, 70(1–3), 183–190. DOI 10.1007/s00107-011-0535-1.

7. Pelit, H., Budakç, M., Sönmez, A. (2018). Density and some mechanical properties of densified and heat post-treated Uludağ fir, linden and black poplar woods. European Journal of Wood and Wood Products, 76(1), 79–87. DOI 10.1007/s00107-017-1182-y. [Google Scholar] [CrossRef]

8. Wang, Z., Yang, X., Sun, B., Chai, Y., Liu, J. et al. (2016). Effect of vacuum heat treatment on the chemical composition of larch wood. Bioresources, 11(3), 5743–5750. [Google Scholar]

9. Meija-Feldmane, A., Cuccui, I., Irbe, I., Morozovs, A., Spulle, U. (2020). Properties of modified wood according to treatment technology and thermo-vacuum process for birch (betula pendula roth) veneers. Bioresources, 15(2), 4150–4164.

10. Sandak, A., Sandak, J., Allegretti, O. (2015). Quality control of vacuum thermally modified wood with near infrared spectroscopy. Vacuum, 114, 44–48. DOI 10.1016/j.vacuum.2014.12.027. [Google Scholar] [CrossRef]

11. Wang, X. H., Fei, B. H., Liu, J. L. (2014). Effect of vacuum heat treatment temperature on physical and mechanical properties of eucalyptus pellita wood. Revista Brasilra De Saúde E Produo Animal, 13(3), 1032–1043. [Google Scholar]

12. Sivrikaya, H., Tesarova, D., Jerabkova, E., Can, A. (2019). Color change and emission of volatile organic compounds from Scots pine exposed to heat and vacuum-heat treatment. Journal of Building Engineering, 26, 100918. DOI 10.1016/j.jobe.2019.100918. [Google Scholar] [CrossRef]

13. Gunduz, G., Aydemir, D., Korkut, S. (2010). The effect of heat treatment on some mechanical properties and color changes of uludag fir wood. Drying Technology, 28(2), 249–255. DOI 10.1080/07373930903530162. [Google Scholar] [CrossRef]

14. Ferrari, S., Cuccui, I., Allegretti, O. (2013). Thermo-vacuum modification of some European softwood and hardwood species treated at different conditions. BioResources, 8(1), 1100–1109. [Google Scholar]

15. Chen, W. H., Hsu, H. C., Lu, K. M., Lee, W. J., Lin, T. C. (2011). Thermal pretreatment of wood (Lauan) block by torrefaction and its influence on the properties of the biomass. Energy, 36(5), 3012–3021. DOI 10.1016/j.energy.2011.02.045. [Google Scholar] [CrossRef]

16. Li, D., Cheng, Y., Li, Y., Zhao, L., Sun, W. et al. (2017). A numerical solution of density distribution function of water adsorption sites on vacuum technical metal surfaces. Vacuum, 136, 14–19. DOI 10.1016/j.vacuum.2016.11.010. [Google Scholar] [CrossRef]

17. Bargery, A. S., Lane, S. J., Barrett, A., Wilson, L., Gilbert, J. S. (2010). The initial responses of hot liquid water released under low atmospheric pressures: experimental insights. Icarus, 210(1), 488–506. DOI 10.1016/j.icarus.2010.06.019.

18. Hong, L., He, Q., Ju, Z., Zhang, H., Brosse, N. et al. (2020). Effect of vacuum hot pressing on the bonding quality and heat transfer performance of plywood. European Journal of Wood and Wood Products, 78(3), 441–447. DOI 10.1007/s00107-020-01531-y. [Google Scholar] [CrossRef]

19. Wang, J., Zhao, G., Ikuho, I. (2000). Effect of oxidation on heat fixation of compressed wood of China fir. Forestry Study in China, 2(1), 18–21. [Google Scholar]

20. Candelier, K., Dumarcay, S., Petrissans, A., Desharnais, L., Gerardin, P. et al. (2013). Comparison of chemical composition and decay durability of heat treated wood cured under different inert atmospheres: Nitrogen or vacuum. Polymer Degradation and Stability, 98(2), 677–681. DOI 10.1016/j.polymdegradstab.2012.10.022. [Google Scholar] [CrossRef]

21. Mburu, F., Dumarcay, D., Bocquet, J. F., Petrissans, M., Gérardin, P. (2008). Effect of chemical modifications caused by heat treatment on mechanical properties of Grevillea robusta wood. Polymer Degradation and Stability, 93(2), 401–405. DOI 10.1016/j.polymdegradstab.2007.11.017. [Google Scholar] [CrossRef]

22. Ding, T., Gu, L., Li, T. (2011). Einfluss einer wrmebehandlung von schnittholz aus mongolischer kiefer unter dampfdruck auf dessen physikalische und mechanische eigenschaften. European Journal of Wood and Wood Products, 69(1), 121–126. DOI 10.1007/s00107-009-0406-1. [Google Scholar] [CrossRef]

23. Sun, P., Heng, M., Sun, S. H., Chen, J. (2011). Analysis of liquid and solid products from liquefaction of paulownia in hot-compressed water. Energy Conversion and Management, 52(2), 924–933. DOI 10.1016/j.enconman.2010.08.020. [Google Scholar] [CrossRef]

24. Vartanian, E., Barres, O., Roque, C. (2015). FTIR spectroscopy of woods: A new approach to study the weathering of the carving face of a sculpture. Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy, 136, 1255–1259. DOI 10.1016/j.saa.2014.10.011.

25. Lin, B. J., Colin, B., Chen, W. H., Petrissans, A., Rousset, P. et al. (2018). Thermal degradation and compositional changes of wood treated in a semi-industrial scale reactor in vacuum. Journal of Analytical and Applied Pyrolysis, 130(3), 8–18. DOI 10.1016/j.jaap.2018.02.005. [Google Scholar] [CrossRef]

26. Tolvaj, L., Persze, L., Albert, L. (2011). Thermal degradation of wood during photodegradation. Journal of Photochemistry and Photobiology B: Biology, 105(1), 90–93. DOI 10.1016/j.jphotobiol.2011.07.005. [Google Scholar] [CrossRef]

27. Zivkovic, V., Arnold, M., Pandey, K. K., Richter, K. and Turkulin, H. (2016). Spectral sensitivity in the photodegradation of fir wood (Abies alba Mill.) surfaces: correspondence of physical and chemical changes in natural weathering. Wood Science and Technology, 50(5), 989–1002. DOI 10.1007/s00226-016-0834-0. [Google Scholar] [CrossRef]

28. Inari, G. N., Petrissans, M., Lambert, J., Ehrhardt, J. J., Gérardin, P. (2006). XPS characterization of wood chemical composition after heat-treatment. Surface and Interface Analysis, 38(10), 1336–1342. DOI 10.1002/sia.2455. [Google Scholar] [CrossRef]

29. Tuong, V. M., Li, J. (2011). Changes caused by heat treatment in chemical composition and some physical properties of acacia hybrid sapwood. Holzforschung, 65(1), 67–72. DOI 10.1515/hf.2010.118. [Google Scholar] [CrossRef]

30. Malek, B. M., Kookande, M. G., Taghiyari, H. R., Mirshokraie, S. A. (2013). Effects of silver nanoparticles and fungal degradation on density and chemical composition of heat-treated poplar wood (Populous euroamerica). European Journal of Wood and Wood Products, 71(4), 491–495. DOI 10.1007/s00107-013-0708-1. [Google Scholar] [CrossRef]

31. Todaro, L., Rita, A., Pucciariello, R., Mecca, M., Hiziroglu, S. (2018). Influence of thermo-vacuum treatment on thermal degradation of various wood species. European Journal of Wood and Wood Products, 76(2), 541–547. DOI 10.1007/s00107-017-1230-7. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |