Open Access

Open Access

ARTICLE

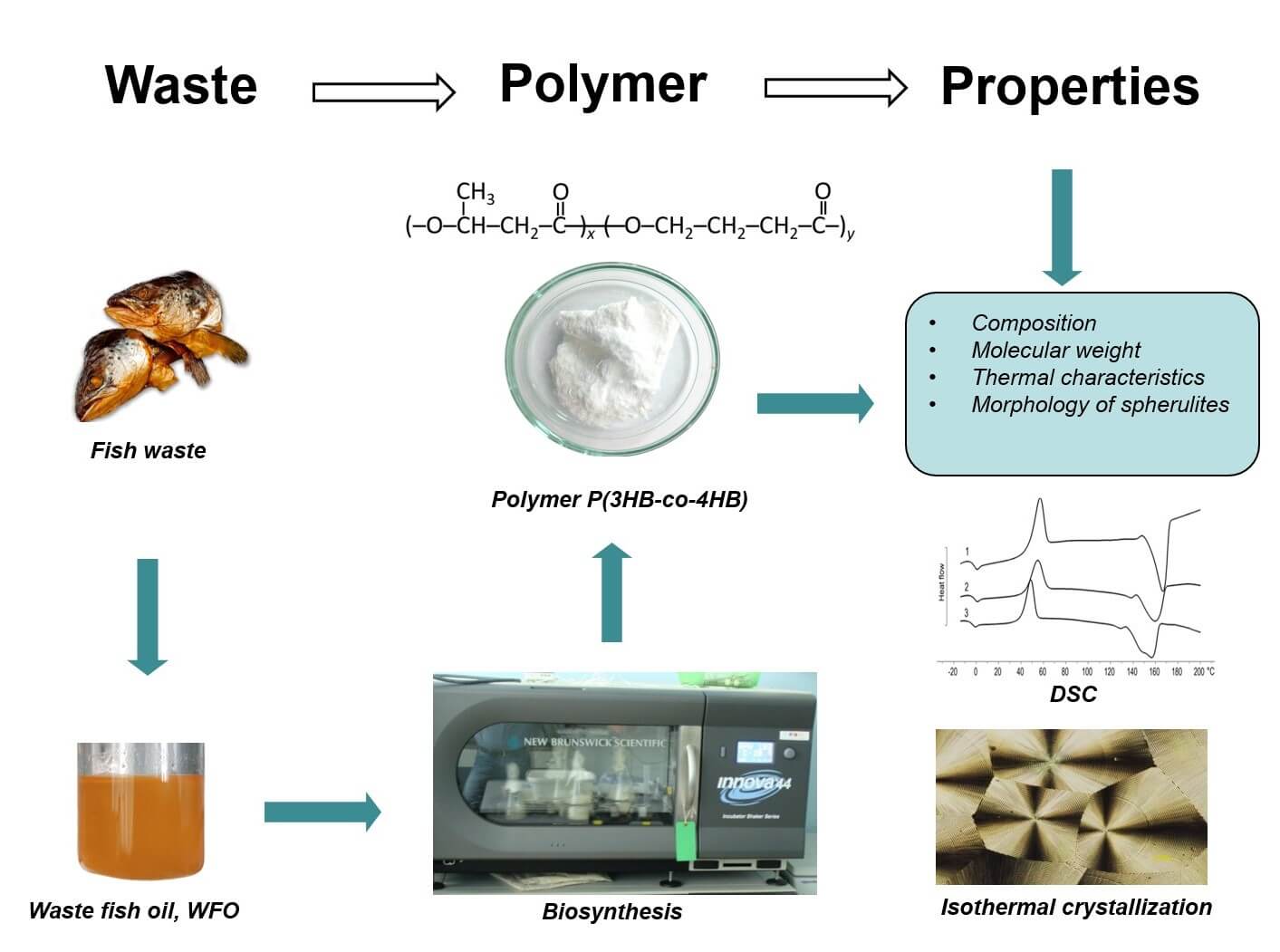

From Waste to Biopolymer: Synthesis of P(3HB-co-4HB) from Renewable Fish Oil

1 Institute of Biophysics SB RAS, Federal Research Center “Krasnoyarsk Science Center SB RAS”, 50/50 Akademgorodok, Krasnoyarsk, 660036, Russia

2 Basic Department of Biotechnology, School of Fundamental Biology and Biotechnology, Siberian Federal University, 79 Svobodnyi Av., Krasnoyarsk, 660041, Russia

3 Kaliningrad State Technical University, Sovetsky Avenue, 1, Kaliningrad, 236022, Russia

4 Institute of Chemistry and Chemical Technology, Federal Research Center “Krasnoyarsk Science Center SB RAS”, 50/24 Akademgorodok, Krasnoyarsk, 660036, Russia

* Corresponding Author: Natalia Zhila. Email:

Journal of Renewable Materials 2025, 13(3), 413-432. https://doi.org/10.32604/jrm.2024.058775

Received 20 September 2024; Accepted 10 December 2024; Issue published 20 March 2025

Abstract

The article presents the results of a study on the possibility of synthesizing biodegradable poly(3-hydroxybutyrate-co-4-hydroxybutyrate) [P(3HB-co-4HB)] from renewable waste fish oil (WFO) by the Cupriavidus necator B-10646 bacterium. For the first time, waste oil generated during the processing of Sprattus balticus in the production of sprats was used as the main carbon substrate for the synthesis of P(3HB-co-4HB), and ε-caprolactone was used as a precursor instead of the more expensive γ-butyrolactone. Samples of P(3HB-co-4HB) with a 4HB monomer content from 7.4 to 11.6 mol.% were synthesized, and values of the bacterial biomass yield and the total yield of the copolymer were comparable with the control (where butyric acid was used as carbon source). The following properties of the samples were studied: molecular weight, temperature characteristics, thermal behavior, isothermal crystallization of melts, and the formation of spherulites. The renewable fatty substrate of complex composition was used to synthesize samples of technologically advanced low-crystallinity P(3HB-co-4HB) with significant proportions of 4HB, without impairing the physicochemical properties of the polymer. The biotechnological process involving the use of renewable WFO and ε-caprolactone can be employed to reduce the costs of producing a promising “green” bioplastic and make it more affordable.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools