Open Access

Open Access

ARTICLE

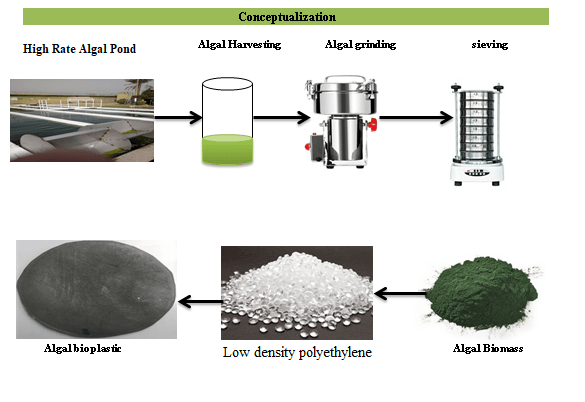

Innovative Bioplastics: Harnessing Microalgae and Low-Density Polyethylene for Sustainable Production

1 Water Pollution Research Department, National Research Center, Giza, P.O. Box 12622, Egypt

2 Institute of Textile Research and Technology, National Research Centre, Giza, P.O. Box 12622, Egypt

3 Packaging Materials Department, National Research Centre, Giza, P.O. Box 12622, Egypt

4 Chemical Engineering and Pilot Plant Department, National Research Centre, Giza, P.O. Box 12622, Egypt

5 Electronics Research Institute (ERI), Cairo, P.O. Box 12622, Egypt

* Corresponding Author: Sayeda M. Abdo. Email:

Journal of Renewable Materials 2025, 13(3), 599-616. https://doi.org/10.32604/jrm.2024.057736

Received 26 August 2024; Accepted 18 November 2024; Issue published 20 March 2025

Abstract

The accumulation of non-biodegradable plastic debris in the environment raises serious concerns about potential long-term effects on the environment, the economy, and waste management. To assess the feasibility of substituting commercial plastics for a biodegradable renewable polymer for many applications, low-density polyethylene (LDPE) was mixed with varying concentrations of algal biomass (AB). Algae are considered a clean, renewable energy source because they don’t harm the environment and can be used to create bioplastics. Algal biomass grown in a high rate algal pond (HRAP) used for wastewater treatment used at 12.5–50 weight percent. Mechanical, thermal, and morphological characteristics of the LDPE/AB mixes were studied. Improved compatibility and uniformity between the LDPE matrix and algal biomass phase were evident in the morphology of LDPE/AB blends. Tensile strength (TS) and elastic modulus (EM) of the prepared LDPE/AB blends significantly decreased to 4.63 and 255 MPa, respectively. Nevertheless, by increasing the concentration of AB up to 25% and 37.5%, the mechanical properties enhanced and raised to (TS = 6.75 MPa, EM = 426 MPa) and (TS = 7 MPa, EM = 494 MPa), respectively. Using 25% and 37.5% of AB significantly enhanced the miscibility and interaction between algal biomass and LDPE polymer. However, increasing the percentage of AB led to a reduction in the thermal stability of the LDPE/AB. In contrast, compatibilized blends demonstrated better thermal stability compared to un-compatibilized blends. These findings indicate that it is possible to develop a blend with improved structural, thermal, and mechanical properties by partially replacing LDPE with biodegradable algal biomass.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools