Open Access

Open Access

ARTICLE

Structural and Mechanical Properties of Bio-Sourced Thermoplastic Materials from Flax and Fatty Acids

1 LERMAB, INRAE, Université de Lorraine, Nancy, 54000, France

2 Research Center for Biomass and Bioproducts, National Research and Innovation Agency (BRIN), Bogor, 16911, Indonesia

3 PLASTINNOV, IUT de Moselle-Est, Université de Lorraine, Saint-Avold, 57500, France

* Corresponding Authors: Firmin Obounou Akong. Email: ; Philippe Gérardin. Email:

(This article belongs to the Special Issue: Valorization of Lignocellulosic Biomass for Functional Materials)

Journal of Renewable Materials 2025, 13(3), 539-552. https://doi.org/10.32604/jrm.2024.056813

Received 31 July 2024; Accepted 25 October 2024; Issue published 20 March 2025

Abstract

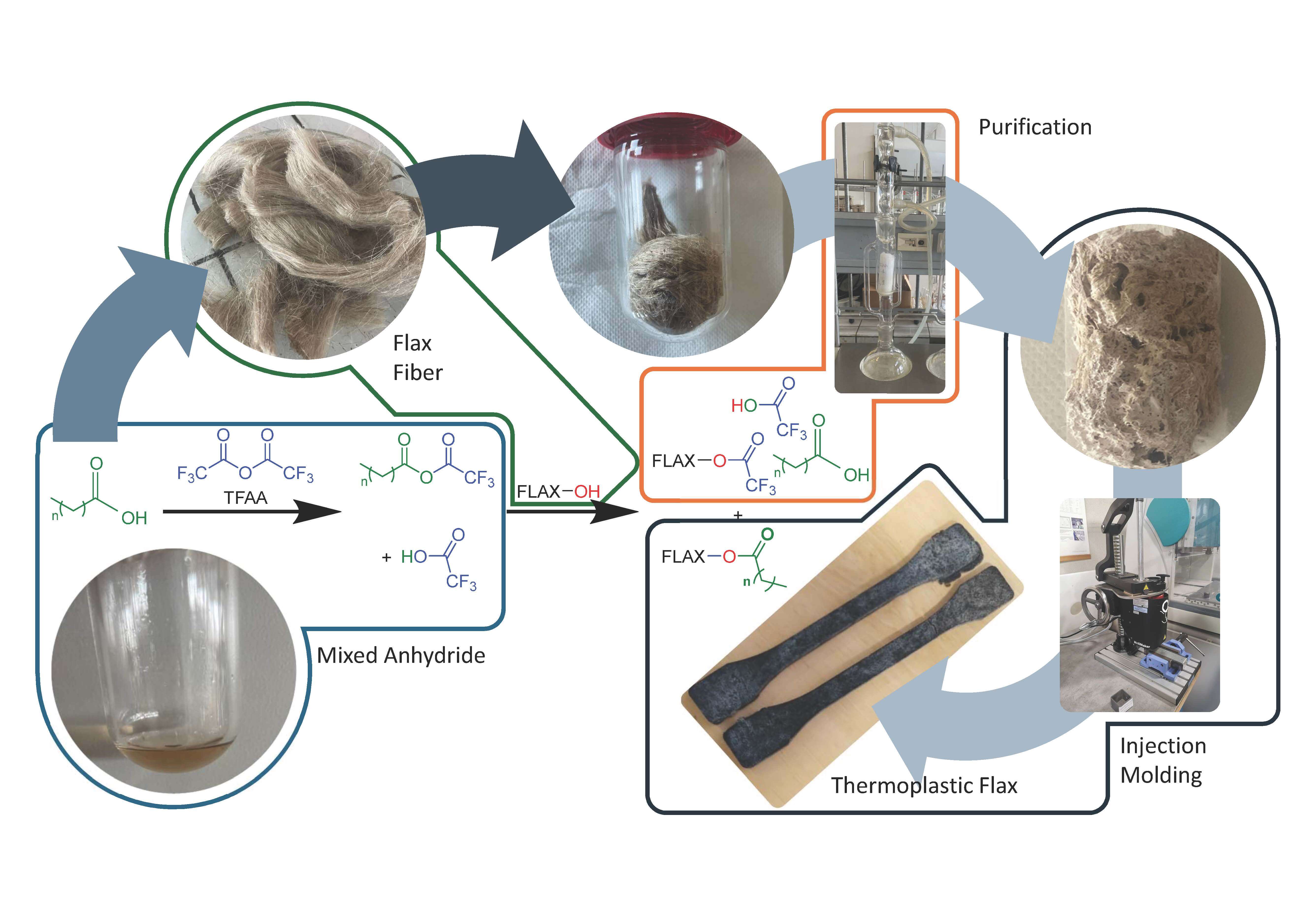

Bio-based thermoplastic film from flax fiber and fatty acid (FA) was obtained using trifluoroacetic anhydride (TFAA) as an impelling agent. Different quantities of TFAA/FA, size of flax fiber, and fatty acids were applied to investigate chemical structure in relation to the mechanical properties. Decreasing the quantity of TFAA/FA by almost half from 1:4 to 1:2.5 (flax to TFAA/FA) only reduces by 22% the weight percent gain (WPG) and ester content and reducing flax fiber size slightly increases the WPG and ester content. All the treatments showed significant chemical structure modification, observed by FTIR and solid CP/MAS 13C NMR, confirming the presence of carbonyl ester groups and alkyl chains, in relatively similar intensities. The crystallinity index (CrI) of esterified flax was evaluated by comparing the signal of solid CP/MAS 13C NMR in crystalline and amorphous regions and CrI was higher in esterified flax using a lower quantity of reagent and longer fatty acid. Esterified flax in a high quantity of reagent showed ductile or flexible behavior. Decreasing the reagent to 1:2.5 significantly increases the tensile strength and Young’s modulus, and decreases the elongation at break, presenting more brittle and stiff material. Using flax fiber in the original size results in slightly higher tensile strength and Young’s modulus and slightly lower elongation than milled flax. The tensile strength and Young’s modulus of stearic acid esterified flax obtained in this research were higher than myristic acid and comparable to the polyethylene plastics-LDPE and HDPE.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools