Open Access

Open Access

ARTICLE

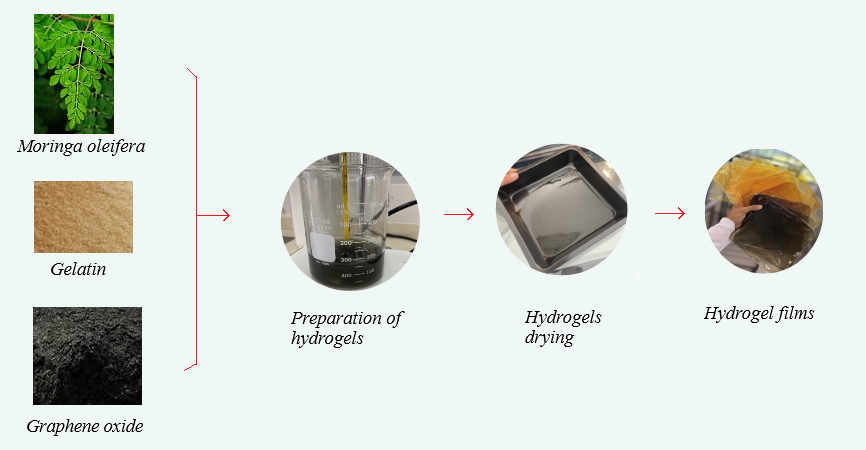

Graphene Oxide and Moringa oleifera Seed Oil Incorporated into Gelatin-Based Films: A Novel Active Food Packaging Material

1 Food Packaging and Shelf-Life Research Group (FP&SL), Food Engineering Department, University of Cartagena, Cartagena de Indias, 130015, Colombia

2 Departamento de Ingeniería Química, Universidad Nacional Autónoma de Honduras, Tegucigalpa, 11101, Honduras

3 Investigador por México-CONAHCYT, Centro de Investigación en Química Aplicada (CIQA), Saltillo, 25294, México

4 Chemistry Program, Department of Natural and Exact Sciences, San Pablo Campus, University of Cartagena, Cartagena, 130015, Colombia

5 Chemical Engineering Program, School of Engineering, Universidad Tecnológica de Bolívar, Cartagena, 130001, Colombia

6 Department of Natural and Exact Science, Universidad de la Costa, Barranquilla, 080002, Colombia

* Corresponding Author: Rodrigo Ortega-Toro. Email:

Journal of Renewable Materials 2025, 13(2), 311-327. https://doi.org/10.32604/jrm.2024.056639

Received 27 July 2024; Accepted 26 November 2024; Issue published 20 February 2025

Abstract

The extensive use of polymeric materials in single-use packaging has driven the need to develop biodegradable alternatives. This study investigates the incorporation of graphene oxide (GO) and Moringa oleifera seed oil (MOSO) into a gelatin matrix to create polymer films and evaluate their potential as active packaging materials. The properties of these films were evaluated using structural, thermal, mechanical, optical, and physicochemical methods to determine their suitability for food packaging applications. The results showed that GO and MOSO were homogeneously dispersed in the gelatin matrix, forming colloidal particles (around 5 µm in diameter). The addition of GO increased opacity by approximately 20 times the base value while MOSO affected light transmittance without impacting opacity. Mechanical properties were affected differently, GO acted as a crosslinking agent reducing elongation and increasing tensile strength at break, on the other hand MOSO acted as a plasticizer, making films more plastic increasing elongation a 30%. These effects counteracted each other, and similar behavior was recorded in differential scanning calorimetry. The films exhibited an improved water vapor resistance, which is crucial for food packaging. These findings indicate that the incorporation of GO and MOSO into a gelatin matrix may produce biodegradable polymer films with enhanced properties, suitable for active packaging in the food industry.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools