Open Access

Open Access

ARTICLE

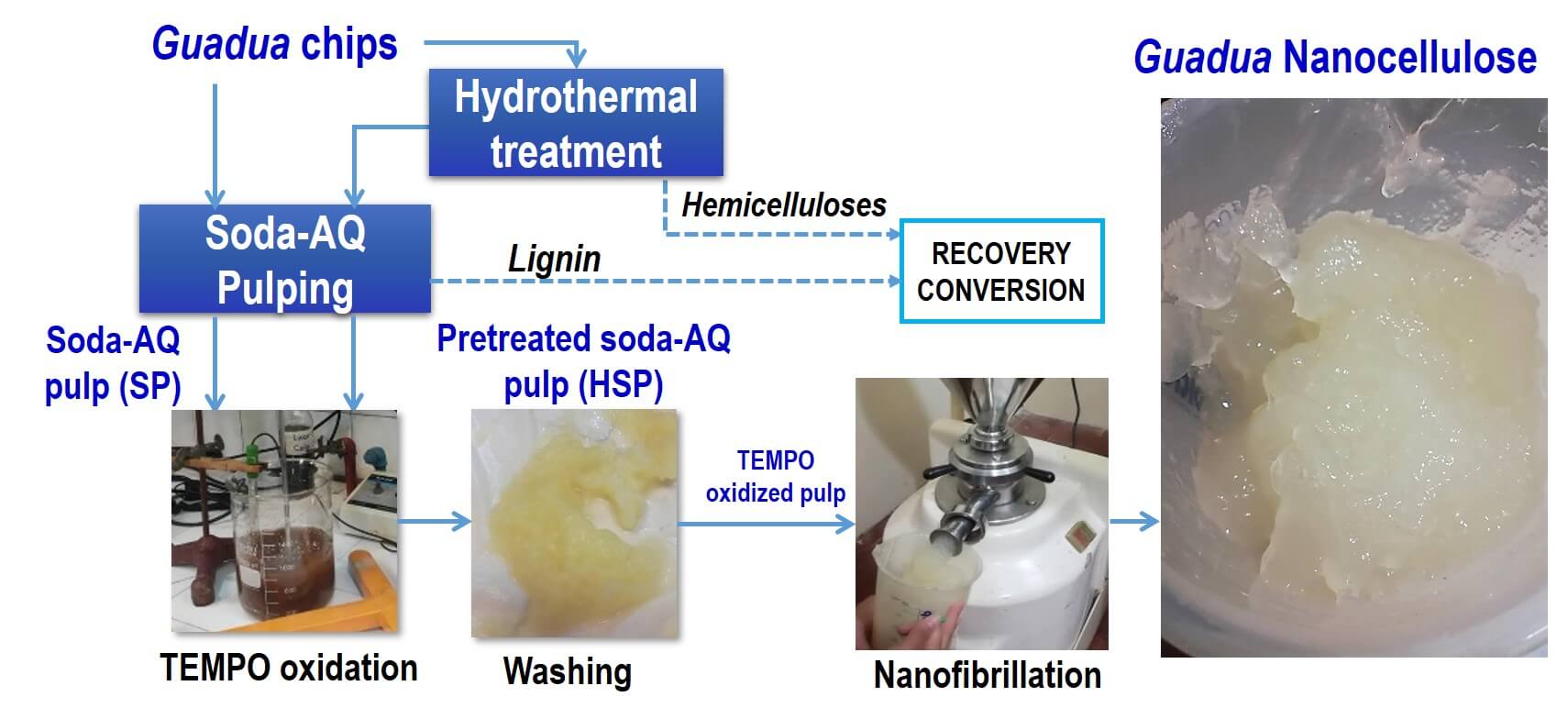

Potential of Bamboo Species Guadua trinii and Guadua angustifolia for Nanocellulose Production

1 Círculo de Investigación del Bambú, Universidad Nacional Agraria La Molina (UNALM), Lima, 15026, Perú

2 Instituto de Materiales de Misiones (IMAM), Universidad Nacional de Misiones (UNaM), Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET), Facultad de Ciencias Exactas, Químicas y Naturales (FCEQYN), Programa de Celulosa y Papel (PROCyP), Posadas, 3300, Argentina

3 Instituto de Materiales de Misiones (IMAM), Universidad Nacional de Misiones (UNaM), Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET), Facultad de Ciencias Forestales (FCF), Eldorado, 3380, Argentina

* Corresponding Author: María Evangelina Vallejos. Email:

Journal of Renewable Materials 2024, 12(9), 1541-1555. https://doi.org/10.32604/jrm.2024.052481

Received 03 April 2024; Accepted 05 August 2024; Issue published 25 September 2024

Abstract

Non-traditional lignocellulosic materials are a significant resource for producing high-value products, including nanocellulose. This work studied the nanocellulose obtention from chemical pulps of the two fast-growing bamboo species, Guadua trinii, and Guadua angustifolia. Chemical pulps were produced by soda-anthraquinone (S) pulping from both autohydrolysis-pretreated (H) and unpretreated bamboo chips. Autohydrolysis-pretreated (SHP) and unpretreated soda-anthraquinone (AQ) (SP) pulps were characterized by yield, Kappa number, alpha, beta, and gamma cellulose, degree of polymerization, water retention value, and crystallinity. The nanocellulose was produced by a sequential chemical oxidation treatment (2,2,6,6-tetramethylpiperidine-1-oxyl, TEMPO reagent) and mechanical nanofibrillation. Nanocellulose was characterized by carboxylic group content and viscosity. The results revealed that autohydrolysis pretreatment resulted in a higher hemicelluloses extraction in G. angustifolia. In contrast, the pulping yield of unpretreated samples was higher for G. trinii, and the soda-AQ pulps from this species exhibited better delignification than the autohydrolysis-pretreated pulps. The crystallinity index values of the obtained pulps were high (>80%), and the alpha-cellulose contents were similar. The viscosities of the aqueous nanocellulose suspensions were higher for the nanocellulose solutions obtained from the unpretreated soda-AQ pulps. Besides, nanocellulose from G. trinii unpretreated soda-AQ pulps had a higher rate of carboxylic groups. The results of this work are significant in assessing the potential of both bamboo species as a source of high-value products within the biorefinery framework because the viscosities of the aqueous nanocellulose suspensions depend on the size and shape of nanofibrils. It has significant importance for industrial unit operations and potential applications.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools