Open Access

Open Access

ARTICLE

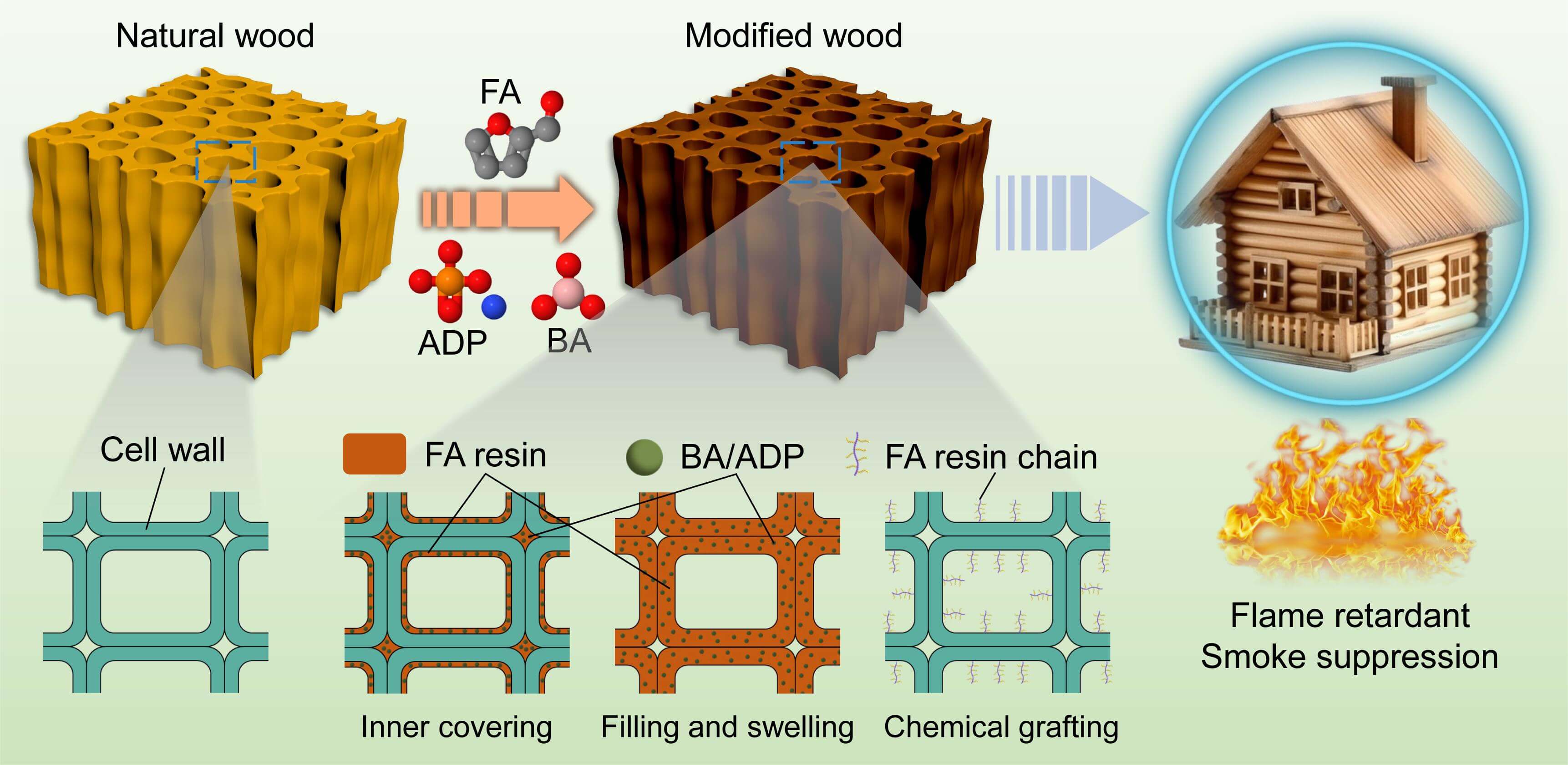

Biobased Furfurylated Poplar Wood for Flame-Retardant Modification with Boric Acid and Ammonium Dihydrogen Phosphate

1 College of Materials Science and Engineering, Central South University of Forestry and Technology, Changsha, 410004, China

2 College of Furniture and Art Design, Central South University of Forestry and Technology, Changsha, 410004, China

* Corresponding Authors: Yiqiang Wu. Email: ; Yingfeng Zuo. Email:

Journal of Renewable Materials 2024, 12(8), 1355-1368. https://doi.org/10.32604/jrm.2024.054050

Received 17 May 2024; Accepted 29 May 2024; Issue published 06 September 2024

Abstract

Furfurylated wood exhibits excellent dimensional stability and corrosion resistance, making it a promising material for constructing buildings, but it is highly flammable. Herein, flame-retardant furfurylated poplar wood was produced via a two-step process utilizing boric acid (BA) and ammonium dihydrogen phosphate (ADP) as flame-retardant components, and biomass-derived furfuryl alcohol (FA) as a modifier. The acidity of BA and ADP allowed them to catalyze the polymerization of FA, which formed a cross-linked network that immobilized BA and ADP inside the wood. The addition of BA/ADP substantially delayed the time to ignition from 10 to 385 s and reduced the total heat release and total smoke release by 58.75% and 77.31%, respectively. Analysis of the pyrolysis process showed that the decomposition products of BA and ADP protected the underlying furfurylated wood and diluted combustible gases. This method significantly improved the fire retardancy and smokeless properties of furfurylated wood, providing promising prospects for its application as an engineering material.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools