Open Access

Open Access

ARTICLE

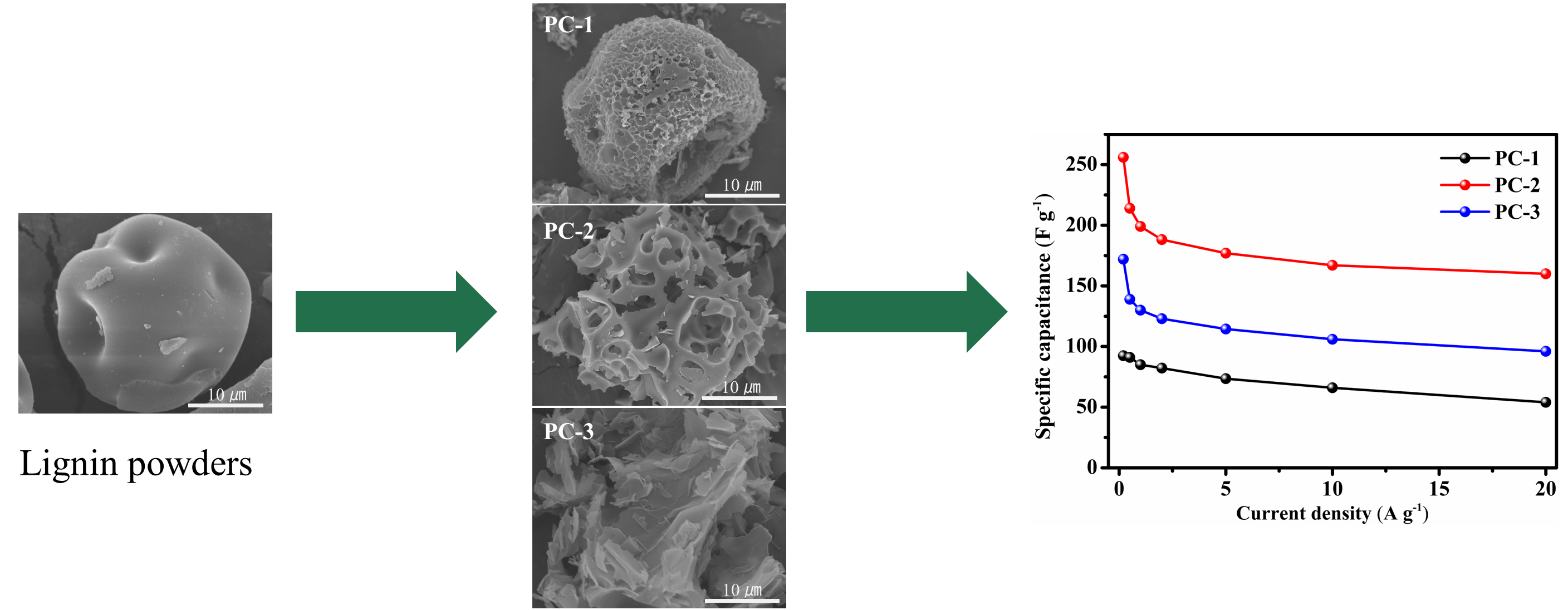

Conversion of Lignin into Porous Carbons for High-Performance Supercapacitors via Spray Drying and KOH Activation: Structure-Properties Relationship and Reaction Mechanism

1 Zhejiang Key Laboratory of Data-Driven High-Safety Energy Materials and Applications, Ningbo Key Laboratory of Special Energy Materials and Chemistry, Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, Ningbo, 315201, China

2 Engineering Laboratory of Advanced Energy Materials, Qianwan Institute of CNITECH, Ningbo, 315336, China

3 School of Physics, Henan Normal University, Xinxiang, 453007, China

4 School of Environment, Henan Normal University, Xinxiang, 453007, China

* Corresponding Authors: Qin Ouyang. Email: ,

; Qing Huang. Email:

Journal of Renewable Materials 2024, 12(7), 1207-1218. https://doi.org/10.32604/jrm.2024.052579

Received 07 April 2024; Accepted 27 May 2024; Issue published 21 August 2024

Abstract

Lignin-derived porous carbons have emerged as promising electrode materials for supercapacitors. However, the challenge remains in designing and controlling their structure to achieve ideal electrochemical performance due to the complex molecular structure of lignin and its intricate chemical reactions during the activation process. In this study, three porous carbons were synthesized from lignin by spray drying and chemical activation with varying KOH ratios. The specific surface area and structural order of the prepared porous carbon continued to increase with the increase of the KOH ratio. Thermogravimetric-mass spectrometry (TG-MS) was employed to track the molecular fragments generated during the pyrolysis of KOH-activated lignin, and the mechanism of the thermochemical conversion was investigated. During the thermochemical conversion of lignin, KOH facilitated the removal of H and CO, leading to the formation of not only more micropores and mesopores, but also more ordered carbon structures. The pore structure exhibited a greater impact than the carbon structure on the electrochemical performance of porous carbon. The optimized porous carbon exhibited a capacitance of 256 F g at a current density of 0.2 A g, making it an ideal electrode material for high-performance supercapacitors.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools