Open Access

Open Access

REVIEW

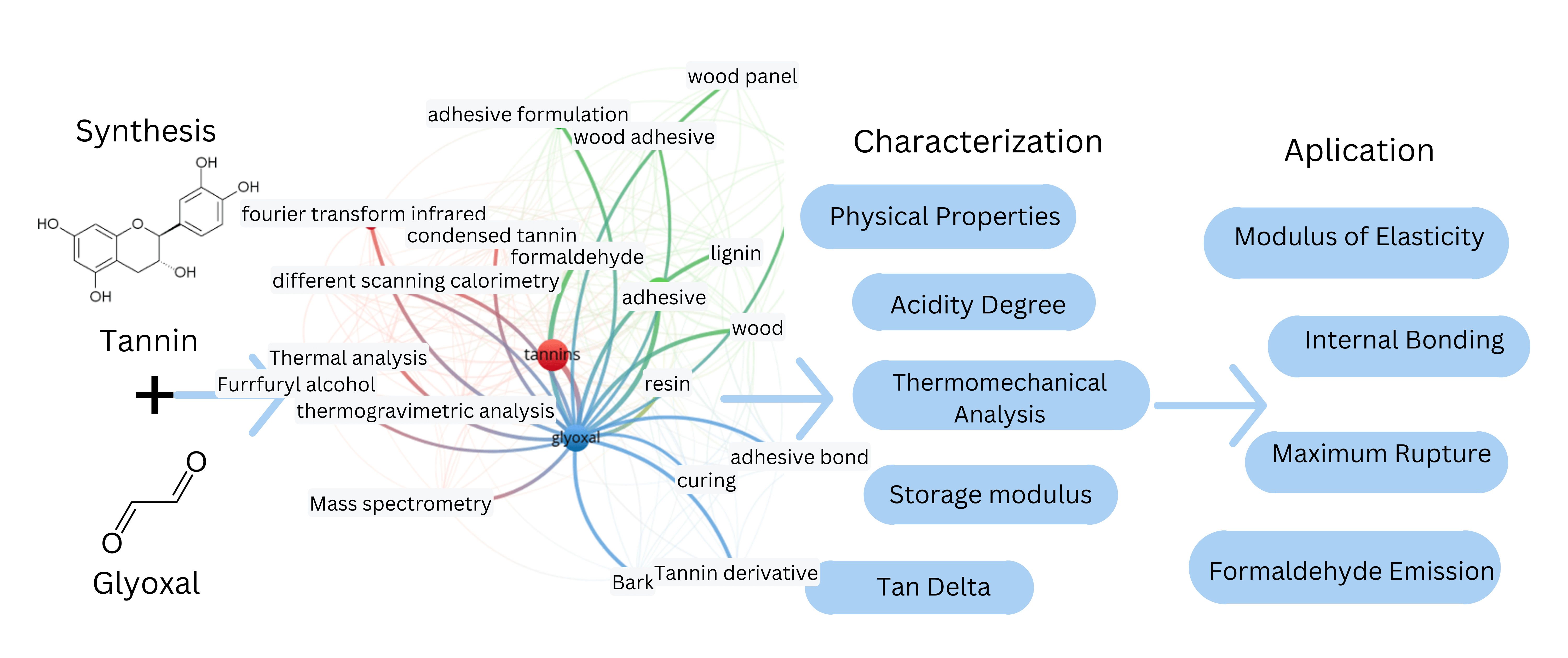

Overview of the Synthesis, Characterization, and Application of Tannin-Glyoxal Adhesive for Wood-Based Composites

1 Research Center for Biomass and Bioproducts, National Research and Innovation Agency, Cibinong, 16911, Indonesia

2 Department of Forest Products, Faculty of Forestry and Environment, IPB University, Bogor, 16680, Indonesia

3 Department of Agro-Industrial Technology, Universitas Padjadjaran, Bandung, 45363, Indonesia

4 Research Collaboration Center for Biomass and Biorefinery, BRIN and Universitas Padjadjaran, Bandung, 45363, Indonesia

5 School of Life Sciences and Technology, Institut Teknologi Bandung, Bandung, 40132, Indonesia

6 Department of Forest Products Technology, Faculty of Forestry, Universitas Sumatera Utara, Medan, 20355, Indonesia

* Corresponding Author: Muhammad Adly Rahandi Lubis. Email:

(This article belongs to the Special Issue: Environmentally Friendly Wood-Based Composites Based on Sustainable Technologies and Renewable Materials)

Journal of Renewable Materials 2024, 12(7), 1165-1186. https://doi.org/10.32604/jrm.2024.051854

Received 17 March 2024; Accepted 03 July 2024; Issue published 21 August 2024

Abstract

More than a century after its initial synthesis, urea-formaldehyde (UF) resins still have dominant applications as adhesives, paints, and coatings. However, formaldehyde in this industry produces formaldehyde emissions that are dangerous to health. Scientists have spent the last decade replacing formaldehyde and phenol with environmentally friendly substances such as glyoxal and tannin to create bio-based adhesives. This review covers recent advances in synthesizing glyoxal tannin-based resins, especially those made from sustainable raw material substitutes and changes made to synthetic processes to improve mechanical properties. The efficacy of using tannin-glyoxal adhesives in producing wood-based composites has been proven. The glyoxylate reaction forms cross-linked bridges between the aromatic sites of the tannin and glyoxal molecular structures. Glyoxal tannin adhesive with a greater percentage of glyoxal than tannin will produce an adhesive with better characteristics. The gel time reduces as the hardener concentration rises from 7.5% to 15% when glyoxal is used in adhesives. However, excessive amounts of glyoxal will result in a decrease in viscosity values. Glyoxal exhibits faster delivery degradation when it reaches a maximum temperature of approximately 130°C, although it initiates the curing process slightly slower at 110°C. Adding glyoxal to tannin-based adhesives can improve the mechanical properties of composite boards. The wet shear strength of the resulting plywood is increased by 105.4% with the addition of 5-weight percent tannin-based resin with glyoxal as a cross-linker in Soy Protein Adhesive. With glyoxal as a hardener, the panels produced showed good internal bond strengths (>0.35 MPa) and met the international standard specifications for interior-grade panels.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools