Open Access

Open Access

REVIEW

A Review on the Advancement of Renewable Natural Fiber Hybrid Composites: Prospects, Challenges, and Industrial Applications

1 Center of Excellence Geopolymer & Green Technology (CEGeoGTech), Universiti Malaysia Perlis, Arau, 02600, Malaysia

2 Faculty of Chemical Engineering Technology, Universiti Malaysia Perlis (UniMAP), Arau, 02600, Malaysia

3 Department of Materials Engineering, University of Technology, Baghdad, 10070, Iraq

4 Department of Chemical Materials, University of Bagdad College of Education for Pure Science Ibn-Alhaitham, Baghdad, 10001, Iraq

5 Department of Computer Techniques Engineering, Al-Rafidain University College, Baghdad, 10001, Iraq

6 Faculty of Electronics Engineering Technology, Universiti Malaysia Perlis, Kampus Uniciti Alam Sg. Chuchuh, Perlis, 02100, Malaysia

7 Research Center (NANOCAT), University of Malaya, Kuala Lumpur, 50603, Malaysia

8 Institute of Nano Electronic Engineering, Universiti Malaysia Perlis, Perlis, 01000, Malaysia

9 Center for Global Health Research, Saveetha Medical College & Hospital, Saveetha Institute of Medical and Technical Sciences (SIMATS), Tamil Nadu, 602 105, India

* Corresponding Author: Mohammed Mohammed. Email:

Journal of Renewable Materials 2024, 12(7), 1237-1290. https://doi.org/10.32604/jrm.2024.051201

Received 29 February 2024; Accepted 13 June 2024; Issue published 21 August 2024

Abstract

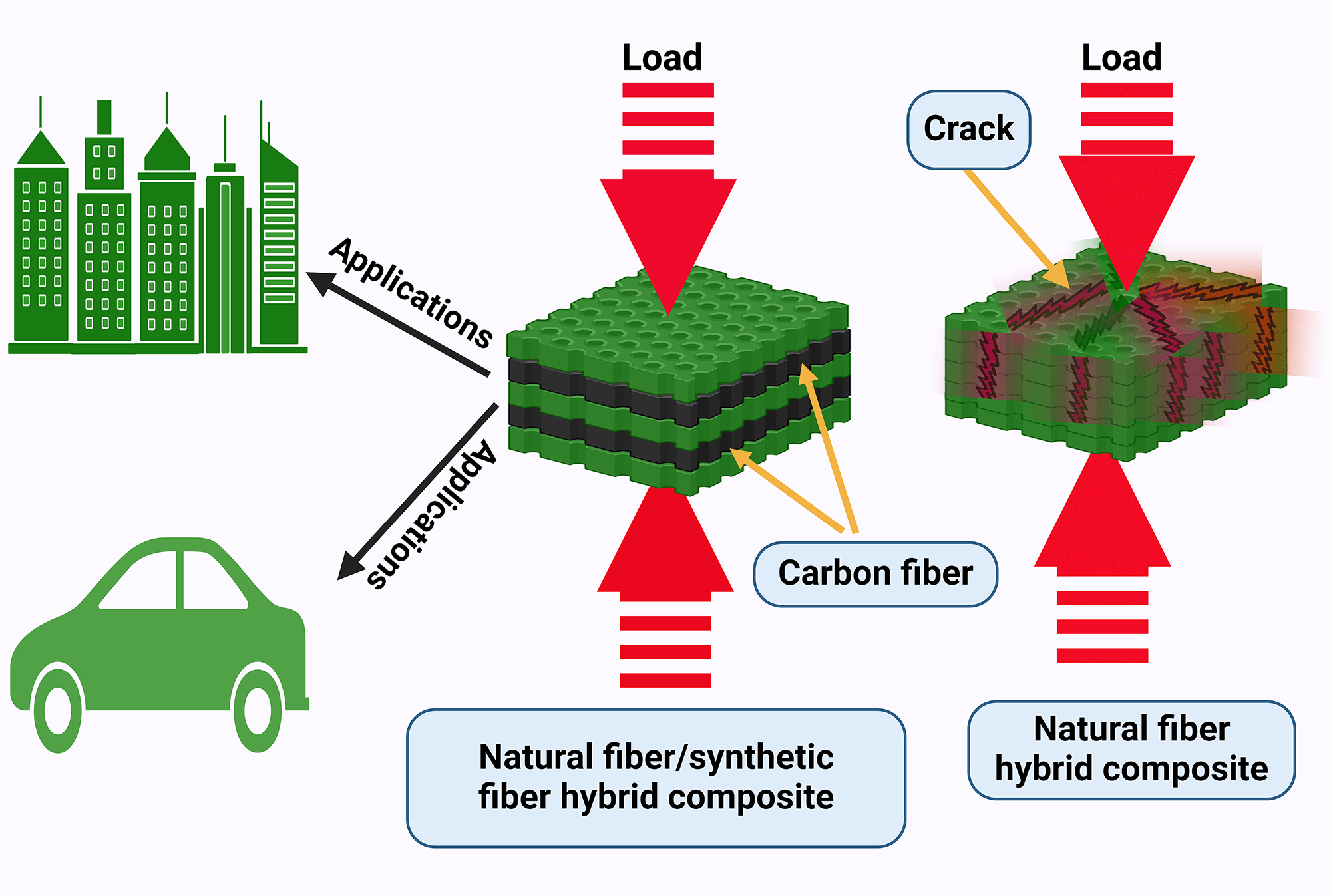

Natural fibre (NFR) reinforced functional polymer composites are quickly becoming an indispensable sustainable material in the transportation industry because of their lightweight, lower cost in manufacture, and adaptability to a wide variety of goods. However, the major difficulties of using these fibres are their existing poor dimensional stability and the extreme hydrophilicity. In assessing the mechanical properties (MP) of composites, the interfacial bonding (IB) happening between the NFR and the polymer matrix (PM) plays an incredibly significant role. When compared to NFR/synthetic fibre hybrid composites, hybrid composites (HC) made up of two separate NFR are less prevalent; yet, these hybrid composites also have the potential to be valuable materials in terms of environmental issues. A new dimension to the flexibility of composites reinforced with NFR is added by the cost-effective manufacture of hybrid composites utilising NFR. The purpose of this study is to offer an overview of the key findings that were presented on hybrid composites. The emphasis was focused on the factors that influence the performance of the natural fiber composites, diverse approaches to enhancing MP, physical, electrical, and thermal characteristics of the HC. HC study in polymer science gains interest for applications in construction and automotive industries.Graphic Abstract

Keywords

Nomenclature

| NFR | Natural fibre |

| MP | Mechanical properties |

| IB | Interfacial bonding |

| PM | Polymer matrix |

| HC | Hybrid composites |

As per Akter et al.’s [1] research, increasing environmental activism, the imperative to protect natural resources, and the increasing severity of regulations enacted by developing nations have all contributed to the inception and growth of natural materials that emphasize the use of renewable resources. All of these aspects were important contributors to the discovery and advancement of natural materials [2–4]. Companies that manufacture composites need to look for plant-based NFR reinforcements such as flax, hemp, sisal, kenaf, and banana in order to provide an alternative to solid wood as a material that will be used in their products. These are all examples of plant-based natural fibres. The fact that lignocellulosic fibres are made from renewable resources that also have a strong attraction to consumers gives them an edge. NFR reinforced polymer composites have been utilized in a broad variety of uses and purposes, including the automotive and aerospace industries, the sports goods market, and the construction sector. “Recent years” have seen “increased application” of NFR reinforced polymer composites in the construction of bridges and buildings [5,6]. Their popularity stems from the beneficial attributes of these materials, such as their lightweight nature, superior strength, outstanding formability, and strong resistance to corrosion and fatigue.

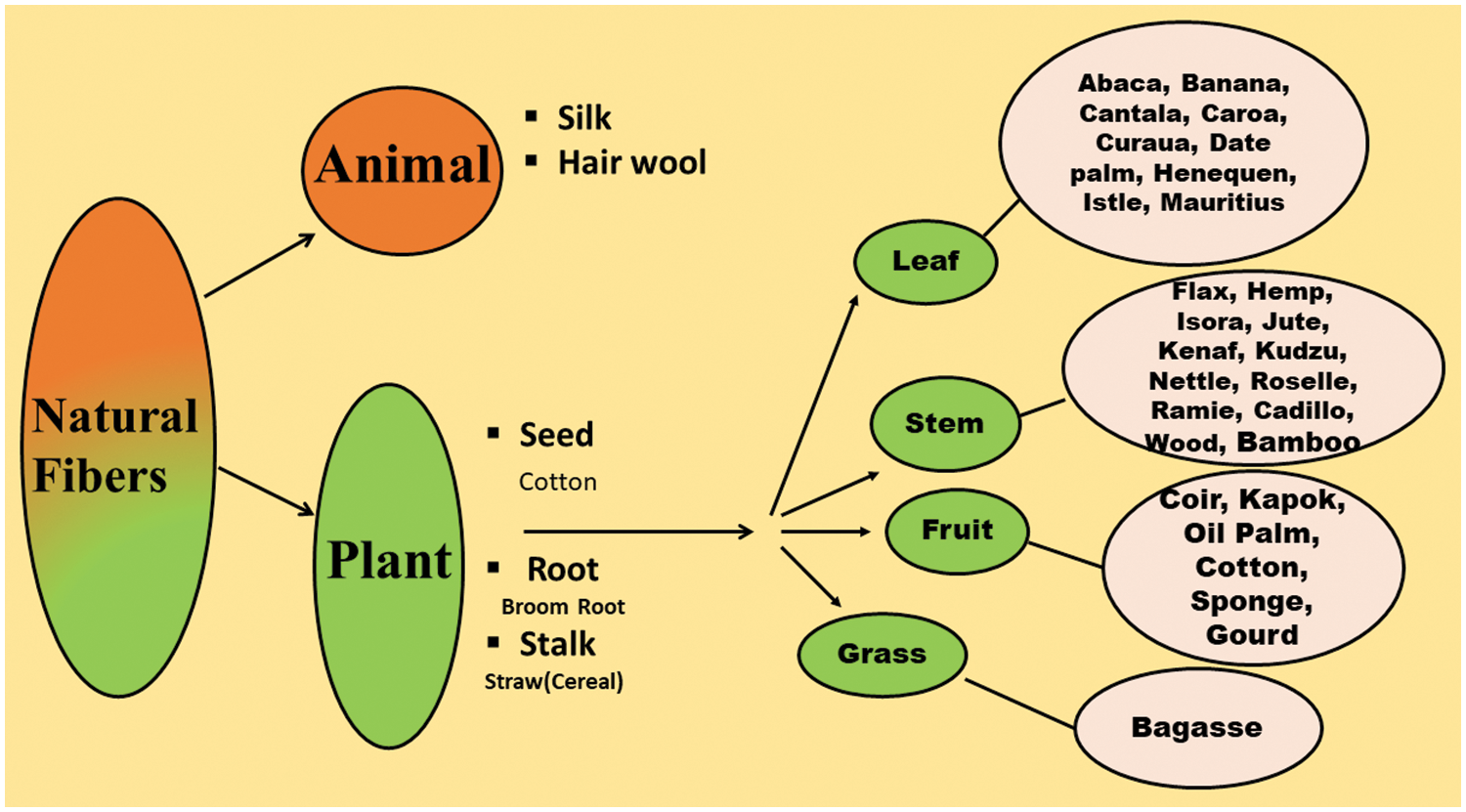

Cotton, pulp, bark, wood, bagasse, and vegetables are some of the numerous forms of natural fibres that may be distinguished from one another based on their respective sources. Cellulose, hemicelluloses, pectins, lignin, and a trace amount of extractives make up the majority of these natural fibres [7,8]. Fig. 1 is a diagrammatic representation of the structural organisation of the three principal elements of the fibre cell wall. The many types of natural fibres are broken out in Fig. 2. Natural fibers, when compared to synthetic ones, provide several benefits including wide availability, cost-effectiveness, recyclability, renewability, biodegradability, low density, advantageous aspect ratios, and considerable strength [9,10]. Natural fibres also have a desirable aspect ratio and moderate strength. NFR composites have the potential to be a material that is both cost-efficient and environmentally friendly, particularly when it comes to automotive body panels, interior designs, construction and industrial panels, as well as false ceilings [11,12].

Figure 1: Chemical structure of natural fiber. The major components are indicated

Figure 2: Subdivision of natural fibers on the basis of origin. Potential preparations from the parts of plants are shown

Biofibers such as oil palm, kenaf, industrial hemp, flax, jute, wood, and multiple grasses are mixed with polymer matrices sourced from both non-renewable (petroleum-based) and renewable resources to manufacture composite materials. The last 10 years have seen a rise in interest in biocomposites due to their ability to compete well with synthetic composites such as glass-polypropylene and glass-epoxy mixtures. It has been shown that hybrid composites that are reinforced with cellulosic fibres may also display high mechanical characteristics [13,14]. These hybrid composites are quite frequently mixed with synthetic fibres such as glass fibres. Polymer composites with hybrid reinforcement that are purely composed of NFR are not very common; yet, these materials hold promise in tackling environmental issues effectively [15–17].

In addition, Plastics are by far the most popular alternative to wood products among the many different materials that may be manufactured. Plastics are used in almost every industry, ranging from simple household products to intricate engineering components. On the other hand, plastics are non-renewable and non-biodegradable [18]. Because the price of petroleum-based products is always going up and there is a shortage of these resources, it is necessary to find adequate alternatives in order to be ecologically conscious. Concerns like the possibility of biodegradation and recycling play a crucial part in the development of novel materials and goods. Natural fibres, as opposed to synthetic fibres, offer numerous advantages concerning both technological and environmental aspects [19,20]. The differences and similarities between NFR and glass fibres are laid out in Table 1.

Natural-synthetic fiber hybrid composites can provide better thermal, electrical, and acoustic properties in addition to their mechanical and environmental benefits [21]. For example, an HC constructed from NFR and carbon fibers can have excellent thermal conductivity, making it useful in applications where heat dissipation is important. Hybrid composites can also be engineered to have specific electrical properties, making them suitable for use in electronic components. Additionally, hybrid composites (HC) combining natural and synthetic fibers can be tailored to meet specific design requirements. By adjusting the fiber types, orientations, and proportions, it is possible to create materials that have the desired properties for a particular application [22]. This design flexibility makes hybrid composites particularly attractive for use in niche markets, where there may be a need for specialized materials with unique properties. Employing NFR-synthetic fiber HC also holds promise for diminishing the environmental footprint of manufacturing procedures. By substituting traditional materials with eco-friendly composites, it is possible to reduce the amount of waste generated and minimize the use of non-renewable resources. The significance of HC stems from its capability to offer a distinctive set of attributes unattainable with single-fiber composites [23]. They offer improved mechanical performance, reduced costs, and increased sustainability, making them an attractive option for a variety of applications. With ongoing research and development in the field, one can anticipate a growing array of innovative applications for these versatile materials [24].

The primary objective of this study is to provide a synopsis of the information that is currently known about the MP of HC. In the early stages, the discourse will include an examination of morphological attributes, structural components, various approaches to improve mechanical properties, and determinants that impact the properties of composites. Following this, a thorough investigation of the thermal and electrical characteristics of NFR composites and hybrids of these materials was carried out. The last topic is the practical use of NFR-reinforced hybrid composites, followed by a discussion of potential future developments. Table 2, presented below, offers a concise overview of the pros and cons associated with natural fiber composites.

2 Components of Natural Fibre Composites

Natural fibers are integral components of composite materials, functioning as the reinforcing phase that bestows the composite with distinct mechanical, thermodynamic, and environmental characteristics [3]. These fibers, which are obtained from a variety of sources including plants, animals, and minerals, provide a number of beneficial qualities that enhance those of the matrix material. Primarily, natural fibers improve the rigidity, strength, and impact resistance of composites, thereby enhancing their mechanical performance [4]. The intrinsically elevated tensile strength of these materials, specifically in regard to fibers such as flax, hemp, or jute, serves to fortify the composite framework, facilitating the efficient dispersion of strain and enhancing its capacity to sustain loads. Furthermore, the orientation and alignment of natural fibers within the matrix can be modified to maximize mechanical properties, thereby enhancing the composite material’s overall performance. In addition, natural fibers provide environmental advantages, which corresponds to the increasing market demand for sustainable and ecologically conscious materials. Originating from sustainable sources, these textiles possess the advantageous qualities of being biodegradable and recyclable, which positions them favorably among sectors endeavoring to diminish their ecological impact. Additionally, their diminished density aids in the formation of lightweight composite structures, which are highly sought after in sectors such as aerospace and automotive where weight reduction is of the utmost importance [4–6].

When considering the matrix materials utilized in the fabrication of composites, thermosetting and thermoplastic polymers are both extensively utilized. When heated, thermosetting resins (e.g., polyester, phenolic, and epoxy) endure irreversible curing reactions that result in the formation of a crosslinked network [8]. This network imparts the composite with superior mechanical properties and dimensional stability. For applications requiring resistance to high temperatures and superior mechanical performance, these resins are favored. Conversely, thermoplastic polymers, such as polypropylene, polyethylene, and polycarbonate, provide several benefits, including robustness, recyclability, and processing simplicity [9]. By virtue of their resistance to chemical degradation, these materials can be repeatedly transformed and melted, facilitating streamlined production processes and potentially enabling recycling at the conclusion of the product’s life cycle [11]. Numerous factors, including desired mechanical properties, processing specifications, cost considerations, and end-use applications, influence the selection of matrix material [16]. Through meticulous fiber selection and combination with suitable matrix materials, researchers and engineers possess the ability to customize composite materials in order to fulfill particular performance requirements while simultaneously adhering to sustainability objectives.

A composite is a material combination that is typically produced by a synthetic or natural assemblage of two or more components that are unique from one another both physically and chemically. The initial component consists of a specific filler or reinforcing agent, known as the discontinuous phase, while the secondary element is a matrix binder that is compatible with the first component. The purpose of combining these two components is to attain particular qualities and attributes [25]. Various unique types of NFR, matrices, and processing methods are employed in the production of composites.

2.1 Mechanical Properties of Natural Fibres

Natural fibers, which exemplify the resourcefulness of nature, have an inherent appeal that transcends their aesthetic value. These filaments, which have been intricately woven over time by the hand of evolution, contain an abundance of mechanical properties that intrigue both scientists and engineers. Commencing an exploration of the captivating domain of natural fibers unveils a realm where the convergence of durability, adaptability, and strength culminates in a magnificent display of material expertise. At the heart of natural fibers lies an exquisite balance of tensile strength and flexibility, virtues honed over millennia of evolutionary refinement. From the sinewy sinews of flax to the resilient tendrils of hemp, each fiber exhibits a unique blend of mechanical prowess, forged through the crucible of nature’s ceaseless innovation. Furthermore, the natural fibers’ hierarchical structure provides an ideal foundation for an intricate web of mechanical marvels. At the macroscopic level, fibers exhibit exceptional tensile strength, which enables them to withstand tremendous burdens without undergoing deformation. However, a more thorough analysis reveals that they possess an immense amount of resilience due to the intermolecular bonds and crystalline domains that collaborate to reinforce their structural integrity. Moreover, natural fibers exhibit an innate capacity for moisture absorption and thermal regulation, attributes that imbue them with unparalleled versatility in a myriad of applications. Whether reinforcing composite materials or adorning haute couture, natural fibers seamlessly adapt to the demands of their environment, embodying the epitome of sustainable elegance [26–28].

NFR derived from plants are lignocellulosic by their very nature and are constructed of components such as cellulose, hemicelluloses, lignin, pectin, and waxy compounds. Table 3 provides an overview of the structural components that make up fibres. Cellulose is regarded as the principal component of the framework that makes up the fibre structure. It gives the fibre strength and rigidity, which contribute to its structural stability. The chemical structure of cellulose is composed of three hydroxyl (OH) groups. Two of them make hydrogen bonds inside the cellulose macromolecules, which is referred to as an intramolecular hydrogen bond, while the remainder of the group establishes hydrogen bonds with other cellulose molecules, which is referred to as an intermolecular hydrogen link [26]. Hemicellulose primarily exists in the main cell wall and consists of branched polymers with diverse chemical structures incorporating five and six carbon sugars. Lignin is amorphous and features an aromatic structure [27,28]. Pectin is composed of intricate polysaccharides with side chains cross-linked by calcium ions and arabinose sugars. Furthermore, the fiber structure contains minor amounts of organic (extractives) and inorganic (ash) components. The colour, odour, and decay resistance of a fibre may be attributed to organic extractives, whereas the abrasive quality of the fibre can be enhanced by inorganic elements. The concept of the structural arrangement of the three fundamental structural components comprising the cell wall of a natural fiber is illustrated in Fig. 3, which contains micrographs of the fiber’s structure. Fig. 4 is a diagrammatic representation of the NFR. Cellulose microfibrils, which are the building blocks of cellulose, each have their own unique cell shape, which is one of the contributing factors that determine the characteristics of the fibre [29]. The cellulose microfibrils that make up the primary and secondary layers of each fibre cell wall are what make up each fibre cell wall. The main cell wall is responsible for the development of the fibre structure, which is then deposited as the cell wall continues to expand. The secondary wall is composed of three layers, with a protracted sequence of helical cellulose microfibrils situated within each layer [30].

Figure 3: SEM micrographs showing natural fiber composition. Lumen and walls are indicated

Figure 4: Diagrammatic depiction of natural fiber composition. The representative parts are displayed

The percentage of cellulose continuously rises as one move from the primary to the secondary layers, but the proportion of hemicellulose remains relatively constant throughout. Lignin content, on the other hand, drops as you go through this process. The formation of cementing materials for the fibre structure is accomplished by the creation of hydrogen bonds between molecules of hemicellulose and fibrils of cellulose. Pectin and lignin are attached to the cellulose and hemicellulose networks, which gives the network an adhesive characteristic that keeps the molecules together. Because of its adhesive characteristics, the fibre has both a high level of strength and a high level of stiffness. The secondary thick layer, often known as S2, is what defines the fibre’s mechanical characteristics. In general, NFR with a greater cellulose content and a smaller microfibrillar angle (the angle between the fibre axis and cellulose microfibrils) have superior qualities in terms of their tensile strength [31–34]. The distinct modulus and elongation at break of NFR suggest their potential to supplant synthetic fibers in engineering polymer composites. Despite the considerably lower strength characteristics of natural fiber reinforced (NFR) materials compared to synthetic fibers, their potential remains undeniable.

A matrix serves as a binding material that maintains the fibers in place and transfers external forces to internal reinforcements. Thermoset and thermoplastic matrices are widely utilized in NFR reinforced polymer composites for various functions [35,36]. Examples of thermoset matrices include unsaturated polyesters, epoxies, and phenolics, while examples of thermoplastic matrices include polypropylenes, polyethylenes, and elastomers. These matrices each have their own unique chemical structure, and their interactions with the surface molecules of the fibres that make up composites may take a variety of forms. Matrix creates a considerable impact on the MP of composites because it performs a significant part in (a) holding the fibers at its place, (b) fiber protection from the environmental changes, (c) stress transfer among the fibers, (d) orienting the fibers, and (e) providing the texture, color and surface quality [37]. Matrix material should be carefully selected to achieve good interfacial bonds between the matrix and fibers. An adequate number of matrix-fiber interactions results in achieving better mechanical properties. Weak interface results in fiber pull out, fiber breakage, cracks in the matrix materials. Matrix material should be selected based on its compatibility with the fibers. The matrix should be thermally compatible to avoid the formation of residual stresses occurred due to variance in the thermal expansion of matrix and fibers. Good fiber-matrix IB shows the physical compatibility of the matrix material. The differences and similarities between thermoset and thermoplastic matrices are laid forth in Table 4. Fig. 5 shows the classification of composites based on materials.

Figure 5: Categorization of composite materials based on matrix and reinforcement

Production techniques specifically designed for natural fiber composites combine the elegance of conventional handiwork with the accuracy of contemporary engineering. These techniques skillfully utilize the inherent qualities of natural fibers and skillfully incorporate them into intricate structures. These methods, which embrace adaptability and sustainability, open the door to environmentally responsible innovation in materials science. One such process is compression molding, an age-old technology that forms a composite mixture under extreme heat and pressure to create a finished product that is both elaborately patterned and robust. Optimal dispersion within the matrix and improved mechanical qualities are fostered by this approach, which takes use of the pliability and robustness of natural fibers [38].

Natural fiber composites are expertly shaped into a variety of shapes via extrusion, another manufacturing mainstay, from thin profiles to complex geometries. Extrusion carefully regulates temperature and pressure to bring fibers and matrices into a harmonious union, producing products that are remarkably resilient and strong. Utilizing state-of-the-art technology, novel techniques such as vacuum infusion and resin transfer molding (RTM) allow natural fibers to be mixed with resins to create composite structures that are incredibly precise and consistent. By carefully balancing the flow dynamics of resins with the permeability of natural fibers, these techniques produce items that are both aesthetically pleasing and highly engineered. In general, the processing methods for NFR composites are conceptually comparable to the processing methods used for processing synthetic fibres. Reinforcements may be made out of fabrics that are either randomly oriented (short), unidirectional (raw and carded), or woven. These types of fabrics can be utilised in either thermoset or thermoplastic matrices. The kind of reinforcement employed relies on the length of the fibre, its orientation, and the type of fibre. “hand layup” is the term used to describe the fundamental production procedure for thermoset composites [38]. The fibre and the matrix will be mixed together by hand at this step of the process. The level of craftsmanship used in this process determines the degree to which the composite will be homogeneous across the sample with regard to its thickness, the ratio of fibres to matrix, and the amount of empty space.

Pultrusion is an additional process that may be utilised for both thermosets and thermoplastics [39]. In the field of composite production, pultrusion stands out as a superb combination of artistic expression and technical accuracy. This painstaking procedure, well regarded for its adaptability and efficiency, embraces thermosets as well as thermoplastics, offering countless opportunities for material synthesis and structural design. At its core, pultrusion embodies a symphony of controlled forces and meticulous attention to detail. Fibers, meticulously arranged in precise orientations, embark on a transformative journey through a resin bath, where they become ensconced in a matrix of polymers, entrusting their strength and resilience to the alchemy of chemical bonding. Pultrusion, at its essence, comprises a harmonious integration of regulated forces and scrupulous attention to detail. Fibers, which have been arranged in exact orientations with great attention to detail, undergo a profound transformation as they are submerged in a resin bath. Within this matrix of polymers, the fibers place their strength and resilience in the hands of chemical bonding. Moreover, the versatility of pultrusion transcends conventional boundaries, offering a canvas upon which designers and engineers may unleash their creativity with unrestrained fervor. From slender rods to intricate profiles, pultrusion molds the raw essence of materials into captivating shapes and structures, each bearing the indelible imprint of meticulous craftsmanship and technological prowess [39,40]. The production of the composite profile is achieved when the reinforcement is drawn through a heated die and then fused with the matrix. Composite fabrication utilizes both compression molding, which involves merging the reinforcement with the matrix before pressing it with a heated plate, and injection molding, where granules of fiber-resin are loaded into the machine, melted into a liquid mass, and then forcibly injected into the mold under high pressure [40]. These procedures require elevated temperatures (above 200°C) and high pressures (5 MPa) for the accomplish reaction between the NFR and the PM. Fig. 6 depicts the process of pultrusion.

Figure 6: Schematic representation of pultrusion process. The complete steps are shown

Furthermore, the manufacture of natural fiber composites has a fascinating new horizon thanks to additive manufacturing, which has limitless creative potential. Through the meticulous layering of fibers and resins, additive manufacturing surpasses traditional constraints, providing designers with unmatched flexibility to actualize their ideas while reducing waste and optimizing productivity. The production techniques developed specifically for natural fiber composites are, in essence, a harmonious union of tradition and innovation; they combine traditional craftsmanship with state-of-the-art technology to create a future that is both resilient and sustainable. These techniques serve as guiding lights of inventiveness as we make our way through the complex field of materials science, leading us toward a future where form and function coexist peacefully.

3 A Summary of Hybrid Polymer Composites Strengthened with Natural Fibers

A hybrid composite material is defined as the amalgamation of two or more reinforcing components in a single matrix, or a blend of multiple matrices with a single reinforcing component. The physical attributes and MP of HC are impacted by various elements such as the fiber aspect ratio, individual fiber attributes, fiber orientation, individual fiber length, IB between the fiber and the PM, and the stacking order of both fibers [41]. The characteristics of HC comprising two elements can be calculated using the rule of mixtures [42], as demonstrated in Eqs. (1) and (2).

In this case, PH represents the property under examination, while P1 and P2 correspond to the respective characteristics of the first and second elements. V1 and V2 denote the volume fractions of the first and second elements, respectively. Most of the research concerning NFR reinforced HC aims to examine the strength attributes in correlation to factors like fiber loading, fiber length, fiber dispersion, fiber alignment, the sequence of fiber layering, the impact of different chemical modifications on NFR, the application of coupling agents, choice of PM, and the interaction between NFR and PM. These studies aim to improve the understanding of how strength varies based on these factors. Researchers [43] examined the influence of fiber loading, ratio, and chemical modification on the MP of sisal and oil palm fiber reinforced natural rubber hybrid composites. It was determined that the longitudinal direction of the composite had the greatest amount of its mechanical qualities, as opposed to the transverse direction. After the fibres were treated with alkali, it was discovered that the IB strength between the natural fibre and the rubber matrix increased. Therefore, the alkali treated fibres displayed the highest possible tensile strength in comparison to the untreated fibre composites.

The hybrid composites were made by combining three distinct fibres, including sisal, jute, and glass, with an epoxy resin in a weight ratio of 30:70 between the fibres and the matrix [44]. A variety of different combinations of composite materials were manufactured in alignment with the ASTM standard and then subjected to tests to determine their mechanical qualities, such as tensile and impact strengths. In comparison to other combinations, the tensile and impact strengths of the HC made of sisal, glass, and epoxy were determined to be the highest. The MP of silk fabric reinforced epoxy composites have been examined, and a minor quantity of glass fibre has been found to be present. The MP of the silk fibre reinforced composites were significantly enhanced by including a trace amount of glass fabric in the mixture. According to the findings, the improvement in the material’s mechanical characteristics was proportional to the weight fraction of fibre content’s greatest degree of increase. They also discovered that the process of hybridization resulted in a decrease in the composites’ ability to absorb water [45].

As a function of the volume percentage of fibre, the luffa fibre and ground nut reinforced epoxy HC that were made by hand lay-up processes. They discovered that composites with a treated fibre content of 40% displayed greater levels of maximal mechanical characteristics than luffa groundnut polymer composites with fibre percentages of 30% and 50%, respectively. Because there was inadequate wetting between the NFR and the PM, the strength was found to be lowest when the fibre content was 50% [46]. The oil palm empty fruit bunches and jute fibres strengthen epoxy matrix HC have been put through a tensile test. When compared to oil palm empty fruit bunches fibres employed by themselves, the tensile strength and modulus of oil palm empty fruit bunches/jute fibre HC were shown to have significantly improved. During the SEM investigation, the hybrid composites demonstrated superior adherence to the matrix in comparison to the pure oil palm empty fruit bunches fibre composite [47].

The term “hybrid” has its roots in both Greek and Latin, and it is now used in a wide variety of scientific contexts. When it comes to polymer composites, HC are defined as these types of systems in which either one kind of reinforcing material is inserted in a combination of multiple matrices (blends) [48], two or more reinforcing and filling materials are exist within a single matrix [49,50], or both techniques are combined. The production of hybrid composites has been made possible via the combination of two or more kinds of lignocellulosic fibres with a single matrix. The performance of HC may be thought of as the weighted total of the separate components, with the goal being to strike a more advantageous balance between the inherent benefits and drawbacks of each component. When utilizing a HC that consists of two or more different forms of fibre, the benefits of one type of fibre may be able to supplement what are missing in another type of fibre. As a direct result of this, it is possible, with the use of appropriate material design, to strike a balance between cost and performance [51]. The robustness of HC is dependent on several elements including the properties of the fiber, the ratio of fiber content in relation to its aspect, the individual fiber length, direction of fiber alignment, the degree of fiber intertwining, the IB between fiber and PM, and the configuration of both fibers, not forgetting the stress level at which each fiber breaks. The hybrid outcomes are maximised when the fibres are extremely compatible with one another in terms of strain [52].

5 Influential Factors on Composite Characteristics

The cellulose structure of fibers consists of both crystalline and amorphous regions, which can be distinguished from one another. The crystallite region facilitates the formation of numerous strong hydrogen bonds within the molecules, leading to the creation of cellulose blocks that are more resistant to penetration by other chemicals. Conversely, the amorphous region demonstrates a high capacity for absorbing colors and resins. Fig. 7 illustrates the schematic representations of crystalline and amorphous region of cellulose. Water molecules from the surrounding environment mingle with hydrophilic hydroxyl groups that are existing in this region. These water molecules may be stored in a normal condition by substances including hemicellulose, lignin, pectin, and waxy substances. As a result, the fibre develops hydrophilic and polar properties, which lessens its compatibility with the non-polar and hydrophobic matrix [53–55]. In order to obtain the desired results with natural fibre, chemical modification is required. These effects include the enlargement of the crystalline area, the elimination of the hydrophilic hydroxyl groups, and the cleaning of surface impurities (waxy substances). Chemical modifications such as mercerization, acetylation, benzoylation, and coupling agents are frequently employed, either with or without the application of heat, in order to modify the surface of the NFR as well as the structure of the NFR.

Figure 7: Schematic representations of crystalline and amorphous region of cellulose

5.2 Thermal Stability of Fibres

Thermal stability is a crucial property of natural fibers, as it determines their ability to withstand or resist decomposition at elevated temperatures. NFR such as cotton, flax, hemp, jute, sisal, and silk are commonly utilized in various applications, including textiles, automotive, construction, and composite materials. In this scenario, comprehending the thermal stability of these fibers is crucial [56]. In most cases, the temperature at which natural fibre begins to degrade is about 240°C. The structural components of the NFR, such as cellulose, hemicelluloses, and lignin, among other things, are sensitive to a wide range of temperatures. According to some reports, the degradation of lignin begins at a temperature of around 200°C, whereas the degradation of hemicelluloses and cellulosic components occurs at higher temperatures [57]. It is possible to improve the fibre’s thermal stability by eliminating a particular amount of the hemicelluloses and lignin elements of the material using one of many different chemical treatments. Both throughout the production process (curing, extrusion, or injection moulding), as well as when the composites are being used in service, the degradation of NFR might be a significant problem for the progression of composites [58,59]. Fig. 8 demonstrates the degradation steps and their effect on the natural fiber.

Figure 8: The degradation steps and their impact in natural fiber polymer composite

Numerous elements influence the thermal stability of NFR, including their chemical composition, crystallinity, and moisture content.

• Chemical composition: NFR are predominantly composed of cellulose, hemicellulose, lignin, pectin, and waxes. Cellulose contributes to the fiber’s strength and stiffness, while hemicellulose and lignin provide thermal stability. The ratio of these components varies across different natural fibers, thus affecting their thermal stability. Generally, fibers with higher cellulose and lignin content exhibit better thermal stability [60].

• Crystallinity: The degree of crystallinity in natural fibers impacts their thermal stability. Higher crystallinity results in improved thermal stability due to the increased organization of cellulose chains, making it more difficult for them to degrade when exposed to heat. Fibers with a higher degree of crystallinity, such as flax and hemp, exhibit better thermal stability than those with a lower degree of crystallinity, like cotton and jute [61].

Moisture content: Natural fibers tend to absorb moisture from the surrounding environment, which can influence their thermal stability. High moisture content can lead to a lower thermal stability, as the absorbed water can act as a plasticizer and weaken the fiber structure. Hence, it is crucial to take into account the moisture content of NFR when assessing their thermal stability [62].

5.3 Fibre Length, Loading and Orientation

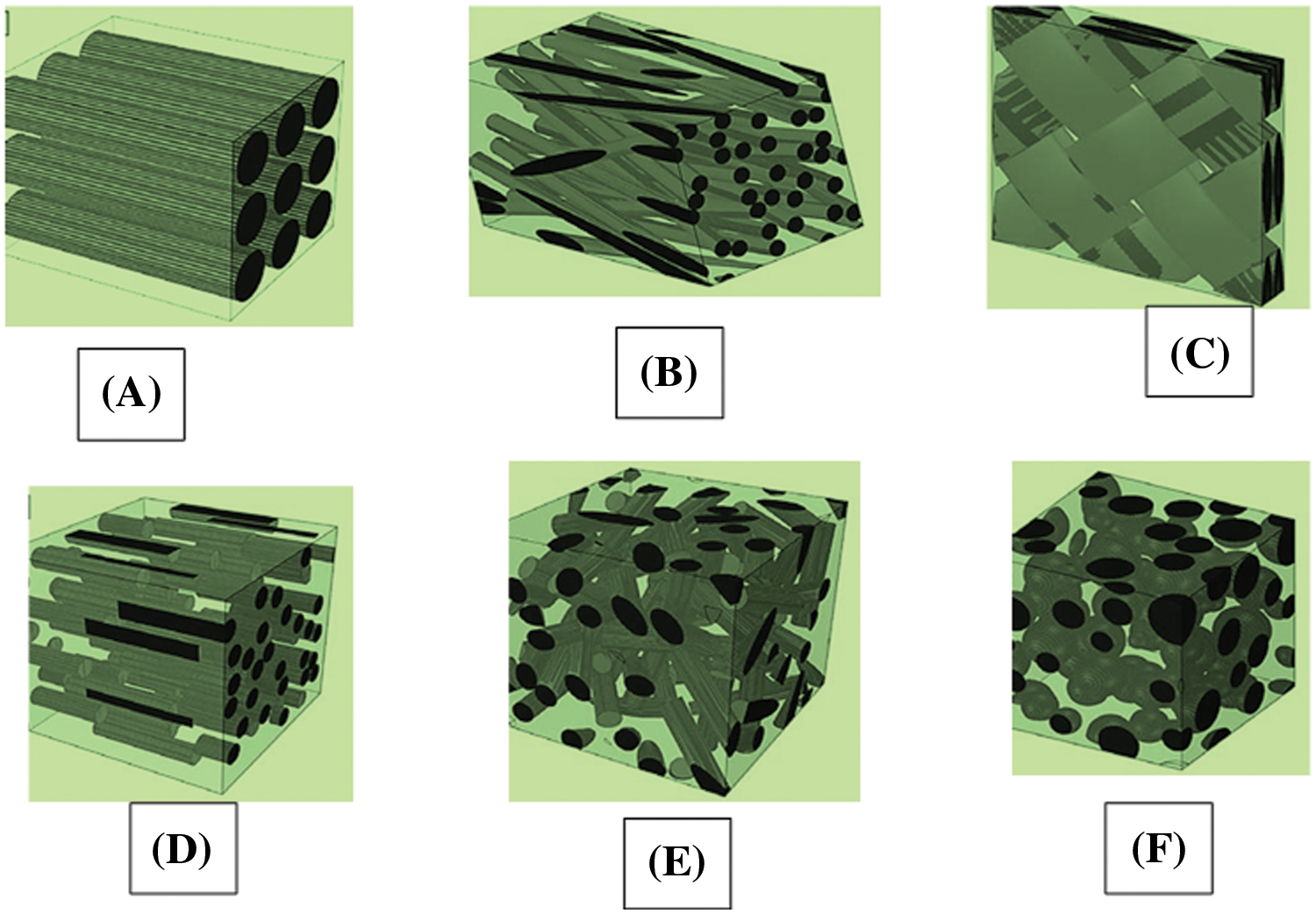

Natural fibers possess unique properties that make them suitable for various applications, particularly in composite materials. Three key aspects that influence their performance are length, loading, and orientation. The length of natural fibers affects their MP, such as tensile strength and stiffness. Longer fibers have better stress transfer and load-bearing capabilities due to the increased aspect ratio, which is the ratio of length to diameter. However, longer fibers can also lead to difficulties in processing and handling. Therefore, an optimal fiber length needs to be determined based on the specific application and composite requirements [63]. In addition, the amount of fibers incorporated into a composite, also known as the fiber loading, significantly impacts the overall mechanical properties [64,65]. Higher fiber loading generally leads to increased stiffness and strength of the composite, since a bigger proportion of the load is carried by the fibres. However, too much fiber can also compromise the material’s durability and workability. Consequently, it is crucial to balance fiber loading to attain the required characteristics without compromising the composite’s performance [66]. Furthermore, the direction and alignment of fibers within the matrix can greatly influence the MP of the composite. Unidirectional fibers, where all fibers are aligned in a single direction, can provide high strength and stiffness along the alignment direction but may lack in other directions. On the other hand, random or multidirectional fiber orientation can offer more balanced properties across all directions, but at the expense of overall strength and stiffness. Designers need to consider the specific application and stress distribution requirements when selecting the appropriate fiber orientation for a composite material [67]. These factors need to be carefully considered and optimized for each specific application to ensure the best possible results [68–70]. Fig. 9 shows classification of composite materials based on type of reinforcement. Fig. 10 shows schematic view of composite reinforcements.

Figure 9: Classification of composite materials based on type of reinforcement

Figure 10: Schematic view of composite reinforcements: (A) unidirectional continuous fibers (B) multidirectional continuous fibers (C) bidirectional continuous fibers (D) aligned short fiber (E) random short fibers (F) particles

The existence of voids in natural fiber polymer composites can substantially impact the MP of these materials. Voids are empty spaces or air pockets that can form within the composite structure during processing or fabrication. These imperfections can arise due to various factors, such as fiber-matrix incompatibility, uneven distribution of NFR, insufficient wetting of NFR by the matrix, or the release of volatile components during curing. The presence of voids can lead to a decline in the overall strength and stiffness of the composite material [71]. Voids interrupt the load-bearing capacity of the NFR and compromise the fiber-matrix IB, which results in decreased stress transfer between the NFR and the PM. This can lead to premature failure of the material under load. Voids function as stress focal points, enhancing the probability of crack beginning and spread in the composite material. This results in a lower fracture toughness, making the composite more susceptible to failure under impact or fatigue loading conditions [72]. Furthermore, the presence of voids can negatively affect the long-term durability and efficiency of NFR composites [73]. Voids can allow the ingress of moisture, leading to fiber swelling, matrix degradation, and increased susceptibility to environmental factors such as UV radiation and temperature fluctuations. This can result in a reduced service life of the composite material. Voids can contribute to an increased coefficient of thermal expansion and reduced dimensional stability of the composite. This can cause problems in applications where tight tolerances and dimensional stability are required. There is a correlation between having a high void content (over 20% by volume) and having a poorer fatigue resistance, a stronger affinity to water diffusion, and an augment in the variance (scatter) in the MP [74,75]. When it comes to composites, a larger fibre content is associated with a greater risk of void formation [75]. Fig. 11 shows pictures taken at a microscopic level of the voids in natural fiber composites. To enhance the MP of NFR hybrid composites and minimize the presence of voids, proper processing techniques and material selection are crucial. For instance, ensuring good fiber-matrix compatibility, using suitable coupling agents or compatibilizers, optimizing fiber loading and distribution, and employing appropriate processing methods can significantly reduce void formation and improve the total effectiveness of NFR polymer hybrid composites.

Figure 11: SEM micrographs of voids in natural fiber composite

5.5 Moisture Absorption of Fibres

NFR, such as sisal, hemp, flax, and jute, have the inclination to absorb moisture from the surrounding atmosphere due to their hydrophilic nature. This moisture absorption can have several implications on the characteristics and performance of NFR-based materials and composites [76]. When NFR absorb moisture, they swell and can cause dimensional changes in the material [77–79]. This swelling can lead to undesirable warping or distortion in composite materials, affecting the dimensional stability and potentially causing problems in applications with strict dimensional tolerances [80,81]. As natural fibers swell, they can generate internal stresses within the composite material [82,83]. These stresses can lead to cracking or delamination in the composite, further affecting its structural integrity and performance [84]. Fig. 12 summarises this process. Moisture absorption can weaken the MP of NFR composites, such as tensile strength, stiffness, and impact resistance. This is due to the hydrolytic degradation of NFR and disruption of the fiber-matrix IB, leading to reduce stress convey between the NFR and the PM. Prolonged exposure to moisture can lead to biological degradation of natural fibers, such as mold growth or rot. This can further compromise the MP and durability of the material. Because of this, one of the most important steps in the process of preparing composites is the removal of moisture from the NFR. It is possible to lessen the amount of moisture that is absorbed by fibres by removing hydrophilic hydroxyl groups from the structure of the fibres using a variety of various chemical treatments [85].

Figure 12: Schematic representation of effect of water on fiber-matrix interface

Natural fibers, derived from plant or animal sources, possess a unique advantage over synthetic fibers due to their biodegradability. This characteristic makes them an eco-friendly option for a wide range of applications, as they can decompose naturally into simpler, environmentally benign components under suitable conditions [86]. A key advantage of employing biodegradable NFR is their diminished environmental footprint. Upon completing their lifespan, materials based on NFR can decompose into benign substances due to the activity of microorganisms like bacteria and fungi. This process helps to minimize waste accumulation in landfills and reduces the overall carbon footprint of the material [87]. The rate and extent of biodegradation of NFR can depend on various factors, including the fiber’s chemical composition, crystallinity, and the presence of lignin or other natural binders. Moreover, environmental circumstances, such as temperature, humidity, and the presence of microorganisms, can also influence the biodegradation process [88]. The terms “biological,” “chemical,” “mechanical,” “thermal,” “photochemical,” and “aqueous” all refer to different types of degradation processes. It is common practise to cite the biodegradability of cellulosic fibre as a positive characteristic that may be used to support the use of these fibres. However, it is required for the composites to remain usable for a number of years in order for them to be used in numerous outdoor applications. Controlling this natural deterioration is crucial in order to lengthen the amount of time they may be used effectively. Modifying the chemical composition of the cell wall is one method that may be used to stop or slow down the natural decomposition process. Thus, potential negative characteristics of cellulosic fibers, such as dimensional instability, flammability, biodegradability, and chemical degradation could be inhibited or decelerated [89,90]. By restricting the accessible OH group on the NFR surface, chemical treatments have the potential to minimise the amount of NFR swelling and biological degradation [91–93]. This is accomplished by lowering the quantity of water that is absorbed by the fibres. While the biodegradability of natural fibers is a desirable trait, it can also be a challenge in certain applications where long-term durability and resistance to environmental factors are required. Therefore, it is crucial to balance the biodegradable nature of natural fibers with their performance, particularly in uses where the material is subjected to humidity, changes in temperature, or other environmental strains. Proper treatments, protective coatings, and the use of HC can help to achieve this balance.

6 Diverse Approaches to Enhancing Mechanical Properties of Natural Fiber Composites

There are a number of different approaches that may be taken in order to augment the MP of NFR polymer composites. These approaches are not yet linear procedures that, if adopted, may result in considerable gains; rather, an active area that is now under development is working to enhance the material features of NFR polymer composites. It is not always the case that mechanical improvement in one application area would immediately provide the same outcome in another particular application. For instance, increasing the hardness of a material may have been ideal for the engineering and manufacturing sectors; however, this may not be essential or desired for medical applications, which may instead choose to increase its adaptability and longevity. Therefore, it will be provided with all possible possibilities, and it will be up to the analysts to pick the best one based on the circumstances. In addition, these strategies may be used in order to have a synergistic impact. The most important aspect that has a part in defining the MP of the NFR reinforced composite is broken down in Table 5.

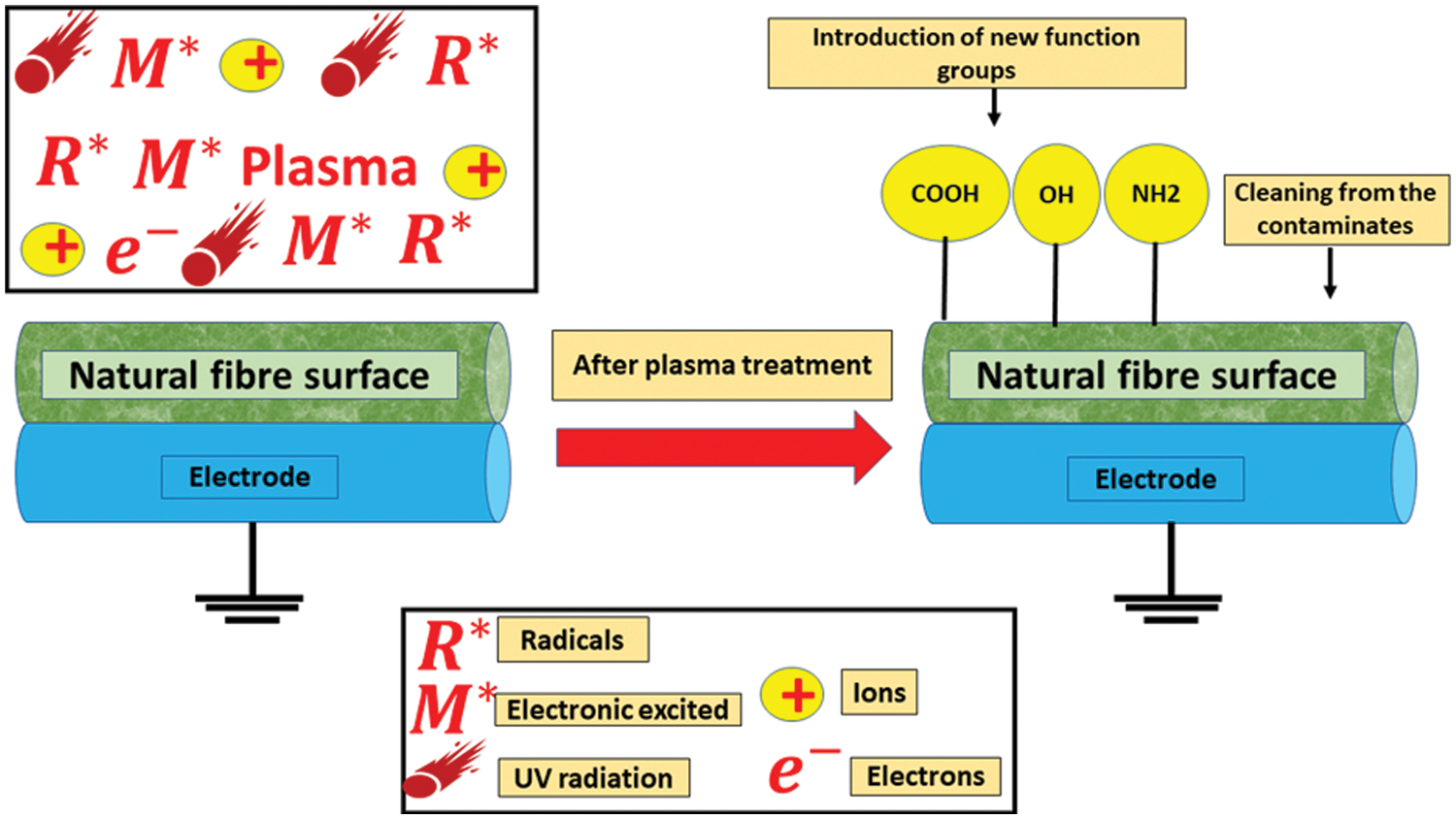

6.1 Fibers Surface Modification

By using a wide variety of surface modification methods, it is possible to significantly mitigate the drawbacks associated with using natural fibres [94,95]. Surface modification techniques may take the form of either physical or chemical treatments. Examples of the former include plasma, ultrasound, and ultraviolet light, while examples of the latter include silane, alkali, acetylation, and benzoylation, as well as sodium chloride [96–98]. Fig. 13 is a schematic representation of the plasma treatment that is applied in order to remove surface impurities (the cleaning effect). The silane treatment of NFR is depicted pictorially in Fig. 14, which contains a schematic illustration of the process. Stretching, calendaring, and thermal treatment are all examples of physical processes that do not alter the chemical makeup of the NFR, but do modify the surface and structural qualities of the NFR, which in turn affects the way the fibre physically bonds to composites. Altering the fibres chemically, on the other hand, enhances their overall qualities as well as the amount of chemical features, which in turn improves their ability to absorb water when combined with a polymer matrix. In addition to this, it cleans the surface of the fibres, removing any undesired substances such as hemicelluloses, lignin, and pectin, which in turn helps to enhance the matrix adhesion [99–101].

Figure 13: Schematic representation of the plasma surface treatment

Figure 14: Schematic representation of silane treatment

Compatibilizers are additives that lower the surface tension of fibres, making it possible for relatively nonpolar polymer matrices to adhere to the fibres’ shape. Matrix enhancements, which are often accomplished by introducing binding substances and polymer matrix compatibilizers, may in fact lead to increases in the permeability and excitability of polymers. These matrix improvements can be obtained. The increased binding that occurs between the matrix and the reinforcement is mostly the result of the utilized of coupling agents. Gargol et al. [102] highlighted the importance of their work on the MP of NFR-Epoxy HC. The composite specimens that were chosen were then subjected to treatment and additional investigation into their mechanical behaviour. The mechanical characterisation showed that the characteristics had improved as a result of hybridization, with enhanced mechanical interlocking and a boost in mechanical strength standing out as the most significant alterations. The research highlights the significance of alkali treatment as well as the potential for improvement of physico-chemical and MP.

Chandrasekar et al. [103] looked at the mechanical characteristics of NFR composites as well as their ability to absorb water. In this paper, the outcomes of studies on the swelling, moisture resistance, and chemical behaviour of composites are discussed, with a primary focus on the materials’ mechanical characteristics. As a result, tests were conducted to examine the material’s bending strength, tensile strength, compression resistance, and thermal stability. It should also be emphasised that, when exposed to high temperatures, polymer composites exhibited a level of stability that was significantly inferior to that of parent resin matrix composites.

Polymer blends can be described as a fusion of two or more polymers, designed to enhance product attributes while also lowering expenses. Blends of polymers may very literally be utilised in the same way as alloys of polymers are. Therefore, blending refers to the process of combining two or more distinct polymers in such a manner as to produce a new substance with characteristics that are only marginally different from those of the individual polymers that were used. Polymer mixing is a versatile process for the production of new synthetic polymers that have significantly improved properties in comparison to the original polymers [104]. This is a tried-and-true approach to solving new issues that are associated with application development.

Blending is an excellent choice since it enables one to combine existing polymers with new ones that have better properties and are also economically viable. Significant numbers of polymer mixes are recorded in the literature by researchers working in academia and industry [105]. When polymers are mixed together, the resulting blends may be liquid or phase-separate. When miscible blends are mixed, the mixing process eventually reaches a molecular-dimensional scale, and the properties of the present PM mix are more similar to those of a single PM. On the other hand, phase-separated blends often reflect the diverse characteristics of the polymers that are involved [106]. Even though miscibility is not very prevalent in blends, the characteristic profile of miscible blends offers advantages over the property profile of separate-phase blends, notably in terms of mechanical qualities. Because of the weak binding that occurs at the phase interface during blending, the majority of various phase blends have variations in the material properties that they possess. Therefore, researchers have devised a variety of strategies to alleviate the effects of these step separation difficulties. As a result, the composites’ essential features may be included in the construction of the polymer matrix. Blending not only physically alters the matrix but also causes it to take on new chemical characteristics. These new chemical qualities may be purposefully introduced into the matrix in order to facilitate improved interaction between the fibres and the blended PM. Many research works have demonstrated that the robust equilibrium of blends can be substantially boosted by fortifying them with synthetic or NFR [107]. This can be accomplished in either direction. Nonetheless, in recent years, bio-fiber reinforcements have made considerable strides due to the numerous benefits they offer compared to synthetic fibers.

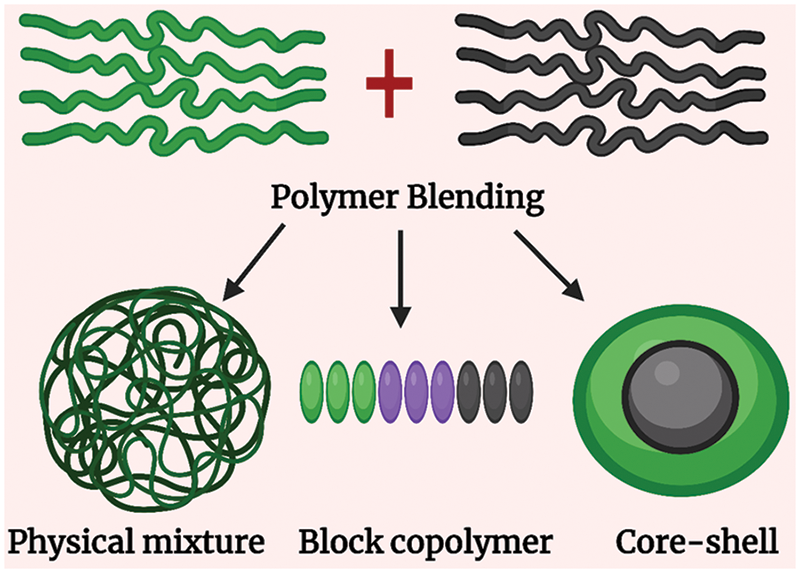

Reddy et al. [108] conducted research on the mixing of epoxy and polyester resin for the production of composite material by reinforcing cordia-dichotoma fibre with granite powder particles. This was done in order to fabricate the composite material. Through testing of the composite material produced, the material’s mechanical and thermal characteristics were examined. Merzah et al. [109] have done research on blended composites made of epoxy and polyester. In this research, the influence of clay in nanodimensions on thermal and morphological qualities was emphasised. It was shown that using 2–3 wt% clay in composites resulted in superior MP than using plain blends. The enhancements featured a 30% growth in tensile strength, a 52% rise in interlaminar shear strength, and a 16% boost in impact strength. Morphological analyses revealed that the material possesses outstanding adhesion and interfacial bonding. Fig. 15 displays a diagrammatic representation of various polymer blending methods, such as physical mixture, block copolymer, and core-shell model. The figure illustrates three primary outcomes of polymer blending: a physical mixture, a block copolymer, and a core-shell structure, using green and black polymers as examples. It highlights the distinct structures resulting from the blending process, from simple mixtures where polymers are mixed but remain separate, to more complex block copolymers with alternating segments, and core-shell structures with one polymer encapsulating the other. These diverse structures are pivotal for advancing material properties and applications in fields like nanotechnology and biomedical engineering, emphasizing the importance of polymer structure manipulation in materials science.

Figure 15: A diagram illustrating various polymer blending techniques, encompassing physical mixture, block copolymer, and core-shell model

Compatibilization is a crucial process in the realm of polymer science, particularly in the creation of polymer blends or composites [110,111]. When two or more immiscible polymers are combined, the goal is to create a stable and homogeneous mixture with improved properties. However, due to the lack of interaction between the different polymer components, achieving this uniformity can be challenging [112]. That is where compatibilization comes into play. Compatibilization involves the use of compatibilizers, which are molecules or additives designed to enhance the compatibility and adhesion between the distinct polymers in a blend. These compatibilizers help improve the interfacial adhesion and reduce the interfacial tension between the immiscible polymers, allowing for better mixing, dispersion, and stability of the final product [113]. There are several methods to achieve compatibilization, such as: Reactive compatibilization, copolymer compatibilization, and polymer surfactant compatibilization. The method of compatibilization is shown here in Fig. 16. The diagram illustrates the role of compatibilizers in polymer blends, comparing blends with and without these molecules. Compatibilizers, depicted as blue structures, enhance interfacial adhesion between the polymers, depicted as yellow and red circles, leading to a more integrated and stable blend. This contrasts with the phase-separated structure observed in blends lacking compatibilizers, where the polymers remain distinct and disconnected. This compatibilization process is crucial for improving the mechanical properties and overall performance of polymer blends, making them suitable for advanced applications in industries like automotive and packaging, where tailored material properties are essential.

Figure 16: Diagrammatic illustration of compatibilization mechanisms

Compatibilization between NFR and the PM is an essential step in the progression of NFR-strengthened polymer composites [114]. The primary aim is to achieve strong adhesion and IB between the NFR and the PM, which can enhance the overall MP, thermal, and physical characteristics of the composite material [115,116]. There are several methods used for compatibilization between NFR and the PM:

• Fiber surface treatment: Chemical or physical modification of NFR surfaces can enhance their compatibility with the polymer matrix. This can include alkali treatment, silane treatment, or acetylation, which can alter the surface properties of NFR, making them more compatible with the polymer matrix [117].

• Matrix modification: The polymer matrix can be modified through the incorporation of functional groups or additives that can react or form hydrogen bonds with the natural fibers. This modification helps enhance the IB between the NFR and the PM, leading to better composite performance [118].

• Coupling agents: These are additives that act as intermediates between the hydrophilic NFR and the hydrophobic PM. Common coupling agents include maleic anhydride grafted polymers, silanes, and isocyanates. They form chemical bonds with both the fibers and the matrix, promoting better interfacial adhesion and compatibility [119].

• Hybrid composites: Incorporating a combination of NFR and synthetic fibers in the PM can improve compatibility and promote better dispersion of fibers within the matrix. This hybridization approach often leads to enhanced MP and physical characteristics in the final composite material [120].

Compatibilization between NFR and the PM is vital to ensure the successful development of NFR-strengthened polymer composites with the desired characteristics for various applications in automotive, construction, and other industries. Fig. 17 is a diagrammatic representation of the chemical interaction processes that occur between the PM and the NFR.

Figure 17: Schematic representation of the chemical interaction mechanisms between the natural fiber and the polymer matrix

6.4 Incorporation of Nanoparticles

There have been several reports of nanoparticles being used in the process of enhancing the characteristics of NFR polymer composites [121–124]. Nanoparticles are defined as “fine particles” that have a volume-to-surface ratio that is very high and in which one or more of their dimensions are smaller than 100 nanometers. The use of these nanoparticles has an effect on the crystallisation process that takes place when the polymer composites are formed, which leads to an improvement in both the thermal and MP of the composites [125–129]. These particles may undergo regulated transformations in order to engage selectively with a certain stage of the composites’ production process. These can be modified to employee as compatibilizers, reacting mainly with the matrix and NFR to create a more robust composite capable of stress transmission. Consequently, this leads to exceptional interplay among the composite’s constituents [130,131].

In order to explore the impact that acid immersion has on the hardness of epoxy-granite composites, Fadhil et al. [132] created composites with varying percentage volumes (5%–20%) of granite powder using the hand lay-up technique. Furthermore, tests of hardness were carried out, which revealed improved hardness with augment in the percentage of granite weight. In addition to this, specimens taken before immersion were found to have a higher hardness than those taken after immersion. The research determined the precise characteristics of granite powder, including its resistance to chemical degradation, its abrasion resistance, and its hardness. The diffusion coefficient fell as the weight percent of granite increased, but it increased at a faster rate as the acidity of the submerged solution became more concentrated. Granite powder and cordia dichotama were both components of the polymer composites that Mugesh Raja et al. [133] studied. Following an investigation into the thermal, mechanical, hygroscopic, and chemical attributes of the newly produced composites, the researchers came to the conclusion that filled composites achieved superior qualities.

Krishnudu et al. [134] conducted a study on CaCO3 filler NFR-reinforced polymer composites. The composites were fabricated using the hand layup method, and their dynamic and thermal properties were examined. The thermal and dynamical mechanical parameters of filler composites were significantly enhanced. In a separate study, the same group of authors investigated the static mechanical and dielectric properties, concluding that filled composites exhibited enhanced dielectric properties along with improved static and dynamic mechanical attributes [135]. This finding stemmed from their analysis of the static MP. Aravindh et al. [136] contributed to a vast and growing collection of literature on the MP of natural fiber polymer hybrid composites. The study examined the impact of various factors, including process parameters and fillers, on the aforementioned properties. The research highlights significant potential for enhancing the MP of NFR composites, in particular with regard to glass fibres. Nanoparticles may be seen in natural fibre nanocomposites, as seen in Fig. 18. Fig. 19 presents a visual representation of hybrid bionanocomposites. The scanning electron microscope (SEM) images (Fig. 18) demonstrate the inclusion of nanoparticles in nano-natural fiber composites, highlighting their varied dispersion and aggregation. The left image shows a dense cluster of irregular nanoparticles, which might suggest a less controlled deposition process, while the right image displays more evenly distributed nanoparticles along fiber structures, indicating a potentially more deliberate placement. This distribution of nanoparticles is crucial as it directly impacts the composite’s properties. For example, a uniform dispersion of nanoparticles can enhance the mechanical strength and durability of the nano-natural fiber composites, improve their functionality in applications such as filtration or reinforcement, and increase their effectiveness in various industrial applications. These images underscore the significant role of nanoparticle integration in optimizing the performance and characteristics of nano-natural fiber composites. An illustrated breakdown of the manufacturing of laminated hybrid bionanocomposites is shown in the Fig. 19, which shows how nanoparticles are selectively integrated with layers of natural and synthetic fibers within a polymer matrix. This in-depth illustration illustrates how a single, layered component becomes a unified, high-performing material. While synthetic fibers improve strength and durability, natural fibers benefit the environment and are lighter. The homogeneous functionality of the composite is ensured by the incorporated nanoparticles, which improve its qualities including mechanical strength and UV resistance. This diagram clearly illustrates how various material types work together, highlighting the promise of composites in sectors like aerospace and automotive where customized, highly durable, and environmentally friendly materials are essential.

Figure 18: SEM micrographs of the presence of nanoparticles in natural fiber nanocomposites

Figure 19: Diagrammatic illustration of the hybrid bionanocomposites

The use of two or more diverse reinforcing forms, shapes, or sizes beneath one composite material is an example of what is meant by the term “hybrid composites.” It has also been said that the qualities of reinforced polymers are dependent on a variety of elements such as: the properties of a single fibre, the strength of the fiber-matrix combination, the fibre surface roughness or resistance, and the degree to which the fibres are intertwined [137]. Lately, investigations into hybrid composites’ properties have focused on combinations of NFR and synthetic fibers, NFR with other NFR, and natural, synthetic, and additive-modified polymeric materials. It is increased owing to the capacity of these composites to change other composites and to grasp features that cannot be reached in produced composites containing single reinforcement that the success of these composites has been achieved. It has been discovered that fiber-reinforced HC exhibit enhanced characteristics in comparison to non-hybrid composites containing only a single reinforcement [138,139]. There have been a number of research investigations that have previously shown that constructing hybrid fibres by incorporating synthetic fibres in varying proportions results in higher-quality composites, especially in addition to MP [140]. It has been noticed that the MP of hybrid NFR/synthetic fibers often improve as the weight percentage of the synthetic fiber increases. This is something that has been seen. In spite of this, the mechanical characteristics of the composites begin to degrade when a specific weight percent of the additional synthetic fibre material has been reached. This can be traced back to weak IB, strong fiber-to-fiber contact, and low wettability. The influence that a variety of different fillers have on the MP of composites was studied by Reddy et al. [141]. The composites were made by independently reinforcing three distinct fillers with prosopis juliflora fibre, and then combining the resulting materials. In their research, the mechanical characteristics of a variety of filled hybrid composites were investigated and analysed.

When producing natural fiber polymer composites, several additional additives or processes are often overlooked but may still influence the final MP and physical characteristics of the material. One example of this is the incorporation of contaminants into the matrix material by means of the inclusion of fibres. These components, as opposed to the nanoparticles, will have an effect on the crystallisation process; however, this is strongly dependent on the chemical structure of the components. It is also important to note that the recrystallization of the composite materials enables the atoms to grow to their full size. This is an important benefit of the recrystallization process. Therefore, the temperatures that are maintained during the annealing process of the materials are really highly crucial to the composite’s ultimate qualities that are achieved. To ensure that the final product has the desired characteristics, extreme caution must be used throughout every stage of production, beginning with the procurement of raw materials and continuing through product packaging.

7 Physical and Mechanical Characteristics of Hybrid Composites

The MP and physical characteristics of HC are largely influenced by several key parameters. These include the proportion and length of the fibres used, which directly impact the composite’s strength and flexibility. Equally important is the orientation of these fibres; their alignment can affect the material’s performance under different stresses. The arrangement of individual fibres also plays a role, with the spatial distribution contributing to the overall structural integrity of the composite [142]. Additionally, the degree to which the fibres intermingle can affect the material’s resilience and durability. This intermingling can create a more uniform structure, leading to improved load distribution when the material is under stress. Lastly, the interfacial adhesion-the bonding strength between the fibre and the matrix-is critical. Strong adhesion can enhance the composite’s resistance to environmental factors, while weak adhesion could lead to premature failure of the material. Therefore, these factors must be carefully controlled during the manufacturing process to optimize the composite’s performance for its intended application [143,144]. Most research on NFR hybrid composites centers around investigating their mechanical properties in relation to factors such as fibre length, fibre quantity, the level of fibre intermingling, the bond strength between fibre and matrix, and the arrangement of both types of fibres. It also examines the impacts of different chemical modifications of fibres and the application of coupling agents. In-depth investigations of this sort have been performed on diverse natural fibre hybrid composites, encompassing materials like carbon fibre, cellulose, hemp, and flax [145].

7.1 Thermoset Hybrid Composites

Researchers create HC by merging fibres with various resins such as epoxy, polyester, phenolic, poly vinyl ester, and poly urethane. Table 6 presents the research conducted on thermoset hybrid composites using both NFR/NFR and NFR/synthetic fibres. The MP of these thermoset biocomposites, as well as the impact of glass hybridization on their mechanical attributes, are discussed in great detail.

7.1.1 Hybrid Composites-Based Epoxy

Alshammari et al. [165–167] conducted a study on the chemical resistance, void content, and MP of HC made from oil palm empty fruit bunches and jute fibres. They found that hybridizing the composites with jute fibres led to enhanced physical characteristics, including water absorption, dimensional stability, and density. The research also examined the impact of fibre bundle loading and modification of bagasse fibre surface on a jute/bagasse hybrid fibre-reinforced epoxy composite. The findings indicated that surface modification significantly enhanced the interaction between the NFR and PM, leading to a considerable enhancement in the MP of the HC [168]. Moreover, this study also offered valuable insights into thermomechanical characteristics and a comprehensive analysis of the interconnected dynamics between fibres and matrix. The primary objective of the research that Sivasankar et al. carried out was to investigate the impact that embedding hemp and abaca fibres in a PM would have on the mechanical characteristics of a composite material. In accordance with the results of the trials, the tensile strength of 30:0 (abaca:hemp fibre) is extraordinarily high, whilst the flexural strength of 40:10 (abaca:hemp fibre) is very high [169].

Ramie, hemp fibres, and coconut shell particle reinforcement with epoxy hybrid composites were subjected to research to determine their mechanical characterisation, which was then presented by Suriyaprakash et al. [170]. The generated samples were subjected to further tests, including tensile testing, impact testing, flexural testing, and water absorption testing, to gain deeper insight into the MP of the material. The hybridization of epoxy composites with hemp and ramie fibres, as the message is given, results in better characteristics of the composites. It was discovered that increasing the percentage composition of hemp fibres in fiber-reinforced composites led to an improvement in the materials’ MP. The water-absorbing and mechanical capabilities of jute and glass fibre reinforced epoxy composites were looked at [171]. The research indicates that the MP of HC fall somewhere in the centre of the spectrum between those of jute composites and those of glass composites. In the context of this research, the researchers are aiming, among other things, to evaluate the effect that water absorption has in a number of different chemical situations, in addition to the effect that boiling water has. It was shown that hybrid composites had a superior water absorption behaviour when compared to jute composite materials and glass composite materials, respectively. The results of this investigation on the loading rate behaviour of jute/glass hybrid reinforced epoxy composites were given [172]. When hybrid composites are exposed to higher loading rates, it has been shown that the hybrid composites are insensitive to the loading rate in terms of the stress at yield, the displacement at yield, and the interlaminar shear strength values [173]. Velu et al. looked into the hybrid composites that were reinforced with carbon, jute, and glass fibres to study their mechanical characteristics [174]. The HC made of carbon, jute, and glass fibre were fabricated with four distinct layers of texture. In preparation for the study, six unique plates were manufactured. The composites were made stronger with the addition of the carbon fibre, which contributed to the improvement. Experimentation also demonstrates that carbon fibre, in comparison to glass fibre and jute fibre, has extremely superior mechanical qualities; nevertheless, the cost of carbon fibre is prohibitively expensive, and the configuration of fibers is crucial in establishing the robustness of the overlay. The hybrid natural fiber/synthetic fibre polymer composites are represented schematically in Fig. 20.

Figure 20: Graphic depiction of hybrid polymer composites composed of natural and synthetic fibers

Through a series of tensile, flexural, and Izod tests, the study [175] that Kudva et al. carried out with the intention of determining the MP of bamboo and carbon fibre reinforced HC was carried out. When compared to bamboo fibre reinforced composites, HC had tensile strengths that were 74.53% higher, flexural strengths that were 41.47% higher, and impact strengths that were 182.24% higher. In comparison to hybrid and bamboo fibre reinforced composites, carbon fibre reinforced composites exhibited improved mechanical capabilities, particularly in terms of tensile and flexural characteristics. According to the findings of the research, composite materials made from a mixture of NFR and synthetic fibres achieve satisfactory levels of mechanical performance. Research was also carried out on the MP of HC crafted from both treated and untreated sisal and glass, reinforced with a blend of epoxy and formaldehyde originating from bisphenol-C [176]. Another study [177] focused on the flexural and compressive attributes of bamboo/glass fibre reinforced epoxy HC. The findings revealed that hybrid bamboo composites utilizing untreated bamboo fibres demonstrated inferior qualities compared to those made with alkali-treated bamboo fibres. This research was aimed at exploring the hybridization of NFR with glass fibres for potential applications in the pipe industry [178]. In a particularly noteworthy project, researchers constructed a passenger car bumper beam using kenaf/glass HC [179]. The findings suggested that the created HC beam possesses MP on par with typical bumper beam material, with the exception of its impact characteristics. The study suggested that kenaf/glass hybrid composites could potentially be employed in the manufacture of automotive structural components.

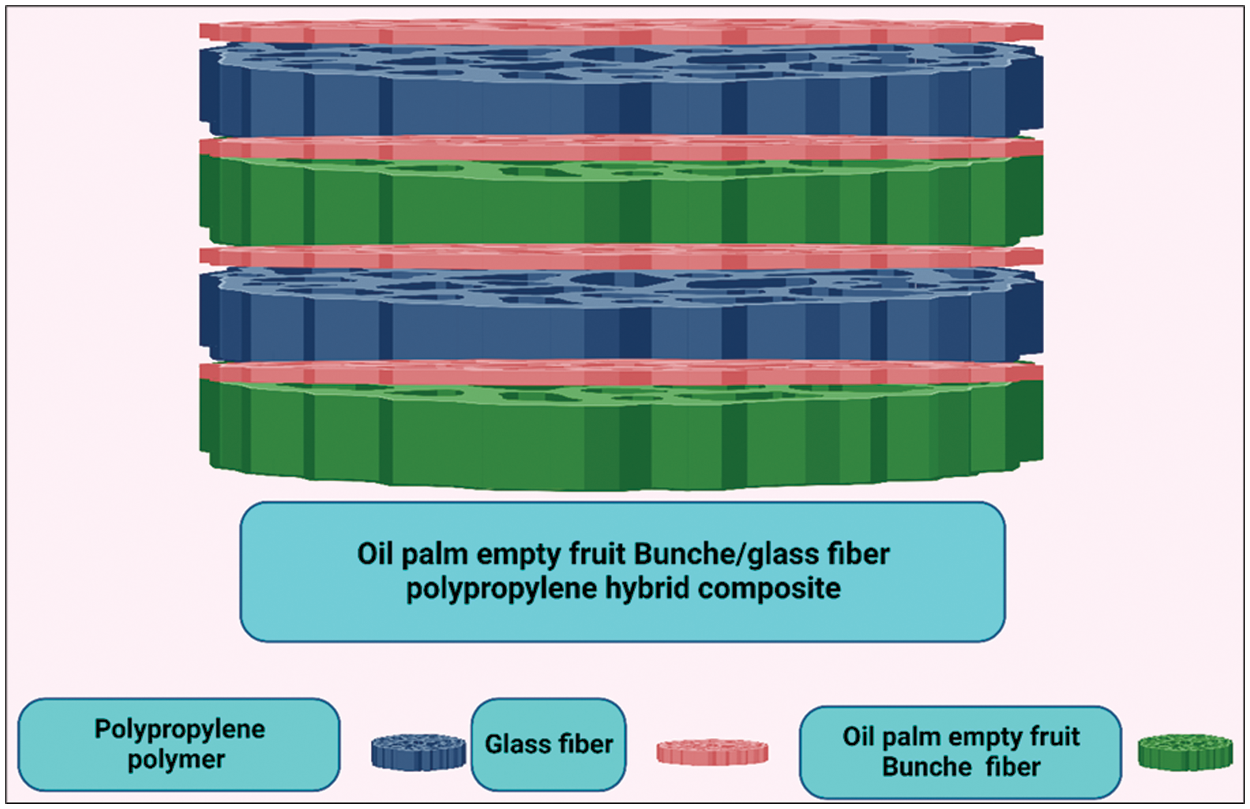

7.1.2 Hybrid Composites-Based Phenolic Resin

Ramlee et al. undertook a study on the use of oil palm empty fruit bunch (OPEFB) and sugarcane bagasse (SCB) fiber, utilized as filler in varying proportions, to create HC utilizing the hand lay-up method, ensuring a total NFR load of 50 wt% [180]. The study established that the performance and characteristics of these hybrid OPEFB/SCB fiber composites surpass those of pure fiber composites. The results highlighted that the HC with a ratio of 7:3 (OPEFB:SCB) exhibited the highest tensile strength and modulus, measuring 5.56 and 661 MPa, respectively. This study contributes to the understanding of agricultural waste as a potential green material alternative, suitable for use as thermal insulation and heat retention in walls, an application vital to the building and construction industry for its energy-saving capabilities. In this work, the tensile, flexural, and impact mechanical characteristics of novolac-type phenolic composites were studied as a function of fibre orientation and roving/fabric factors [181]. These composites were reinforced with jute/cotton hybrid woven fabrics. According to the results of the study, the characteristics of the roving or fabric, in addition to the orientation of the test, both had a major impact on the composite charateristics. In terms of the composites’ overall mechanical characteristics, the best results were generated by the tests conducted in the direction of the jute roving. Research [182] delved into the hybrid effect of glass fibre and oil palm empty fruit bunches (OPEFB) fibre on the tensile, flexural, and impact response of the phenol-formaldehyde composite. The integration of glass fibres led to an enhancement in the composite’s performance as a whole. However, increasing the volume fraction of OPEFB fibre resulted in a decline in the hybrid composite’s density and impact strength. Similarly, an increment in the volume fraction of OPEFB fibre caused a slight decrease in the hardness of the hybrid composite. Hybrid composites containing a volume fraction of 0.74 of OPEFB fibre demonstrated the greatest impact strength observed. Hybrid composites comprising glass and phenolic outperformed composites made solely of oil palm.

In the research conducted by Feng et al. [183], they used the hand layup method to fabricate hybrid composites, hybridizing treated pineapple leaf fibre (PALF) and kenaf fibre (KF) with the aim of enhancing the MP of untreated HC. They prepared silane treated PALF/KF phenolic HC with varying fibre fractions to assess mechanical properties, comparing them with untreated PALF/KF phenolic HC. It was found that silane treatment of the fibres resulted in better mechanical performance in the hybrid composites, making them suitable for use in the manufacturing of building structures, materials, and automobile components. The hybrid PALF/KF polymer composites are shown in a schematic format in Fig. 21.

Figure 21: Diagrammatic depiction of the hybrid PALF/KF phenolic composites

7.1.3 Hybrid Composites-Based Polyester