Open Access

Open Access

ARTICLE

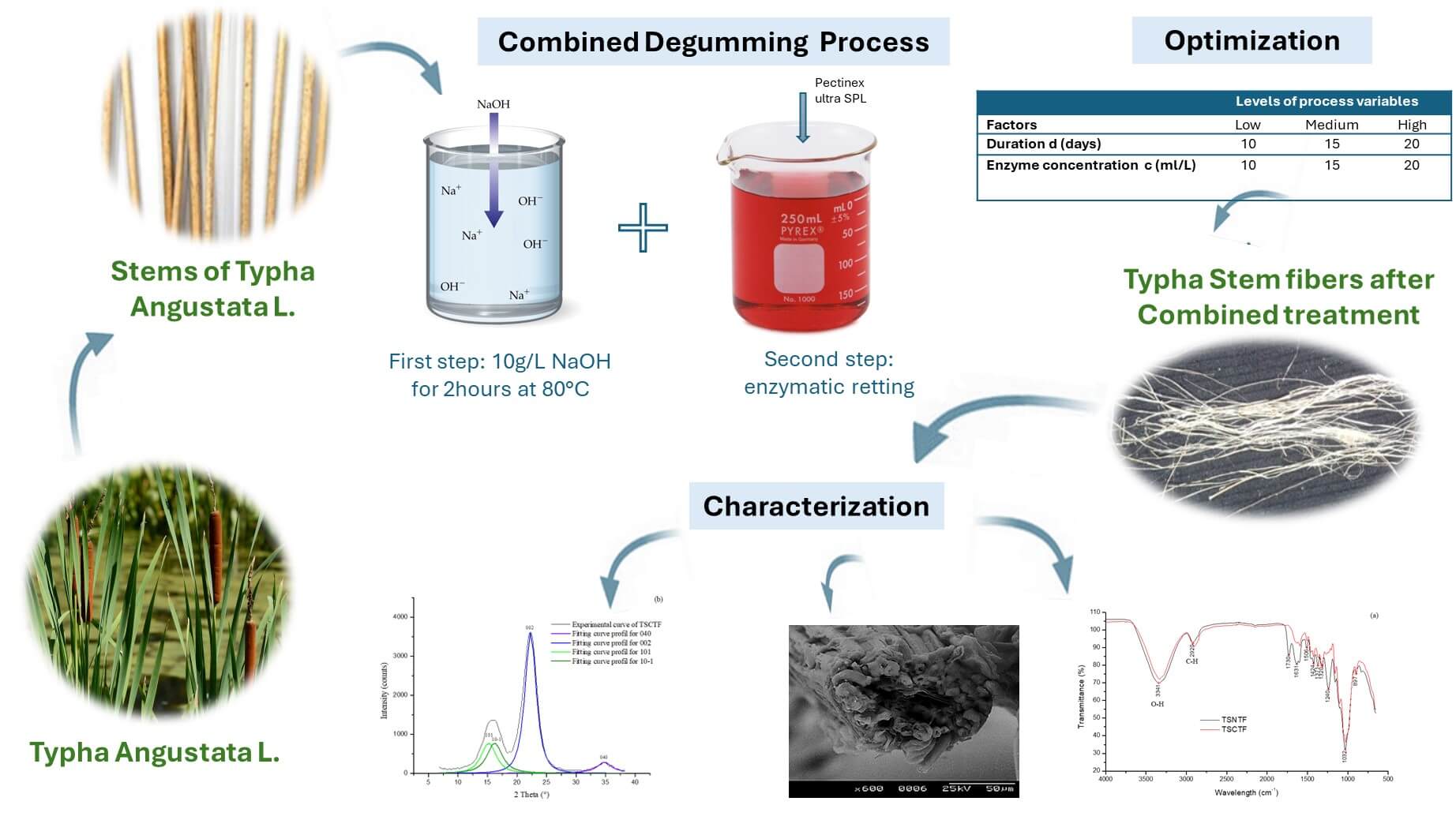

Optimization and Characterization of Combined Degumming Process of Typha angustata L. Stem Fibers

Laboratory of Textile Engineering (LGTex), University of Monastir, Ksar Hellal, 5070, Tunisia

* Corresponding Author: Sana Rezig. Email:

Journal of Renewable Materials 2024, 12(6), 1071-1086. https://doi.org/10.32604/jrm.2024.049935

Received 23 January 2024; Accepted 12 April 2024; Issue published 02 August 2024

Abstract

Plant derived natural fibers have been widely investigated as alternatives to synthetic fibers in reinforcing polymers. Researchers over the years have explored many plant fibers using different extraction processes to study their physical, chemical, and mechanical properties. In this context, the present study relates to the extraction, characterization, and optimization of Typha angustata L. stem fibers. For this purpose, desirability functions and response surface methodology were applied to simultaneously optimize the diameter (D), linear density (LD); yield (Y), lignin fraction (L), and tenacity (T) of Typha stem fibers. Typha stems have been subjected to both alkali (NaOH) and enzymatic (pectinex ultra-SPL) treatments. Three levels of process variables including enzyme concentration (10, 15, and 20 ml/L) and treatment duration (10, 15, and 20 days) were used to design the experiments according to the factorial design. Experimental results were examined by analysis of variance and fitted to second order polynomial model using multiple regression analysis. The Derringer’s desirability function released that the values of process variables generating optimized diameter, linear density, yield, lignin ratio and tenacity are 20 ml/L and 20 days for concentration of pectinex ultra-SPL enzyme and treatment duration, respectively. Confirmation was performed and high degree of correlation was found between the experimental and statistical values. Moreover, the morphological structure has been investigated by the scanning electron microscope, showing a crenelated structure of ultimate fiber bundles of cellulose composing the Typha fiber. Compared to Typha stem non-treated fibers (TSNTF), Typha stem combined treated fibers (TSCTF), brings to improve mechanical properties. This change in mechanical properties is affected by modifying the fiber structure showing alpha cellulose of (66.86%) and lignin ratio of (10.83%) with a crystallinity index of (58.47%).Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools