Open Access

Open Access

ARTICLE

Study of Hygrothermal Behavior of Bio-Sourced Material Treated Ecologically for Improving Thermal Performance of Buildings

1 National School of Architecture Agadir, New Complex Ibn Zohr Agadir, Hay dakhla, 80 000, Morocco

2 EMDD, CERNE2D, University Mohammed V in Rabat, Est Salé, Salé Medina, Morocco

3 Physics Department, LPMAT Laboratory, Faculty of Sciences Ain Chock, Hassan II University, Casablanca, Morocco

4 Architectural Engineering Department College of Engineering, Najran University, Najran, 66426, Saudi Arabia

5 The Centre of Scientific and Engineering Research, Najran University, Najran, Saudi Arabia

* Corresponding Author: Soumia Mounir. Email:

(This article belongs to the Special Issue: Renewable Materials and Advanced Technologies for Sustainability)

Journal of Renewable Materials 2024, 12(5), 1007-1027. https://doi.org/10.32604/jrm.2024.049392

Received 05 January 2024; Accepted 11 March 2024; Issue published 17 July 2024

Abstract

Creating sustainable cities is the only way to live in a clean environment, and this problem can be solved by using bio-sourced and recycled materials. For this purpose, the authors contribute to the valuation of sheep wool waste as an eco-friendly material to be used in insulation. The paper investigates the thermal, hygrothermal, and biological aspects of sheep wool by testing a traditional treatment. The biological method of aerobic mesophilic flora has been applied. Fluorescence X was used to determine the chemical composition of the materials used. Also, thermal characterization has been conducted. The thermal conductivity is above 0.046 (W·m·K) and the thermal diffusivity is 1.56.10 m·s. Besides, the energy efficiency of using sheep wool in buildings was studied. Furthermore, its humidity behavior was evaluated in different aspects in both winter and summer. Results of biological analyses show the efficiency of the treatment by removing the majority of the microorganisms: the value of yeast and mildew was reduced from 38.10 to 2.10 (UFC·g). In addition to that, sheep wool permits obtaining a low thermal transmittance on the scale of the walls and low cooling needs on the scale of the building with a gain of 45% and 52%, respectively.Keywords

Nomenclature

| PCA | Plate count agar |

| | Thermal conductivity (W·m−1·K−1) |

| A | Thermal diffusivity (m2·s−1) |

Creating sustainable cities and sustainable rural areas has become a necessity in the global context of the increase in greenhouse gas emissions and the temperature of the earth; however, buildings are a huge sector of energy consuming, which is why the use of insulation is the most effective way to reduce pollution, carbon emissions, and energy consumption by acting on the building envelope. Sheep wool is a bio-sourced material with a low carbon footprint, which allows the construction of sustainable buildings and then assures sustainable cities. The use of this material for insulation, using the traditional treatment proposed in this study, will make sheep wool affordable for both rural and urban inhabitants, and industrial insulating material will also benefit from this study by using this treatment that does not pollute the environment. The authors valued the use of sheep wool as an insulating building material using a traditional treatment, which will be useful for citizens and industry, and it will also be a manner of waste management, especially in Arabian countries where this material is thrown everywhere in the feast of Aid Al Adha. The paper gives a clear idea about the thermal properties of sheep wool in terms of thermal conductivity and thermal diffusivity; however, the hygrothermal behavior is clearly shown in this study. The novelty of this paper is the use of traditional treatments for sheep wool to remove microorganisms in a simple way that can be used by industrialists and inhabitants of rural areas. Also, the paper gives a clear idea about the thermal and hygrothermal behavior of sheep wool and its energy efficiency when it is used in buildings. In this paper, the authors tried to investigate the effect of a traditional treatment to remove microorganisms from sheep wool by analyzing the physico-chemical elements of sheep wool and the materials used for this natural treatment. For this purpose, the fluorescence X method has been conducted, and a biological study has been done using the total aerobic mesophilic flora to see the effect of this treatment on removing microorganisms. Moreover, a thermal characterization using the hot wire and flash methods was done to determine the thermal properties of sheep wool. Furthermore, an investigation of the hygrothermal behavior of this material was studied in the winter and summer seasons, and finally, a study of the thermal transmittance using this insulating material and an analysis of its energy efficiency by determining the cooling need with and without insulation by sheep wool were conducted over a year using the tools TRNSYS.

In this context, several studies have been done concerning insulating materials. As the work of Jelle [1] studied the state of the art of both traditional and possible development of other materials, it treats wool as an insulating material that presents good thermal properties; however, the work did not determine the thermal properties of sheep wool. That is why the contribution of our work consists of conducting thermal characterization of sheep wool by determining thermal conductivity and thermal diffusivity. Pennachio et al. [2] studied the characteristics of new ecological panels of sheep wool and hemp. Thermal conductivity was measured, and results show that this thermal property is influenced by temperature and humidity, which vary from 0.039 to 0.044 (W·m−1·K−1). Thermal transmittance was evaluated using the heat flowmeter, and the value obtained shows good results compared to fiberglass and mineral wool. The acoustic study also evaluated the weighted sound absorption, and panels with sheep wool present a low coefficient of 0.55. This study proves the efficiency of sheep wool in the building sector. Based on this study, the authors contribute to this work by studying the thermal and hygrothermal behavior of sheep’s wool in both the winter and summer seasons. Corscadden et al. [3] infer that sheep wool must be promoted to be integrated into the building because it is a bioproduct, a natural and renewable resource in the construction industry, and it was used in a pilot project. This study proves that our research solves this problem by promoting industrial use of this material based on the proposed traditional treatment. Patnaik et al. [4] considered a specimen of 100% wool, and they say that wool is a natural fiber obtained from shearing the short one of sheep considered a waste. Sheep wool has many outstanding properties, including excellent insulation and low flammability.

The work of Zach et al. [5] explains the necessity for the authors to study sheep wool as a bio-sourced material with good thermal properties in order to improve comfort in buildings and reduce carbon emissions. The work of Zach et al. [5] responded to the demand for increasing ecological materials by supporting research and publications on alternative materials in which they specify the thermal and acoustic properties of sheep wool and conclude that sheep wool has comparable characteristics with conventional materials. This work contributes to the same logic for authors to contribute to the valuation of alternative materials in construction, such as sheep wool, for the purpose of reducing pollution and improving the ambiance of buildings.

In addition, Tiza et al. [6] assessed the role of bamboo and sheep wool fiber on sustainability in construction in order to save energy and use those materials in the industry. The authors described the characteristics of bamboo in terms of species, mechanical, biological, and moisture aspects: it has a tensile strength of up to 370 N·mm−2, production energy lower than steel, and energy 50 times lower than steel in its industrialization. By analyzing this work, we tried to study the traditional biological treatment of sheep wool and the moisture aspect of the bio-sourced material, sheep wool, to analyze its characteristics compared to other alternative materials. Ghermezgoli et al. [7] studied the thermal and acoustical properties of samples of wool fabrics. Results indicate that fabrics made from wool fiber show interesting properties compared to mineral wool with less impact on the environment, which pushes the authors of our work to study the thermal characterization and energy efficiency of sheep wool to compare its physical characteristics with other industrial materials. Meanwhile, Dénes et al. [8] assessed the properties of sheep wool in the reinforcement of concrete compared to materials such as polypropylene and polyacrylonitrile. Results indicate that the performance of wool fibers is less than that of polypropylene; however, it can replace hydrocarbon-based products, with wool yielding carbon between 16% and 25% after being treated, stabilized at 160°C for 10 min in the presence of air, and carbonized at 800°C in an atmosphere containing nitrogen. By analyzing this work, the authors of this paper confirm the necessity of studying the material sheep wool as an insulating building material that has similar properties as other industrial ones.

The work of Mounir et al. [9] studied the thermal characterization and thermal inertia of the composite clay-wool and revealed the important effect of wool combined with clay in terms of thermal inertia parameters: damping factor, delay of temperature, and heat flow. They also estimated the low carbon impact of the clay-wool on the environment. This work proves the utility of studying wool as an insulating building material that possesses good thermal inertia. Maaloufa et al. [10] also investigated the mechanical characteristics and the effect of insulating materials such as fiber on improving the flexure strength of composites. The work of Alyousef et al. [11] studied the management of wool waste as an element integrated with concrete as a cheap material. For this goal, the authors investigated the mechanical and microstructural properties of eight samples mixed with four kinds of concrete. Results indicated that the incorporation of wool fiber in concrete decreased the compressive strength; however, the tensile and flexural strength values of the concrete improved. Also, the microstructural characteristics of sheep wool fiber reinforced concrete were found to have good bonding and low voids. The work of Mounir et al. [9] and Alyoussef et al. [11] proves the excellent mechanical properties of sheep wool in improving flexural strength, not only in terms of thermal properties but also in terms of mechanical characteristics. The work of Parlato et al. [12] studied the possibility of valuing sheep wool as an insulation material by developing a chain product industry in Italy; they studied the correct scale required for sustainable production of sheep wool insulation products. Our work contributes to the same context of promoting the use of sheep wool in industry as an eco-friendly material with excellent thermal properties.

The use of fibers as additives with the main matrix improves the insulating properties of materials, as the research of Zormati et al. [13] analyzed the effect of using cellulose nanofibers as an admixture in cement mortars. The authors investigated the physical properties of the new composite as the thermal conductivity, and they found a value between 0.95 and 2.25 (W·m−1·K−1). This finding encourages the authors of this research to investigate the insulating properties of sheep wool as a fiber.

Management of waste is the only way to reduce pollution and obtain a clean environment, as the work of Alsamaraie et al. [14] assessed the benefit of using feather as an insulating material due to its low thermal conductivity ranges from 0.024 to 0.034 (W·m−1·K−1), its low density of 0.68 g.cm−3, and its chemical composition and microstructure of trap air, which produce a good barrier. According to those properties, the feather can be used as an effective thermal and acoustic insulation material even if its use presents some limitations, such as the restriction by the U.K. to use this material, its biodegradation decomposes, and the fire resistance of the thermal insulation, which is a crucial concern. The work of Aloulou et al. [15] investigated the influence of nanofiber wood as an industrial waste on the properties of fresh cement mortar. Results showed that the compressive strength increased by more than 50% and the thermal conductivity decreased by adding 1% of nanofiber wood. Those findings can be explained by the modification of the chemical composition of the cement mortar by reducing the quantity of water and minimizing the pores. Also, it is observed that the hydration of cement increased due to the introduction of nanofiber wood, which contains calcium silicate gel and portlandite. Abdulmunem et al. [16] assessed the role of adding palm oil as a sustainable and passive cooling material for lithium batteries because when the ion lithium battery temperature increases, the power produced decreases. Palm fatty acid distillate (PFEA) was chosen as a Phase Change Material (PCM) to contribute to the reduction of LIB cells temperature and the increase of cells’ electrical power. Abdulmunem et al. [17] revealed that feather waste can be used with phase change material as insulation because it delivers excellent thermal and acoustic insulation, and by doing so, the cooling load and the electricity cost decreased. The authors developed a new bio-composite material based on PCM and feather waste (WCF) within polyvinyl chloride panels. Results indicate that the integration of WCF by a ratio of 75% improved the acoustic insulation by 9%, reduced the cooling load by 20.3%, and increased by 22.5% the electricity cost savings for the testing room located in Baghdad city. According to those studies, the authors of this research tried to manage the waste of sheep wool as an insulating material in buildings due to the interesting properties of additives and the improvement of thermal and mechanical properties of materials.

The research gap and objectives of this study are to promote the use of sheep wool in rural and urban areas by proposing an ecological treatment using Silini Folgariss and Camphor. The results of this treatment were determined by the method of aerobic mesophilic flora. Also, this research gives a clear idea about the thermal properties of this material by determining the thermal conductivity, which shows the power of insulating buildings, and investigating the thermal diffusivity to give a clear idea about the thermal inertia behavior of this bio-sourced material. Moreover, this work assesses the hygrothermal behavior of sheep wool in different forms compacted and expanded in both winter and summer, which permits understanding the behavior of this material toward humidity. Furthermore, the research studied the energy efficiency of this material used in buildings by evaluating the thermal transmittance and cooling needs during a year in dry climates. Finally, the research contributes to the management of sheep wool waste by proposing to use it as an insulating material in buildings treated ecologically.

2.1 Description of the Materials Used

The method of treating sheep wool was described below:

• Washing sheep wool with Silini Folgariss traditional material;

• Sun-backed specimen of sheep wool;

• Use of camphor to kill microorganisms;

• Use of traditional combs, which women utilize to prepare carpet.

The wool used was taken from the sheep, as shown in Fig. 1, and treated with Silini Folgariss, as illustrated in Fig. 2 and camphor. The diameter of sheep wool studied is described in paragraph 3.6 before and after treatment; however, the length is between 3.5 and 6.5 cm. Sheep wool has important thermal and environmental characteristics. It has a low density of 20 kg.m−3. Its thermal performance was characterized, and Fig. 1 shows the sample studied.

Figure 1: Specimen of sheep wool studied

Figure 2: Specimen of Tighecht (Silini Folgariss) used in washing sheep wool

The camphor studied as shown in Fig. 3 is a traditional composite, which is a solid bicyclic organic composite taken from the camphor tree; its natural aspect is shown in Fig. 3. Its chemical formula is C6H16O. It is found in many plants [18], such as in the wood of the camphor laurel (Cinnamomum camphora), a large evergreen tree found in Asia, and also in the unrelated Kapur tree, which is a tall timber tree from the same region. It also occurs in some other related trees in the laurel family, notably Ocotea usambarensis, and in the oil rosemary leaves. The mint family contains 10% to 20% camphor, while camphorweed (Heterotheca) only contains 5%. Camphor can also be synthetically produced from the oil of turpentine. Tables 1–3 show the chemical components of the materials, respectively, sheep wool, camphor, and silini folgariss.

Figure 3: Camphor in its natural aspect

Wool is continuously exposed to contamination by microorganisms of all kinds (pathogenic or not, as well as bacteria and fungi), which are able to multiply rapidly under favorable conditions (moisture). This leads to a loss of resistance or other forms of degradation in wool fibers. In order to use this natural material in construction, we tested a traditional treatment (Silini Folgariss and camphor) to eliminate these microorganisms.

2.3.1 Description of the Mesophilic Aerobic Flora

The mesophilic aerobic flora method was used to determine the effect of the microbiological treatment on removing organisms from sheep wool. Samples are shown in Figs. 4 and 5. The wool used came from sheep. The authors prepared three samples: a sample of raw wool, a sample of wool washed with tighecht, and a third sample corresponding to wool treated with tighecht and camphor.

Figure 4: Samples of the first test using silini folgariss

Figure 5: Samples of the second test using tighecht and camphor

Mesophilic aerobic flora is a technical indicator that represents the total microbial load. These are all bacteria, yeasts, and mildew capable of developing in aerobiosis on well-defined culture media. After preparation of the samples and appropriate dilutions, the microbiological analysis of the three wool samples was carried out on the count of total aerobic mesophilic flora (FMAT): yeast and mildew.

The abundance of the Total Aerobic Mesophilic Flora (FMAT), which provides information on the overall bacterial load, was estimated on PCA (Plate Count Agar) medium incubated for 48 h at 30°C according to the Moroccan standard [19]. And is expressed as CFU (colony forming units).

The enumeration of yeast and mildew counts is done on PDA (Potato Dextro Agar) medium after incubation for 48 h at 30°C for yeast and 5–7 days at 25°C for mildew according to the Moroccan standard [19]. The tests are repeated three times.

The hot wire method was used to characterize the thermal conductivity of sheep wool [20–22], as illustrated in Fig. 6. Eqs. (1)–(10) describe the principle of this method.

Figure 6: Principle of the hot wire method

To determine the resolution of the heat in Eq. (1) based on the initial and limit conditions in Eqs. (2) and (3) of this system using the quadrupole method, we write the formula of the Laplace transform Ts(t) in this way, as represented in Eq. (6).

where

Θs is the Laplace transform of the difference Ts(t) − Ts(t = 0)

Θ is the Laplace transform of the difference T(t) − T(t = 0)

Rc the resistance of contact in the interface heating element/sample

CS: heat capacity of thermocouple-resistance

λ: thermal conductivity of the sample

a: thermal diffusivity of the sample

P: Laplace variable

r0: radius of hot wire element

L: Length of the hot wire

ϕ0: dissipated power in the heating element

I0, I1, K0, K1: Bessel Functions

If we consider a thin wire (r0 small) and if we are in the long time (

Using Laplace transform inverse, we calculate the temperature Ts(t) in the length time as shown in Eq. (12).

where γ = 0.57721 is the constant of Euler.

The drawing function Ts (t) − Ts (0) in function of ln(t) is a linear curve of slope

The thermal diffusivity of the wool samples studied was characterized using the flash method [23–25].

The behavior towards humidity was studied by saturating samples of sheep wool as presented in Fig. 7, with water compacted volume and none compacted volume, and the results were reported according to the weight measured during a lot of days at 24°C.

Figure 7: Sheep wool samples to study their humidity behavior-a) Compacted wool-b) Combed wool

The weight of dried samples is 2 g before being saturated with water. The saturated mass of sheep wool measured 28 g at time zero before the experience.

A simulation study concerning the cooling needs during a year has been done using the tool TRNSYS, which evaluates the cooling needs in each hour during the year. The building studied is a simple ground floor with 60 m2 located in Marrakech, a city with arid weather. The building contains one floor composed of four double glazing windows built with full brick, whose characteristics are λ = 0.19 (W·m−1·K−1); C = 0.794 (KJ·K−1); and ρ = 1700 (kg·m−3). The software TRNSYS permits the evaluation of cooling needs for each hour during a year.

By counting the microbial load of the wool, it is possible to establish the link between the presence and absence of microorganisms and the effect of washing with tighecht and camphor treatment. The results obtained are shown in Table 4.

According to Table 4, the authors observe that concerning the method of aerobic mesophilic flora, the raw wool contains 18.105 (UFC·g−1); however, by the treatment of Tighecht, this value decreased to 12.104 (UFC·g−1), which represents a decrease of 93%; nonetheless, using Tighecht and camphor, the value of microorganisms decreased to 8.104 (UFC·g−1), which represents a decrease of 95.5% compared to the raw materials. The study of the percentage of yeast and mildew in sheep wool indicates that the raw wool contains 38.102 (UFC·g−1), but when the authors used the treatment Tighecht, this value decreased to 6.102 (UFC·g−1), which represents a decrease of 84% of yeast and mildew, and finally, by adding Tighecht and camphor, this value decreased to 2.102 (UFC·g−1) of yeast and mildew responsible for the degradation of wool, which represents a decrease of 94.73%. The analysis of those results proves the efficiency of this natural treatment to eliminate microorganisms from the sheep’s wool. The authors conclude that the studied treatment of wool facilitates the building sector’s use of a natural and ecological insulating material, sheep wool, in construction.

The analysis of the fluorescence method as illustrated in Tables 1–3 proves that sheep wool is composed of carbon and oxygen in the majority of elements as an organic material; however, camphor is composed of CaO and SO3 as illustrated in Table 2, while silina folgariss is composed of oxygen, carbon, and a small percentage of calcium and silicon, which does not exceed 1%.

The plot of Ts(t) – Ts(t=0) in function of ln(t) is a linear curve with a slope

λ = 0.05 W·m−1· K−1 ± 0.01

λ = 0.046 W·m−1·K−1 ± 0.01

Results of thermal conductivity were presented according to Figs. 8 and 9 using the hot wire method. The authors observe that the thermal conductivity for the first experiment, according to Fig. 8, is 0.05 (W·m−1·K−1); however, concerning the second experiment, Fig. 9, the authors remark that the value of thermal conductivity is 0.046 (W·m−1·K−1).

Figure 8: The first experiment concerning the plot of sheep wool curve in function of time using hot wire method

Figure 9: The second experiment concerning the plot of sheep wool curve in function of time using hot wire method

a (Degiovanni) = 1.25.10−06 m²·s−1

a (Parker) = 1.57.10−06 m²·s−1

a (Complete) = 1.55.10−06 m²·s−1 ± 0.02

The thermal diffusivity was evaluated using the complete model, and the authors found a value of 1.5580.10−06 m².s−1, which is confirmed by the Degiovanni and Parker models as shown in Fig. 10.

Figure 10: Thermogram of temperature in function of time using flash method

The results obtained were compared to the work of Zach et al. [5] and the work of Pennacchio et al. [2], the work of Jerman et al. [26] as represented in Table 5, which seems to be comparable to those works at an ambient temperature of 20°C.

Tables 6 and 7 represent the results of measuring humid sheep wool samples in the summer season. The temperature is 30°C, and the authors observe that the combed sheep wool sample loses humidity more quickly than the compacted sample; the total weight lost is 26 g over three days.

The authors observed, according to Figs. 11 and 12, that the combed sheep wool sample loses weight more quickly than the compacted sample in a total weight of both samples of 26 g, and the combed or expanded sheep wool always loses 1 g of water more than the compacted sheep wool in a period of three days during the summer.

Figure 11: Weight of humid samples for expanded sheep wool in summer

Figure 12: Weight of humid samples for compacted sheep wool in summer

Tables 8 and 9 represent the results of measuring humid sheep wool samples in the winter season, when the temperature is 18°C. The authors observe, according to Figs. 13 and 14, that the combed sheep wool sample loses humidity more quickly than the compacted one, and the total weight lost is 26 g during six days.

Figure 13: Comparison of humidity behavior of compacted sheep wool samples in winter

Figure 14: Comparison of humidity behavior of expanded sheep wool samples in winter

3.6 Analysis of Microstructure of the Sheep Wool Fiber Treated by Silini Folgariss and Camphor

The authors studied the microstructure of the sheep wool fiber before and after treatment to see the effect of the treatment used on its diameter. Figs. 15 and 16 show the morphology of the fiber before and after treatment. According to Fig. 15, the diameter of sheep’s wool that is not treated is between 52.612 and 25.816 μm, and the length is between 3.5 and 6.5 cm. However, the diameter of sheep’s wool after treatment represented in Fig. 16 is between 30.479 and 18.963 μm, and the length is between 3.5 and 6.5 cm, which means that the ecological treatment used reduces the diameter of sheep’s wool because it eliminates the deposits of the lipid layer on the surface of the cortex. The results obtained have been confirmed by the literature concerning the work of Alyoussef et al. [27] and Moore et al. [28], which proves the efficiency of the ecological treatment used instead of the chemical treatments used by other researchers.

Figure 15: The diameters of sheep wool fibers before treatment using the scanning electron microscopy

Figure 16: The diameters of sheep wool fibers after treatment using the scanning electron microscopy

3.7 Study of the Energy Efficiency of Sheep Wool Applied to Buildings

The thermal transmittance was calculated according to ISO 6949 [29,30], and the relation is shown in the Eq. (14) below:

Τhe composition of walls is described in Table 10 below:

According to Table 10, thermal transmittance was calculated for both kinds of walls. Concerning the non-isolated one, we obtained a value of 1.94 (W·m−2·K−1) and the isolated one of 1.06 (W·m−2·K−1), and the authors obtained a gain of 45% by insulating walls using sheep wool. The gain obtained is 45%.

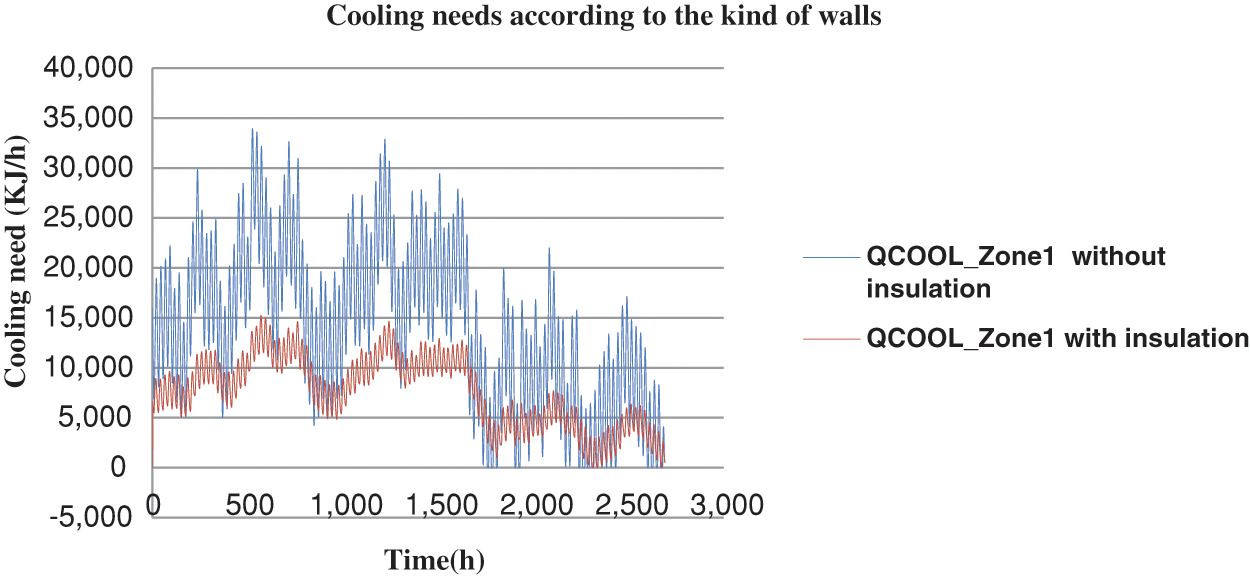

The building studied is a simple ground floor with 60 m2 located in Marrakech, a city with arid weather whose altitude is 457 m, whose longitude is 7°59′, and whose latitude is 31°38′. The building contains one floor composed of four double-glazing windows built in full brick whose characteristics are λ = 0.19 (W·m−1·K−1); C = 0.794 (KJ·K−1); and ρ = 1700 (kg·m−3) as described in Table 9. Simulation was conducted over a year, and data on cooling needs was calculated every hour during the year, results are illustrated in Fig. 17.

Figure 17: Comparison of cooling need for both kinds of walls

The gain obtained was calculated according to the Eq. (15).

An analysis of Fig. 17 concerning the building studied was conducted on both cases: the building without insulation and the building isolated by sheep wool demonstrate the cooling needs increasing in summer at 1.45 × 104 (KJ·h−1) for the isolated building by sheep wool; however, for the building without insulation, it is at 3 × 104 (KJ·h−1). We conclude that by using sheep’s wool insulation, we gain 52%.

Histogram 1 clearly shows the difference in cooling energy needs between the walls isolated by sheep wool and the ones without sheep wool.

Histogram 1: Comparison of cooling need concerning the kind of walls building studied

Analysis of Histogram 1 was done concerning the cooling need for one year; the authors observe that the total cooling need concerning the isolated building by sheep wool is 2.8 × 107 (KJ·h−1) during one year. However, concerning the non-isolated building, it is 5.45 × 107 (KJ·h−1). We conclude that by using the insulating material sheep wool, we obtain a reduction of 48% in the cooling need during a year. The authors deduce that using sheep wool will significantly reduce the energy consumption of buildings, so by insulating the envelope, we will assure the best energy efficiency.

The results were compared with the work of Anjum et al. [31], who studied the thermophysical properties of bricks containing waste; the thermophysical properties of the rocks under the influence of moisture and temperature are reviewed; the construction of eco-friendly and thermally insulated bricks by adding waste materials is examined in depth in terms of energy savings; and the results prove that adding insulation to bricks permits a significant gain in terms of energy.

3.7.3 Study of the Economic Performance of the Treatment Studied

An economic study was conducted to evaluate the price of the proposed treatment and the Table 11 showed the data of this study.

Table 11 shows the price of the treatment proposed, which is a range between the minimum and the maximum price. According to the results, the minimum price per kg is 3.75 MAD in Moroccan dirhams, 0.34 in euro, and 1.02 in American dollar; however, for the maximum price per kg, it is 6.5 MAD in Moroccan dirhams, 0.6 in Euro, and 0.65 in American dollar.

This paper investigates the thermal, hygrothermal, and microbiological treatment of the raw material, sheep wool, as an insulating material in the building using a traditional treatment to remove microorganisms from it. The traditional treatment of sheep wool consists of using silini folgariss and camphor in order to wash and treat the sheep wool studied. Biological analyses were conducted, and the results prove the efficiency of the treatment. Thermal characterization show that the sheep’s wool thermal conductivity is above 0.046 (W·m−1·K−1), however, the thermal diffusivity is 1.55.10−6 m2·s−1. Also, the hygrothermal study in the summer and winter was done for two kinds of sheep wool, combed and compacted, to study the impact of introducing air on the hygrothermal behavior of this material. The results prove that the combed wool removes humidity more quickly than the compacted wool. Besides, in winter, we need the double time compared to summer to remove the same quantity of water. Moreover, the study evaluates the impact of sheep wool on the building sector in terms of energy. Results show a reduction of 45% in terms of thermal transmittance. Furthermore, the research was extended to the scale of the building by simulating the cooling needs of an arid climate in both cases with and without sheep wool; the results show a gain of 48% during a year. This study encourages the industry to use and adopt an ecological method to treat and use sheep wool as an eco-friendly material that presents a lot of beneficial health aspects and to understand the hygrothermal behavior of this insulating material. From the perspective of this work, the authors estimate extending the biological study in order to specify the microorganisms that exist in sheep wool and what kind of microorganisms have been removed from sheep wool using the proposed traditional treatment.

Acknowledgement: The authors are thankful to the LEMTA-INPL NANCY for their help so as to realize this work.

Funding Statement: The authors received no specific funding for this study.

Author Contributions: The authors confirm contribution to the paper as follows: study conception and design: S. Mounir, Y. Maaloufa, F.Z. Wardi, Y.A. Dodo, M. Slaoui; data collection: S. Mounir, F.Z. Wardi, Y. Maaloufa, S. Ibn Elhaj, M. Slaoui; analysis and interpretation of results: S. Mounir, A. Khabbazi; draft manuscript preparation: S. Mounir, Y. Maaloufa, Y.A. Dodo. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The authors confirm that the data supporting the findings of this study are available within the article.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Jelle BP. Traditional, state-of-the-art and future thermal building insulation materials and solutions–Properties, requirements and possibilities. Energy Build. 2011 Oct;43(10):2549–63. [Google Scholar]

2. Pennacchio R, Savio L, Bosia D, Thiebat F, Piccablotto G, Patrucco A, et al. Fitness: sheep-wool and hemp sustainable insulation panels. Enrgy Proced. 2017 Mar 1;111:287–97. [Google Scholar]

3. Corscadden KW, Biggs JN, Stiles DK. Sheep’s wool insulation: a sustainable alternatice use of renewable ressource. Ressour Conserv Recycl. 2014;86(C):9–15. [Google Scholar]

4. Patnaik A, Mvubu M, Muniyasamy S, Botha A, Anandjiwala RD. Thermal and sound insulation materials from waste wool and recycled polyester fibers and their biodegradation studies. Energy Build. 2015 Apr 1;92:161–9. [Google Scholar]

5. Zach J, Korjenic A, Petránek V, Hroudová J, Bednar T. Performance evaluation and research of alternative thermal insulations based on sheep wool. Energy Build. 2012 Jun 1;49:246–53. [Google Scholar]

6. Tiza TM, Singh SK, Kumar L, Shettar MP, Singh SP. Assessing the potentials of Bamboo and sheep wool fiber as sustainable construction materials: a review. Mater Today Proc. 2021 Jan 1;47:4484–9. [Google Scholar]

7. Ghermezgoli ZM, Moezzi M, Yekrang J, Rafat SA, Soltani P, Barez F. Sound absorption and thermal insulation characteristics of fabrics made of pure and crossbred sheep waste wool. J Build Eng. 2021 Mar 1;35:102060. [Google Scholar]

8. Dénes O, Florea I, Manea DL. Utilization of sheep wool as a building material. Procedia Manuf. 2019 Jan 1;32:236–41. [Google Scholar]

9. Mounir S, Maaloufa Y, Abdelhamid K, El Harrouni K. Characterization of thermal inertia and footprint carbon of clay-wool, clay-cork, and clay-plastic composites. Key Eng Mater. 2021;886:213–27. [Google Scholar]

10. Maaloufa Y, Mounir S, Abdelhamid K, El Harrouni K. Influence of the kind and the shape of insulating materials on the mechanical properties of the composites plaster-granular cork and plaster-fiber alpha. Key Eng Mater. 2021;886:241–55. [Google Scholar]

11. Alyousef R, Alabduljabbar H, Mohammadhosseini H, Mohamed AM, Siddika A, Alrshoudi F, et al. Utilization of sheep wool as potential fibrous materials in the production of concrete composites. J Build Eng. 2020 Jul 1;30:101216. [Google Scholar]

12. Parlato MCM, Porto SMC, Valenti F. Assessment of sheep wool waste as new resource for green building elements. Build Environ. 2022 Nov 1;225:109596. [Google Scholar]

13. Zormati S, Aloulou F, Sammouda H. Effects of cationic surfactant on fresh and hardened properties of cement-based mortar. J Renew Mater. 2023;11(5):2345–65. [Google Scholar]

14. Alsamaraie ARA, Samin PM, Mazali II, Jadallah AA, Sultan KF. Insulation materials based on recycled feather waste: a review. Tikrit J Eng Sci. 2023 Mar 31;30(1):104–11. [Google Scholar]

15. Aloulou F, Alila S, Sammouda H. Stabilization and evaluation of modified nanofiber flour wood on the properties of cement-baszd mortar. J Renew Mater. 2019;7(8):763–74. doi:10.32604/jrm.2019.04071. [Google Scholar] [CrossRef]

16. Abdulmunem AR, Hamed HM, Samin PM, Mazali II, Sopian K. Thermal management of lithium-ion batteries using palm fatty acid distillate as a sustainable bio-phase change material. J Energy Storage. 2023 Dec 15;73:109187. [Google Scholar]

17. Abdulmunem AR, Samin PM, Sopian K, Hoseinzadeh S, Al-Jaber HA, Garcia DA. Waste chicken feathers integrated with phase change materials as new inner insulation envelope for buildings. J Energy Storage. 2022 Dec 1;56:106130. [Google Scholar]

18. Camphor. Wikipedia. Available from: https://en.wikipedia.org/w/index.php?title=Camphor&oldid=1215167469. [Accessed 2023]. [Google Scholar]

19. Afnor EDITIONS. NF EN ISO 4833-1. 2013. Available from: https://www.boutique.afnor.org/fr-fr/norme/nf-en-iso-48331/microbiologie-des-aliments-methode-horizontale-pour-le-denombrement-des-mic/fa163727/42192. [Accessed 2013]. [Google Scholar]

20. Li F, Shang F, Cheng S, Ma W, Jin H, Zhang X, et al. Thermal conductivity measurements of the H2/CO2 mixture using the short-hot-wire method at 323.15–620.05 K and 2.14–9.37 MPa. Int J Hydrog Energy. 2020 Nov 6;45(55):31213–24. [Google Scholar]

21. Bobda F, Claude Damfeu J, Ngono Mvondo RR, Meukam P, Jannot Y. Thermal properties measurement of two tropical wood species as a function of their water content using the parallel hot wire method. Constr Build Mater. 2022 Feb 21;320:125974. [Google Scholar]

22. Jannot Y, Degiovanni A, Schick V, Meulemans J. Apparent thermal conductivity measurement of anisotropic insulating materials at high temperature by the parallel hot-wire method. Int J Therm Sci. 2021 Feb 1;160:106672. [Google Scholar]

23. Parker WJ, Jenkins RJ, Butler CP, Abbott GL. Flash method of determining thermal diffusivity, heat capacity, and thermal conductivity. J Appl Phys. 1961 Sep 1;32(9):1679–84. [Google Scholar]

24. Degiovanni A, Laurent M, Prost R. Mesure automatique de la diffusivité thermique. Rev Phys Appliquée. 1979;14(11):927–32. [Google Scholar]

25. Degiovanni A, Laurent M. Une nouvelle technique d’identification de la diffusivité thermique pour la méthode « flash ». Rev Phys Appliquée. 1986;21(3):229–37. [Google Scholar]

26. Jerman M, Palomar I, Kočí V, Černý R. Thermal and hygric properties of biomaterials suitable for interior thermal insulation systems in historical and traditional buildings. Build Environ. 2019 May 1;154:81–8. [Google Scholar]

27. Alyousef R, Alabduljabbar H, Mohammadhosseini H, Mohamed AM, Siddika A, Alrshoudi F. Utilization of sheep wool as potential fibrous materials in the production of concrete composites. J Build Eng. 2020 Jul;30:101216. [Google Scholar]

28. Moore KE, Mangos DN, Slattery AD, Raston CL, Boulos RA. Wool deconstruction using a benign eutectic melt. RSC Adv. 2016 Feb 16;6(24):20095–101. [Google Scholar]

29. Chahwane L. Valorisation de l’inertie thermique pour la performance énergétique des bâtiments [phdthesis]. Université de Grenoble; 2011. Available from: https://theses.hal.science/tel-00701170. [Accessed 2011]. [Google Scholar]

30. Asdrubali F, Baldinelli G. Thermal transmittance measurements with the hot box method: calibration, experimental procedures, and uncertainty analyses of three different approaches. Energy Build. 2011 Jul;43(7):1618–26. [Google Scholar]

31. Anjum F, Yasin Naz M, Ghaffar A, Kamran K, Shukrullah S, Ullah S. Sustainable insulating porous building materials for energy-saving perspective: stones to environmentally friendly bricks. Constr Build Mater. 2022 Feb 7;318:125930. [Google Scholar]

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools