Open Access

Open Access

ARTICLE

Comparative Analysis of Reaction to Fire and Flammability of Hemp Shives Insulation Boards with Incorporated Microencapsulated Phase Change Materials

1 Institute of Architecture and Design, Riga Technical University, Riga, LV-1048, Latvia

2 Forest and Wood Products Research and Development Institute, Jelgava, LV-3001, Latvia

* Corresponding Author: Inga Zotova. Email:

(This article belongs to the Special Issue: Renewable Materials and Advanced Technologies for Sustainability)

Journal of Renewable Materials 2024, 12(3), 603-613. https://doi.org/10.32604/jrm.2024.047607

Received 10 November 2023; Accepted 29 December 2023; Issue published 11 April 2024

Abstract

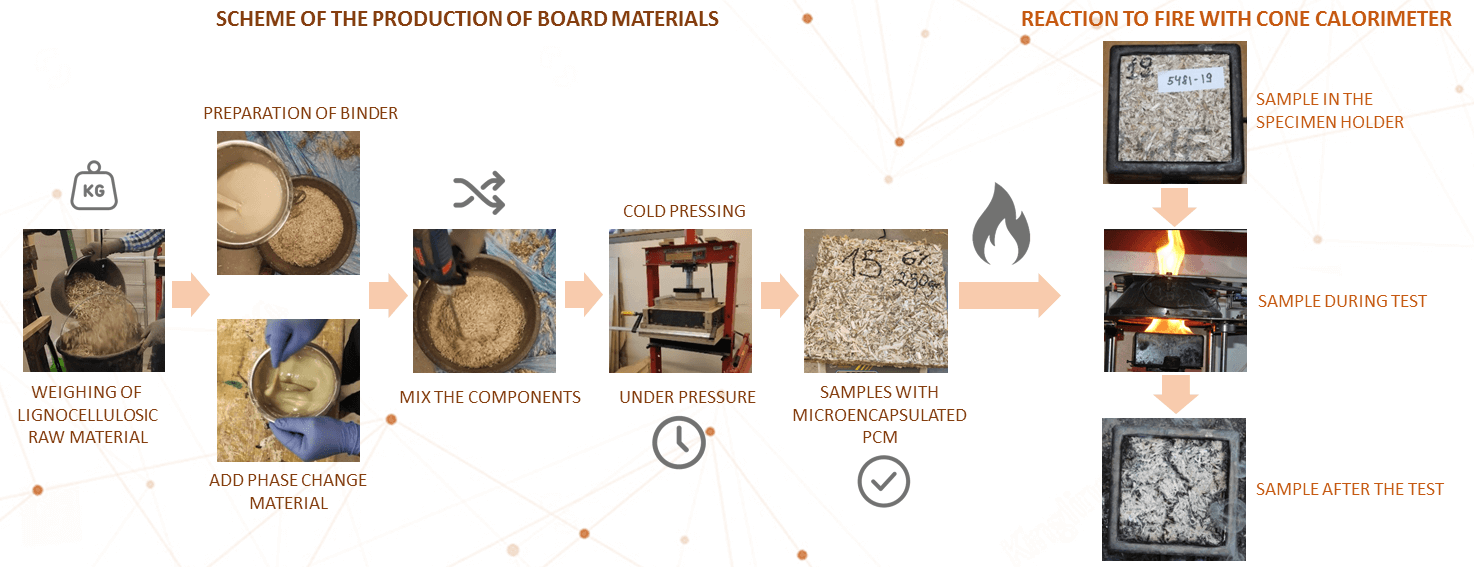

Nowadays buildings contain innovative materials, materials from local resources, production surpluses and rapidly renewable natural resources. Phase Change Materials (PCM) are one such group of novel materials which reduce building energy consumption. With the wider availability of microencapsulated PCM, there is an opportunity to develop a new type of insulating materials, combinate PCM with traditional insulation materials for latent heat energy storage. These materials are typically flammable and are located on the interior wall finishing yet there has been no detailed assessment of their fire performance. In this research work prototypes of low-density insulating boards for indoor spaces from hemp shives using carbamide resin binder and cold pressing were studied. Bench-scale cone calorimeter tests were conducted to evaluate fire risk, with a focus on assessing material flammability properties and the influence of PCM on the results. In this research, the amount of smoke, heat release rate, effective heat of combustion, specific extinction coefficient, mass loss, carbon dioxide yield, specific loss factor, ignition time of hemp straws samples and samples of hemp straws with 10% and without PCM admixture were compared. There is a risk of flammability for PCM and their fire reaction has not been evaluated when incorporating PCM into interior wall finishing boards. The obtained results can be used by designers to balance the potential energy savings of using PCM with a more complete understanding and predictability of the associated fire risk when using the proposed boards. It also allows for appropriate risk mitigation strategies.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools