Open Access

Open Access

ARTICLE

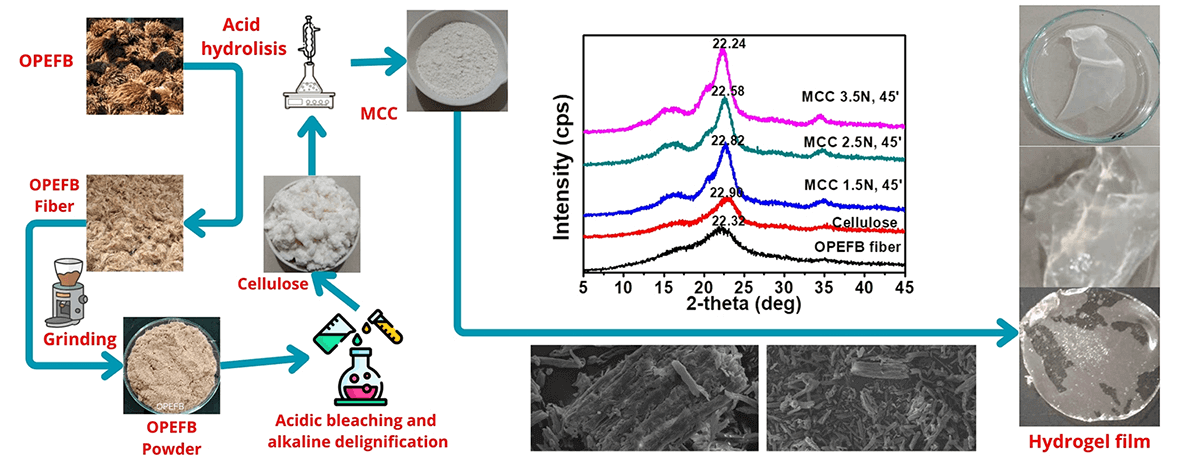

Characterization and Selection of Microcrystalline Cellulose from Oil Palm Empty Fruit Bunches for Strengthening Hydrogel Films

1 Department of Agroindustrial Technology, Faculty of Agriculture, Universitas Lambung Mangkurat, Jl A Yani Km 36, Banjarbaru, South Kalimantan, 70714, Indonesia

2 Doctoral Programme of Agroindustrial Technology, Faculty of Agricultural Technology, Universitas Gadjah Mada, Jl Flora No. 1, Bulaksumur, Yogyakarta, 55281, Indonesia

3 Department of Agroindustrial Technology, Faculty of Agricultural Technology, Universitas Gadjah Mada, Jl Flora No. 1, Bulaksumur, Yogyakarta, 55281, Indonesia

* Corresponding Authors: Susi Susi. Email: ; Makhmudun Ainuri. Email:

Journal of Renewable Materials 2024, 12(3), 513-537. https://doi.org/10.32604/jrm.2024.045586

Received 31 August 2023; Accepted 29 December 2023; Issue published 11 April 2024

Abstract

Microcrystalline cellulose (MCC) is one of the cellulose derivatives produced as a result of the depolymerization of a part of cellulose to achieve high crystallinity. When implemented in other polymers, high crystallinity correlates with greater strength and stiffnes, but it can reduce the water-holding capacity. The acid concentration and hydrolysis time will affect the acquisition of crystallinity and water absorption capacity, both of which have significance as properties of hydrogel filler. The study aimed to evaluate the properties and select the MCC generated from varying the proportion of hydrochloric acid (HCl) and the appropriate hydrolysis time as a filler for film hydrogel. MCC was produced by hydrolyzing cellulose of oil palm empty fruit bunches (OPEFB) with the HCl solution at varied concentrations and periods. The results show that the longer hydrolysis times and higher HCl concentrations increase crystallinity and density while lowering yield and water absorption. The extensive acid hydrolysis reduces the amorphous area significantly, allowing the depolymerization to occur and extend the crystalline area. The morphological properties of the MCC, which are smaller but compact, indicate the presence of disintegrating and diminishing structures. A 2.5 N HCl concentration and a 45-min hydrolysis time succeed in sufficient crystallinity as well as maintaining good water absorption capacity. The treatment produced MCC with absorption capacity of 4.03 ± 0.26 g/g, swelling capacity of 5.03 ± 0.26 g/g, loss on drying of 1.44% ± 0.36, bulk and tapped density of 0.27 ± 0.031 g/cm3 and 0.3 ± 0.006 g/cm3, respectively, with a crystallinity index of 88.89% ± 4.76 and a crystallite size of 4.23 ± 0.70 nm. The MCC generated could potentially be utilized as a hydrogel film filler, since a given proportion will be able to maintain the strength of the hydrogel, not readily dissolve but absorb water significantly.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools