Open Access

Open Access

ARTICLE

Effect of Adhesive Type on the Quality of Coconut Shell Charcoal Briquettes Prepared by the Screw Extruder Machine

1 Department of Mechanical Engineering, Faculty of Engineering, Universitas Negeri Semarang, Gunung pati, Semarang, 50229, Indonesia

2 Arka Tama Indonesia, Co., Ltd., Karawang, West Java, 41382, Indonesia

3 Department of Mechanical Engineering, Dili Institute of Technology, Ai-meti Laran Street, Dili, Timor Leste

* Corresponding Author: Samsudin Anis. Email:

Journal of Renewable Materials 2024, 12(2), 381-396. https://doi.org/10.32604/jrm.2023.047128

Received 26 October 2023; Accepted 27 November 2023; Issue published 11 March 2024

Abstract

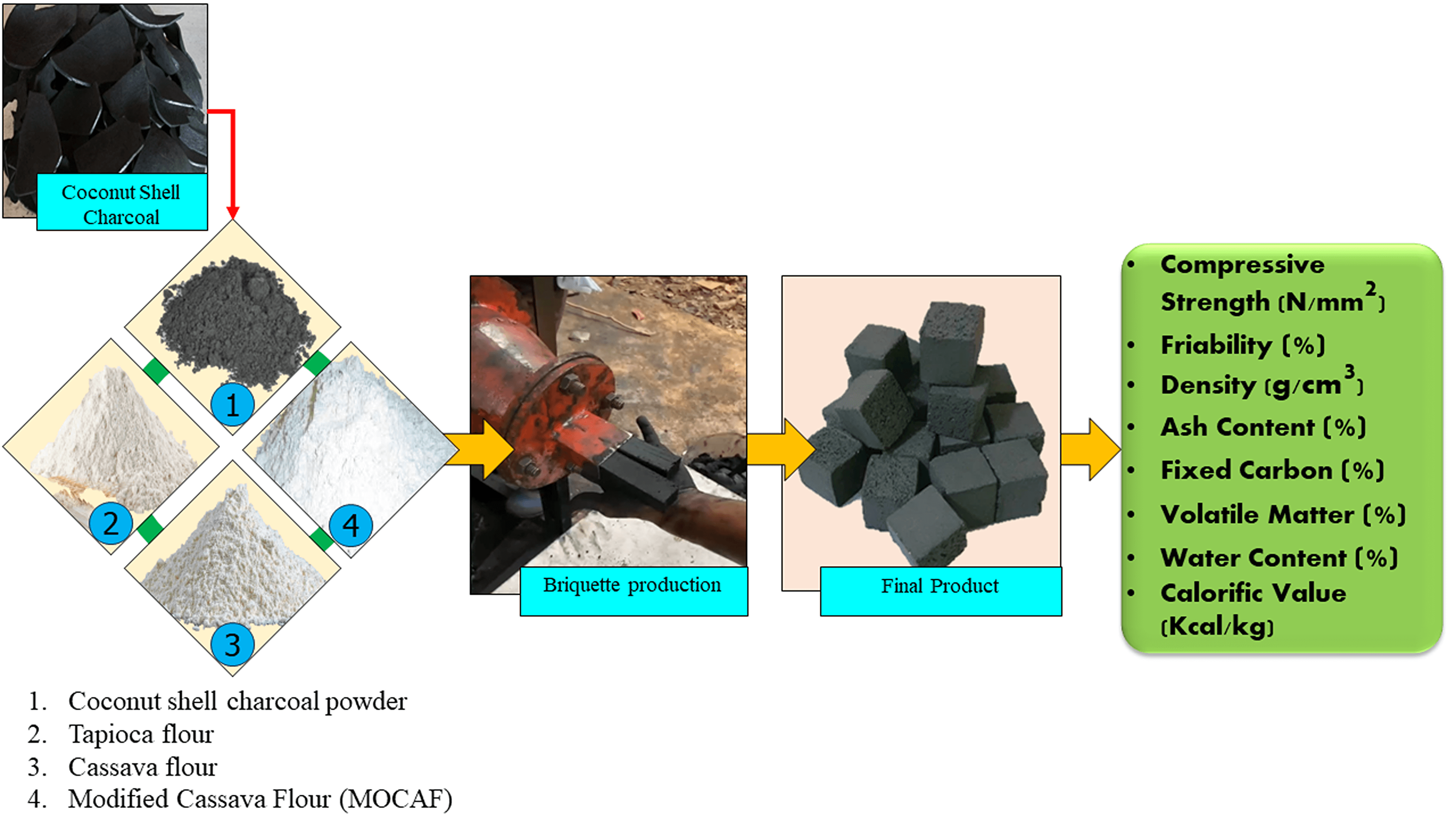

Indonesia is one of the largest coconut-producing countries in the world. The utilization of coconut shell waste into briquettes will increase the selling value and become a great export opportunity. However, the effect of adhesives on the quality of coconut shell charcoal briquettes made using screw extruder machine has not been widely studied. This study aims to determine the effect of adhesive type on the quality of coconut shell charcoal briquettes. The process of fabricating briquettes in this study included crushing, mixing, blending, pressing, and drying. In the mixing process, 3 types of adhesives were used, namely tapioca flour (Briquette_1), cassava flour (Briquette_2), and modified cassava flour (Briquette_3) with a concentration of 5% of the weight of coconut shell charcoal powders. The quality of the resulting briquettes and commercial briquettes will be evaluated by moisture content, ash content, volatile matter, fixed carbon, calorific value, density, compressive, and drop test testing. The results of this research showed that the type of adhesive had a significant effect on the quality of the briquettes produced. Specimen Briquette_1 had better quality than commercial briquettes (Briquette_4) and other briquette specimens. The test results showed that Briquette_1 produced briquettes with better compressive strength and friability than the other specimens, at 6.95 N/mm2 and 4.44%, respectively. The moisture content, ash content, fixed carbon, and calorific value of Briquette_1 have met the requirements set by the Indonesian National Standard (SNI) number 01-6235-2000. Meanwhile, the volatile matter content and density of Briquette_1 are by the standards of Japan and the United States America (USA).Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools