Open Access

Open Access

ARTICLE

Color and Gloss Changes of a Lignin-Based Polyurethane Coating under Accelerated Weathering

1 Department of Wood Science and Technology, Faculty of Natural Resources, Tarbiat Modares University, Tehran, Iran

2 Department of Resin and Additives, Institute for Color Science and Technology, P.O. Box 16765-654, Tehran, Iran

3 LERMAB, University of Lorraine, Blvd des Aiguillettes, Nancy, 54000, France

4 Wood Science and Engineering, Luleå University of Technology, Skellefteå, Sweden

* Corresponding Authors: Farhood Najafi. Email: ; Antonio Pizzi. Email:

Journal of Renewable Materials 2024, 12(2), 305-323. https://doi.org/10.32604/jrm.2023.043953

Received 17 July 2023; Accepted 28 September 2023; Issue published 11 March 2024

Abstract

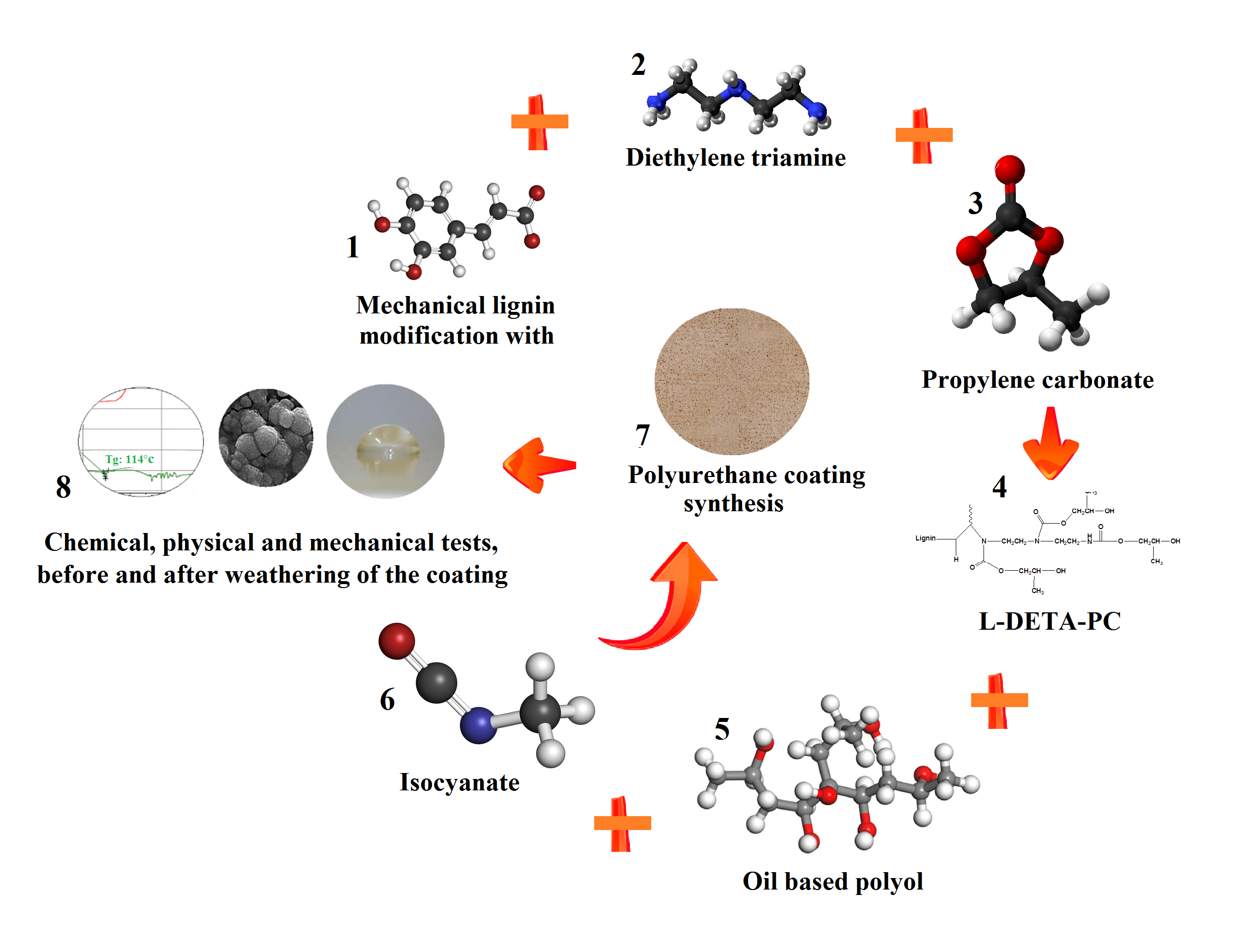

The purpose of this research study was to investigate the properties of polyurethane coatings based on lignin nano-particles. For this purpose, the prepared coatings were applied to pine wood surfaces and weathered artificially. Subsequently, color and gloss of the coatings were measured before and after the weathering test. Field emission scanning electron microscopy (FE-SEM) micrographs prepared from the coatings showed that the average size of nano-particles in the polyurethane substrate was approximately 500 nm. Nuclear magnetic resonance (13C-NMR) spectroscopy showed that strong urethane bonds were formed in the nano-lignin-based polyurethane. Differential calorimetric analysis (DSC) test revealed that the glass-transition temperature (Tg) of lignin nano-particles modified with diethylenetriamine (DETA) was 112.8°C and Tg of lignin nano-particles modified with ethylenediamine (EDA) was 102.5°C, which is lower than the Tg of un-modified lignin (114.6°C) and lignin modified with DETA (126.8°C) and lignin modified with EDA (131.3°C). The coatings modified with lignin nano-particles had a greater change in gloss. The lignin nano-particles in the modified coating are trapping hydroxyl radicals which reduces photoactivity and yellowing of the polyurethane by about 3 times compared to unmodified polyurethane coatings. After weathering test, the nano-lignin-based coating had a rougher surface with a lower contact angle (0.78°) compared to the unmodified polyurethane coating (0.85°).Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools