Open Access

Open Access

ARTICLE

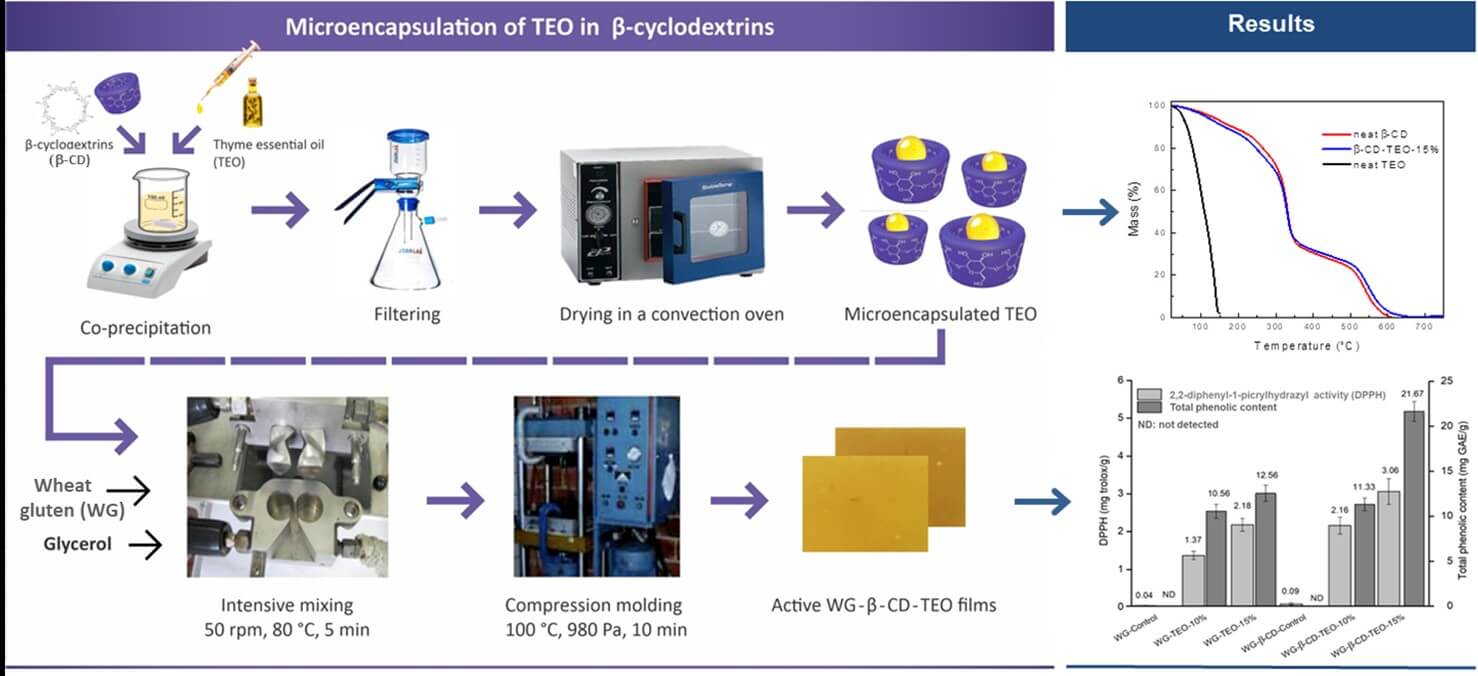

Multifunctional Films Based on Wheat Gluten and Microencapsulated Thyme Essential Oil

1 Instituto de Investigaciones en Ciencia y Tecnología de Materiales, Facultad de Ingeniería, Universidad Nacional de Mar del Plata-Consejo Nacional de Investigaciones Científicas y Técnicas, Mar del Plata, 7600, Argentina

2 Grupo de Investigación en Ingeniería en Alimentos, Facultad de Ingeniería, Universidad Nacional de Mar del Plata-Consejo Nacional de Investigaciones Científicas y Técnicas, Mar del Plata, 7600, Argentina

* Corresponding Author: María Roberta Ansorena. Email:

(This article belongs to the Special Issue: Recent Advances on Renewable Materials)

Journal of Renewable Materials 2024, 12(12), 2049-2068. https://doi.org/10.32604/jrm.2024.055151

Received 19 June 2024; Accepted 01 November 2024; Issue published 20 December 2024

Abstract

In this work, active and edible films for food packaging were obtained by intensive mixing and compression molding of the wheat gluten (WG) glycerol-plasticized paste. Thyme essential oil (TEO, 10 and 15 wt.%) was incorporated as the active component microencapsulated in β-cyclodextrins (β-CD) and included directly into the biopolymer matrix for comparison. It was found that films incorporating microencapsulated TEO are more soluble in water (total soluble matter (dry method) of about 33% and 36.6% vs. 22.4% and 18.6%, for films containing 10% and 15% TEO, respectively) but less rigid than those obtained with free oil (elastic tensile moduli of 6.9 and 3.1 vs. 9.9 and 6.8 MPa, for films containing 10% and 15% TEO, respectively), although the water vapor permeability of the former is lower (4.95 10−9 and 6.29 10−9 vs. 8.85 10−9 and 11.13 10−9 g/Pa*s*m, for films containing 10% and 15% TEO, respectively). Active films containing both free and encapsulated TEO inhibited gram (+) as well as gram (−) bacteria and exhibited enlarged antioxidant properties, with the latter presenting slightly better performance. In addition, encapsulation slowed the release rate of TEO from the films, allowing the bioactive to remain active in the film for much longer. Therefore, the present work revealed that films prepared from TEO/β-CD microcapsules included in compression-molded wheat gluten matrices showed great potential to be used as an active food packaging.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools