Open Access

Open Access

ARTICLE

Influence of Recycling Waste Glass as Fine Aggregate on the Concrete Properties

1

Department of Civil Engineering, Bilad Alrafidain University College, Diyala, 32001, Iraq

2

Department of Civil Engineering, College of Engineering, University of Diyala, Diyala, 32001, Iraq

3

Department of Civil Engineering, Zakir Husain Engineering College, Aligarh Muslim University, Aligarh, 202002, India

4

Department of Civil Engineering, College of Engineering, University of Duhok, Duhok, 42001, Iraq

5

Department of Civil Engineering, College of Engineering, Nawroz University, Duhok, 42001, Iraq

6

Department of Chemical Engineering, College of Engineering, King Khalid University, Abha, 61421, Saudi Arabia

7

Department of Civil Engineering, College of Engineering, King Khalid University, Abha, 61421, Saudi Arabia

8

Department of Civil Engineering, High Institute of Technological Studies, Mrezgua University Campus, Nabeul, 8000, Tunisia

* Corresponding Authors: Rafal A. Hadi. Email: ; Shaker Qaidi. Email:

(This article belongs to the Special Issue: Potential Materials Towards Sustainable Construction)

Journal of Renewable Materials 2023, 11(6), 2925-2940. https://doi.org/10.32604/jrm.2023.025558

Received 19 July 2022; Accepted 24 August 2022; Issue published 27 April 2023

Abstract

Recent years have witnessed an increase in the quantity of waste glass (WG) across the globe. Replacing the fine aggregate with WG is one of the steps toward preserving the natural resources of the environment and creating low-cost concrete. The present study is concerned with replacing fine aggregates with glass powder (GP) at (0%, 15%, 30%, and 50%). It has studied the fresh and hardened properties (compressive strength, tensile strength, hardened density, and slump) for all the mentioned percent replacements. The findings have shown that all mixtures containing GP gave acceptable slump results within the design limits (2–5 cm) according to ACI standard 211.1. It has been observed that increasing the proportion of GP led to a decrease in the weight of concrete. Lastly, replacing GP with sand by 30% has led to an increase in the compressive strength by about 2.4% and 12.45%, and the tensile strength by about 2.5% and 26.54% at 7- and 28-d, respectively in comparison to normal concrete.Keywords

Concrete is the most commonly used commercially produced building material, and its popularity is expanding rapidly day by day [1–3]. The most important constituent materials used in the manufacture of concrete are cement and aggregate [4–6]. These are essential materials for the construction field [7–10].

The quantity of waste glass (WG) produced has gradually redoubled in recent years due to the increasing demand for glass products such as packaging or container glass, bulb glass, and flat glass. The majority of WG has a limited life and has been dropped in lowland areas; it must be reused to minimize environmental concerns because it is not biodegradable [11–13]. Recycling and reducing waste are key parts of a waste-management system since they contribute to conserving natural resources, reducing requests for waste landfill space, and reducing pollution of water and air [14].

Various unique properties of natural glass such as the silicate nature of glass, non-water absorbing, high hardness, and high resistance against corrosion and heat encouraged different researchers to use glass in the concrete mixture and study its effect on the properties of concrete [11–13]. Various studies have verified the partial replacement of glass powder as a partial substitute for fine aggregates in concrete. Ling et al. [15] investigated the effects of recycled glass cullet as a partial substitute for river sand at 10%, 20%, and 30% on the slump, tensile strength, compressive strength, static modulus of elasticity, and density of self-compact concrete (SCC) and found a direct proportion between the results of the slump and the replacement ratios, while a clear decrease in the other mechanical characteristics of (SCC) mixes as the glass aggregate content increased [16–18]. Shekhawat et al. [16] used four different percentages (10%, 20%, 30%, and 40%) of glass waste as a partial substitute for fine aggregate in ordinary concrete (M-25) to study the hardened properties such as compressive strength, tensile strength, and density in addition to a slump. The highest results for slump were recorded by replacing sand by 40% with WG, while for the other characteristics, it was noted that there was an increase in compressive strength up to 30% replacement of fine aggregates by WG, and splitting tensile strength decreased with increasing waste glass content [19,20]. Arivalagan et al. [19] verified the effect of glass dust (GD) on some properties of concrete such as compressive strength, tensile strength, and flexural strength by replacing fine aggregates with GD at (10%, 20%, and 30%). They found a significant decrease in a slump was reached with an increase in the replacement ratio of GD. In comparison, the compression resistance increased up to 20% replacement level, as well as the tensile strength and flexural strength, which started decreasing after 20% replacement of GD by fine aggregate. They studied the effects of the partial replacement of glass powder with fine aggregates (10%, 20%, 30%, and 40%) on the compressive strength, tensile strength, and workability of concrete. Kassed et al. [20] studied the effects of the partial replacement of glass powder with fine aggregates at various rates (10%, 20%, 30%, and 40%) on the compressive strength, tensile strength, and workability of concrete. A clear decrease was found in the results of the slump when increasing the percentage of glass powder in the mixture. The compressive strength was increased for 10% replacement, after which it began to decrease gradually by increasing the percentage of glass powder content. The tensile strength decreased significantly when adding glass powder compared to the reference concrete mix. The main goal of the current study is to check the properties of normal concrete (30-M) (compressive strength, tensile strength, density, and slump) by recycling glass waste at rates of 15%, 30%, and 50% as a partial replacement for fine aggregate.

Ordinary Portland cement, type I, known commercially as Krista, conforms to Iraqi specifications No. 5/1984 [21]. It was used during the current study and its properties are shown in Table 1 and Fig. 1.

Figure 1: Ordinary portland cement

Drinkable water was used for mixing and curing concrete. According to the ASTM standard specification [22], it was clean and free of harmful amounts of oil, organic materials, and other bad things.

The coarse aggregate used for making normal concrete was natural aggregate with a 20 mm maximum particle size. Fig. 2, Tables 2 and 3 show the grading of this type of aggregate and the physical characteristics, respectively. Findings showed that the physical characteristics and the coarse aggregate grading were within the requirements of the Iraqi specifications (I.Q.S No. 45, 1984) [23].

Figure 2: Natural coarse aggregate

The fine aggregate used in the making of normal concrete was natural sand (Al-Ukhaider). The sand was free from clay and other impurities. Fig. 3a shows the preparation of natural sand to dry before use; Fig. 3b shows the preparation of sand for the sieve analysis test; Table 4 and Fig. 5 show the sieve analysis of the used sand, which complied with the requirements of Iraqi specification (I.Q.S No. 45, 1984) [23].

Figure 3: (a) Graded natural sand (Al-Ukhaider), (b) Sieve analysis of natural fine aggregate

Typically, glass is made using sand, lime, and soda. The glass used in light bulbs, cookware, and windowpanes is not recyclable due to unique additions such as ceramics and other contaminants. Table 5 shows the chemical properties of the glass powder (GP) that was used in this study.

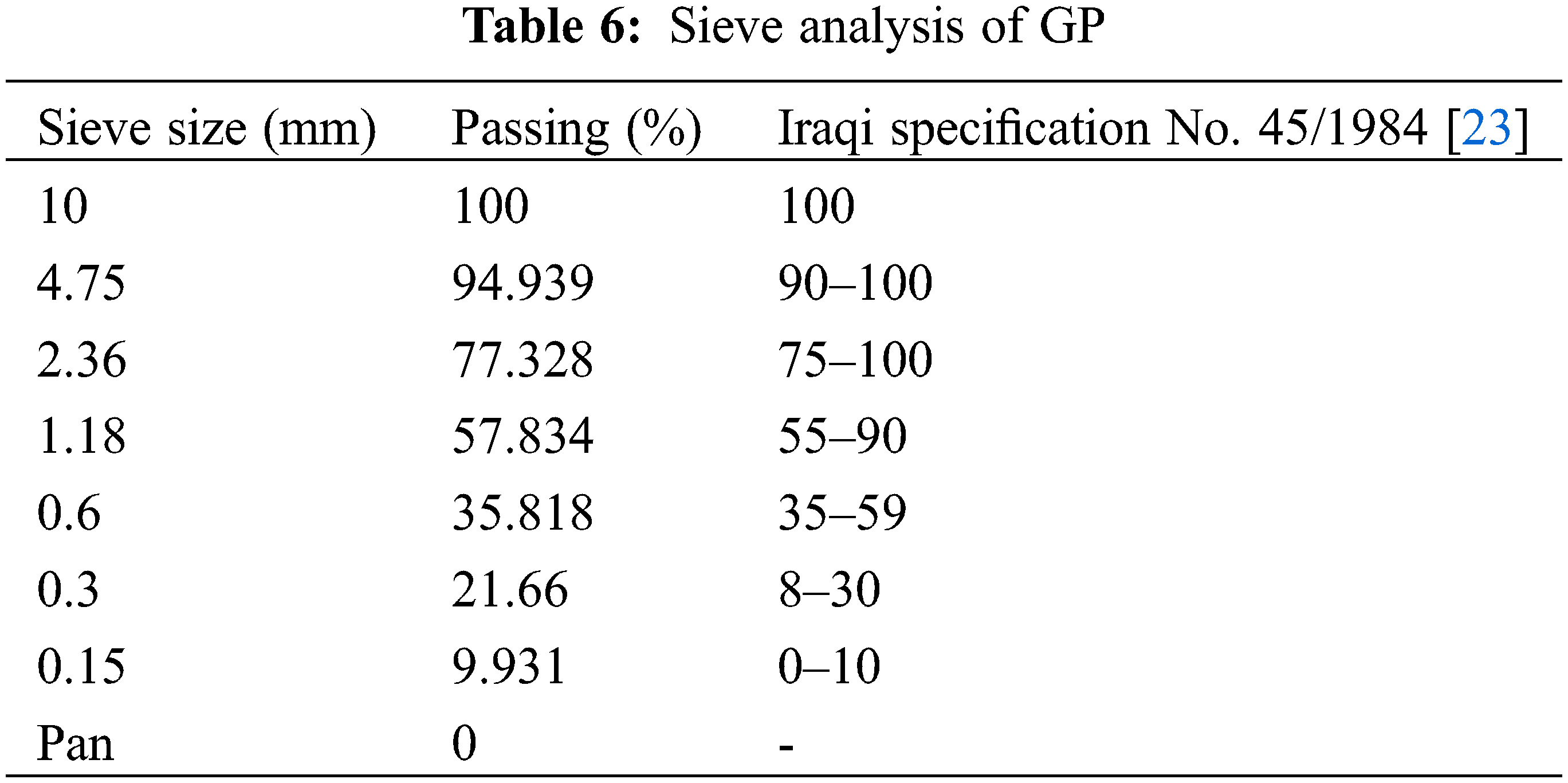

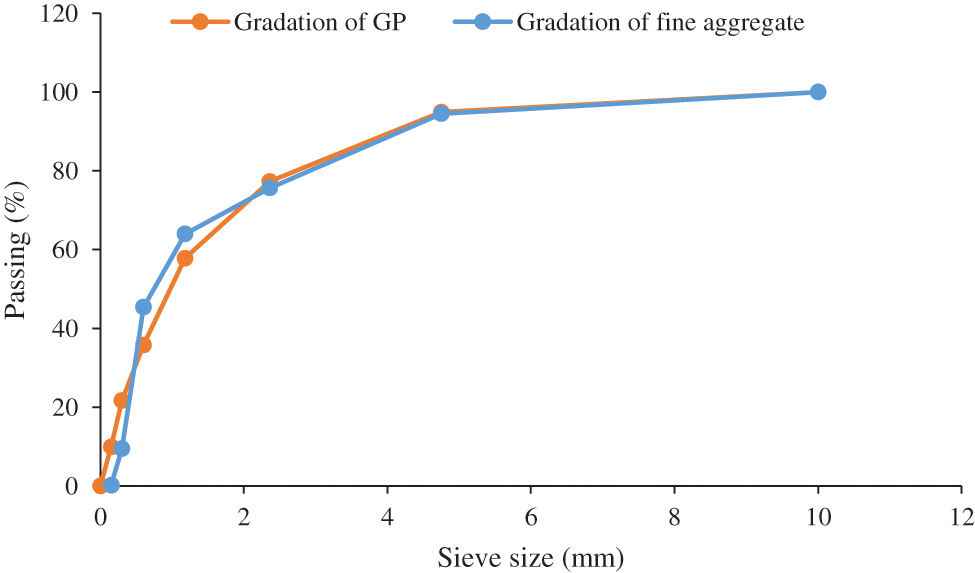

In the current study, the glass was broken as in Fig. 4a and then crushed into very small particles (GP) as shown in Fig. 4b to use it as a partial substitute in different proportions from sand in normal concrete. Table 6 and Fig. 5 show the sieve analysis of GP.

Figure 4: (a) Waste GLASS (WG), (b) Glass Powder (GP)

Figure 5: Gradation of GP and fine aggregate

Normal concrete mixes were designed according to ACI-211. The concrete mix was designed with a slump of 20–50 mm and a 28-d cube compressive strength of 30 MPa in mind. The use of different ratios of GP (15%, 30%, 50%) as a partial substitute for fine aggregate. Mix details of normal concrete are given in Table 7.

Cement, fine and coarse aggregates were prepared and stored in the same condition as in the laboratory for their use in normal concrete production. The WG was broken and collected in a carton box and then crushed by a grinding machine shown in Fig. 6 to turn it into a powder with small particles approximately equal to those of sand.

Figure 6: Grinding machine

In the mixer, the batch GP, coarse aggregate, and fine aggregate were mixed for 60 s. The cement was then added and mixed for 30 s until all materials were overlapping. Water is added gradually as the mixing process continues for two minutes until a homogenous mix is obtained. The procedure of the mixing process is shown in Fig. 7.

Figure 7: Mixing procedure

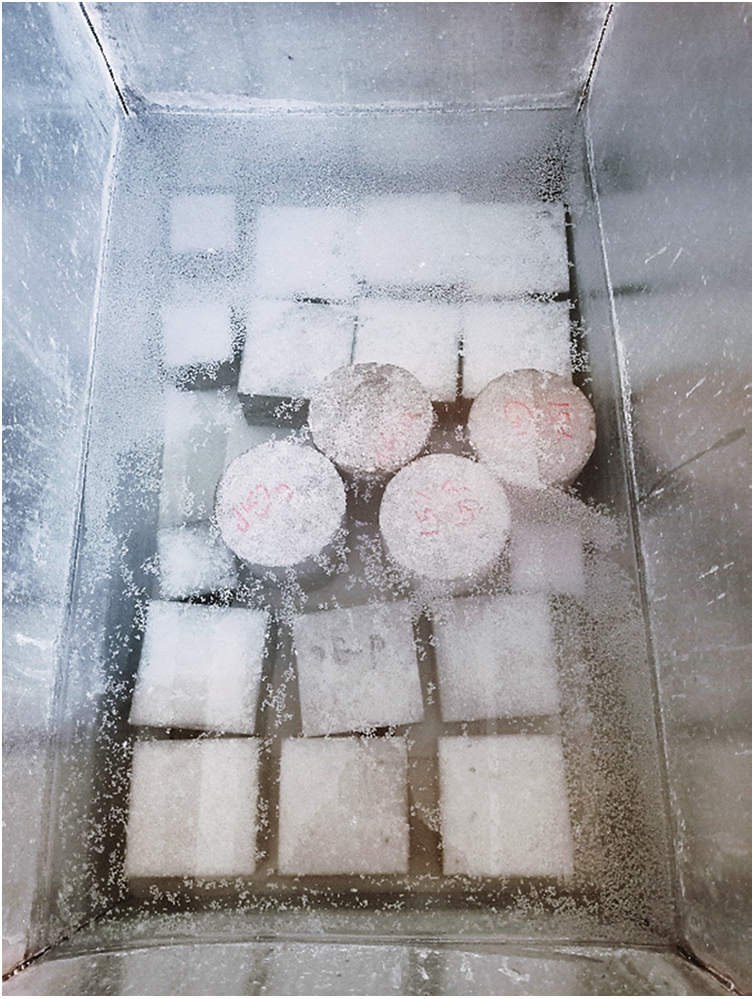

Cube-shaped molds with dimensions of 15 × 15 × 15 cm, 10 × 10 × 10 cm, and cylinders with dimensions of 15 × 30 cm were used to test the compressive strength, hardened density, and tensile strength, respectively. After the mixing process was completed, the inside surfaces of molds were coated with a thin layer of oil for easy de-molding, and then concrete was poured with the use of a vibrating machine (Fig. 8) to prevent any segregation of the concrete components after hardening. Then the surface of the samples is leveled using a trowel (Fig. 9). The molds were opened after 24 h of casting, and the specimens were placed in curing pools at a laboratory temperature of 25.2°C (Fig. 10).

Figure 8: Using the vibrator machine during casting the specimens

Figure 9: Leveling the surface of specimens

Figure 10: Curing of normal concrete specimens

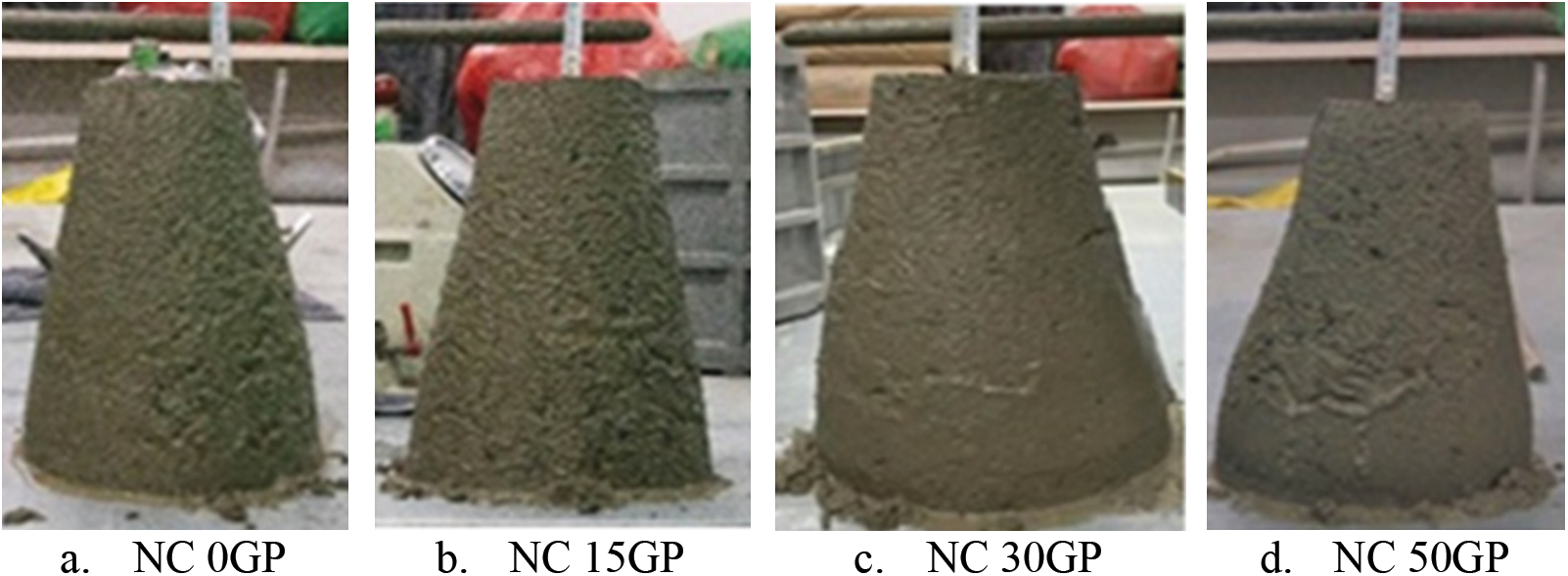

This test technique conforms to ASTM C143 [24] standards. As shown in Fig. 11, the vertical distance between the original and displaced location of the center of the concrete’s top surface is measured and reported as the concrete’s slump.

Figure 11: Slump test

The compressive strength of normal concrete is a significant property because it indirectly provides other mechanical characteristics such as flexural strength, tensile splitting strength, and elasticity modulus. The compression test is done as shown in Fig. 12 according to ACI 318. And by using the following equation:

Figure 12: Compressive strength test

3.3 Splitting Tensile Strength Test

This test is a method to measure the tensile strength of concrete by the application of a diametric compressive force on a cylindrical concrete specimen placed with its axis horizontal between the plates of a testing machine according to ASTM C496 [25], as shown in Fig. 13. The following equation was used to figure out the splitting tensile strength of all tested samples:

where:

fct: is the concrete splitting tensile strength (MPa),

P: is the maximum load applied by the testing machine (N),

L: the cylinder length (mm), and d is the cylinder diameter (mm).

Figure 13: Splitting tensile strength test

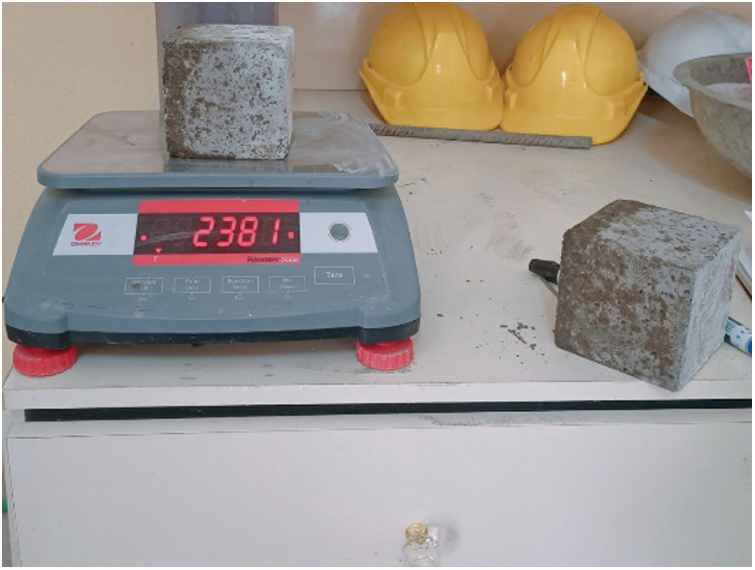

To study the effect of GP on the density of hardened concrete at 7- and 28-d, cubes with dimensions of 10 × 10 × 10 cm were cast, and after the end of the prescribed curing period, the cube was weighed on a sensitive scale as shown in Fig. 14. The density is then found by dividing the weight by the cube’s volume, as shown in the following equation:

where:

M = Mass of hardened concrete (Kg)

V = Volume of the concrete cube (m3)

Figure 14: Hardened density test

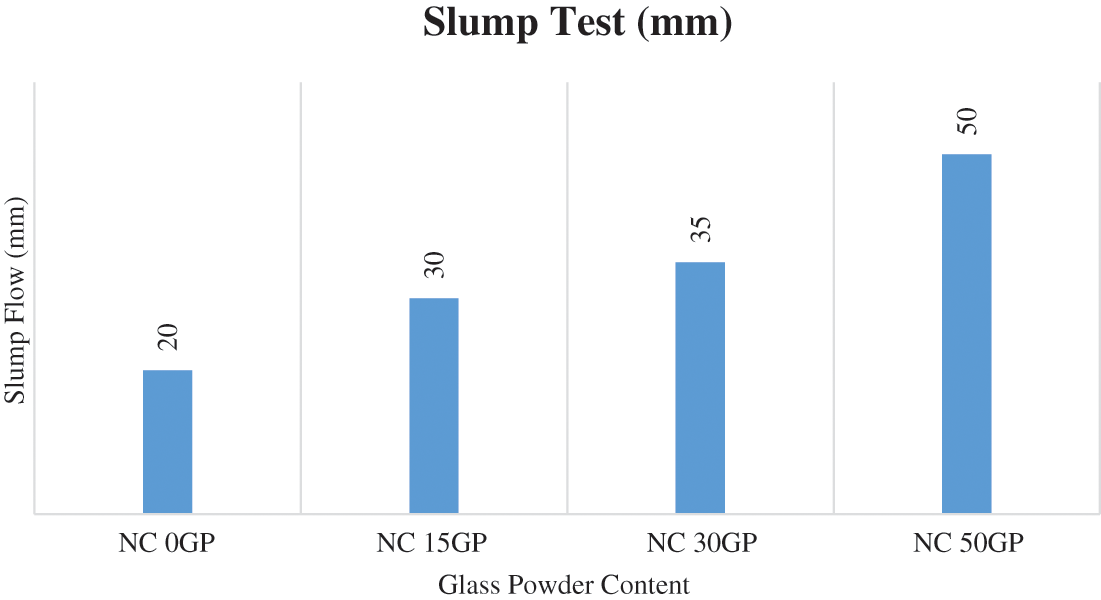

The most common method for testing the workability of concrete is the slump test, which can be conducted in the laboratory or on-site. It is not good for extremely wet or extremely dry concrete. After assessing the workability of concrete prepared using WG powder at various degrees of substitution, it was found that all mixes containing GP had acceptable slump measurements within the design limitations (20–50 mm) specified by ACI 211, as seen in Table 8, Figs. 15 and 16. There is a slight increase in the slump when the content of glass powder increases because glass is a solid material and therefore does not absorb water, unlike fine aggregates, and that leads to improving the workability of concrete.

Figure 15: Slump cone test

Figure 16: Slump cone test results after 150 s

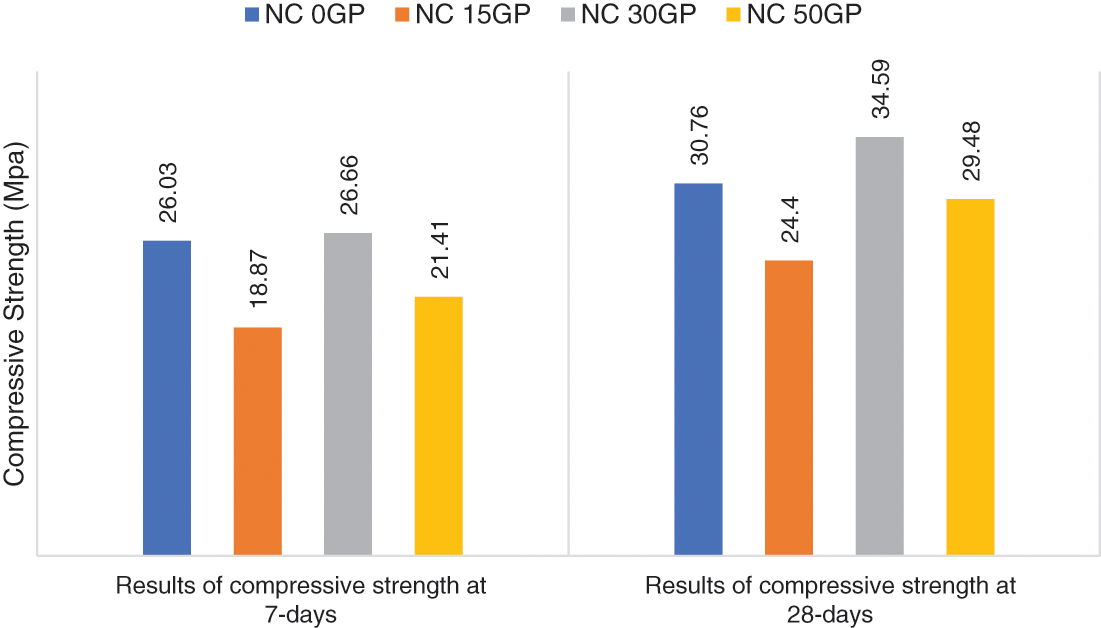

4.2 Findings of Compressive Strength

As an indication of the other mechanical characteristics, compressive strength is the most significant characteristic. Where the other criteria were typically well-correlated with compressive strength. Fig. 17 shows how different GP ratios change compression at 7- and 28-d.

Figure 17: Findings of compressive strength

The findings showed that the best proportion of replacing sand with GP was 30%, which increased the compressive strength by 2.4% and 12.45% at 7- and 28-d, respectively, compared to the control specimens (NC 0GP). As for the percentage of 15% substitute, it decreased the compressive strength by 27.5% and 20.68%, as well as the ratio of 50% substitute, which caused a relatively small decrease in compressive strength by 17.75% and 4.16% at 7- and 28-d, respectively. The weak compressive strength when using a high content of glass powder is due to the smoothness of the glass particles and thus the lack of cohesion between them and the cement paste [26–29].

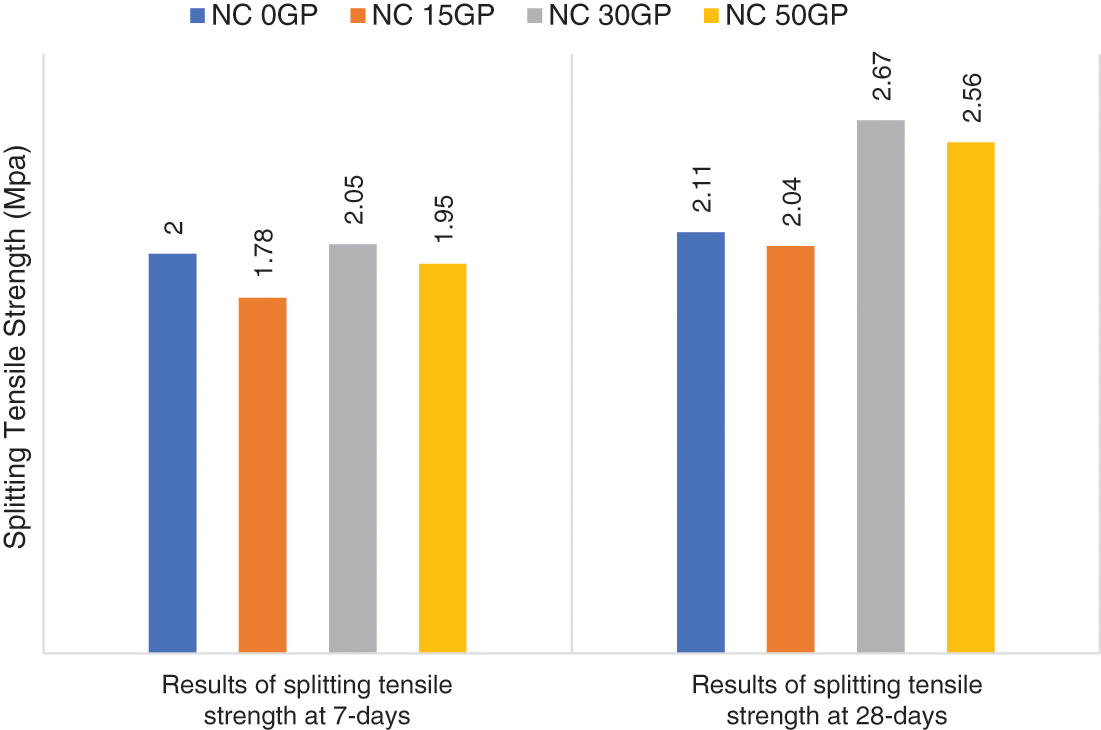

4.3 Findings of Splitting Tensile Strength

The test was done using the same machine for compressive strength on 150 × 300 mm cylinder specimens by placing them horizontally. The effect of different ratios of GP on the splitting tensile strength of concrete is shown in Fig. 18.

Figure 18: Findings of splitting tensile strength

The findings show that the best tensile strength was obtained by using a 30% substitute ratio of GP. Compared to the reference specimens, it made the tensile strength go up by 2.5% at 7-d and 26.54% at 28-d.

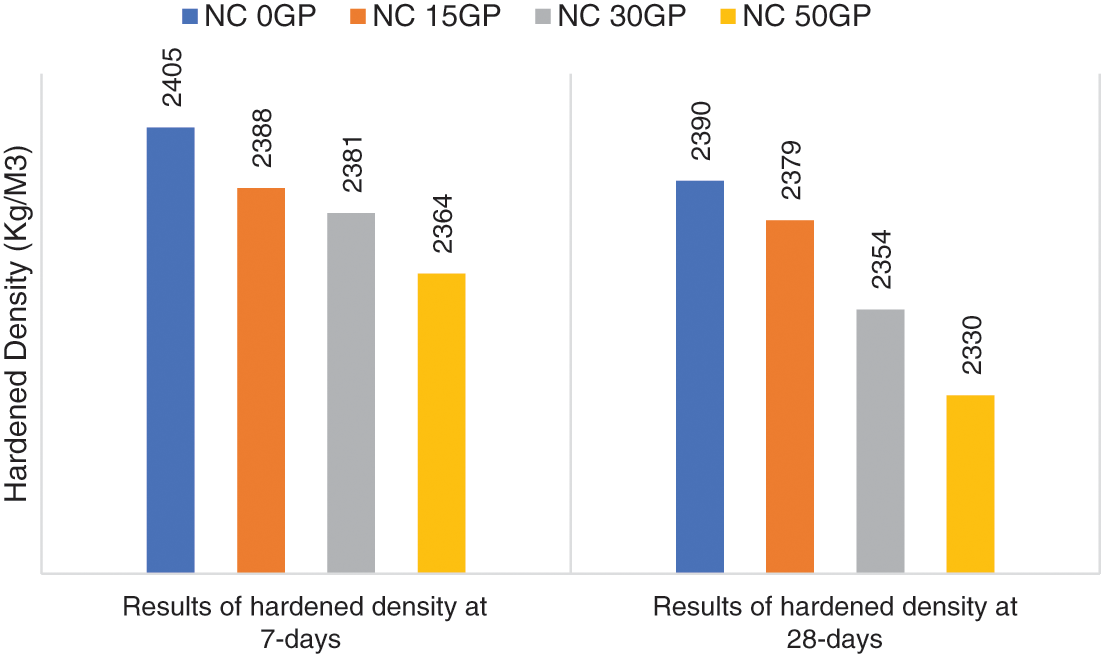

4.4 Findings of Hardened Density Test

By observing the findings presented in Fig. 19, we notice a reduction in the weight of concrete with an increase in the percentage of GP, where the lowest weight of concrete (2364 Kg/m3) and the highest weight of concrete (2332 Kg/m3) were recorded at 7- and 28-d, respectively, using a 50% substitute percentage of GP.

Figure 19: Findings of hardened density

Finally, more or less the behavior of adding waste materials to concrete with fresh and hardened properties can be found in the literature reports here.

The following observations were made based on the experimental examination of the usage of WG powder as a substitute for fine aggregate in concrete:

1. All mixes containing GP gave slightly increased slump results compared to the reference mixture but still acceptable findings within the design limits (2–5 cm) according to ACI standard 211.1.

2. Both sand and GP are graded uniformly and per Iraqi standard No. 45/1984.

3. Due to the low specific weight of glass compared to the specific weight of sand, adding more GP causes the weight of the concrete to go down.

4. Because the specific gravity of the glass cullet is less than that of the granite sand, the hardened density is less.

5. Replacing GP with sand by 30% leads to an increase in the compressive strength by about 2.4% and 12.45% and the tensile strength by about 2.5% and 26.54% at 7- and 28-d, respectively, compared to normal concrete (without GP).

6. The increase in mechanical properties was probably achieved thanks to the use of fine glass aggregate particles, which enhance the aggregate-cement matrix bonding strength, and the use of green glass aggregate with a higher Mohs hardness.

7. Based on the results above, it seems that the increase in mechanical properties of concrete with the addition of glass powder is probably resulting from the pozzolanic activity. This will be the subject of further research, in which tests for other types of cement, other types of glass waste and its mixes, and different contents and the size of the aggregate particle, with particular emphasis on long-term fatigue tests, are planned to be conducted.

The following suggestions may be considered for future work:

1. Study the effect of GP as a partial substitute for cement.

2. A study of how using GP as a partial replacement for fine aggregate affects the flexibility of concrete.

3. Study of higher percentages of GP as a partial substitute for fine aggregates.

Acknowledgement: This research work is supported by the Deanship of Scientific Research at King Khalid University under Grant No. RGP. 2/246/43. Moreover, the authors thank Dr. Bareq Raad Raheem (PhD in English Language, Department of English, Aligarh Muslim University) for the proofreading of the paper.

Funding Statement: This research work is supported by the Deanship of Scientific Research at King Khalid University under Grant No. RGP. 2/246/43.

Conflicts of Interest: The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

1. Ahmed, S. N., Hamah Sor, N., Ahmed, M. A., Qaidi, S. M. A. (2022). Thermal conductivity and hardened behavior of eco-friendly concrete incorporating waste polypropylene as fine aggregate. Materials Today: Proceedings, 57, 818–823. https://doi.org/10.1016/j.matpr.2022.02.417 [Google Scholar] [CrossRef]

2. Al-Tayeb, M. M., Aisheh, Y. I. A., Qaidi, S. M. A., Tayeh, B. A. (2022). Experimental and simulation study on the impact resistance of concrete to replace high amounts of fine aggregate with plastic waste. Case Studies in Construction Materials, 17, e01324. https://doi.org/10.1016/j.cscm.2022.e01324 [Google Scholar] [CrossRef]

3. Almeshal, I., Al-Tayeb, M. M., Qaidi, S. M. A., Abu Bakar, B. H., Tayeh, B. A. (2022). Mechanical properties of eco-friendly cements-based glass powder in aggressive medium. Materials Today: Proceedings, 58, 1582–1587. https://doi.org/10.1016/j.matpr.2022.03.613 [Google Scholar] [CrossRef]

4. Cao, M., Khan, M. (2021). Effectiveness of multiscale hybrid fiber reinforced cementitious composites under single degree of freedom hydraulic shaking table. Structural Concrete, 22(1), 535–549. https://doi.org/10.1002/suco.201900228 [Google Scholar] [CrossRef]

5. Cao, M., Khan, M., Ahmed, S. (2020). Effectiveness of calcium carbonate whisker in cementitious composites. Periodica Polytechnica. Civil Engineering, 64(1), 265. https://doi.org/10.3311/PPci.14288 [Google Scholar] [CrossRef]

6. ASTM International Committee C09 on Concrete and Concrete Aggregates (2017). Standard test method for splitting tensile strength of cylindrical concrete specimens1. ASTM International. [Google Scholar]

7. de Castro, S., de Brito, J. (2013). Evaluation of the durability of concrete made with crushed glass aggregates. Journal of Cleaner Production, 41, 7–14. https://doi.org/10.1016/j.jclepro.2012.09.021 [Google Scholar] [CrossRef]

8. Serpa, D., de Brito, J., Pontes, J. (2015). Concrete made with recycled glass aggregates: Mechanical performance. ACI Materials Journal, 112(1). https://doi.org/10.14359/51687366 [Google Scholar] [CrossRef]

9. Faraj, R. H., Ahmed, H. U., Rafiq, S., Sor, N. H., Ibrahim, D. F. et al. (2022). Performance of self-compacting mortars modified with nanoparticles: A systematic review and modeling. Cleaner Materials, 4, 100086. https://doi.org/10.1016/j.clema.2022.100086 [Google Scholar] [CrossRef]

10. Khan, M., Ali, M. (2019). Improvement in concrete behavior with fly ash, silica-fume and coconut fibres. Construction and Building Materials, 203, 174–187. https://doi.org/10.1016/j.conbuildmat.2019.01.103 [Google Scholar] [CrossRef]

11. Khan, M., Rehman, A., Ali, M. (2020). Efficiency of silica-fume content in plain and natural fiber reinforced concrete for concrete road. Construction and Building Materials, 244, 118382. https://doi.org/10.1016/j.conbuildmat.2020.118382 [Google Scholar] [CrossRef]

12. Kou, S. C., Poon, C. S. (2009). Properties of self-compacting concrete prepared with recycled glass aggregate. Cement and Concrete Composites, 31(2), 107–113. https://doi.org/10.1016/j.cemconcomp.2008.12.002 [Google Scholar] [CrossRef]

13. Lam, C. S., Poon, C. S., Chan, D. (2007). Enhancing the performance of pre-cast concrete blocks by incorporating waste glass–ASR consideration. Cement and Concrete Composites, 29(8), 616–625. https://doi.org/10.1016/j.cemconcomp.2007.03.008 [Google Scholar] [CrossRef]

14. Lee, G., Poon, C. S., Wong, Y. L., Ling, T. C. (2013). Effects of recycled fine glass aggregates on the properties of dry–mixed concrete blocks. Construction and Building Materials, 38, 638–643. https://doi.org/10.1016/j.conbuildmat.2012.09.017 [Google Scholar] [CrossRef]

15. Ling, T. C., Poon, C. S., Wong, H. W. (2013). Management and recycling of waste glass in concrete products: Current situations in Hong Kong. Resources, Conservation and Recycling, 70, 25–31. https://doi.org/10.1016/j.resconrec.2012.10.006 [Google Scholar] [CrossRef]

16. Shekhawat, B. S., Aggarwal, D. V. (2014). Utilisation of waste glass powder in concrete–A literature review. International Journal of Innovative Research in Science, Engineering and Technology, 3(7), 1329–1333. [Google Scholar]

17. Najm, H. M., Khan, S. A. R. A. (2022). Mechanical and microstructural analysis of waste ceramic optimal concrete reinforced by hybrid fibers materials: A comprehensive study. Journal of Architectural Environment & Structural Engineering Research, 5, 11–33. [Google Scholar]

18. Najm, H. M., Nanayakkara, O., Ahmad, M., Sabri Sabri, M. M. (2022). Colour change of sustainable concrete containing waste ceramic and hybrid fibre: Effect of temperature. Materials, 15(6), 2174. https://doi.org/10.3390/ma15062174 [Google Scholar] [PubMed] [CrossRef]

19. Arivalagan, S., Sethuraman, V. (2021). Experimental study on the mechanical properties of concrete by partial replacement of glass powder as fine aggregate: An environmental friendly approach. Materials Today: Proceedings, 45, 6035–6041. [Google Scholar]

20. Kassed, G. J., Ali, S. K. (2021). Reuse of glass waste as a partial replacement to fine aggregates in concrete. Journal of Engineering, 27(8), 43–58. https://doi.org/10.31026/j.eng.2021.08.04 [Google Scholar] [CrossRef]

21. No, I. S. (1984). Portland cement. Baghdad-Iraq: The Iraqi Central Organization for Standardization and Quality Control. [Google Scholar]

22. ASTM-C1602 (2012). Standard specification for mixing water used in the hydraulic cement concrete. West Conshohocken, PA, USA: ASTM International. [Google Scholar]

23. Limit, I. S. (1984). I.Q.S No. 45―Aggregate from natural sources for concrete and construction, ||. Bagdad: Central Organization for Standardization and Quality Control. [Google Scholar]

24. ASTM-C143 (2012). Standard test method for slump of hydraulic-cement concrete. West Conshohocken, PA: ASTM International. [Google Scholar]

25. ASTM-C496 (2012). Standard test method for splitting tensile strength of cylindrical concrete specimens. West Conshohocken, PA: ASTM International. [Google Scholar]

26. Saeed, A., Najm, H. M., Hassan, A., Qaidi, S., Sabri, M. M. S. et al. (2022). A comprehensive study on the effect of regular and staggered openings on the seismic performance of shear walls. Buildings, 12(9), 1293. https://doi.org/10.3390/buildings12091293 [Google Scholar] [CrossRef]

27. Qaidi, S., Najm, H. M., Abed, S. M., Özkılıç, Y. O., Al Dughaishi, H. et al. (2022). Concrete containing waste glass as an environmentally friendly aggregate: A review on fresh and mechanical characteristics. Materials, 15(18), 6222. https://doi.org/10.3390/ma15186222 [Google Scholar] [PubMed] [CrossRef]

28. Xie, C., Cao, M., Guan, J., Liu, Z., Khan, M. (2021). Improvement of boundary effect model in multi-scale hybrid fibers reinforced cementitious composite and prediction of its structural failure behavior. Composites Part B: Engineering, 224, 109219. https://doi.org/10.1016/j.compositesb.2021.109219 [Google Scholar] [CrossRef]

29. Renuka, G., Melinamani, S., Nadaf, A., Pawar, A., Allipur, B. (2020). The partial replacement of fine aggregate by glass powder. International Journal of Futures Research and Development, 1(1), 89–98. https://doi.org/10.46625/IJFRD [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools