Open Access

Open Access

ARTICLE

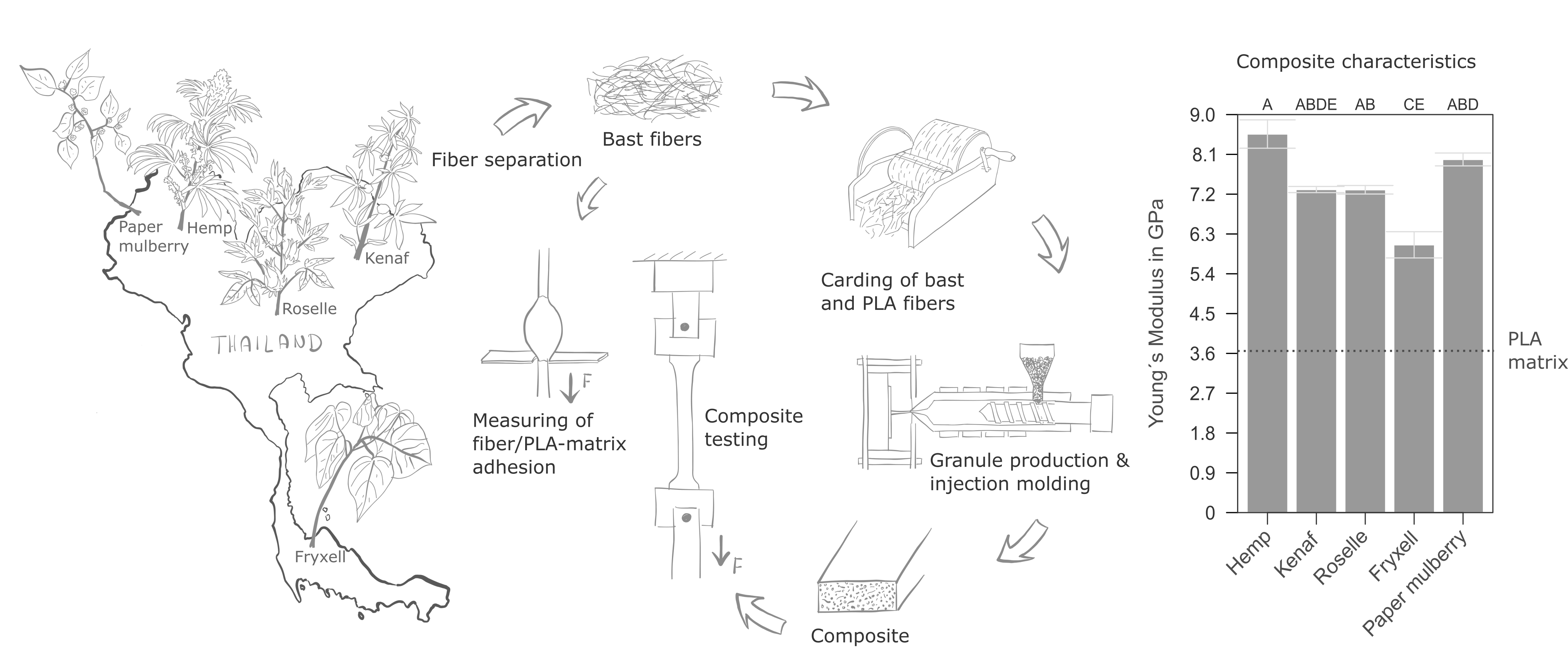

Potential of Thai Bast Fibers for Injection Molded PLA Composites

1 The Biological Materials Group, Department of Biomimetics, HSB-City University of Applied Sciences, Bremen, D-28199, Germany

2 Department of Botany, Faculty of Liberal Arts and Science, Kasetsart University, Kamphaeng Saen, Nakhon Pathom, 73140, Thailand

3 Bioproduct Science, Department of Science, Faculty of Liberal Art and Science, Kasetsart University, Kamphaeng Saen, Nakhon Pathom, 73140, Thailand

4 Department of Science and Mathematics, Faculty of Science and Technology, Rajamangala University of Technology Tawan-Ok, Chonburi, 20110, Thailand

* Corresponding Author: Nina Graupner. Email:

(This article belongs to the Special Issue: Natural Fibre Composites: Design, Materials Selection and Fabrication)

Journal of Renewable Materials 2023, 11(5), 2279-2300. https://doi.org/10.32604/jrm.2023.025529

Received 18 July 2022; Accepted 30 September 2022; Issue published 13 February 2023

Abstract

Thailand has a huge variability of bast fiber plants, some of which have been little researched regarding their applicability in composites. Bast fiber(bundle)s from different species were investigated and incorporated into a polylactide (PLA) matrix by injection molding. Hemp and kenaf were used as well-studied fibers, while roselle, Fryxell and paper mulberry are less extensively characterized. Tensile strength, tensile modulus and interfacial shear strength (IFSS) of single fiber(bundle)s were highest for hemp, followed by kenaf, roselle, Fryxell and paper mulberry. Despite the lower tensile strength and IFSS of paper mulberry, the highest tensile strength was achieved for the paper mulberry/PLA composite followed by hemp/PLA. Scanning electron microscope (SEM) analyses showed that the single cells in paper mulberry fiber bundles, in contrast to the other fiber types investigated, were only partially bonded to each other, which explains the lower strength of the fiber bundles. The higher aspect ratio of fiber(bundle)s of paper mulberry in the PLA composite can explain the good composite characteristics. Apart from hemp, paper mulberry shows the best reinforcing effect in the PLA matrix and offers interesting potential for composite applications. Compared to neat PLA, the tensile strength could be increased by 24% and the tensile modulus by 54%.Graphic Abstract

Keywords

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools