Open Access

Open Access

ARTICLE

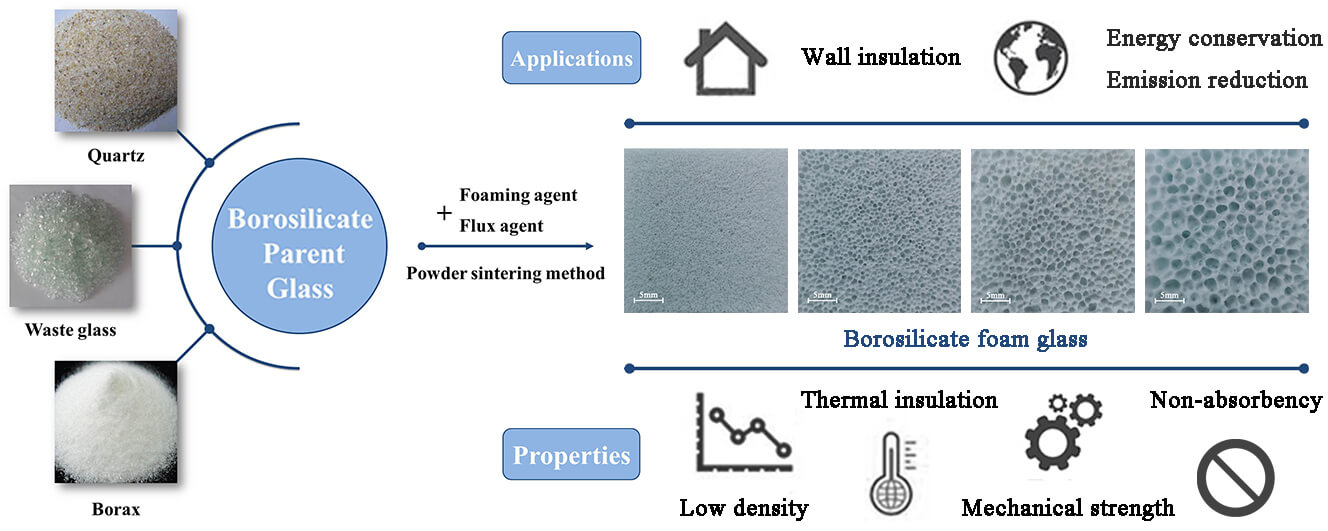

Preparation and Study of Borosilicate Foam Glass with High Thermal Insulation and Mechanical Strength

1 School of Material Science and Engineering, Shanghai University, Shanghai, China

2 Huichang New Material Co., Ltd., Xuancheng, China

3 Changda Thermal Insulation Technology Co., Ltd., Xuancheng, China

* Corresponding Author: Jianjun Xie. Email:

(This article belongs to the Special Issue: Renewable Material from Agricultural Waste and By-Product and Its Applications)

Journal of Renewable Materials 2023, 11(5), 2125-2141. https://doi.org/10.32604/jrm.2023.025127

Received 23 June 2022; Accepted 29 July 2022; Issue published 13 February 2023

Abstract

Foam glass is a kind of green building material that is widely used because of its excellent thermal insulation and mechanical properties. In this study, the borosilicate foam glass was fabricated by powder sintering method using recycled soda lime waste glass, quartz, and borax as the primary raw materials. CaCO3 was used as a foaming agent and Na2CO3 as a flux agent. Results showed that as the quartz content decreases from 30 to 17.5 wt.% and borax content increases from 5 to 17.5 wt.%, the pore size, porosity, and thermal insulation of borosilicate foam glass increase significantly, while the compressive strength decreases slightly. When the content of quartz and borax are both 17.5 wt.%, borosilicate foam glass with outstanding performance can be prepared, whose pore distribution is uniform, mean pore size is 1.93 mm, total porosity is 83.44%, thermal conductivity is 0.0711 W/(m⋅K), and compressive strength is 2.37 MPa. Finally, the influences of foaming agent content, flux agent content, foaming temperature, and holding time on the pore structure and various properties of borosilicate foam glass were investigated by orthogonal test. According to the results, the foaming temperature has a significant effect, and appropriate foaming agent content, flux agent content, and holding time help to form a uniform pore structure, thereby improving the thermal insulation and mechanical strength of the borosilicate foam glass.Graphic Abstract

Keywords

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools