Open Access

Open Access

REVIEW

Recycling Carbon Resources from Waste PET to Reduce Carbon Dioxide Emission: Carbonization Technology Review and Perspective

1 Faculty of Printing, Packaging Engineering and Digital Media Technology, Xi’an University of Technology, Xi’an, 710048, China

2 School of Materials Science and Engineering, Jingdezhen Ceramic Institute, Jingdezhen, 333403, China

3 Environmental Resources and Material Industry Technology Research Institute of Zhongzhao Construction Groups, Guangzhou, 510623, China

4 Research Institute, Transfar Chemicals Group, Hangzhou, 311215, China

5 Key Laboratory of Auxiliary Chemistry and Technology for Chemical Industry, Ministry of Education, Shaanxi University of Science and Technology, Xi’an, 710021, China

6 Shaanxi Collaborative Innovation Center of Industrial Auxiliary Chemistry and Technology, Shaanxi University of Science and Technology, Xi’an, 710021, China

* Corresponding Author: Xing Zhou. Email:

Journal of Renewable Materials 2023, 11(5), 2085-2108. https://doi.org/10.32604/jrm.2023.025032

Received 18 June 2022; Accepted 13 September 2022; Issue published 13 February 2023

Abstract

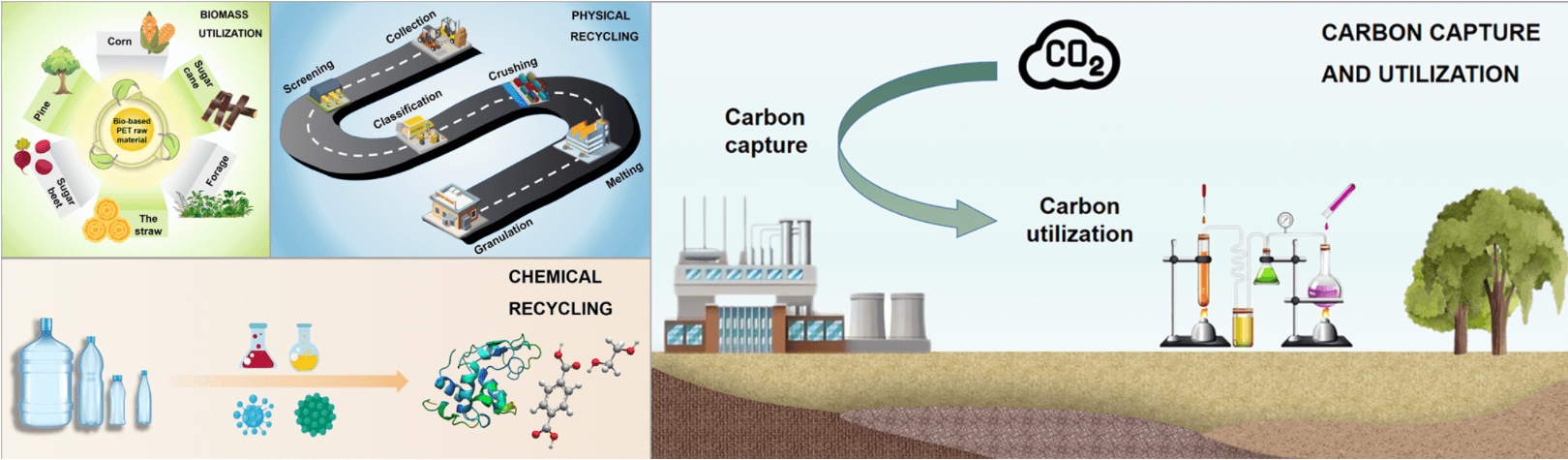

Greenhouse gas emissions from waste plastics have caused global warming all over the world, which has been a central threat to the ecological environment for humans, flora and fauna. Among waste plastics, waste polyethylene terephthalate (PET) is attractive due to its excellent stability and degradation-resistant. Therefore, merging China’s carbon peak and carbon neutrality goals would be beneficial. In this review, we summarize the current state-of-the-art of carbon emission decrease from a multi-scale perspective technologically. We suggest that the carbon peak for waste PET can be achieved by employing the closed-loop supply chain, including recycling, biomass utilization, carbon capture and utilization. Waste PET can be a valuable and renewable resource in the whole life cycle. Undoubtedly, all kinds of PET plastics can be ultimately converted into CO2, which can also be feedstock for various kinds of chemical products, including ethyl alcohol, formic acid, soda ash, PU, starch and so on. As a result, the closed-loop supply chain can help the PET plastics industry drastically reduce its carbon footprint.Graphic Abstract

Keywords

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools