Open Access

Open Access

ARTICLE

Hydration Characteristics and Mechanical Properties of Cement-Based Materials Modified by Calcined Zeolite and Montmorillonite

1

Faculty of Materials Science and Chemistry, Key Laboratory of Geological Survey and Evaluation of Ministry of Education, China

University of Geosciences, Wuhan, 430074, China

2

Key Laboratory of Advanced Building Materials of Anhui Province, Anhui Jianzhu University, Hefei, 230022, China

3

Guangxi Key Laboratory of New Energy and Building Energy Saving, Guilin University of Technology, Guilin, 541004, China

4

Key Laboratory of Road Structure and Materials of Ministry of Transport, Chang’an University, Xi’an, 710064, China

5

University of Southern Queensland, Centre for Sustainable Agricultural Systems, Toowoomba, QLD, 4350, Australia

6

State Key Laboratory of Silicate Materials for Architectures, Wuhan University of Technology, Wuhan, 430070, China

7

Key Laboratory for Green & Advanced Civil Engineering Materials and Application Technology of Hunan Province, College of Civil

Engineering, Hunan University, Changsha, 410082, China

* Corresponding Authors: Ping Duan. Email: ; Yingcan Zhu. Email:

Journal of Renewable Materials 2023, 11(5), 2191-2208. https://doi.org/10.32604/jrm.2023.025197

Received 27 June 2022; Accepted 02 September 2022; Issue published 13 February 2023

Abstract

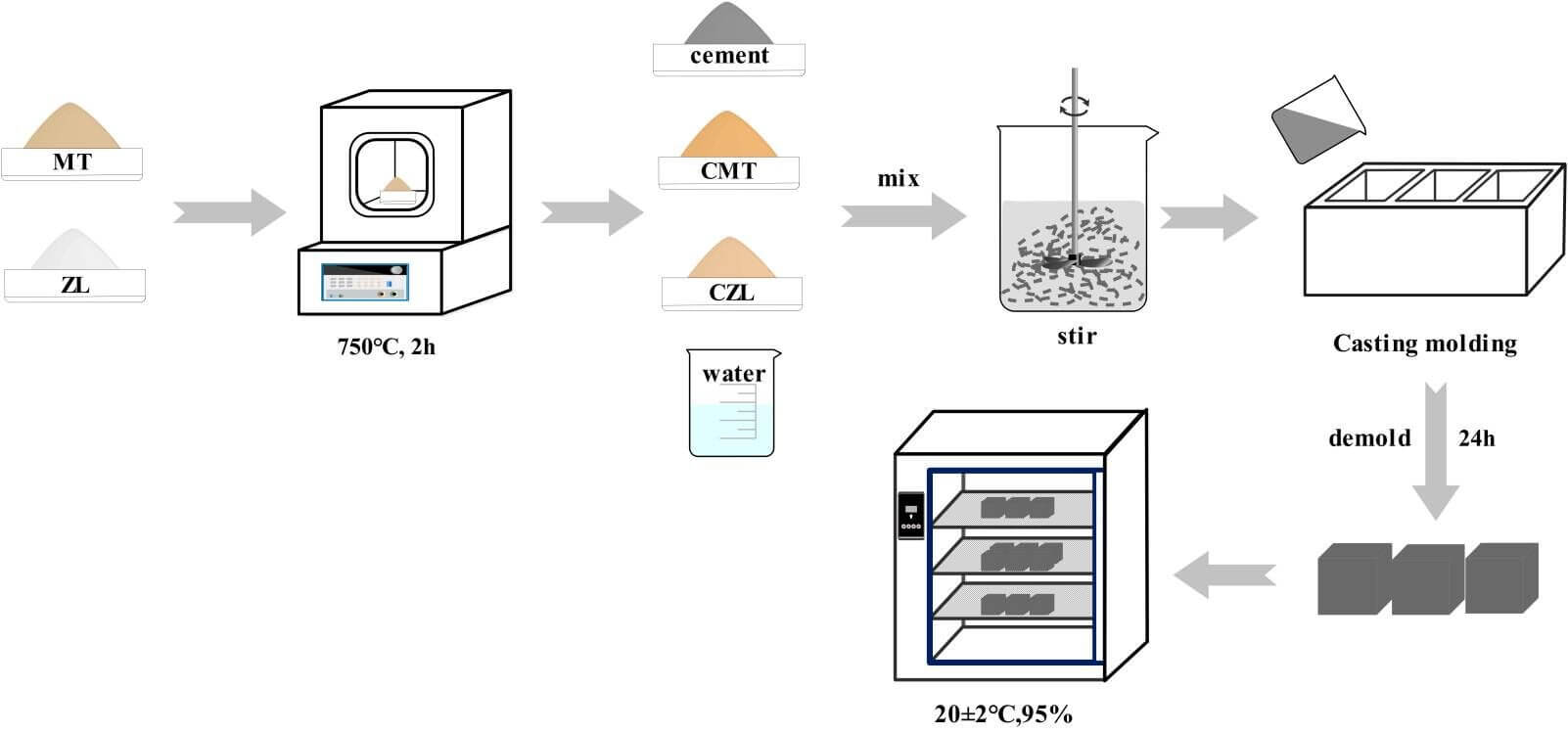

Montmorillonite and clinoptilolite zeolite were used as representative materials to prepare calcined clay-cement binary cementitious materials in order to study the effect of calcination treatment on the activation of clay minerals and the activity difference between layered and framed clays in this research. The influence of different calcined clay content (2%, 4%, 6%, 8%, 10%) on the fluidity, compressive strength, microstructure, phase change, and hydration heat of cement-based materials were analyzed. The calcined clay improves the fluidity of cement-based materials as compared with the uncalcined group. The addition of calcined montmorillonite (CMT) improves the development of mechanical strength, and the optimal compressive strength reaches 85 MPa at 28 days with 8% CMT. However, the activity of calcined clinoptilolite zeolite (CZL) is weak with few reaction sites, which slightly reduced the mechanical strength as compared to the blank sample. The addition of CMT changes the microscopic morphology of hydration products such as C-S-H and C-A-H, leading to the formation and transformation of ettringite in the early stage. It promotes the gradual polymerization of Si-O bonds into SiO-Si bonds simultaneously, which accelerates the early hydration process. However, CZL acts mainly as a filling function in the cementitious system. In brief, CMT as an admixture can improve the mechanical properties of cement, but CZL has little effect. This work provides a guideline for the applications of calcined clay in cement, considering the influence of clay type on workability and mechanical strength.Graphic Abstract

Keywords

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools