Open Access

Open Access

ARTICLE

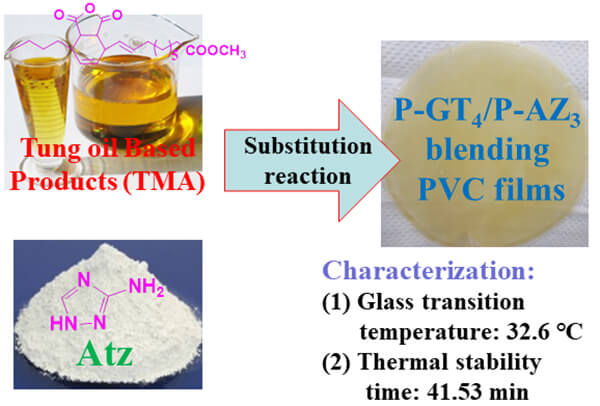

Synergistic Modification of PVC with Nitrogen-Containing Heterocycle and Tung-Oil Based Derivative for Enhanced Heat Stabilization and Plasticization Behavior

1 School of Agricultural Engineering, Jiangsu University, Zhenjiang, 212013, China

2 Institute of Chemical Industry of Forest Products, Chinese Academy of Forestry (CAF), Nanjing, 210042, China

3 Key Laboratory of Chemistry and Engineering of Forest Products, State Ethnic Affairs Commission, Guangxi Key Laboratory of Chemistry and Engineering of Forest Products, Guangxi University for Nationalities, Nanning, 530006, China

4 Research Center of Fluid Machinery Engineering and Technology, Jiangsu University, Zhenjiang, 212013, China

* Corresponding Author: Puyou Jia. Email:

Journal of Renewable Materials 2023, 11(4), 2015-2031. https://doi.org/10.32604/jrm.2023.026063

Received 13 August 2022; Accepted 21 September 2022; Issue published 01 December 2022

Abstract

The additives present in polyvinyl chloride (PVC) materials are the major source of organic by-products during PVC degradation. The thermal stabilizer and plasticizer are the main additives that endow PVC with the required properties during its processing. However, these two additives easily migrate when samples are obtained by physical mixing of the additives with PVC. This causes the reduction of PVC sample efficacy and the increase in the formation of organic by-products in the radiolysis process. In this work, two kinds of grafted PVC samples (tung-oil derivative grafted PVC and Atz grafted PVC, abbreviated as P-GT4 and P-AZ3) were synthesized by chemical grafting of 3-amino-1,2,4-triazole (Atz) and tung-oil derivative on PVC, respectively. These two PVC samples were then blended at different mass ratios to obtain hybrid PVC materials with excellent plasticization, thermal stability and migration resistance ability. Differential scanning calorimetry (DSC), discoloration, Congo red test and thermogravimetric analysis (TGA) showed that when the mass ratio of P-GT4 to P-AZ3 in the mixed PVC resin was 1:3, the resulting P1:3-GT4-AZ3 (P4) presented the best plasticization and thermal stability. The kinetics of thermal decomposition showed that the activation energy of P4 was much higher than that of the reference material [PVC/DOTP/CaSt2/ZnSt2, PVC/CZ41 for short] at mass loss α = 20% and 80%. In addition, the leaching test showed that P4 material possessed excellent migration resistance ability.Graphic Abstract

Keywords

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools