Open Access

Open Access

ARTICLE

Preparation and Properties of Vegetable-Oil-Based Thioether Polyol and Ethyl Cellulose Supramolecular Composite Films

1 College of Materials Science and Technology, Beijing Forestry University, Beijing, 100083, China

2 Institute of Chemical Industry of Forestry Products, CFA, Nanjing, 210042, China

3 National Engineering Lab. for Biomass Chemical Utilization, Nanjing, 210042, China

4 Key Lab. of Chemical Engineering of Forest Products, National Forestry and Grassland Administration, Nanjing, 210042, China

5 Key Lab. of Biomass Energy and Material, Nanjing, 210042, China

6 Jiangsu Co-Innovation Center of Efficient Processing and Utilization of Forest Resources, Nanjing, 210042, China

* Corresponding Authors: Jian Fang. Email: ; Shouhai Li. Email:

(This article belongs to the Special Issue: Renewable Biomass as a Platform for Preparing Green Chemistry)

Journal of Renewable Materials 2023, 11(4), 1937-1950. https://doi.org/10.32604/jrm.2023.025126

Received 23 June 2022; Accepted 04 August 2022; Issue published 01 December 2022

Abstract

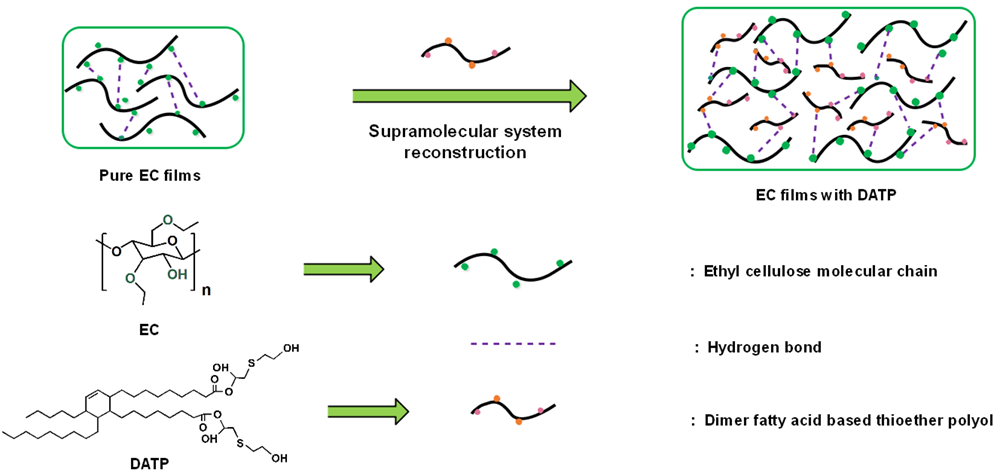

Ethyl cellulose (EC), an important biomass-based material, has excellent film-forming properties. Nevertheless, the high interchain hydrogen bond interaction leads to a high glass transition temperature of EC, which makes it too brittle to be used widely. The hydroxyl group on EC can form a supramolecular system in the form of a non-covalent bond with an effective plasticizer. In this study, an important vegetable-oil-based derivative named dimer fatty acid was used to prepare a novel special plasticizer for EC. Dimer-fatty-acid-based thioether polyol (DATP) was synthesized and used to modify ethyl cellulose films. The supramolecular composite films of DATP and ethyl cellulose were designed using the newly-formed van der Waals force. The thermal stability, morphology, hydrophilicity, and mechanical properties of the composite films were all tested. Pure EC is fragile, and the addition of DATP makes the ethyl cellulose films more flexible. The elongation at the break of EC supramolecular films increased and the tensile strength decreased with the increasing DATP content. The elongation at the break of EC/DATP (60/40) and EC/DATP (50/50) was up to 40.3% and 43.4%, respectively. Noticeably, the thermal initial degradation temperature of the film with 10% DATP is higher than that of pure EC, which may be attributed to the formation of a better supramolecular system in this composite film. The application of bio-based material (EC) is environmentally friendly, and the novel DATP can be used as a special and effective plasticizer to prepare flexible EC films, making it more widely used in energy, chemical industry, materials, agriculture, medicine, and other fields.Graphic Abstract

Keywords

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools