Open Access

Open Access

ARTICLE

Experimental Study on the Compressive Strength of Concrete with Different Wheat Straw Treatment Techniques

1

Tunnel and Underground Engineering Research Center of Jiangsu Province (TERC), Nanjing, 210041, China

2

School of Civil Engineering and Architecture, Anhui University of Science & Technology, Huainan, 232001, China

3

School of Earth Sciences and Engineering, Nanjing University, Nanjing, 210023, China

4

The First Geological Brigade of Jiangsu Geology and Mineral Exploration Bureau, Nanjing, 210041, China

* Corresponding Author: Liang Wen. Email:

Journal of Renewable Materials 2023, 11(10), 3681-3692. https://doi.org/10.32604/jrm.2023.027671

Received 08 November 2022; Accepted 27 December 2022; Issue published 10 August 2023

Abstract

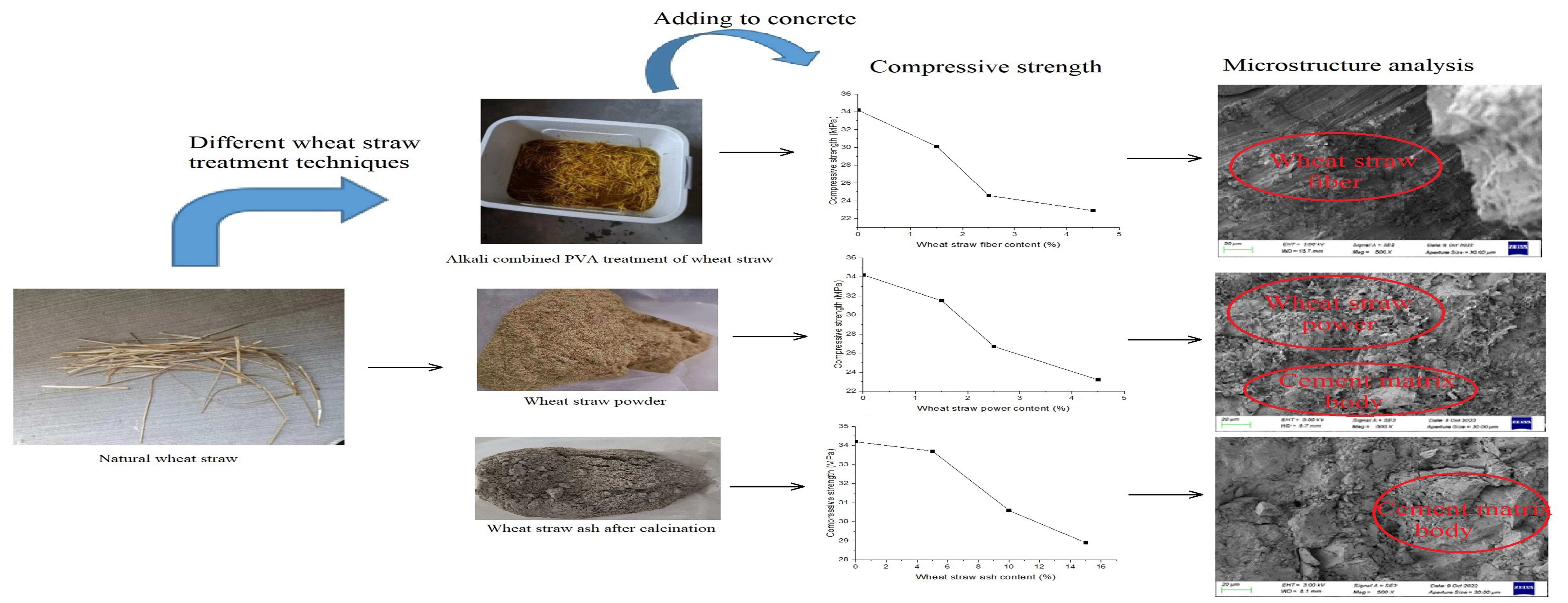

The treatment of wheat straw is very difficult, and its utilization rate is very low; accumulation causes air pollution and even fire. To make full use of wheat straw resources, we examined how using different physical and chemical methods to treat the wheat straw which can improve its strength abilities, or enhance the activity of wheat straw ash. In terms of concrete additives, it can reduce the amount of cement used. In this paper, we found that alkali treatment can significantly improve the tensile strength of wheat straw fiber, but polyvinyl alcohol treatment has no obvious effect on the strength of wheat straw fiber after alkali treatment. At the same time, we analyzed the wheat straw fiber microstructure through scanning electron microscopy, and we also studied the wheat straw ash chemical composition after 600°C high-temperature treatment. Through the compressive strength test, we found that the strength of concrete decreases with increasing of wheat straw fiber and wheat straw powder content, and the compressive strength of concrete with wheat straw ash instead of 5% cement decreases little, and the strength of the concrete also decreases with the increasing of wheat straw ash. Through the macroscopic observation of the failure form of concrete, we found that the failure form of concrete with wheat straw ash is similar to that of common concrete, while the failure degree of concrete with wheat straw fiber and wheat straw powder is weakened. Through the scanning electron microscope test of the concrete, it was found that wheat straw fiber has an effect on the cracking of concrete and the inner compactness of concrete can also be affected by adding wheat straw ash and wheat straw powder.Graphic Abstract

Keywords

As a large agricultural producer, China produces a lot of crop waste; for example, straw is a byproduct of agricultural production. With the enhancement of people’s awareness of environmental protection, it is becoming increasingly difficult to dispose of such waste resources. In contrast, we know that straw-reinforced soil bodies can improve the strength of soil and enhance the deformation ability of soil [1,2]. Based on the study of straw reinforcement in soil, we will explore the utilization of wheat straw resources in concrete.

As a building material, concrete is needed in very large quantities in engineering construction. The most important cementing material is cement in the ratio of concrete, but both the production and use of cement consume many resources and emit many greenhouse gases [3]. The use of straw to prepare concrete is an effective method of resource utilization, and it can reduce cement consumption while providing effective treatment of straw waste. This method for cement production is environmentally friendly and sustainable, and the straw resources can also be conveniently and cheaply obtained. It is very meaningful to study the application of straw resources in concrete, and adding different forms of straw or straw ash with different contents to make concrete is feasible [4,5].

Straw resources are an economical and renewable resource, and research on their use in the application of concrete is of great significance. However, straw contains more cellulose, hemicellulose and lignin sugar, and hemicellulose and sugar have a bad impact on the concrete performance. In addition, the binding force of straw is limited, so it is different from steel fiber, glass fiber and other conventional concrete fibers [6,7]. Straw can be added to concrete in many forms, such as straw fiber, straw powder, or straw ash. Sheridan et al. [3] produced rapeseed straw concrete, which is made of aggregate, water and lime binder, and found that the compressive strength of rapeseed straw concrete is higher than that of hemp straw concrete. Jiang et al. [8] found that alkali modification of wheat straw fiber can improve the wheat straw fiber cement-based composites, and this method has an important significance for the development and application of the wheat straw fiber cement-based composites. Ammari et al. [9] provided four methods of straw treatment and found that the hot water treatment of straw fiber added into the sand concrete with higher compressive strength than no treatment of straw for sand concrete. Belhadj et al. [10] mixed wheat straw, wood shavings fiber and sand concrete to make lightweight concrete, and found that wheat straw can compensate for the shrinkage, which is not up to the standard of only adding wood shavings fiber to sand concrete, and it can also improve its strength. El-Sayed [11] believed that rice husk ash not only substantially improves the compressive strength but also can improve the fire resistance of ultra-high performance concrete. The application of plant straw in concrete, such as rice straw fiber [5] and cotton straw [12], has been proven feasible.

When the plant straw is burnt into organic ash, it can be added to the concrete, and the performance of the concrete is also very good [13–15]. This may be because of the following reasons, plant ash has pozzolana properties, which are very important and contribute to hydration and the strength of the concrete. Therefore, this kind of ash can be used in building materials for sustainable built environments [16,17]. Rice husk ash added to the concrete can reduce the workability of concrete and improve its mechanical properties [18–20]. Al-Akhras et al. [21] investigated the effect of wheat straw ash (WSA) on the mechanical strength of autoclaved mortar, and found that replacing the aggregate with WSA can increase the mechanical strength compared with that of the control mortar specimen.

It can be seen from the above research that it is feasible to study crop waste in construction materials, but crop straw contains sugar and hemicellulose and has a low binding force. Therefore, crop straws should be treated in different ways. It is of great significance to study which form of straw treatment results in the best mechanical properties for the concrete. The compressive strength of concrete may be reflected in part by the mechanical properties of the materials. This study examines wheat straw fiber (WSF), WSA and wheat straw powder (WSP) as additives to concrete and studies their effects on the concrete compressive strength. This study may serve as a reference for the application of straw resources in concrete production.

It should be noted that the concrete consists of sand, cement, gravel and water. To reduce the water consumption in the concrete and maintain its slump, a water reducer was added. WSF, WSP and WSA were also used in this study.

Ordinary Portland cement (P.O 42.5) was selected for the test that met the Common Portland Cement Standard Specification (GB 175-2007) [22].

The water used in the concrete mixing process is the drinking water of Huainan, Anhui Province.

2.1.3 Coarse Aggregate and Sand

Coarse aggregate is continuously graded gravel with particle size of 5∼15 mm. The fine aggregate is river sand that is the medium sand. The coarse aggregate and the sand all met the Standard for Technical Requirements and Test Method of Sand and Crushed Stone (or Gravel) for Ordinary Concrete (JGJ 52-2006) [23].

2.1.4 Wheat Straw and Wheat Straw Powder

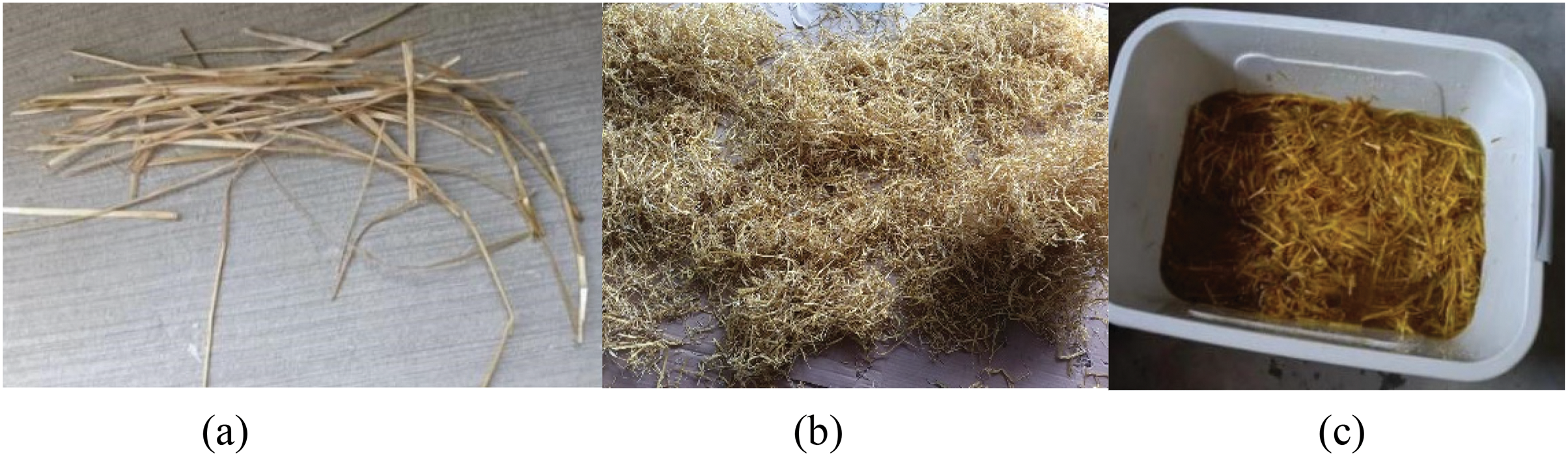

WSF was from Bozhou City, Anhui Province. The wheat straw was dried in the sun, and then the wheat straw samples were immersed in 20 g·L−1 NaOH solution for 24 h, rinsed until the pH value was neutral, and then dried by natural air. Because the wheat straw needed to be embalmed, the modified polyvinyl alcohol (PVA) was used as the reinforcing agent to soak it for 3 days, then the wheat straw was removed to air dry (see Fig. 1). And then cut the WSF into 2 to 5 cm strips by a hay cutter, the production process of WSP is to crush WSF into powder by a shredder.

Figure 1: Straw images of different treatments. (a) Untreated wheat straw (b) Alkali treatment of wheat straw (c) Alkali combined PVA treatment of wheat straw

The washed wheat straw was burned to ash by natural combustion, calcined at 600°C high temperature for 5 h, and sifted through a 200 mesh sieve. As shown in Fig. 2, we know that the color of WSA is dark before calcination and gray after calcination.

Figure 2: WSA changes before and after calcination

2.2.1 Test Block Production and Maintenance

The mixing ratio of the concrete samples is as follows: cement:water:stone:sand = 1:0.45:1.94:1.94, and the water reducer is added at 2.5% of the quality of the cement. The parameters of WSF and WSP were calculated as the percentage of cement mass, and the parameters of WSA were calculated by replacing cement quantity as a standard. A 100 mm × 100 mm × 100 mm cube test block was prepared for the compressive strength test. To make the straw evenly distributed in concrete, first, the stone and river sand were mixed evenly. Secondly, cement was added to continue to stir evenly, straw was added to mix evenly, and a water reducer was added to the water and mixed evenly. And finally the water was added to mix again. The mixtures were placed into the concrete mold. Because the actual strength of concrete in the construction is less than that in the laboratory, to better approximate the actual strength of the construction, manual vibration is used. After the manual vibration was finished, the surface of the test block was wiped and left for 24 h, and then the test block was placed in the maintenance box. The curing temperature was 20°C ± 2°C and the humidity was more than 95%, and then it was kept under the standard conditions for 28 days.

Compressive strength test: The sample was taken out of the curing box and the water was wiped off the sample surface, and then the sample was put on the pressure tester to test the compressive strength. The compressive strength testing instrument adopts electro-hydraulic servo universal testing machine (Exceed model E64.605), and the compressive strength test accords to Standard for Test Methods of Concrete Physical and Mechanical Properties (GB/T 50081-2019) [24].

Scanning electron microscope (SEM) test: We sampled the inside of the concrete, and the interface between the WSF and concrete was the object of our observation. For the concrete with WSP or WSA, we needed to observe the internal structure of the concrete, and then the samples were polished according to the test needs.

3.1 Effects of Different Treatments on WSF Properties

3.1.1 Tensile Strength of Treated WSF

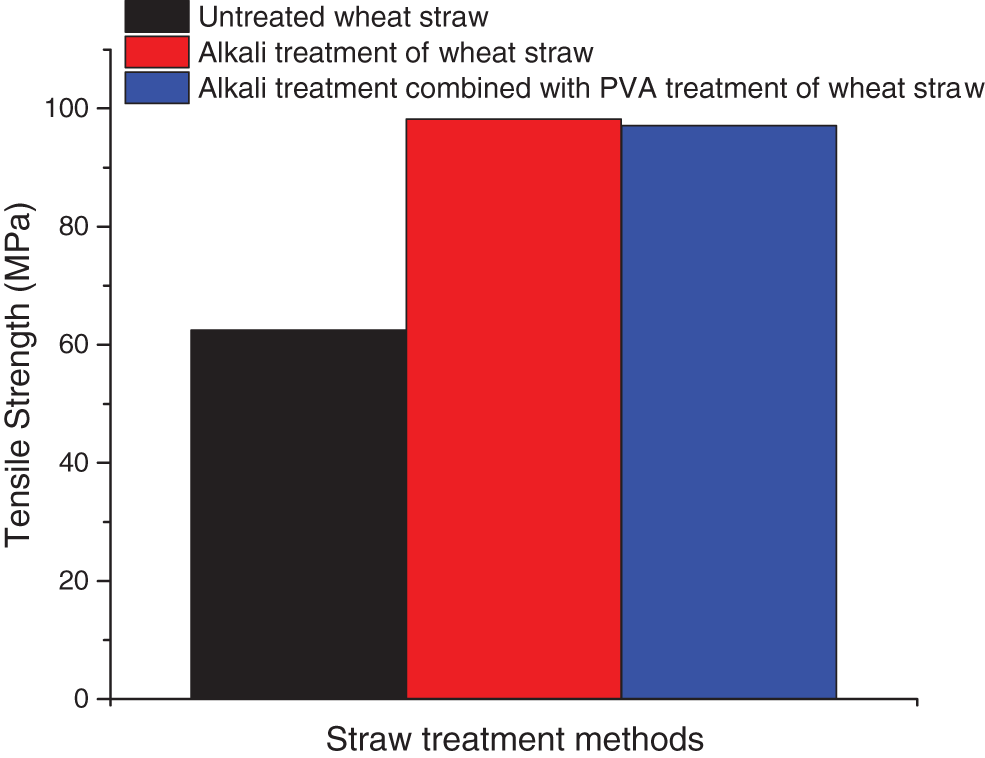

Fig. 3 shows the change in the tensile strength of straw fiber after alkali treatment and alkali combined with PVA treatment. Alkali treatment can improve the tensile strength of WSF, but after the treatment of WSF with alkali combined with PVA, the WSF tensile strength shows little change. Lignin and hemicellulose can be effectively eliminated by soaking WSF in sodium hydroxide; the structures of lignin and hemicellulose are destroyed, and the mechanical properties of wheat straw increase with increasing cellulose content per unit area because of the strong interactions between molecular chains. Cellulose can form intramolecular and intermolecular hydrogen bonds, and it is the bearing part of wheat straw, so its tensile strength and elastic modulus are relatively large [25,26]. The PVA treatment of alkali-treated WSF can enhance the anti-corrosion property, but it has little effect on improving its mechanical properties [1].

Figure 3: The tensile strength of the treated WSF

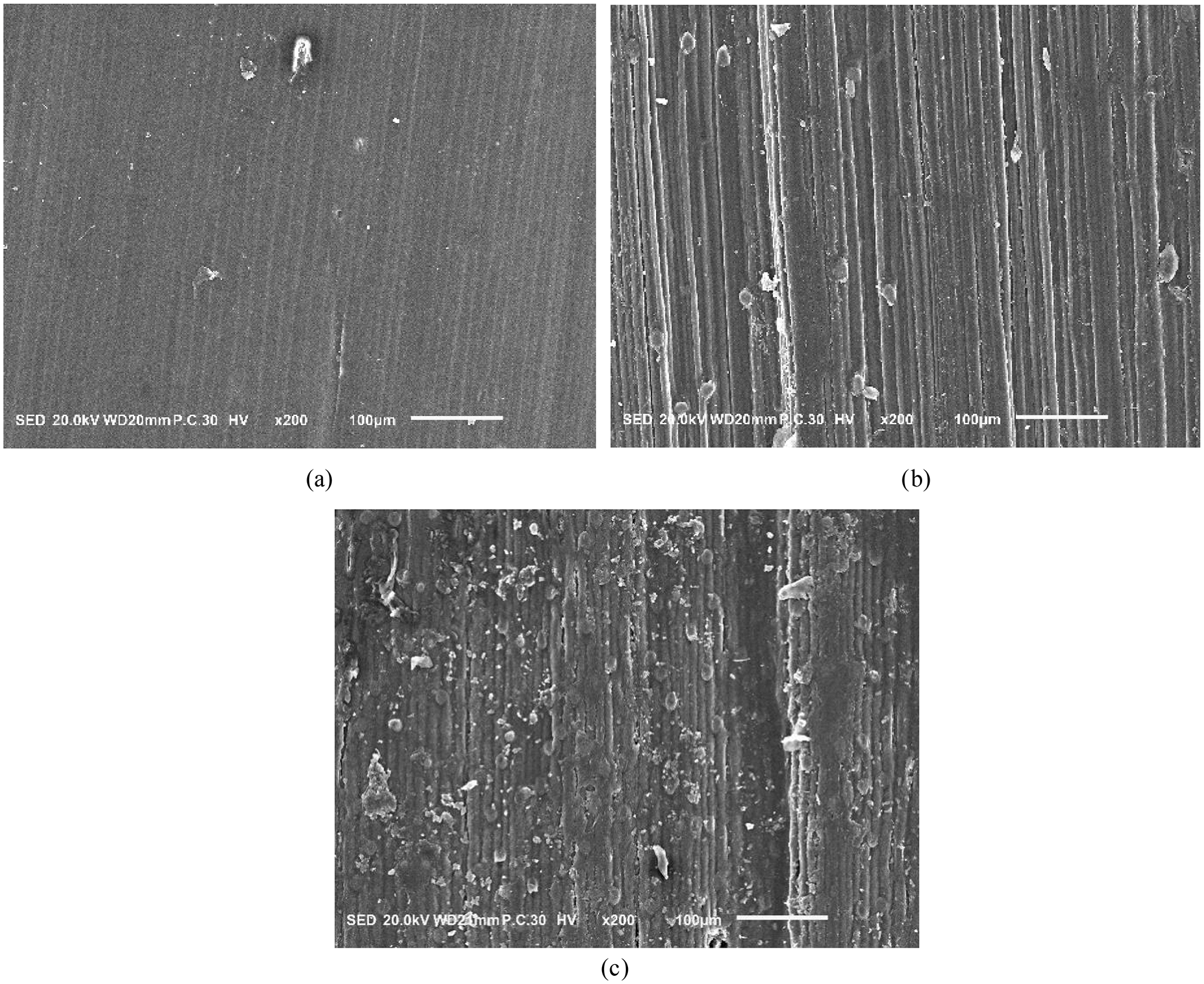

3.1.2 Microstructure of Straw and Oxide Composition of Straw Ash

Fig. 4 is the SEM image of straw fiber after alkali treatment and alkali combined with PVA treatment. The surface of untreated WSF is smooth, flat and compact. After alkali treatment, the WSF surface exhibited streaking and filamentation phenomena, and the wax layer on the surface fell off, which indicated that the alkali treatment affected the hemicellulose and lignin of the WSF [26]. After alkali treatment combined with PVA treatment of WSF, PVA adsorbed on the surface of the WSF, and the surface of the longitudinal stripes were adsorbed by PVA, because the adsorption of the film is irreversible, so this treatment successfully realized the anti-corrosion treatment function of WSF [1,12].

Figure 4: Microstructure diagrams of WSF: (a) Untreated WSF (b) Alkali treated of WSF (c) Alkali combined with PVA treatment WSF

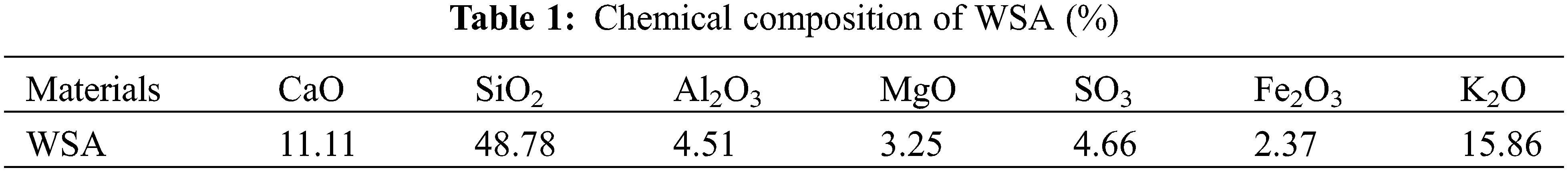

Unstable compounds formed by some volatile elements may be volatilized at high temperature, while more stable elements can form more stable compounds, and temperature has little effect on them [27,28]. Table 1 shows the chemical composition of straw ash after calcination. After calcination treatment, the contents of CaO, SiO2 and Al2O3 in WSA were 11.11%, 48.78% and 4.51%, respectively, and SiO2 was the main oxide component in the WSA, which was relatively high.

3.2 Compressive Strength of Concrete with Different Straw Treatments

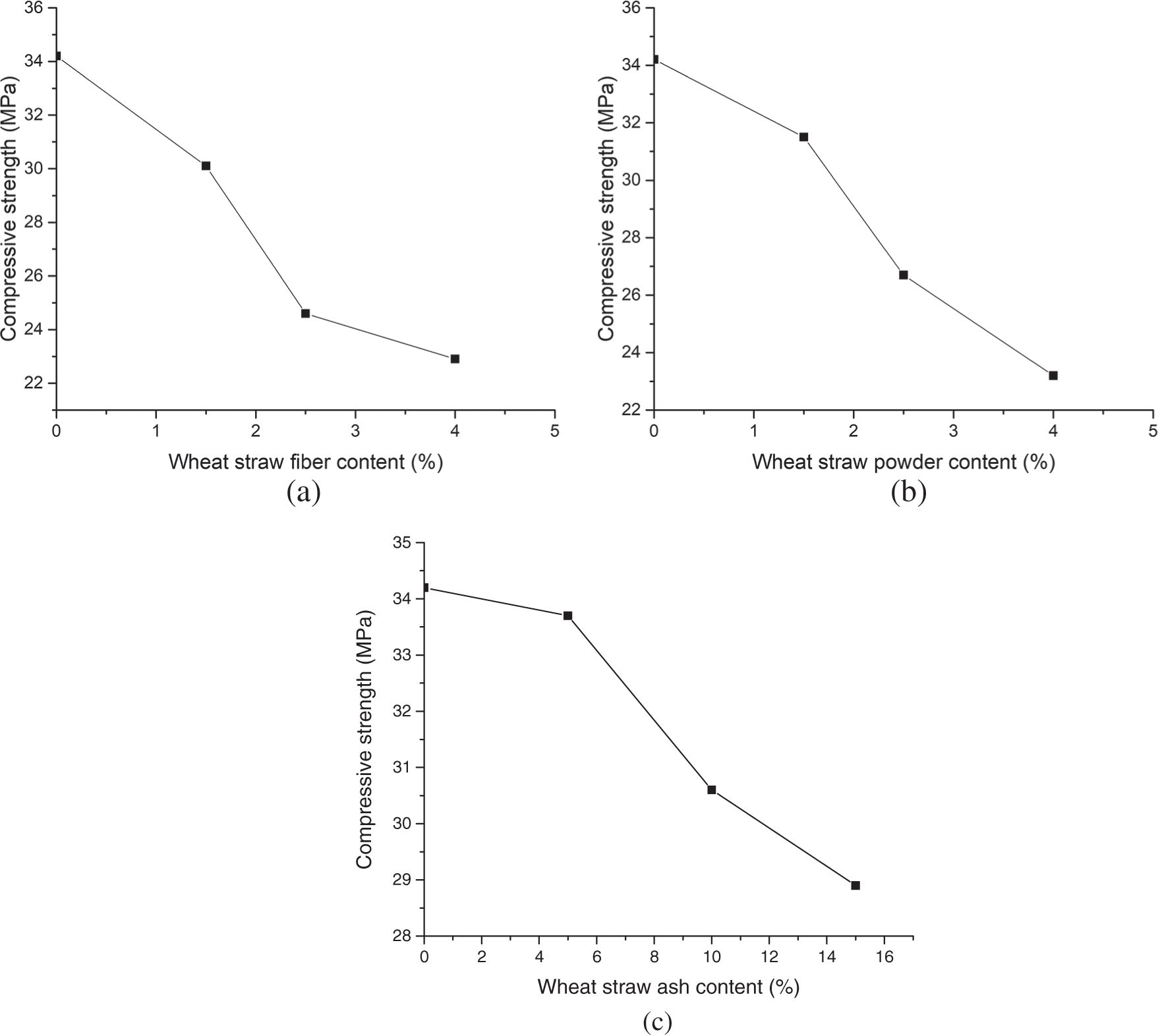

From Fig. 5a, when the WSF content is 1.5%, the compressive strength of the concrete is 30.1 MPa. We can also find that the compressive strength after WSF added to concrete decreases as the content increases. The addition of WSF did not improve the strength of concrete from the image. This may be due to the following reasons. One is the weakness in the interfacial transition zone between the wheat straw fiber and cement matrix, and the existence of these weaknesses decreases the strength of concrete [29]. Another reason is that the strength of WSF is low, and the overall strength of concrete decreases after the WSF added to concrete. The last reason may be that the type of wheat straw also plays a certain role in the tensile strength of wheat straw, and then on the compressive strength of the concrete.

Figure 5: Relationship between compressive strength of concrete and added straw content. (a) Effect of WSF on concrete strength (b) Effect of WSP on concrete strength (c) Effect of WSA on concrete strength

From Fig. 5b, when the WSP content is 1.5%, the compressive strength of the concrete is 31.5 MPa. We can also find that the compressive strength after WSP added to concrete decreases with increasing WSP content. The most obvious difference between Figs. 5a and 5b is the magnitude of the reduction in the concrete compressive strength, which has nothing to do with how the wheat straw is fiber or powder. For my point of view, the straw powder has a certain water absorption capacity, and does not produce hydration products with water, and the straw powder itself is low strength, and the surface area is large, while filling the internal void of concrete, the interaction between the cementing material and the aggregate is hindered, therefore, the strength of concrete decreases.

From Fig. 5c, when the WSA content instead of cement is 5%, the compressive strength of concrete is 33.7 MPa, and the compressive strength of concrete still decreases with increasing ash content. This result is consistent with the results in the literature [30,31], but it is also different from the results in the literatures [17,32]. This paper believes that there are two reasons for this result; One is that particle size of straw ash has a great influence on the activity of straw ash after replacing concrete [33,34]. The other reason is that the ash composition of wheat straw in different regions is different; that is the proportion of active components in the ash of wheat straw in varieties in different regions is quite different, so the experimental results are different. In addition, if straw is added to the concrete, only a small amount of straw can be added. A large amount of straw added to concrete has a great influence on the compressive strength of concrete; therefore, it is not desirable to add a large amount of straw to concrete. This paper also shows that with the WSA added in the concrete, the impact on the compressive strength of concrete is the least, followed by the addition of WSP, and finally the WSF.

3.3 Macromorphology Analysis of Straw Concrete Failure

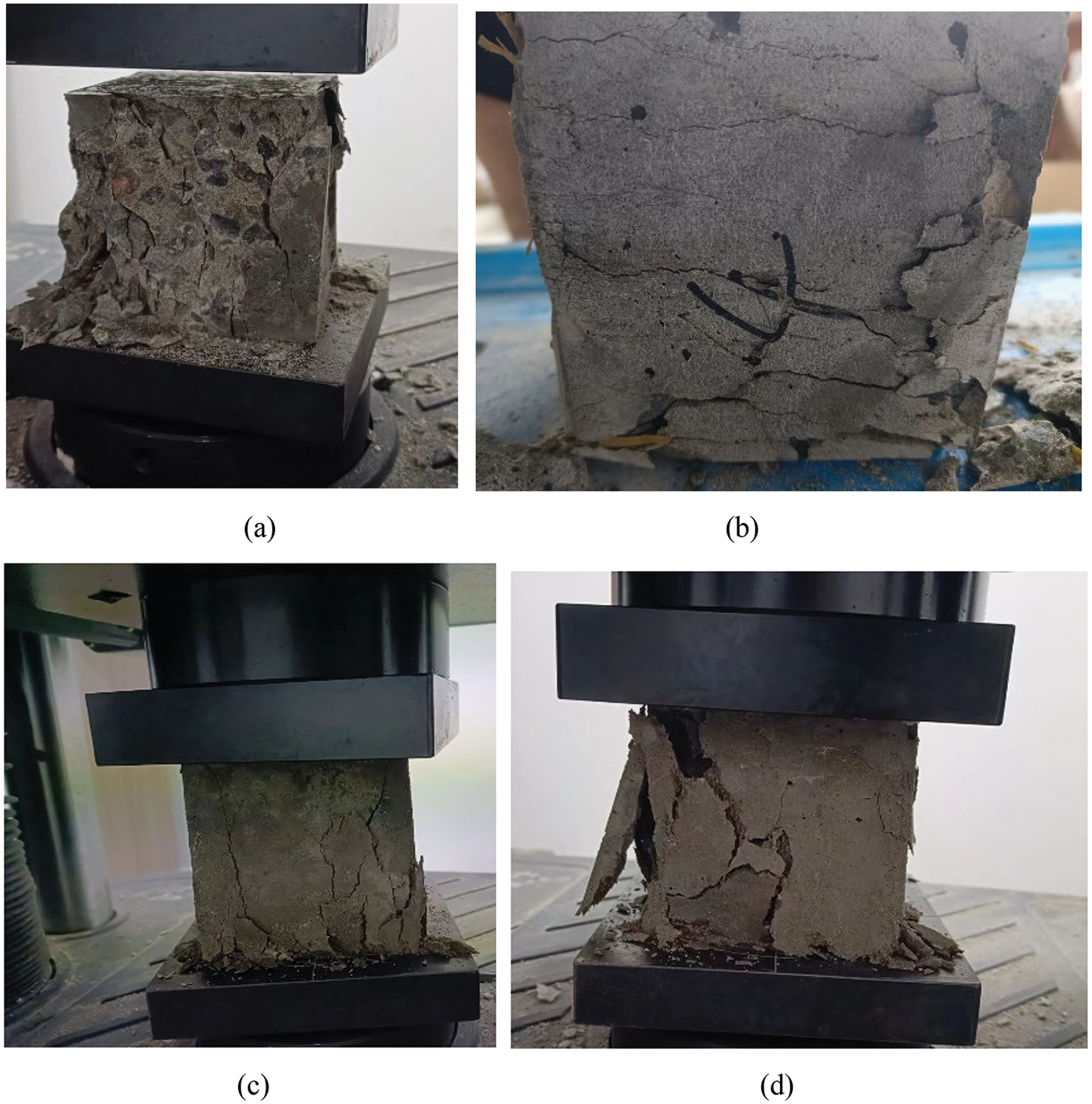

The failure of concrete is characterized by brittle failure. In Fig. 6a, the failure mode of the concrete presents a crushing failure mode and cracks through the whole concrete test block. In the compression of the specimen, the concrete aggregate splits or even breaks, and a brittle failure sound can be heard when the concrete is damaged. When the WSF added to the concrete, we find that the failure form of the concrete is impeded in Fig. 6b; the damage degree of the concrete is obviously weakened; the partially broken concrete fragment is connected by the WSF; and the size of the cracks is obviously smaller, this is because the fiber plays a reinforcing role [29,35]. When the concrete is damaged, the concrete is bound by the straw fiber, and straw fiber also has a certain energy absorption effect, alleviating the damage of concrete. In Fig. 6c, we find that the damage degree of concrete with WSP has also been improved to a certain extent, and the number and size of cracks are also small, it has similar failure characteristics with that in Fig. 6b, which may be related to the filling effect and energy absorption effect of straw powder. In Fig. 6d, the damage state and process of concrete are similar to those in Fig. 6a because straw ash has a certain volcanic ash activity, so it plays a similar role to cement, and can replace cement to a certain extent.

Figure 6: Concrete failure cracks: (a) Common concrete (b) Concrete with WSF (c) Concrete with WSP (d) Concrete with WSA

3.4 Microstructure Analysis of Straw Concrete

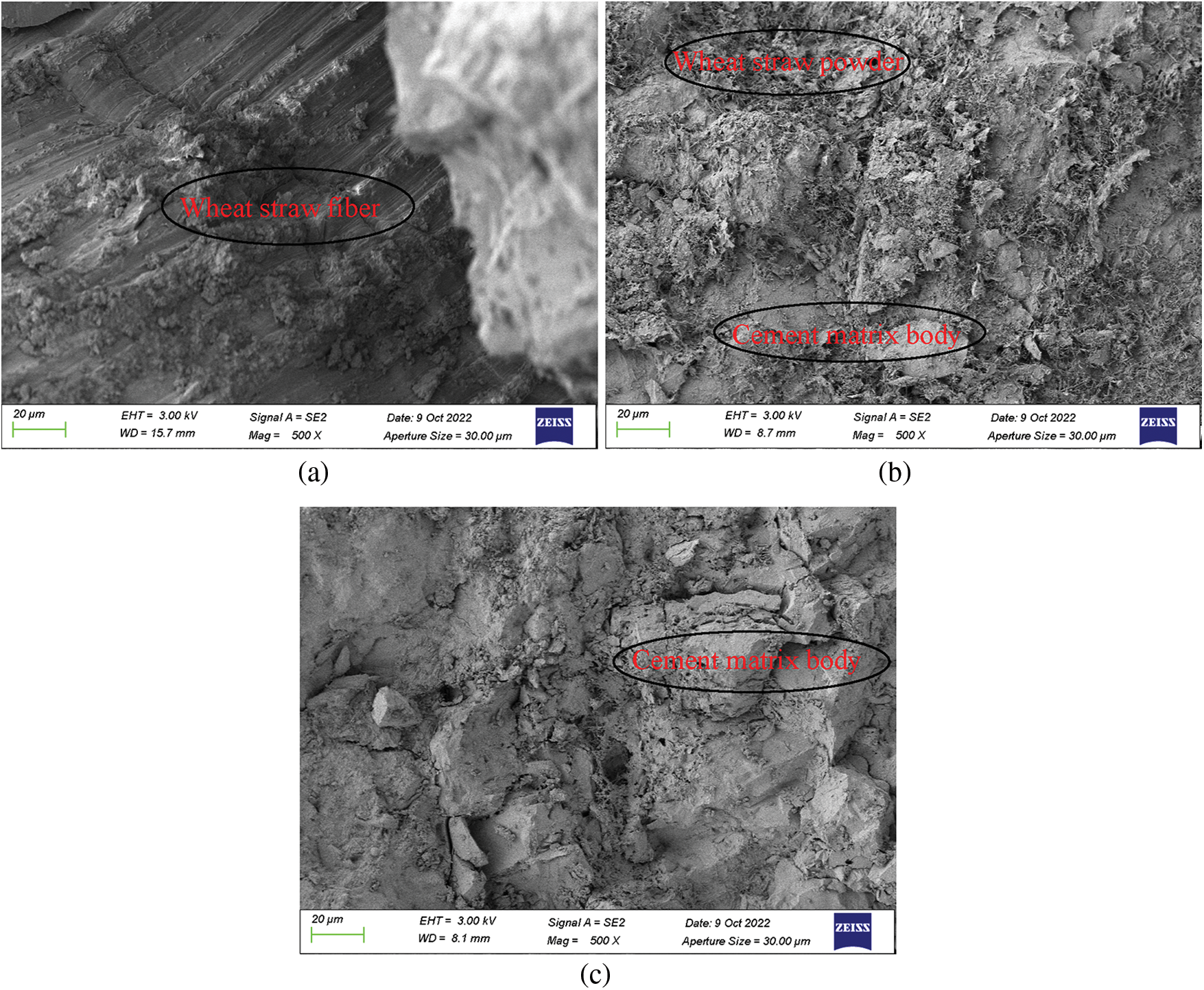

The different connections of the microstructure of the straw fiber and cement matrix in Fig. 7a show that even in the specimen after destruction, the fiber and cement matrix are still closely connected. Wheat straw fiber build-in into the cement matrix can effectively prevent the occurrence of microcracks and expansion to reduce the continued production of cracks. Macroscopically, the specimen exhibits ductile failure without breaking, as shown in Fig. 6b. The WSP was adsorbed on the surface of the observed sample and was filled in the internal void of the concrete. The concrete porosity decreases when the WSP fills the concrete void in Fig. 7b, which also confirms that straw powder has a fine particle size, a larger specific surface area, and a certain void filling effect. As shown in Fig. 7c, small particles of straw ash fill the internal voids of concrete, which is the filling effect of straw ash. At the same time, straw ash has a certain volcanic ash activity, and participates in the hydration reaction of cement to a certain extent. Moreover, hydration products also continuously fill the internal pore structure of concrete.

Figure 7: Scanning electron microscopy images of the concretes: (a) Concrete with WSF (b) Concrete with WSP (c) Concrete with WSA

3.5 Thoughts on the Straw Concrete

Adding straw fiber to concrete can reduce the weight of concrete because of straw’s light weight. Thus when used as a building material, straw can reduce the building weigh. Studies have shown that the thermal conductivity coefficient decreases when straw is added to concrete [12,36]. This characteristic provides the necessary conditions for straw to be used as a kind of thermal insulation material. Straw may be used not only as a new kind of thermal insulation building material but also in deep mining, which has the problem of mining thermal damage because of the influence of ground temperature. Adding straw to shotcrete is also very meaningful for solving the problem of thermal damage. Straw as concrete reinforcement material has shortcomings of insufficient tensile strength and easily corrodes. The research in this paper has increased the tensile strength of straw and solved the corrosion problem of straw to a certain extent, which provides a feasible method for straw resources to be widely used in concrete. Ash concrete mechanical properties are associated not only with the active ingredient of ash, but also associated with the particle size of ash [13,37–39]. In this paper, straw ash particle is screened through 200 mesh sieve screening, and it was found that when the amount of straw ash was 5%, the compressive strength changed little, so the straw ash in concrete in practical engineering should be a small amount to add into the concrete. In the future, we need to consider the influence of straw ash particle size on the strength of the concrete. We also need to consider other performance indicators of straw concrete, such as impermeability and crack resistance. We should further explore the application potential of straw resources in the field of concrete, and broaden the application prospects. Straw fiber and straw powder added into the concrete, decrease the concrete’s strength. To solve this problem, we should find a way to make the straw fiber into a kind of composite material, and then added into the concrete. Alternatively, other materials (such as steel fiber) can be added to the concrete to compensate for straw fiber’s tensile strength.

1. Alkali treatment can obviously improve the tensile strength of WSF. Alkali combined with PVA treatment of WSF has little effect on tensile strength compared with the only alkali treatment, but the tensile strength is higher than that of the untreated WSF.

2. When the content of WSF and WSP is 1.5%, the concrete compressive strength is 30.1 and 31.5 MPa, respectively. When the content of cement is replaced by 5% WSA, the compressive strength of concrete is 33.7 MPa. The content of WSF and WSP added to the concrete should be controlled by less than 1.5%, and the content of WSA added should be controlled by less than 5%, which has little influence on the compressive strength of concrete.

3. The failure deformation of concrete with WSF and WSP is weak, while the failure deformation of concrete with WSA is larger, which is similar to the brittle failure of concrete. WSF can affect the cracks in the concrete, and WSP and WSA can affect the compactness of concrete.

4. In engineering, if we chose WSF or WSA to add the concrete, WSF should be treated with alkali combined with PVA, and WSA should be treated with high temperature and grinding.

5. In consideration of saving cement and the mechanical properties of concrete, it is recommended first to choose straw ash, then straw powder, and then straw fiber.

6. As for WSF and WSA added to concrete, we believe that it is very necessary to study their effects on the thermal conductivity, impermeability and crack resistance of the concrete, etc., and these need our further study.

Funding Statement: This study was Supported by the Opening Project of Tunnel and Underground Engineering Research Center of Jiangsu Province (TERC) (2021-SDJJ-08).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Li, M., Chai, S., Zhang, Y., Du, H., Wei, L. (2012). Feasibility of saline soil reinforced with treated wheat straw and lime. Soils and Foundations, 52, 228–238. https://doi.org/10.1016/j.sandf.2012.02.003 [Google Scholar] [CrossRef]

2. Hao, J., Huang, J., Yao, J., Zhang, Z., Zhang, H. (2021). Unconfined compression strength and mesostructure of reinforced soil with wheat straw. Bulletin of Engineering Geology and the Environment, 80, 9173–9183. https://doi.org/10.1007/s10064-021-02473-2 [Google Scholar] [CrossRef]

3. Sheridan, J., Sonebi, M., Taylor, S., Amziane, S. (2020). The effect of a polyacrylic acid viscosity modifying agent on the mechanical, thermal and transport properties of hemp and rapeseed straw concrete. Construction and Building Materials, 235, 117536. https://doi.org/10.1016/j.conbuildmat.2019.117536 [Google Scholar] [CrossRef]

4. Memon, S. A., Javed, U., Haris, M., Khushnood, R. A., Kim, J. (2021). Incorporation of wheat straw ash as partial sand replacement for production of eco-friendly concrete. Materials, 14, 2078. https://doi.org/10.3390/ma14082078 [Google Scholar] [PubMed] [CrossRef]

5. Xie, X., Gou, G., Wei, X., Zhou, Z., Jiang, M. et al. (2016). Influence of pretreatment of rice straw on hydration of straw fiber filled cement based composites. Construction and Building Materials, 113, 449–455. https://doi.org/10.1016/j.conbuildmat.2016.03.088 [Google Scholar] [CrossRef]

6. Song, P. S., Wu, J. C., Hwang, S., Sheu, B. C. (2005). Assessment of statistical variations in impact resistance of high-strength concrete and high-strength steel fiber-reinforced concrete. Cement and Concrete Research, 35, 393–399. https://doi.org/10.1016/j.cemconres.2004.07.021 [Google Scholar] [CrossRef]

7. Wang, Q., Song, H., Li, Y., Wang, F., Hu, Z. et al. (2021). Experimental study on the performance of graded glass fiber reinforced concrete (G-GRC) based on engineering application. Materials, 14, 1149. https://doi.org/10.3390/ma14051149 [Google Scholar] [PubMed] [CrossRef]

8. Jiang, D., An, P., Cui, S., Sun, S., Zhang, J. et al. (2020). Effect of modification methods of wheat straw fibers on water absorbency and mechanical properties of wheat straw fiber cement-based composites. Advances in Materials Science and Engineering, 2020, 5031025. https://doi.org/10.1155/2020/5031025 [Google Scholar] [CrossRef]

9. Ammari, M. S., Belhadj, B., Bederina, M., Ferhat, A., Quéneudec, M. (2020). Contribution of hybrid fibers on the improvement of sand concrete properties: Barley straws treated with hot water and steel fibers. Construction and Building Materials, 233, 117374. https://doi.org/10.1016/j.conbuildmat.2019.117374 [Google Scholar] [CrossRef]

10. Belhadj, B., Bederina, M., Montrelay, N., Houessou, J., Quéneudec, M. (2014). Effect of substitution of wood shavings by barley straws on the physico-mechanical properties of lightweight sand concrete. Construction and Building Materials, 66, 247–258. https://doi.org/10.1016/j.conbuildmat.2014.05.090 [Google Scholar] [CrossRef]

11. El-Sayed, T. A. (2021). Improving the performance of UHPC columns exposed to axial load and elevated temperature. Case Studies in Construction Materials, 15, e00748. https://doi.org/10.1016/j.cscm.2021.e00748 [Google Scholar] [CrossRef]

12. Huang, J., Pang, J., Liu, G., Mo, Y., Jiang, P. et al. (2019). A new heat insulation shotcrete mixed with basalt and plant fibers. Advances in Civil Engineering, 2019, 6376807. https://doi.org/10.1155/2019/6376807 [Google Scholar] [CrossRef]

13. Wei, J., Meyer, C. (2016). Utilization of rice husk ash in green natural fiber-reinforced cement composites: Mitigating degradation of sisal fiber. Cement and Concrete Research, 81, 94–111. https://doi.org/10.1016/j.cemconres.2015.12.001 [Google Scholar] [CrossRef]

14. Hasnain, M. H., Javed, U., Ali, A., Saeed Zafar, M. (2021). Eco-friendly utilization of rice husk ash and bagasse ash blend as partial sand replacement in self-compacting concrete. Construction and Building Materials, 273, 121753. https://doi.org/10.1016/j.conbuildmat.2020.121753 [Google Scholar] [CrossRef]

15. Tavares, J. C., Lucena, L. F. L., Henriques, G. F., Ferreira, R. L. S., dos Anjos, M. A. S. (2022). Use of banana leaf ash as partial replacement of portland cement in eco-friendly concretes. Construction and Building Materials, 346, 128467. https://doi.org/10.1016/j.conbuildmat.2022.128467 [Google Scholar] [CrossRef]

16. Vishavkarma, A., Harish, K. V. (2022). Effect of rice husk ash on permeation characteristic of cementitious mortar. Materials Today: Proceedings, 61, 406–412. https://doi.org/10.1016/j.matpr.2021.10.448 [Google Scholar] [CrossRef]

17. Memon, S., Wahid, I., Khan, M., Tanoli, M., Bimaganbetova, M. (2018). Environmentally friendly utilization of wheat straw ash in cement-based composites. Sustainability, 10, 1322. https://doi.org/10.3390/su10051322 [Google Scholar] [CrossRef]

18. Santhosh, K. G., Subhani, S. M., Bahurudeen, A. (2022). Recycling of palm oil fuel ash and rice husk ash in the cleaner production of concrete. Journal of Cleaner Production, 354, 131736. https://doi.org/10.1016/j.jclepro.2022.131736 [Google Scholar] [CrossRef]

19. Hakeem, I. Y., Agwa, I. S., Tayeh, B. A., Abd-Elrahman, M. H. (2022). Effect of using a combination of rice husk and olive waste ashes on high-strength concrete properties. Case Studies in Construction Materials, 17, e01486. https://doi.org/10.1016/j.cscm.2022.e01486 [Google Scholar] [CrossRef]

20. Hakeem, I. Y., Amin, M., Zeyad, A. M., Tayeh, B. A., Maglad, A. M. et al. (2022). Effects of nano sized sesame stalk and rice straw ashes on high-strength concrete properties. Journal of Cleaner Production, 370, 133542. https://doi.org/10.1016/j.jclepro.2022.133542 [Google Scholar] [CrossRef]

21. Al-Akhras, N. M., Abu-Alfoul, B. A. (2002). Effect of wheat straw ash on mechanical properties of autoclaved mortar. Cement and Concrete Research, 32, 859–863. https://doi.org/10.1016/S0008-8846(02)00716-0 [Google Scholar] [CrossRef]

22. GB 175-2007 (2007). Common Portland Cement. [Google Scholar]

23. JGJ 52-2006 (2006). Standard for Technical Requirements and Test Method of Sand and Crushed Stone (or Gravel) for Ordinary Concrete. [Google Scholar]

24. GB/T 50081-2019 (2019). Standard for Test Methods of Concrete Physical and Mechanical Properties. [Google Scholar]

25. Ciannamea, E. M., Stefani, P. M., Ruseckaite, R. A. (2010). Medium-density particleboards from modified rice husks and soybean protein concentrate-based adhesives. Bioresource Technology, 101, 818–825. https://doi.org/10.1016/j.biortech.2009.08.084 [Google Scholar] [PubMed] [CrossRef]

26. He, C., Fu, L., Xiong, J., Diao, H. (2016). Study on the microstructure and properties of wheat straw with different treatments. Journal of Nanjing Agricultural University, 39, 325–331. [Google Scholar]

27. Qi, T., Zhang, S., Feng, G., Xu, G. (2019). Physical and chemical characterization of Chinese fallen poplar leaf ash effects of the calcining temperature and aqueous solution. Wood and Fiber Science, 51, 309–319. https://doi.org/10.22382/wfs-2019-xxx [Google Scholar] [CrossRef]

28. Xu, J., Li, S., Liu, S. (2019). Investigation on the ash properties of straw. Journal of Engineering for Themal Energy and Power, 34, 137–141, 154. [Google Scholar]

29. Zhou, C., Cai, L., Chen, Z., Li, J. (2020). Effect of kenaf fiber on mechanical properties of high-strength cement composites. Construction and Building Materials, 263, 121007. https://doi.org/10.1016/j.conbuildmat.2020.121007 [Google Scholar] [CrossRef]

30. Hameed, M. A. A. K., Razzq Alzerjawi, A. K., Mahdi, Z. A. (2021). Studying the behavior of the concrete mixture with wheat straw as part of the cement. Journal of Physics: Conference Series, 1973, 012174. https://doi.org/10.1088/1742-6596/1973/1/012174 [Google Scholar] [CrossRef]

31. Rolón, B. G., Castañeda, P. F. (2021). Mechanical resistance and corrosion of concrete added with ashes of corn, sorghum, and wheat. Cleaner Materials, 2, 100028. https://doi.org/10.1016/j.clema.2021.100028 [Google Scholar] [CrossRef]

32. Khan, K., Ishfaq, M., Amin, M. N., Shahzada, K., Wahab, N. et al. (2022). Evaluation of mechanical and microstructural properties and global warming potential of green concrete with wheat straw ash and silica fume. Materials, 15. https://doi.org/10.3390/ma15093177 [Google Scholar] [PubMed] [CrossRef]

33. Qudoos, A., Kim, H. G., Atta ur, R., Ryou, J. S. (2018). Effect of mechanical processing on the pozzolanic efficiency and the microstructure development of wheat straw ash blended cement composites. Construction and Building Materials, 193, 481–490. https://doi.org/10.1016/j.conbuildmat.2018.10.229 [Google Scholar] [CrossRef]

34. Biricik, H., Aköz, F., Berktay, I., Tulgar, A. N. (1999). Study of pozzolanic properties of wheat straw ash. Cement and Concrete Research, 29, 637–643. https://doi.org/10.1016/S0008-8846(98)00249-X [Google Scholar] [CrossRef]

35. Yang, G., Bi, J., Dong, Z., Li, Y., Liu, Y. (2022). Experimental study on dynamic tensile properties of macro-polypropylene fiber reinforced cementitious composites. International Journal of Concrete Structures and Materials, 16, 66. https://doi.org/10.1186/s40069-022-00559-z [Google Scholar] [CrossRef]

36. Obeid, M. H., Douzane, O., Freitas Dutra, L., Promis, G., Laidoudi, B. et al. (2022). Physical and mechanical properties of rapeseed straw concrete. Materials, 15, 8611. https://doi.org/10.3390/ma15238611 [Google Scholar] [PubMed] [CrossRef]

37. Amaral, R. C., Rohden, A. B., Garcez, M. R., de Oliveira Andrade, J. J. (2022). Reuse of wood ash from biomass combustion in non-structural concrete: Mechanical properties, durability, and eco-efficiency. Journal of Material Cycles and Waste Management, 24, 2439–454. https://doi.org/10.1007/s10163-022-01493-8 [Google Scholar] [CrossRef]

38. Alonso, M. M., Gascó, C., Morales, M. M., Suárez-Navarro, J. A., Zamorano, M. et al. (2019). Olive biomass ash as an alternative activator in geopolymer formation: A study of strength, radiology and leaching behaviour. Cement and Concrete Composites, 104, 103384. https://doi.org/10.1016/j.cemconcomp.2019.103384 [Google Scholar] [CrossRef]

39. Alkheder, S., Obaidat, Y. T., Taamneh, M. (2016). Effect of olive waste (Husk) on behavior of cement paste. Case Studies in Construction Materials, 5, 19–25. https://doi.org/10.1016/j.cscm.2016.05.001 [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools