| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2023.022097

ARTICLE

Microwave Drying of Scots Pine Lumber: Structure Changes, Its Effect on Liquid Permeability

1China National Bamboo Research Center, Key Laboratory of High Efficient Processing of Bamboo of Zhejiang Province, Hangzhou, China

2Nanjing Forestry University, Nanjing, China

3Central South University of Forestry and Technology, Changsha, China

*Corresponding Author: Weiqi Leng. Email: wleng@njfu.edu.cn

Received: 21 February 2022; Accepted: 02 April 2022

Abstract: Microwave (MW) drying method was adopted to enhance the liquid permeability of Scots pine lumber. Structure changes were characterized by stereoscope microscope, scanned electron microscope (SEM) and transmission electron microscope (TEM) examination. Pore parameters before and after MW treatment were detected by mercury intrusion porosimetry (MIP) method, and the effect of structure changes on liquid permeability were analyzed. As stereoscope microscope, SEM and TEM examination results shown, macro and micro checks mainly developed at intercellcular of tracheids, intercellular of ray parenchyma and tracheid, while these checks extend main along the radial-longitudinal plane. Pit border destruction, aspirated pits’ orus translocation and micro-checks in tracheid cell wall were also observed. MIP test shown that pore volume and pore area increased as macro and micro checks generated to form new cavities. Microstructure changes would increase the quantity of pores or enlarge the pore diameter. Liquid flow pathways increased as macro and micro checks generated, aspirated pits reopened to form new pathways; liquid flow efficiency improved as porosity, pore volume and pore diameter increase which facilitate the liquid flow.

Keywords: Microwave drying; structure change; pore structure; liquid permeability; Scots pine lumber

The role of wood in modern economy is becoming more and more important as it combines many excellent properties such as biodegradable, good strength to weight ratio, aesthetic appearance, etc. [1–3]. However, it also suffers from a number of disadvantages (e.g., dimensional changes in response to altering atmospheric conditions, susceptibility to biological attack) [3]. Wood modification is a means of overcoming or ameliorating its disadvantages [2]. Various methods have been adopted for the properties modification by impregnation of wood with chemicals [3–6]. Properties modification effectiveness was primarily determined by the effectiveness of impregnation [7]. Since a number of wood species have relative poor liquid permeability which causes problems during impregnation, there are methods used to improve the liquid permeability of lumber, which eventually enhance the chemical impregnate and wood modification result [7–10].

MW drying method was adopted for solid wood products and veneer drying as it can dry wood with higher rates and produce relatively uniform moisture content. Previous studies revealed that liquid permeability improved together with mechanical properties changes after MW treatment [8–11]. When intensive MW was applied to wood, steam pressure generated within the wood cells. Under high internal pressure, microstructure such as pit membranes in cell walls, tyloses in vessels, and weak ray cells may rupture to form new pathways which facilitate the transportation of liquids [12–17]. Microstructural changes after MW treatment have been investigated in previous studies [8,15]. However, the relationship between microstructure changes and liquid permeability of MW-treated wood still need to be uncovered. Moreover, wood liquid permeability relates closely with its porous structure at the macroscopic, microscopic and molecular levels [2,8,18–20], it is therefore important to bridge the structure changes with pore parameters changes, and mechanism of the lumber’s liquid permeability improvements after MW-treatment can be then revealed.

The present study took stereoscope microscope, scanned electron microscope (SEM) and transmission electron microscope (TEM) to examine the structure changes of MW-dried lumber at macro, micro and ultrastructure level. Pore parameters before and after MW treatment was detected by MIP method, and the correspond pore diameter ranges and its changes of specific structure were verified. Then illustration of the liquid permeability from the aspect of structure changes was done.

2.1 Material and Microwave Drying Process

Scots pine (Pinus sylvestris L.) lumbers with dimension of 60 cm × 20 cm × 2 cm (longitudinal × tangential × radial) and air-dry density of 0.4~0.6 g/cm3 were used as experimental material. The initial moisture content of the lumber is 80~100%. Lumbers were treated by MW with power of 20 kW (915 MHz) for 60 s. Both MW-treated and control samples were air dried to moisture content of 10~12% for further processing.

2.2 Structure Changes Examination

1) Stereoscope Microscope Examination

Stereoscope microscope (OLYMPUS, BX61) was used to locate the macroscopic checks generated after MW drying. The magnification was 120 while the cross section of the samples for both MW-dried and control samples were observed.

2) SEM Examination

Microstructures of both MW-dried and control samples were examined using SEM (KEKY-EM 3200) with magnification of about 1000. A comparison of the microstructures, such as micro-checks between the intercellular layer of ray cells and tracheids, destruction of pit membranes, and damage of cell walls before and after MW-treatment were carried out, and the correlation of microstructure changes with liquid permeability were analyzed.

3) TEM Examination

The ultrastructure such as pits, cell wall, intercecullar layer before and after MW-treatment were observed by TEM examination (JEM1230, acceleration voltage of 80 kV, magnification of about 4000~8000). Radial and tangential section samples were prepared after the softening, dehydration, resin embedding, slicing and dying processes. A comparison of the ultrastructure between MW dried and control sample was conducted.

MIP tests were conducted (MICROMERITICS AutoPore IV 9500 ) for porosity, pore volume, and other pore structure parameters testing of both MW-treated and control samples. The samples with dimensions of 10 mm × 6 mm × 6 mm (longitudinal × tangential × radial) were cut from both MW-treated and control samples (MC of about 9%). Three samples were tested, respectively.

Tests were conducted by two processes of low pressure and high pressure to increase the pressure up steadily from 0 to 400 MPa. Pore volume was derived from the quantity of the intruded mercury while pore size distribution can be calculated according to Eq. (1) [21].

r is the pore radius, p is the pressure, γ is the surface tension of mercury (0.48 N/m), and θ is the wetting angle of mercury (141°) [22].

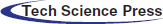

Fig. 1 shows the macrostructure changes in transverse of Scots pine lumbers after MW-treatment. It was observed that macro-checks generated in intercellular of tracheid, intercellular of ray parenchyma and tracheid. Some of the checks stretched from the intercellular of tracheid to intercellular of ray parenchyma and tracheid (Figs. 1B and 1C). As shown in Fig. 1B, checks in latewood generated in intercellular of ray parenchyma and tracheid, while it stretched to intercellular of tracheids in earlywood. This may contribute by different intercellular strength. Since latewood has densified structure which exhibit higher joint strength at intercellular of tracheids than that in intercellular of ray parenchyma and tracheid, the failure is easier to develop in intercellular of ray parenchyma and tracheid in latewood. However, the joint strength at intercellular of tracheids decreases in earlywood. As it has thinner tracheid cell wall and lower specific gravity, it was supposed that less substances was deposited in intercellular of the tracheid, which result in decreased strength in intercellular of the tracheids. Checks are apt to develop through regions with low strength. That is why the check in intercellular of ray parenchyma and tracheid in latewood stretching to intercellular of tracheids in earlywood was observed. Besides, checks also generated at the resin canal of treated lumbers. As resin canal is the pathway constructed by circled secretory parenchyma cells, the strength in this region is also relatively low, and the checks easy to generate in this region under high pressure during MW-treatment.

Figure 1: Transverse section of Scots pine lumber under stereoscopic microscope: (A) Control; (B) Checks in middle lamella; (C) Checks in longitudinal resin canal

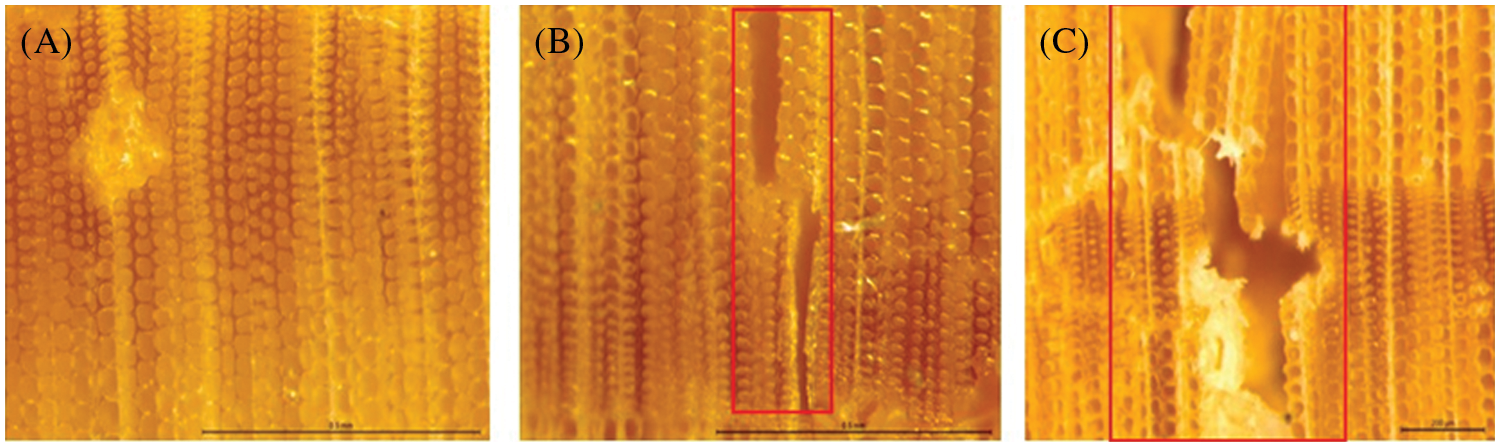

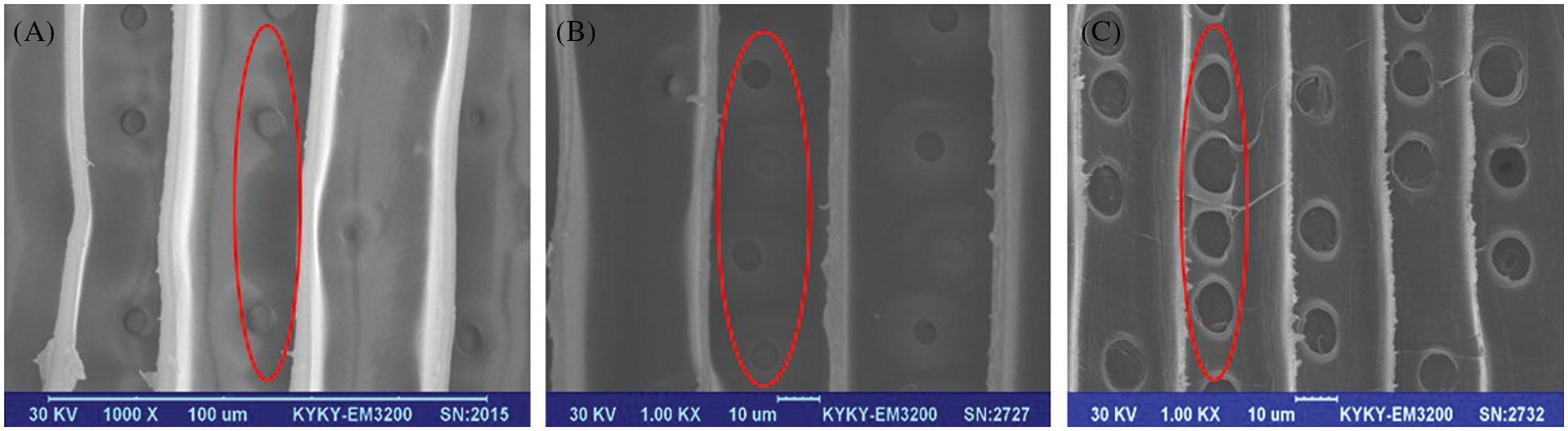

Above analysis shown macrostructure changes of MW-treated lumbers by stereoscopic microscope, while SEM examination can be used for locating the microstructure changes of MW-treated lumbers. Figs 2 and 3 show the SEM examination results. It was indicated that microstructure changes of Scots pine lumber after MW drying mainly located at intercellular of ray parenchyma (Fig. 2B), bordered pits (Figs. 3B and 3C), etc. Similar as stereoscope microscope examination results, micro checks in intercellular of ray parenchyma were confirmed (Fig. 2B). Micro checks developed to form macro checks along longitudinal-radial plane of MW treated lumbers. Checks developed to form new pathways to facilitate the liquid flow in lumbers, hence possibly enhance the liquid permeability of MW-treated lumbers.

Figure 2: Checks in the intercellular of ray cells and tracheid: (A) Control; (B) Checks in treated sample

Figure 3: Pits in longitudinal tracheid of both control and MW-dried Scots pine lumber: (A) Control; (B) reopen of aspiration pits; (C) destruction of pit membranes

Damages on bordered pits can also be confirmed by SEM examination with a magnification of about 1000. As shown in Fig. 3, a large portion of aspirated pits can be found in untreated lumber (Fig. 3A), while many aspirated pits reopened after MW-treatment (Fig. 3B). Besides, pit border destruction (Fig. 3C) can also be found in treated lumbers. The aspirated pits block the transportation of water and other molecules into the cell wall and tracheid lumen [21]. If effective treatment has done to break through the liquid paths blocked by aspirated pits, then liquid permeation in the MW-treated lumbers may become easier, which means the MW-treatment induced microstructure changes are effective for modifying the liquid permeability of Scots pine lumbers.

Cell lumen and pits on cell walls construct the macro capillary system while microcrystalline cellulose, microfibrils and fibrils construct the micro capillary system in lumbers. Liquid permeability of MW-treated lumbers is not only affected by the changes in macro capillary system, but also closely related with the changes in the micro capillary system [23,24]. By stereoscopic microscope and SEM examination, the structure changes in macro capillary system of MW-treated lumbers were revealed. However, the changes in micro capillary system still cannot be confirmed by above analysis.

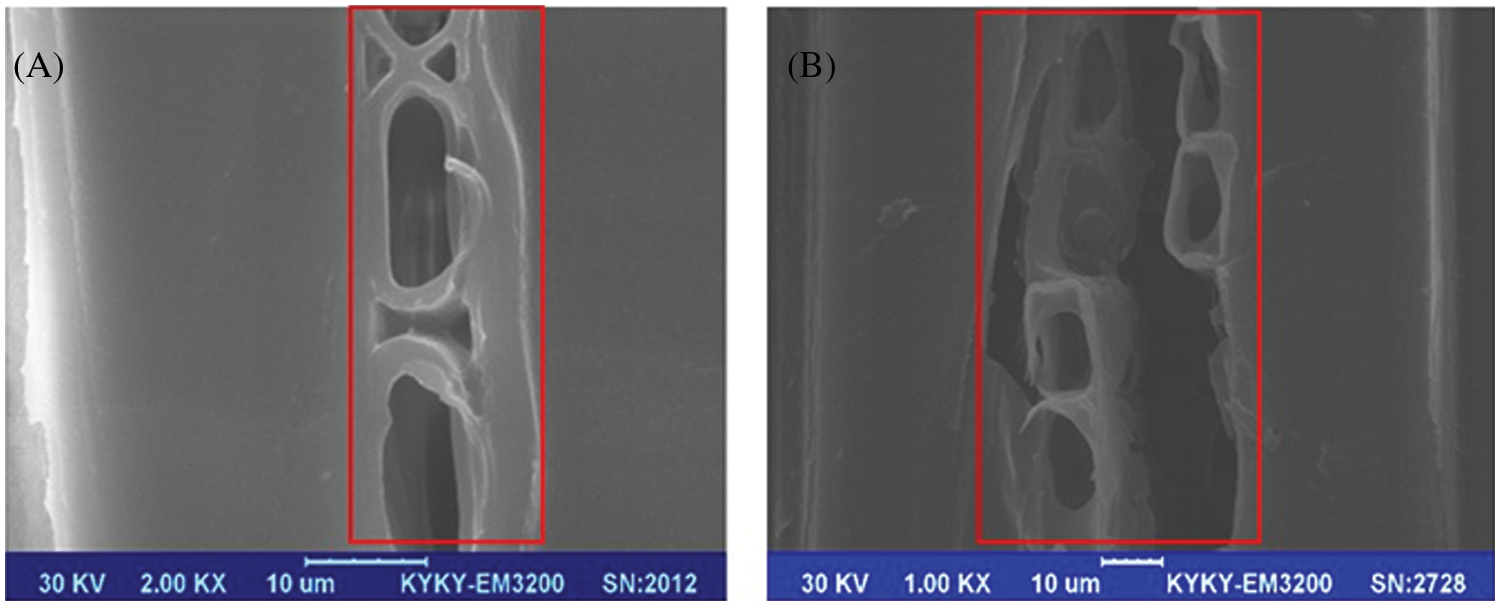

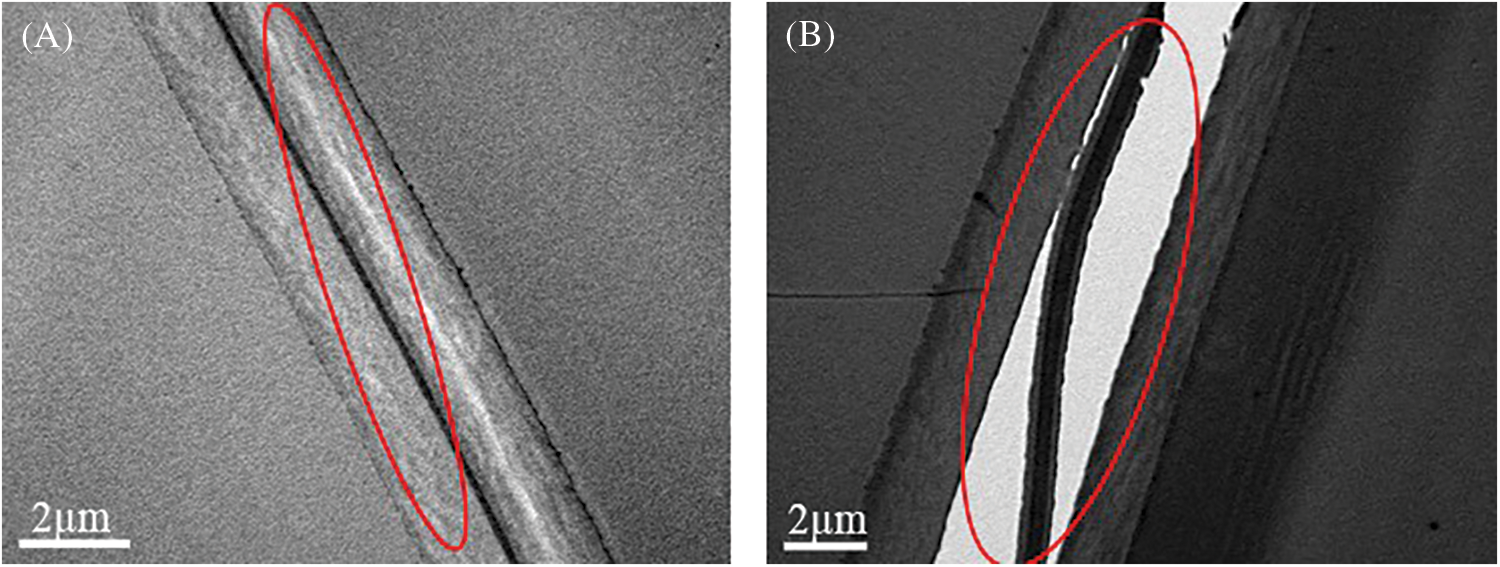

TEM provide higher magnification for ultrastructure examination of the lumber with high resolution. Figs. 4–6 show the ultrastructure changes of MW-treated lumbers. Micro checks can be found in the intercellular of tracheid cells (Fig. 4B). It was in accordance with stereoscope microscope and SEM examination results. Besides, it is clear that the compound lamella keeps intact while the S1 layer separate with S2 layer to form the micro-checks between tracheid cells.

Figure 4: Rupture in intercellcular layer of tracheid: (A) Control; (B) Check in the intercellular

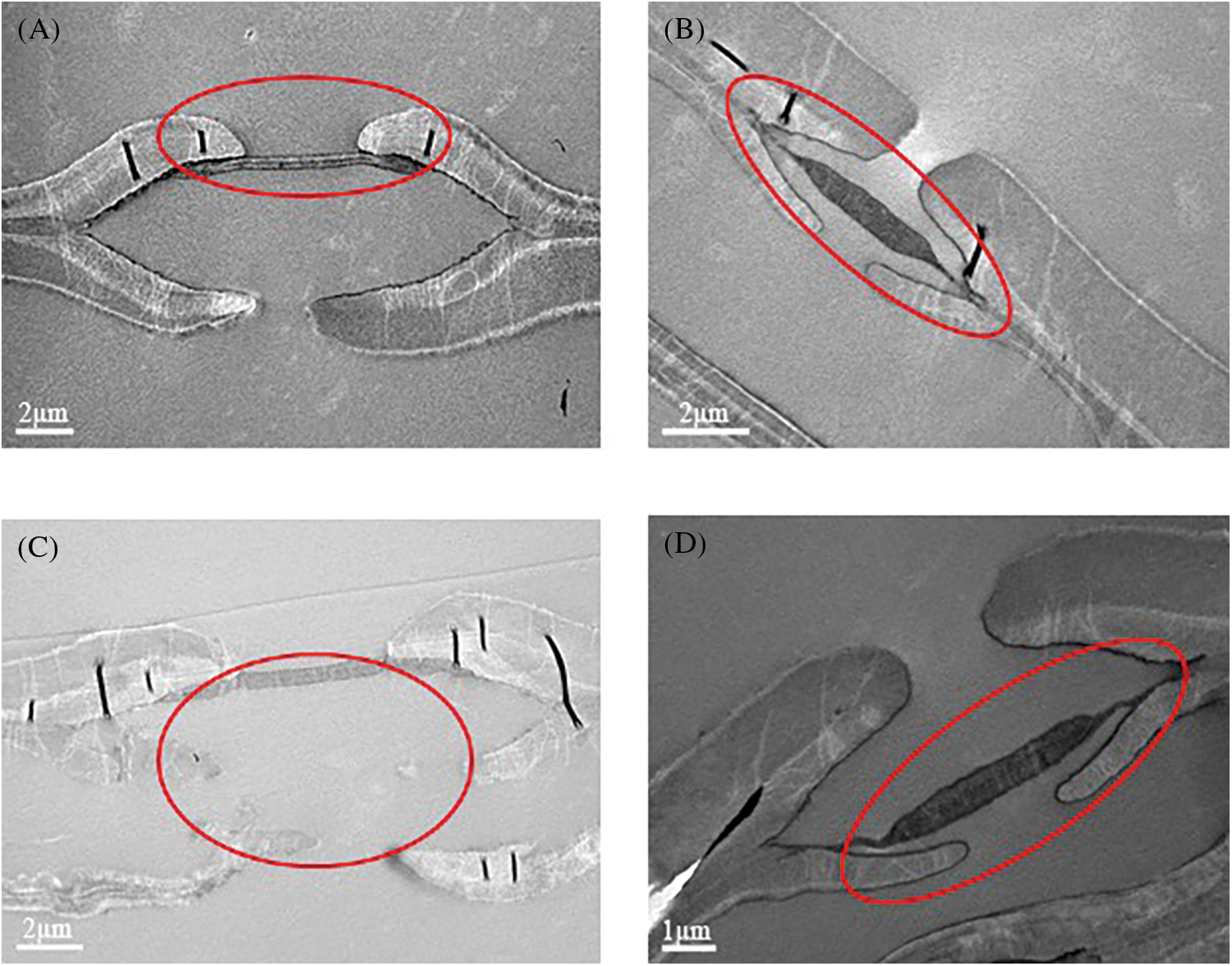

Figure 5: Bordered pits on tracheid cell wall: (A) Control; (B, C) Reopen of the aspirated pits; (D) Destroy of pit border

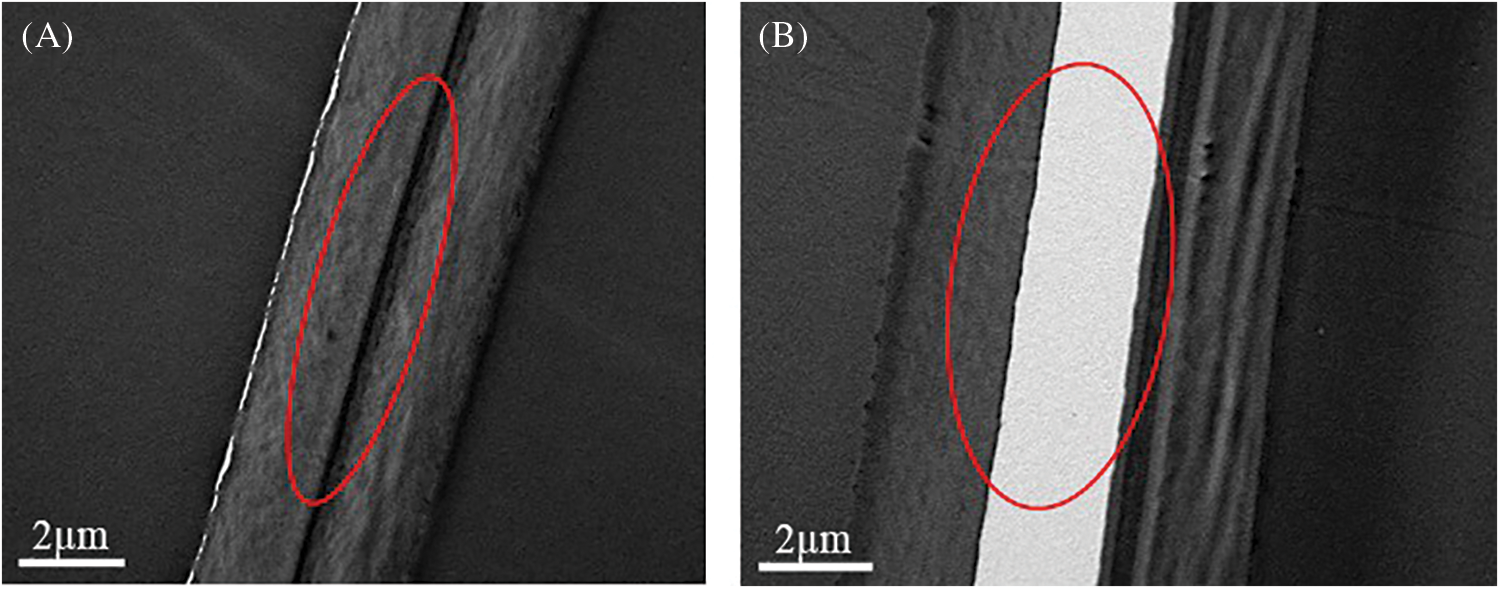

Figure 6: TEM images of tracheid cell wall before and after MW-treatment: (A) Control; (B) Check on cell wall

Except for micro checks generated in the intercellular of tracheid cells, some of the aspirated pit can also be observed as its orus moved toward the middle of pit chamber after MW-treatment (Figs. 5B and 5D). Then the pit aperture reopened to facilitate the liquid permeation through tracheid cells. Besides, the destroy of pit border can be observed in treated samples (Fig. 5C), which broaden the pit aperture and make the liquid flow much easier.

Micro checks can be found in tracheid cell wall of MW-treated lumbers with a magnification of about 8000 (Fig. 6B). As amorphous region in S2 layer of tracheid cell wall contain free water before MW-treatment, the vapor pressure increased when free water evaporated. As long as the vapor pressure is higher than the joint strength of fibrils, micro checks easy to develop in this region.

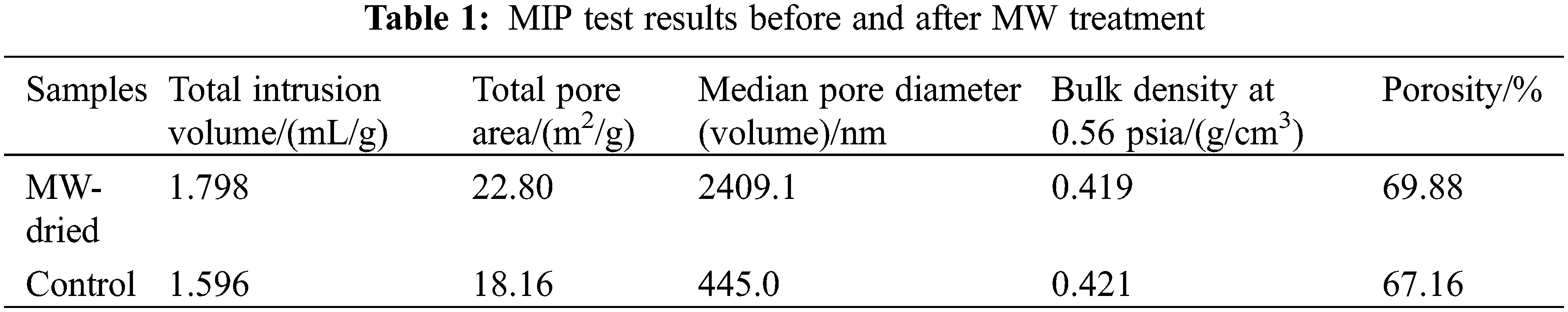

3.2 Pore Parameters Characterization

MIP test results shows the pore structure changes induced by macro and micro structure changes after MW-treatment. It was indicated from Table 1 that the porosity of MW-treated sample increased moderately with almost the same density of samples before and after MW-treatment. Pore volume and pore area increased as macro and micro checks generated to form new cavities. Besides, it can be concluded from median pore diameter (volume) increase that the newly developed macro and micro checks have larger scale of pore diameter than originally existed pores in control samples. These checks contribute greatly to the pore volume of treated sample. Moreover, there are possibility that structure changes such as pit border destruction or orus translocation could be effective for increasing the quantity of pores or enlarging the pore diameter.

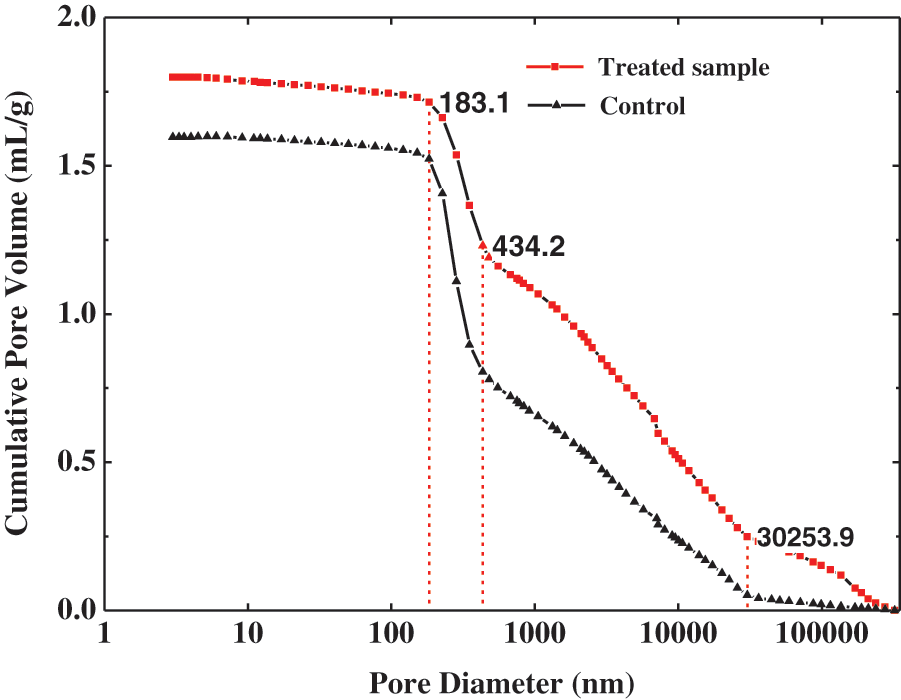

Fig. 7 displayed the cumulative pore volume vs. pore diameter of Scots pine before and after MW-treatment. It can be inferred that there was a dramatic increase of pore volume when pore diameter is larger than 30,253.9 nm. The correspond structure changes in treated lumber may be macro checks developed at regions such as intercellular of tracheid cells, intercellular of ray parenchyma and tracheid cell or the resin canals [25] which were located by stereoscope microscope and SEM examination. In the pore diameter range from 434.2 nm to 30,253.9 nm, the increment of pore volume for MW-treated sample is relatively higher than control sample. This may contribute by pit border destruction or orus translocation as located by SEM and TEM examination. Accompanied by these structure changes, pore diameter turned to be larger, or some originally blocked pores turned opened. As to the pore diameter range from 183.1 nm to 434.2 nm, the increment of pore volume for MW-dried sample is obviously lower than control sample. This may be resulted from the phenomenon that part of the pores with diameter originally in this range transferred to the range from 434.2 nm to 30,253.9 nm after MW-treatment. Assumed that there was no newly developed pores during MW-treatment, it is therefore treated sample has less pores in this diameter range compared with control sample, and the increment of pore volume is lower than control sample. When the pore diameter is smaller than 183.1 nm, the increment of pore volume is almost the same for both treated and control samples, which means the pores with diameter in this range keep almost unchanged after MW-treatment.

Figure 7: Cumulative pore volume vs. pore diameter of Scots pine before and after MW-treatment

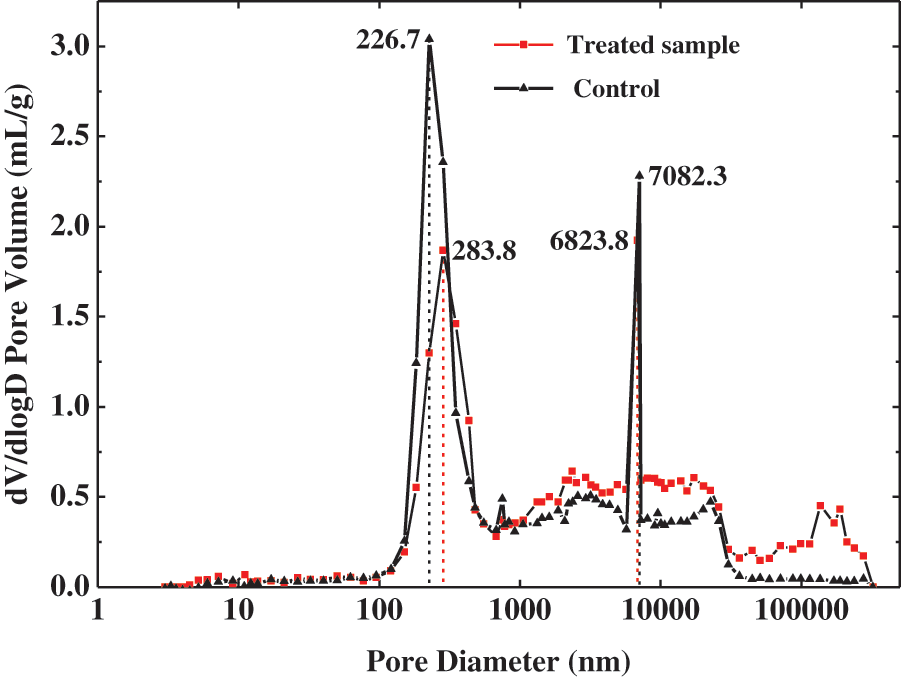

Pore diameter distributions of MW-treated and control samples was displayed in Fig. 8 which refers to pore volumes calculated using the log of the differential pore diameters. In the pore diameter range around 100,000 nm, there was an abrupt increase for treated sample while the value for control sample is approximate to 0, which means almost no pores with diameter in this range existed in control sample. As macro checks generated after MW-treatment, correspond macro pores developed to contribute to pore volume. As to the diameter range around tracheid lumen, it was indicated that diameter of tracheid lumen changed moderately (control sample: 7082.3 nm; MW-treated sample: 6823.8 nm) [26]. Although most of the tracheid cells kept the same level of pore diameter before and after MW-treatment, some smaller tracheid openings such as bordered pits increased, and micro-checks developed in intercellular of tracheid cells also contributed to pore volume after MW-treatment. Moreover, high vapor pressure generated during MW-treatment would possibly result in the expansion of tracheid lumen [9,10,13]. It is therefore that tracheid lumen diameter distributed in a wider range for MW-treated sample while its peak value correspond to tracheid lumen diameter is lower than control sample. Similar phenomenon can also be found in diameter range around 250 nm (control sample: 226.7 nm; MW-dried sample: 283.8 nm). As some micro pores in bordered pits enlarged after MW-treatment, the diameter distribute range turned wider while the peak value turned lower. When pore diameter is smaller than 100 nm, its contribution to pore volume is relatively small, and the pore diameter distribution for both MW-treated and control samples was nearly the same.

Figure 8: Log differential intrusion versus pore diameter of Scots pine before and after MW-treatment

3.3 Mechanism of Liquid Permeability Improvement

As a kind of natural porous biomaterial, wood has complicated anatomical structure which is crucial toward understanding its liquid permeability. Wood permeability may change to a great extent due to its structure variation [27–29]. Since structure changes were ascertained by above tests, it is possible to analyze the effects of MW-treatment on liquid permeability of the lumber.

There are two major aspects governing liquid permeability of the lumber before and after MW-treatment: liquid flow pathways and liquid flow efficiency [30]. When illustrating the mechanism of liquid permeability improvement from the aspect of liquid flow pathways in wood, it is well-known that longitudinal and transverse transportation are major directions of liquid flow in lumbers [30–32]. Longitudinal liquid flow mainly through tracheid lumen and bordered pits in the region of overlap of two tracheid ends [32]. Liquid flow is highly relying on the number and the state of bordered pits (whether the pits were aspirated or not). After MW-treatment, macro and micro checks developed along the longitudinal-radial plane. It created new paths for liquid flow in both longitudinal and radial direction. At the same time, pit border destruction or orus translocation located by SEM and TEM examination also contribute greatly to the longitudinal liquid permeability enhancement of treated lumber. As to the transverse liquid flow, tangential flow is primarily through longitudinal tracheids and intertracheid bordered pits [29,30] while ray parenchyma cells are regarded as the main radial pathways [32,33]. Bordered pits occur mainly on the radial wall of the tracheids and can be larger than the pits on tangential walls [31–34]. It is therefore the effect of pit border destruction or orus translocation on improvement of tangential liquid permeability is more significant than that on radial [35]. Additionally, macro and micro checks developed along the longitudinal-radial plane would possibly improve the radial liquid flow.

Secondly, porosity and pore structure of wood are important parameters for illustrating the mechanism of liquid permeability improvement from the aspect of liquid flow efficiency. As MIP test results shown, porosity of MW-treated lumber is higher than control sample, which means comparatively more voids in treated lumbers. Then liquid flow is more fluent as original flow path has more connections for liquid flow. Besides, median pore diameter (volume) increased as newly developed macro and micro checks have larger scale of pore diameter than originally existed pores in control samples. Larger pores make the liquid flow in lumbers more efficient. Moreover, structure changes would increase the quantity of pores or enlarge the pore diameter. As Fig. 8 shown, around the diameter range of tracheid lumen, the expansion of cell lumens was observed, and some smaller tracheid openings such as bordered pits increased (control sample: 7082.3 nm; MW-dried sample: 6823.8 nm). Moreover, some micro pores in bordered pits enlarged after MW-treatment (control sample: 226.7 nm; MW-treated sample: 283.8 nm). Since the liquid flow efficiency is proportional to the pore diameter, above pore structure changes would facilitate the liquid flow [36,37].

Additionally, accompanied by pore structure changes, the distribution of extractives deposited in lumber would also change after MW-treatment. Previous reports shown that resin can be removed in lumbers by MW-treatment [38]. Scots pine lumber is rich in resin content, and the resin may block the pores which effect the liquid flow. After MW-treatment, resin content decreased while blocked pores reopened, and micropores in pit membranes increased to facilitate the liquid flow [37–39]. It is therefore the resin removing can be helpful for enhancing the liquid permeability of Scots pine lumber.

Through stereoscopic microscope, SEM and TEM examination, macro and micro checks, ultrastructure changes can be observed in MW-treated Scots pine lumber. Macro and micro checks mainly located at intercellcular of tracheids, intercellular of ray parenchyma and tracheid, while the checks primarily extend along the radial-longitudinal plane of the lumber. Pit border destruction, aspirated pits’ orus moved toward the middle of pit chamber and micro-checks in tracheid cell wall can also be observed.

Structure changes eventually resulted in porosity and pore structure changes which were ascertained by MIP test. The pore volume and pore area increased as macro and micro checks generated to form new cavities. Median pore diameter (volume) increased as newly developed macro and micro checks have larger scale of pore diameter than originally existed pores. pit border destruction, orus translocation or micro-checks developed in intercellular of tracheid cells would increase the quantity of pores or enlarge the pore diameter.

Liquid permeability of MW-treated Scots pine lumber enhanced after MW-treatment: liquid flow pathways increased as macro and micro checks generated, and aspirated pits reopened to form new pathways; liquid flow efficiency improved as structure changes resulted porosity, pore volume and pore diameter increase which facilitate the liquid flow; extractive (resin) removing can be helpful for enhancing the liquid permeability of Scots pine lumber.

Funding Statement: The presented work is supported by Key Research & Development Program of Zhejiang Province (2021C02012) and Chinese National Natural Science Foundation, Study on Pore Structure and Liquid Permeate Mechanism of Moso Bamboo (31700489).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Pajchrowski, G., Noskowiak, A., Lewandowska, A., Strykowski, W. (2014). Wood as a building material in the light of environmental assessment of full life cycle of four buildings. Construction & Building Materials, 52(2), 428–436. DOI 10.1016/j.conbuildmat.2013.11.066. [Google Scholar] [CrossRef]

2. Hill, C. A. S. (2006). Wood modification: Chemical, thermal and other processes. Chichester England Hoboken NJ, John Wiley & Sons. [Google Scholar]

3. Liu, M. H., Lyu, S. Y., Cai, L., P., Tang, J., Huang, Z. H. et al. (2021). Performance improvement of radiata pine wood by combining impregnation of furfuryl alcohol resin and densification for making fretboard materials. Industrial Crops and Products, 172, 114029. DOI 10.1016/j.indcrop.2021.114029. [Google Scholar] [CrossRef]

4. Okon, K. E., Lin, F., Lin, X., Huang, B. (2017). Modification of Chinese fir (Cunninghamia lanceolata L.) wood by silicone oil heat treatment with microwave pretreatment. European Journal of Wood and Wood Products, 76(1), 221–228. DOI 10.1007/s00107-017-1165-z. [Google Scholar] [CrossRef]

5. Esteves, B. M., Pereira, H. M. (2009). Wood modification by heat treatment: A review. BioResources, 4(1), 370–404. [Google Scholar]

6. Torgovnikov, G., Vinden, P. (2010). Microwave wood modification technology and its applications. Forest Products Journal, 60(6), 173–182. DOI 10.1007/978-3-540-32944-2_32. [Google Scholar] [CrossRef]

7. Zhang, D., He, Q., Du, B. Yu, J., B., Zhu, X. D. et al. (2022). High permeability of boron along the transverse direction of wood under high-voltage electrostatic field (HVEF) treatment. Journal of Renewable Materials, 10(3), 721–734. DOI 10.32604/jrm.2022.016793. [Google Scholar] [CrossRef]

8. He, S., Lin, L. Y., Fu, F., Zhou, Y. D., Fan, M. Z. (2014). Microwave treatment for enhancing the liquid permeability of Chinese fir. BioResources, 9(2), 1924–1938. DOI 10.15376/biores.9.2.1924-1938. [Google Scholar] [CrossRef]

9. He, S., Lin, L. Y., Fu, F., Zhou, Y. D. (2014). Experimental study of six species of wood treated by microwave. Journal of Microwaves, 30(4), 90–96. [Google Scholar]

10. He, S., Yu, H., Wu, Z. X., Chen, Y. H., Fu, F. (2016). Effect of microwave treatment on liquid impregnate property of Pinus Sylvestris L. var lumber. Journal of Microwaves, 32(6), 90–96. DOI 10.14183/j.cnki.1005-6122.201606021. [Google Scholar] [CrossRef]

11. Xu, E. G., Lin, L. Y., Li, S. M. (2021). Effect of microwave treatment on moisture sorption isotherm of Mongolian scotch pine. Chinese Journal of Wood Science and Technology, 35(1), 20–25. DOI 10.12326/j.2096-9694.2020093. [Google Scholar] [CrossRef]

12. Jiang, T., Zhou, Z. F., Wang, Q. W. (2006). Effects of intensive microwave irradiation on the permeability of Larch wood. Scientia Silvae Sinicae, 42(11), 87–92. DOI 10.11707/j.1001-7488.20061116. [Google Scholar] [CrossRef]

13. Du, G., Wang, S., Cai, Z. (2005). Microwave drying of wood strands. Drying Technology, 23(12), 2421–2436. DOI 10.1080/07373930500340494. [Google Scholar] [CrossRef]

14. Vinden, P., Torgovnikov, G. (2003). Microwave modification of wood. Proceedings of the First European Conference on Wood Modification, pp. 169–176. Ghent, Belgium. [Google Scholar]

15. Torgovnikov, G., Vinden, P. (2000). New wood based materials TORGVIN and VINTORG. Proceedings of the Fifth Pacific Rim Bio-Based Composite Symposium, pp. 756–764. Canberra, Australia: Australian National University Press. [Google Scholar]

16. Vinden, P., Torgovnikov, G., Przewloka, S. (2007). The manufacture of solid wood composites from microwave modified wood. Proceedings of the International Panel Products Symposium, pp. 111–120. Bangor, England, Bangor University Press. [Google Scholar]

17. Sugiyanto, K., Vinden, P., Torgovnikov, G. (2010). Microwave surface modification of Pinus radiata peeler cores: technical and cost analyses. Forest Products Joural, 60(4), 346–352. DOI 10.13073/0015-7473-60.4.346. [Google Scholar] [CrossRef]

18. Bao, F. C., Lu, J. X., Zhao, Y. K. (2001). Effect of bordered pit torus position on permeability in Chinese yezo spruce. Wood and Fiber Science, 33(2), 193–199. DOI 10.1002/jcu.10093. [Google Scholar] [CrossRef]

19. Torgovnikov, G., Vinden, P. (2009). High-intensity microwave wood modification for increasing permeability. Forest Products Journal, 59(4), 84–92. DOI 10.1111/j.1439-0329.2008.00574.x. [Google Scholar] [CrossRef]

20. Aumann, C. A., Ford, E. D. (2006). Simulation of effects of wood microstructure on water transport. Tree Physiology, 26(3), 285–301. DOI 10.1093/treephys/26.3.285. [Google Scholar] [CrossRef]

21. Washburn, E. W. (1921). Note on a method of determining the distribution of pore sizes in a porous material. PNAS, 7(4), 115–116. DOI 10.1073/pnas.7.4.115. [Google Scholar] [CrossRef]

22. Junghans, K., Niemz, P., Bächle, F. (2005). Investigations into the influence of thermal treatment on the porosity of spruce. European Journal of Wood and Wood Products, 63(3), 243–344. DOI 10.1007/s00107-004-0553-3. [Google Scholar] [CrossRef]

23. Biziks, V., Andersons, B., Beļkova, Ļ., Kapaca, E., Militz, H. (2013). Changes in the microstructure of birch wood after hydrothermal treatment. Wood Science and Technology, 47(4), 717–735. DOI 10.1007/s00226-013-0531-1. [Google Scholar] [CrossRef]

24. Yin, S. C. (2002). Wood science. Beijing: Press of Chinese Forestry. [Google Scholar]

25. Plötze, M., Niemz, P. (2011). Porosity and pore size distribution of different wood types as determined by mercury intrusion porosimetry. European Journal of Wood and Wood Products, 69(4), 649–657. DOI 10.1007/s00107-010-0504-0. [Google Scholar] [CrossRef]

26. He, S., Xu, J., Wu, Z. X., Chen, Y. H. (2017). Compare of porous structure of moso bamboo and Pinus sylvestris L. lumber. Journal of Nanjing Forestry University (Natural Sciences Edition), 41(2), 157–162. DOI 10.3969/issn.1000-2006-2017.02.023. [Google Scholar] [CrossRef]

27. Tarmian, A., Perre, P. (2009). Air permeability in longitudinal and radial directions of compression wood of Picea abies L. and tension wood of Fagus sylvatica L. Holzforschung, 63(3), 352–356. DOI 10.1515/HF.2009.048. [Google Scholar] [CrossRef]

28. Sebastion, L. P., Cote, W. A., Skaar, C. (1965). Relationship of gas phase permeability to ultrastructure of white spruce wood. Forest Product Journal, 15(9), 394–404. [Google Scholar]

29. Erickson, H. D. (1970). Permeability of southern pine wood: A review. Wood Science, 2(3), 149–158. [Google Scholar]

30. He, S., Chen, Y. H., Wu, Z. X., Hu, Y. A. (2020). Research progress on wood /bamboo microscopic fluid transportation. Journal of Forestry Engineering, 5(2), 12–19. DOI 10.13360/j.issn.2096-1359.201906043. [Google Scholar] [CrossRef]

31. Keith, C. T., Chauret, G. (1998). Anatomical studies of CCA penetration associated with conventional (tooth) and with micro (needle) incising. Wood and Fiber Science, 20(2), 197–208. [Google Scholar]

32. Ahmed, S. A., Chun, S. K. (2011). Permeability of Tectona grandis L. as affected by wood structure. Wood Science and Technology, 45(3), 487–500. DOI 10.1007/s00226-010-0335-5. [Google Scholar] [CrossRef]

33. Lehringer, C. H., Hillebrand, K., Schwarze, F. W. (2009). A review on promising approaches for liquid permeability improvement in softwood. Wood and Fiber Science, 41(4), 373–385. DOI 10.1007/s00468-009-0368-2. [Google Scholar] [CrossRef]

34. Baines, E. F. (2007). The current status of commercial waterborne preservative treatment spruce, pp. 14–26. London, UK: Br. Wood Preservation Association. [Google Scholar]

35. Liu, Y., Li, X. J., Fu, F. (2010). Microwave deresination of Masson pine: Model formulation and solution. Scientia Silvae Sinicae, 46(11), 115–118. DOI 10.3724/SP.J.1238.2010.00474. [Google Scholar] [CrossRef]

36. Matsumura, J., Tsutsumi, J., Kazuyuki, O. (1995). Relationship of bordered pit aspiration occurring during to longitudinal gas permeability in karamatsu (Larix leptolepis) woods natural and freeze dried. Mokuzai Gakkaishl, 41(4), 433–439. [Google Scholar]

37. Mohammad, E., Asghar, T., Kambiz, P. (2015). Permeability of poplar normal wood and tension wood bioincised by Physisporinus vitreus and Xylaria longipes. International Biodeterioration & Biodegradation, 105, 178–184. DOI 10.1016/j.ibiod.2015.09.003. [Google Scholar] [CrossRef]

38. Hadi, D., Asghar, T., Mehdi, F. (2013). Mass transfer through microwave-treated Fir wood (Abies alba L.A gymnosperm species with torus-margo pit membrane. Drying Technology, 31(3), 359–364. DOI 10.1080/07373937.2012.736908. [Google Scholar] [CrossRef]

39. Mantanis, G. I., Young, R. A., Rowell, R. M. (1995). Swelling of wood. Part III. Effect of temperature and extraetives on rate and maximum swelling. Holzforschung, 49(3), 239–248. DOI 10.1515/hfsg.1995.49.3.239. [Google Scholar] [CrossRef]