Open Access

Open Access

ARTICLE

Optimization of Photo-Fenton Catalyst Preparation Based Bamboo Carbon Fiber by Response Surface Methodology

1 College of Materials Science and Engineering, Central South University of Forestry and Technology, Changsha, 410004, China

2 Hunan Taohuajiang Bamboo Science & Technology Co., Ltd., Yiyang, 413400, China

3 Department of Wood and Forest Sciences, Laval University, Quebec, G1V 0A6, Canada

* Corresponding Authors: Jinbo Hu. Email: ; Gonggang Liu. Email:

Journal of Renewable Materials 2023, 11(1), 147-165. https://doi.org/10.32604/jrm.2023.021306

Received 07 January 2022; Accepted 01 April 2022; Issue published 10 August 2022

Abstract

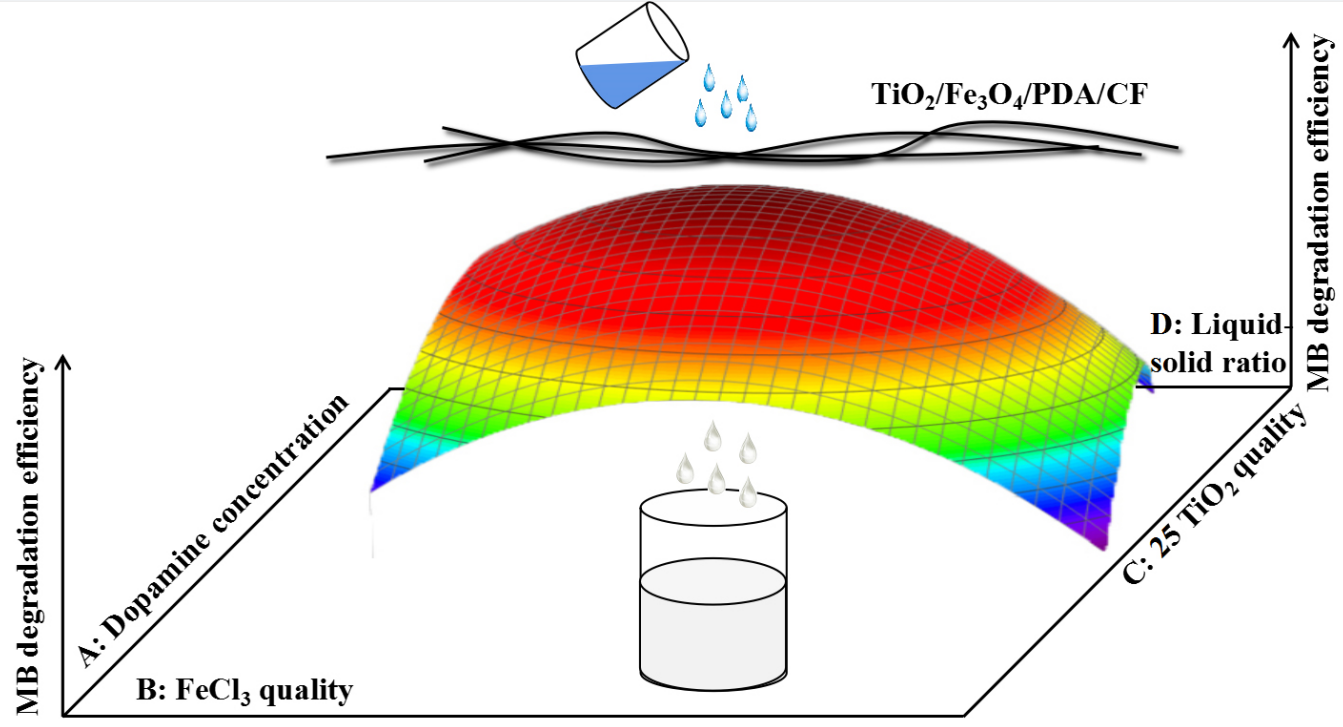

In this paper, the residue from bamboo factory has been used to design photo-Fenton catalyst, which has the advantages of low cost and magnetic recycling. The photo-Fenton catalytic performance of the biocarbon-based catalyst was excellent and its optimal preparation process was also explored by response surface methodology. First, bamboo-carbon fiber was selected as the photo-Fenton catalyst carrier. Subsequently, the surface of the carbon fiber was modified, with which dopamine, nano-Fe3O4 and nano-TiO2 were successively loaded by hydrothermal method. After examined single factor tests, four factors including dopamine concentration, ferric chloride mass, P25 titanium dioxide mass and liquid-solid ratio were selected to the characteristic values. The degradation efficiency of photo-Fenton catalyst to methylene blue (MB) solution was treated as the response value. After the analysis of the response surface optimization, it was showed that the significance sequence of the selected 4 factors in terms of the MB degradation efficiency was arranged as following: dopamine concentration > liquid-solid ratio > P25 titanium dioxide quality > ferric chloride quality. The optimal process parameters of fiber-carbon catalyst were affirmed as following: the 1.7 mg/mL concentration of dopamine, the 1.2 g mass of ferric chloride, the 0.2 g mass of P25 titanium dioxide and the liquid-solid ratio of 170 mL/g. The experiment-measured average MB degradation efficiency performed by the optimized catalyst was 99.3%, which was nearly similar to the model-predicted value of 98.9%. It showed that the prediction model and response surface model were accurate and reliable. The results from response surface optimization could provide a good reference to design bamboo-based Fenton-like catalyst with excellent catalytic performance.Graphic Abstract

Keywords

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools