Open Access

Open Access

ARTICLE

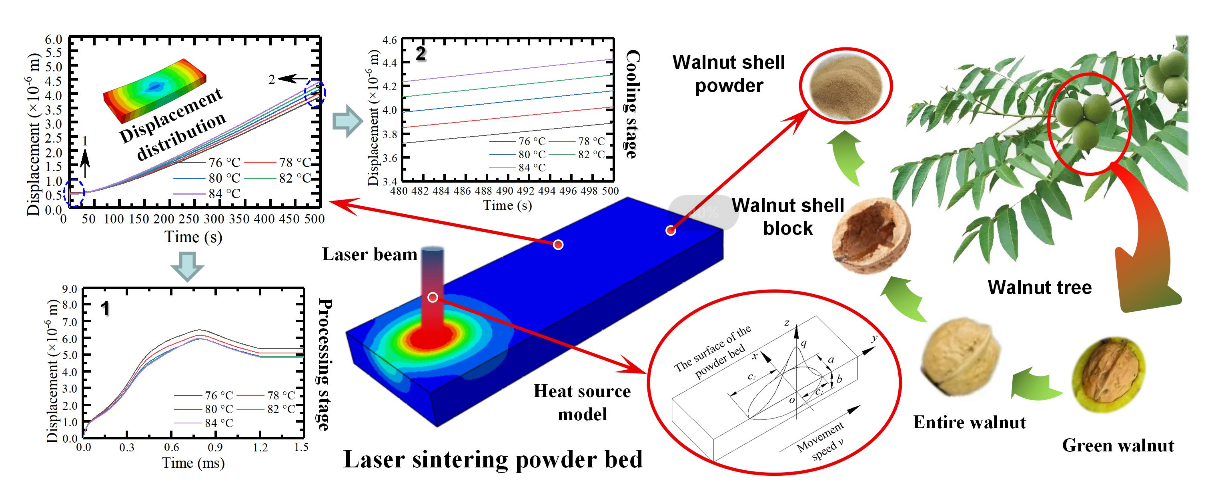

Simulation Analysis of Stress Field of Walnut Shell Composite Powder in Laser Additive Manufacturing Forming

1

College of Mechanical Science and Engineering, Northeast Petroleum University, Daqing, 163318, China

2

College of Mechanical and Electrical Engineering, Northeast Forestry University, Harbin, 150040, China

3

Research and Development Center of 3D Printing Material and Technology, Northeast Forestry University, Harbin, 150040, China

* Corresponding Authors: Suling Wang. Email: ; Ting Jiang. Email:

(This article belongs to the Special Issue: Computational Tools for Renewable Materials)

Journal of Renewable Materials 2023, 11(1), 333-347. https://doi.org/10.32604/jrm.2022.022296

Received 03 March 2022; Accepted 04 May 2022; Issue published 10 August 2022

Abstract

A calculation model of stress field in laser additive manufacturing of walnut shell composite powder (walnut shell/Co-PES powder) was established. The DFLUX subroutine was used to implement the moveable application of a double ellipsoid heat source by considering the mechanical properties varying with temperature. The stress field was simulated by the sequential coupling method, and the experimental results were in good accordance with the simulation results. In addition, the distribution and variation of stress and strain field were obtained in the process of laser additive manufacturing of walnut shell composite powder. The displacement of laser additive manufacturing walnut shell composite parts gradually decreased with increasing preheating temperature, decreasing laser power and increasing scanning speed. During the cooling process, the displacement of laser additive manufacturing of walnut shell composite parts gradually increased with the increasing preheating temperature, decreasing scanning speed and increasing laser power.Graphic Abstract

Keywords

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools