Open Access

Open Access

ARTICLE

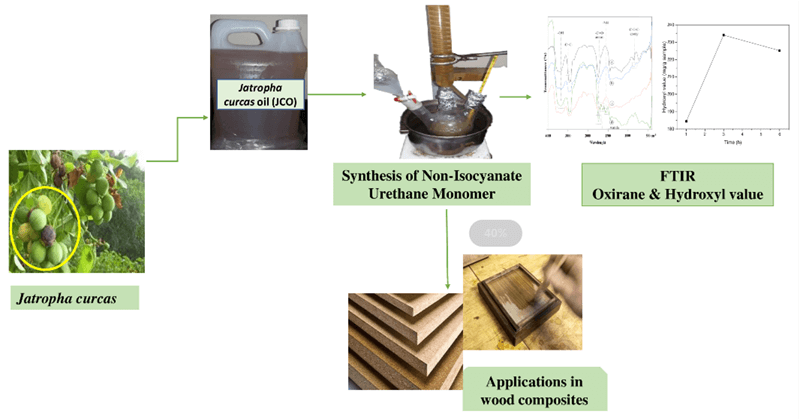

Development and Characterization of Eco-Friendly Non-Isocyanate Urethane Monomer from Jatropha curcas Oil for Wood Composite Applications

1

Department of Chemistry, Universitas Negeri Semarang, Semarang, 50229, Indonesia

2

Research Center for Chemistry, National Research and Innovation Agency (BRIN), Serpong, 15314, Indonesia

3

Research Center for Biomass and Bioproducts, National Research and Innovation Agency (BRIN), Cibinong, 16911, Indonesia

4

Department of Forest Product, Faculty of Forestry, Universitas Sumatera Utara, Medan, 20155, Indonesia

5

JATI-Sumatran Forestry Analysis Study Center, Medan, 20155, Indonesia

6

Faculty of Forest Industry, University of Forestry, Sofia, 1797, Bulgaria

7

Laboratory of Biopolymer and Derivatives, Institute of Tropical Forestry and Forest Product, Universiti Putra Malaysia, Selangor,

43400, Malaysia

8

Department of Forest Products, Faculty of Forestry and Environment, IPB University, Bogor, 16680, Indonesia

9

Faculty of Wood Sciences and Technology, Technical University in Zvolen, Zvolen, 96001, Slovakia

* Corresponding Authors: Muhammad Ghozali. Email: ; Widya Fatriasari. Email: widya.fatriasari@ biomaterial.lipi.go.id;

Journal of Renewable Materials 2023, 11(1), 41-59. https://doi.org/10.32604/jrm.2022.023151

Received 12 April 2022; Accepted 01 May 2022; Issue published 10 August 2022

Abstract

The aim of this research work was to evaluate the potential of using renewable natural feedstock, i.e., Jatropha curcas oil (JCO) for the synthesis of non-isocyanate polyurethane (NIPU) resin for wood composite applications. Commercial polyurethane (PU) is synthesized through a polycondensation reaction between isocyanate and polyol. However, utilizing toxic and unsustainable isocyanates for obtaining PU could contribute to negative impacts on the environment and human health. Therefore, the development of PU from eco-friendly and sustainable resources without the isocyanate route is required. In this work, tetra-n-butyl ammonium bromide was used as the activator to open the epoxy ring with 3-Aminopropyltriethoxisylane as a catalyst to yield urethane of JCO (UJCO). The UJCO were characterized by Fourier Transform Infra-Red spectroscopy (FTIR) and their oxirane, and hydroxyl values were measured. The result showed that a decrease in oxirane value was found while the hydroxyl value was increased during the time, confirming that the urethane group was formed. The presence of functional groups in FTIR spectra at wave numbers 1732.08, 1562.34, and 3348.42 cm−1 indicates the functional groups of C = O (urethane carbonyl), –NH, and –OH, respectively confirmed this finding. The potential applications of NIPU in the wood composite were also outlined.Graphic Abstract

Keywords

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools