Open Access

Open Access

ARTICLE

Characterization of Nanocomposite Membrane Based Bacterial Cellulose Made of Pineapple Waste Reinforced by Graphite Nanoplatelets

1

Center of Excellence for Cellulose Composite (CECCom), Department of Mechanical Engineering, Universitas Negeri Malang,

Malang, 65145, Indonesia

2

Centre of Advanced Material for Renewable Energy (CAMRY), Universitas Negeri Malang, Malang, 65145, Indonesia

3

Master Program of Mechanical Engineering, Faculty of Engineering, Universitas Negeri Malang, Malang, 65145, Indonesia

4

Department of Aquatic Resources Management, Faculty of Fisheries and Marine Sciences, Brawijaya University,

Malang, 65145, Indonesia

5

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Negeri Malang, Malang, 65145, Indonesia

6

Department of Materials Science & Engineering, Incheon National University, Incheon, 464-742, South Korea

* Corresponding Author: Heru Suryanto. Email:

Journal of Renewable Materials 2022, 10(9), 2455-2465. https://doi.org/10.32604/jrm.2022.020478

Received 25 November 2021; Accepted 25 February 2022; Issue published 30 May 2022

Abstract

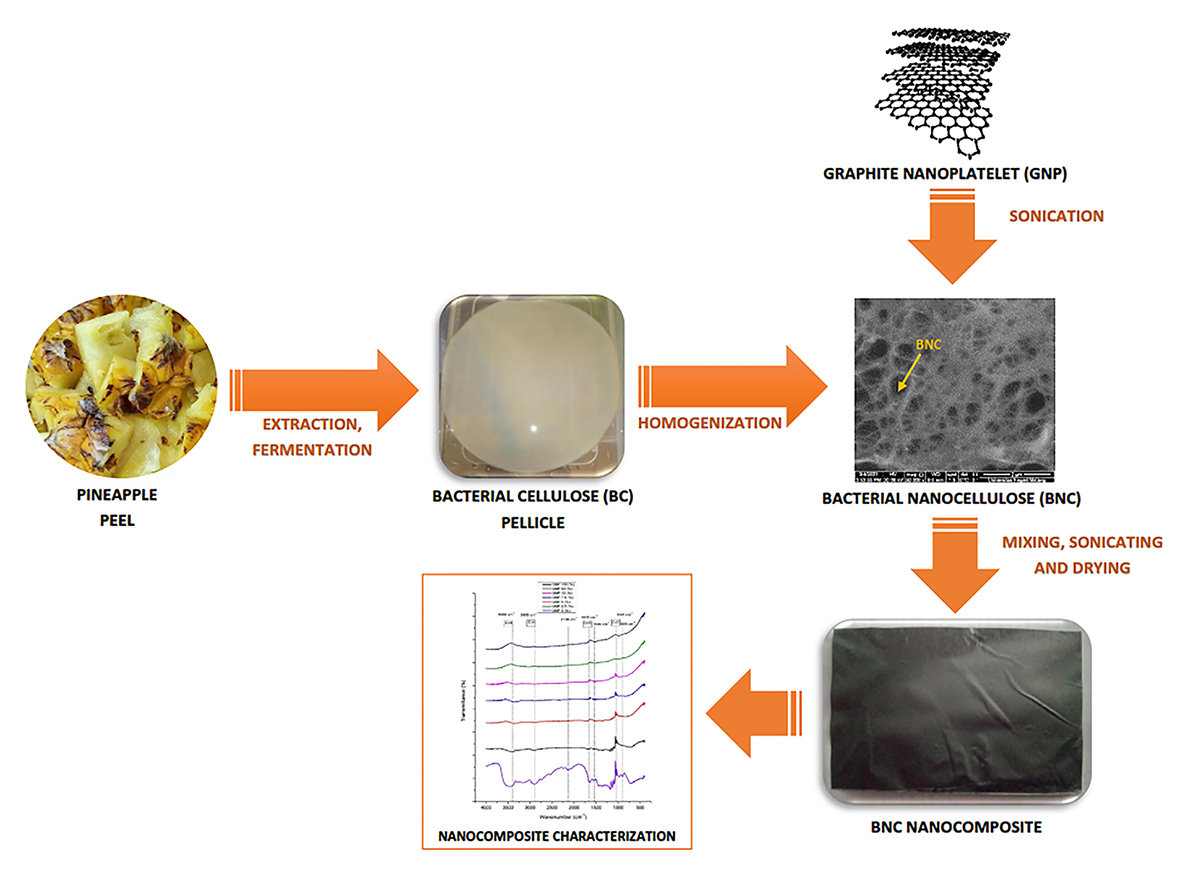

Waste is the main problem for the environment. Handling waste for various useful applications has a benefit for the future. This work has been studied for handling pineapple peel waste to make composite film bacterial cellulose nanocomposite membrane (BCNM) with addition graphite nanoplatelet (GNP). The concentration of GNP in the membrane influence the membrane properties. The bacterial cellulose (BC) pellicle was synthesized by using media from pineapple peel waste extract. BC pellicle is cleaned with water and NaOH solution to be free from impactors. BCNM is synthesized through the mechanical disintegration stage. The results of disintegration using high pressure homogenizer at 150 bar and five cycles. BCNM/GNP is synthesized with varying addition of GNP of 2.5, 5.0, 10 and 100 wt% of dry bacterial nanocellulose (BNC). The BC and GNP solution were dried in an oven for 14 h at 80°C. BCNM morphology was observed using SEM. GNP is dispersed and distributed in the BC matrix as reinforcement. FTIR analysis shows many peaks of BNC less pronounced with increasing of GNP. The higher concentration of GNP, the rougher of BCNM. The optimum tensile strength of BCNM was achieved after addition GNP of 2.5 wt%.Graphic Abstract

Keywords

Cite This Article

Copyright © 2022 The Author(s). Published by Tech Science Press.

Copyright © 2022 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools